@droftarts, @Phaedrux, @engikeneer, thank you all for your replies. Turned out to be a faulty heater cartridge. I received a new heater cartridge from an official E3D reseller. It has the correct resistance and is working well.

I suspect the original 30w heater was faulty from the start. When I first got my V6 3 years ago, I think I was only ever able to tune to around 260 and now that I'm printing close to that, it wasn't stable while also pushing filament through.

Also, there is adequate space between the heatsink and heater block.

Glad to have my printer back. Thanks for the help!

Best posts made by breadandbudder

-

RE: Extruder temp undershoots, even in auto tuneposted in Tuning and tweaking

-

RE: X/Y axis not homing after new configposted in General Discussion

@Veti

I figured it out. I feel so dumb.I had connected the X axis motor to the wrong header. The Y axis is fine. I've been building computers for almost 9 years. I should know by now to check all connections first. I think it's good that I left this problem alone for a month and came back to it fresh.

I'm not sure what happened with the firmware version. I followed along with a guide on youtube from 'Design Prototype Test' and his files.

Thanks for helping! Even if it was to figure out what wasn't the problem.

It's now 6:00 am and all is right in the world.

Latest posts made by breadandbudder

-

RE: Extruder temp undershoots, even in auto tuneposted in Tuning and tweaking

@droftarts, @Phaedrux, @engikeneer, thank you all for your replies. Turned out to be a faulty heater cartridge. I received a new heater cartridge from an official E3D reseller. It has the correct resistance and is working well.

I suspect the original 30w heater was faulty from the start. When I first got my V6 3 years ago, I think I was only ever able to tune to around 260 and now that I'm printing close to that, it wasn't stable while also pushing filament through.

Also, there is adequate space between the heatsink and heater block.

Glad to have my printer back. Thanks for the help! -

RE: Extruder temp undershoots, even in auto tuneposted in Tuning and tweaking

@droftarts The wiring was actually the next thing I was going to check. Did not know the resistance could change with temperature though.

Here's what I've done so far:

-Removed and reseated thermistor and heater cartridge in heater block.

-Cut and reseated heater wires in screw terminal. Auto-tune was working at 260 degrees, but not higher.

-No heat felt at screw terminal during testing.

-After a failed auto-tune while it was still hot, I measured the resistance and it was the same. Not sure if that was the right way to test that.

-Cut extension off of heater wires (21.2 ohms now vs 21.3 before). Same result from auto-tune. 260 works, but not higher.

-Switched from E0 to E1 terminal. Same thing.At this point, I think I need to replace the heater. I'm looking at a E3D 24v 40w heater cartridge, but higher wattage ones are cheaper and more abundant on Amazon. I'm just not sure I feel comfortable with more power draw, though it seems my original Ender 3 PSU should be able to support it. Could I get a 50w or 60w cartridge and run it lower by setting the P value lower in the M303 command? Any suggestions on where to source a quality heater cartridge relatively quickly?

-

Extruder temp undershoots, even in auto tuneposted in Tuning and tweaking

Hi, all. I was just finishing up a project for a family member when my hotend stopped working. I've tried searching for solutions, but keep seeing the same pages with no solutions. Any help would be greatly appreciated.

The problem:

