@droftarts and @dc42 thank you very much!

Posts made by brunofporto

-

Is it possible to have my Duex to deal with a laser engraver?posted in General Discussion

I have a Duet 2 Ethernet happily working on my 3D printer for years now. And I have a Duex expansion board that I bought back in the day to be able to make a multi tool printer.

Is it possible to use the Duex to control the laser engraver steppers and laser module in such way that when I enter laser mode then The duet only controls the laser engraver.

So, using the same Duet board to controll both the 3d printer and the laser engraver, not at the same time, but without the need to dedicate my controller board to a single device?

Thanks!

-

RE: CoreXY homingposted in Documentation

@dc42 said in CoreXY homing:

Assuming that you are using one of our standard stable builds of RRF, I can't see any way that RRF could fail to execute a G90 command. Please check using M115 or M122 exactly which firmware version you are using and tell us.

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.4.5 ELECTRONICS: Duet Ethernet 1.02 or later FIRMWARE_DATE: 2022-11-30 19:36:12

Thanks, I will remove the "fine hope" part

-

RE: CoreXY homingposted in Documentation

@mrehorstdmd yes. But the topic here is fail to detect the G90 command after the last movement. It was solved by a M400.

I using latest firmware release on a Duet 2 Ethernet

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"forkLIFT" ; set printer name M669 K1 ; select CoreXY mode ; Network M551 P"notyourbusiness" ; set password M552 P0.0.0.0 S1 ; enable network and uses defined IP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S0 ; physical drive 3 goes backwards M569 P4 S0 ; physical drive 4 goes backwards M584 X0 Y1 Z2:4 E3 ; set drive mapping M350 E256 I0 ; configure microstepping without interpolation M350 X16 Y16 Z16:16 I1 ; configure microstepping with interpolation M92 X80.18 Y79.71 Z398.98 E6640 ; set steps per mm M201 X700 Y700 Z100 E3000 ; Set accelerations (mm/s^2) M201.1 X300 Y300 Z20 ; Set reduced acceleration for special move types M203 X15000 Y15000 Z1400 E3600 ; Set maximum speeds (mm/min) ;M204 P500 T2500 ; Set printing and travel accelerations M566 X720 Y720 Z300 E3600 ; Set maximum instantaneous speed changes (mm/min) M906 X1800 Y1800 Z1500 E1500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X298 Y300 Z290 S0 ; set axis maxima ; Endstops M574 X1 S3 ; configure sensorless endstop for low end on X M574 Y1 S3 ; configure sensorless endstop for low end on Y M574 Z1 S2 ; configure Z-probe endstop for low end on Z M915 X Y R0 F0 S4 ; Configuring Sensorless Homing ; Z-Probe M950 S0 C"exp.heater7" ; create servo/gpio 0 on heater 7 pin on expansion connector M558 P5 C"^zprobe.in" H5 F120 T12000 ; set Z probe type to switch and the dive height + speeds G31 P600 X0 Y-41.9 Z0.321 ; set Z probe trigger value, offset and trigger height M557 X20:278 Y0:258 P5:5 ; Define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S285 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ; Tools M563 P0 S"Basic" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue T0 ; select first tool M703 ; reload loaded filament settings M912 P0 S-23.6 ; MCU temperature Calibration M501 ; load saved parameters from non-volatile memory -

RE: CoreXY homingposted in Documentation

@mrehorstdmd No misaligment for sure. It clearly move X when it fails to detect the first stall "jump".

As it move diagonally on the first move it is only using one motor. When it fails to detect the first stall it forces a few steps into Y0 making X move by consequence. If I set it to be more sensitive it does not happens at all BUT it also detect false hits.

No steel core belts also. The prints are well calibrated along 5 to 150mm on both axis and without skeweness and right angle reference parts are perpendicular.

But the homing issue is not the topic of this thread.

The topic here is that the printer fails to detect G90 after the fine home Y (line 9 of the example above) and it caused issues. A m400 failsafe that.

I will open another post to discuss the homeall issues

As soon as I have time to describe it and organize to post I put the link here.

As soon as I have time to describe it and organize to post I put the link here. -

RE: Scanning Z probe support in RRF 3.5posted in Beta Firmware

@dc42 plus the issue with different types of surfaces...... Still have my laser filament sensor

I like @CNCModeller idea of the indirect measurement with a ball but then there is the dynamic problem of a ball "jumping" on small defects or residual first layers.

-

RE: Scanning Z probe support in RRF 3.5posted in Beta Firmware

@dc42 One can always use a mall single beam LIDAR as those small ones used by drones..... Those are not tailored for small distances but something similar for short distances may exist.

-

CoreXY homingposted in Documentation

I was having a lot of issues with my homing with my CoreXY printer depending on the relative position of the tool head at the start of the home all. The home X, Y and Z individually worked like a charm but the Home all was always a surprise.

As a good Duet user I go to the documentation, cleaned my home all g file and started from scratch testing it line by line.

I will discuss it in more detail on other post but here is something I noted that is an Issue with the current example.

Sometimes after the homeall my printer did not register the G90 and was kept at the relative movement!

I did need to add a M400 after the last homing movement before the G90 and the Z homing sequence.

Another issue is that sometimes when homing the Y it moved a few mm the X so it is a good practice to go back a few mm both X and Y after the coarse homing to avoid it.

G91 ; relative mode G1 H1 X-240 Y-240 F3000 ; coarse home X or Y G1 H1 X-240 ; coarse home X G1 H1 Y-240 ; coarse home Y G1 X4 Y4 F600 ; move away from the endstops G1 H1 X-10 ; fine home X G1 X4 Y4 F600 ; move away from the endstops ; this last one avoids the "residual" X movement that can or not happens when stalling at Y homing. G1 H1 Y-20 ; fine home Y M400 ; wait for movement to finish G90 ; Absolute positioning ; Z homing section follows ... -

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

@gloomyandy Nope. Duet 2 Ethernet v1.02 (the one before the on board fuses).

-

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

Ok... No differences at all from the same gcode from PA 0.5 to 1.3 with 3.3 and 3.4.2

-

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

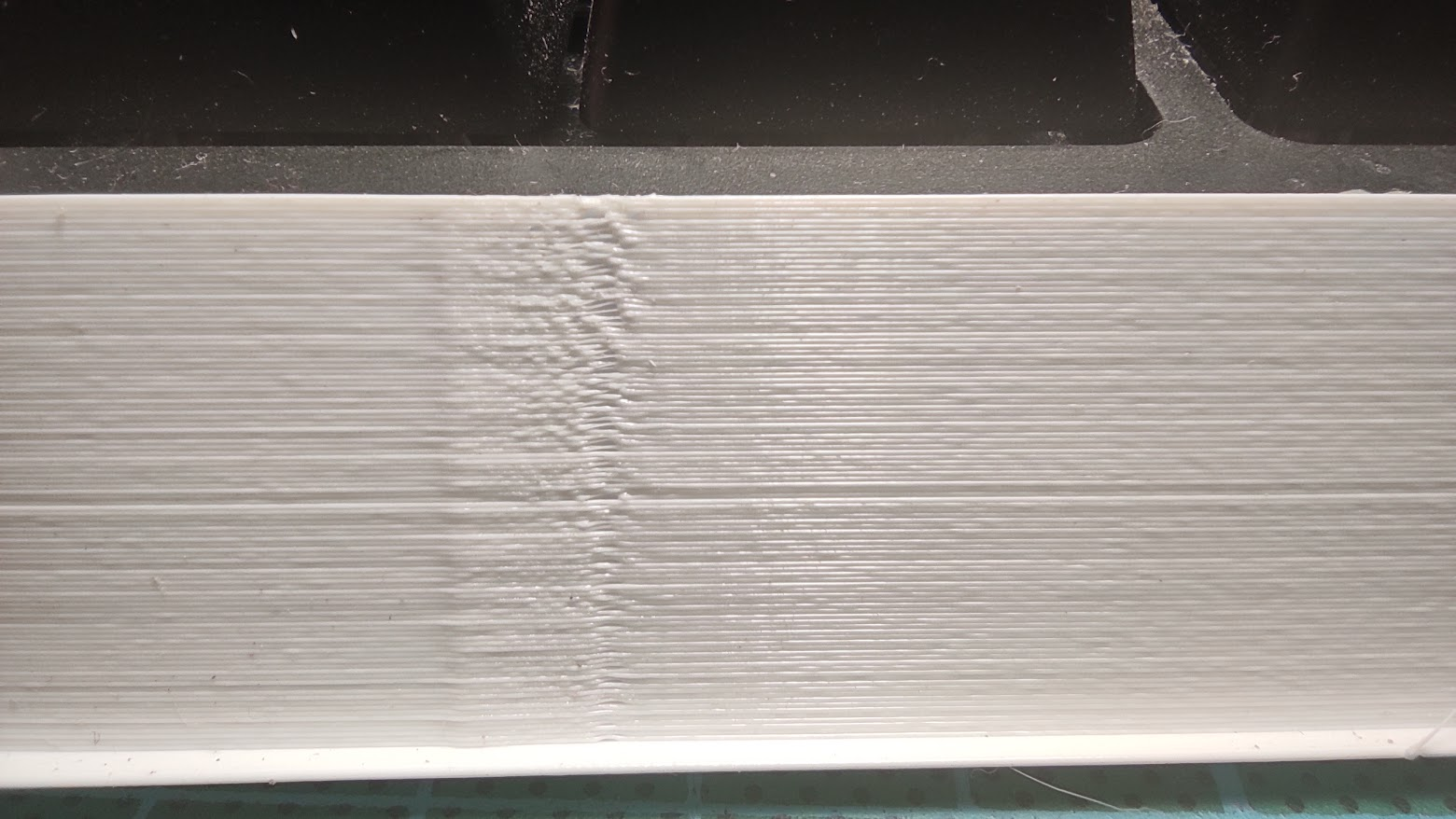

I am having several issues with PA too.... The test using the python script have bulges AND under extrusion even on very high values of PA.

Here an example for PLA from 0.5 to 0.9 - The bulge NEVER disappear even when the under extrusion after starts to show.In the past there always a clear transition where the slow segments had the same width and no under extrusion after.

Also I simply cannot find a value of PA + Retract that lead to good results. It starts to to cause excessive retraction and blocking issues much before solving any oozing.

I reviewed all my hardware looking for possible issues and after finding this thread I think it is related.

It is very severe with small details and curved surfaces (like round small posts for retraction tuning) it is so severe that sometimes and entire layer is mission while others spurts excessive material. For straight lines - like a small cube walls - only the bulge is apparent and the under extrusion after the bulge for higher PA.

I had not updated my board for a long time and the issues started after the update to 3.4 - I do not remember what older version I had before.

But the issues are the same: Excess extrusion even with very high PA with under extrusion right after for higher PA. I had not of these issues before.

I will test 3.4.2 now and then roll back to 3.3 and repeat the Python script test to compare.

-

Have folders as a sub menu button on paneldueposted in PanelDue

I like the fact that I can use numbers to show the macros I most use and I would like to have a submenu, for example, to load different filaments.

Now I can only show four macros as buttons. If I could add a prescript to the folder name making it appear like a submenu button would be nice.

Thanks.

-

RE: Indirect (bearing) laser filament monitor conceptposted in Filament Monitor

@adrian52 What is curious is that I had similar results (high precision with total measured length compared to predicted by slicer) with direct filament readings!!! It was precise enough that I could even calibrate extrusion steps/mm with it. Even with filaments that I had horrible max and min results.

-

RE: My multi input, multi material, mixing hot endposted in My Duet controlled machine

@deckingman Amazing

Will follow. There should be some pressure losses within the mixing chamber that I am curious to the effects!

Will follow. There should be some pressure losses within the mixing chamber that I am curious to the effects! -

RE: Indirect (bearing) laser filament monitor conceptposted in Filament Monitor

@crash69 Loved your solution for the barings holder!!!!! These bearings are easier to find around here and also cheaper. I'll buy them ASAP and test your design.

Thanks!

Thanks! -

RE: Indirect (bearing) laser filament monitor conceptposted in Filament Monitor

Great information!!!!!!

I used to compare the slicer predicted total length with the sensor reported total length. How does this correlate with the sensor distance?