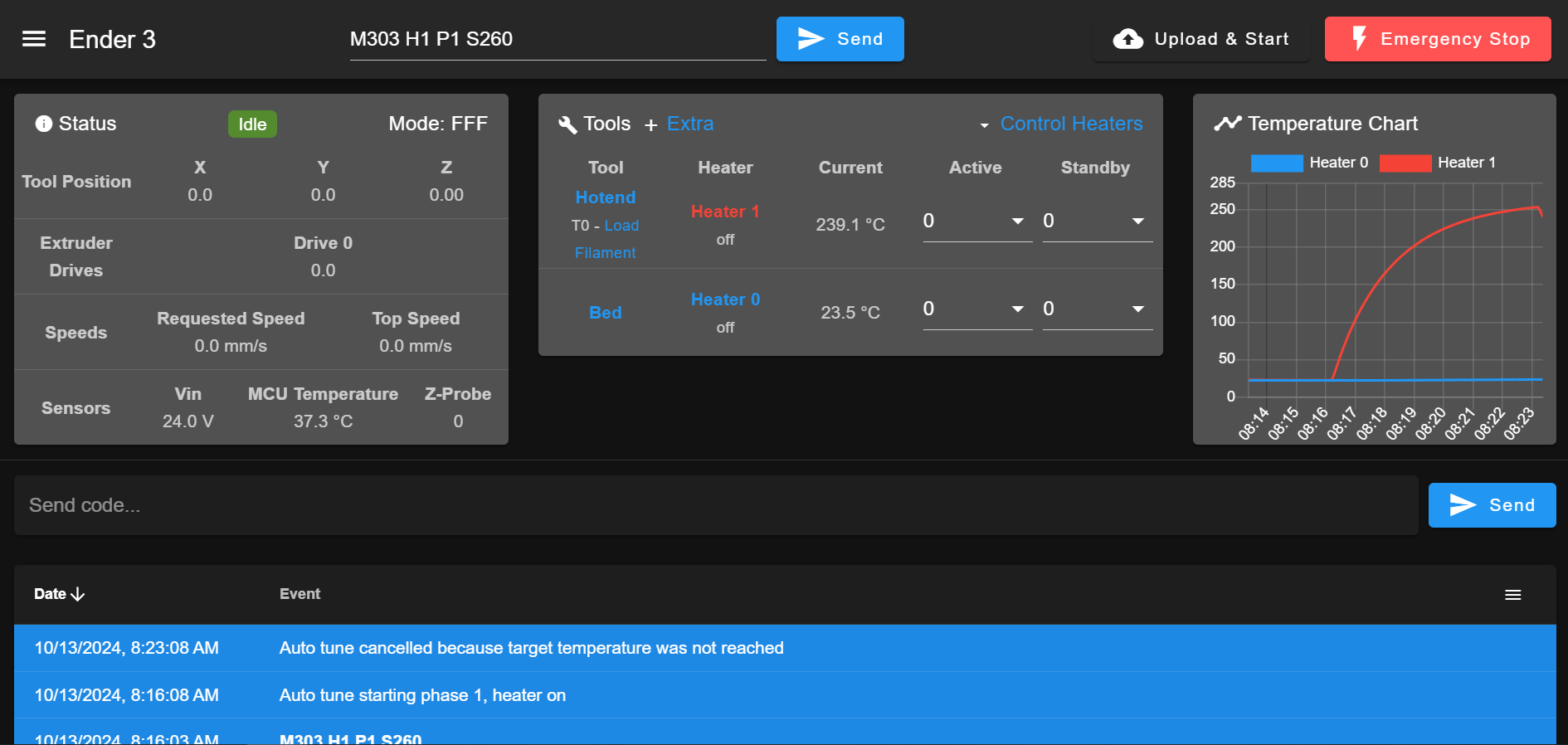

Most of the way through an 11 hour print (ASA, 260°), I noticed the hotend temperature was fluctuating down about 4 degrees and back up over about 5 minutes and just kept doing that. I attempted to auto tune the heater using "M303 H1 P1 S280" and a range of lower temps and tried increasing the dead time to 30, but each attempt resulted in "Auto tune cancelled because target temperature was not reached" (see screenshot example). If I try to heat it outside of auto tune, the temp plateaus 5-10 degrees short of the target. I checked and the heater cartridge and thermistor are not loose.

My setup:

I have an E3D V6 30w (with silicone sock) connected to a Duet 2 Maestro running firmware version 3.2 and Duet Web Control 3.4.6. I extended the wires for both the heater and thermistor and it had been working for many hours of printing before this. The resistance is 21.3 ohm. I normally print ABS at 245 and only just started printing ASA at 260 for the last 30 hours of print time.Side question: what is the default dead time/ what should I set that to?

-

RE: X/Y axis not homing after new configposted in General Discussion

@Veti

I figured it out. I feel so dumb.I had connected the X axis motor to the wrong header. The Y axis is fine. I've been building computers for almost 9 years. I should know by now to check all connections first. I think it's good that I left this problem alone for a month and came back to it fresh.

I'm not sure what happened with the firmware version. I followed along with a guide on youtube from 'Design Prototype Test' and his files.

Thanks for helping! Even if it was to figure out what wasn't the problem.

It's now 6:00 am and all is right in the world.

-

RE: X/Y axis not homing after new configposted in General Discussion

@Veti what do I need to change to get it to work? I tried reading up on the codes, but nothing is sticking out to me.

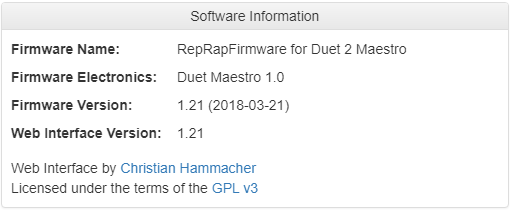

Here's a screenshot from my Duet 2 Maestro interface showing the 1.21 firmware version:

-

RE: X/Y axis not homing after new configposted in General Discussion

@Veti My bad. I think I tried both 2.03 and 3.2.

And I just edited the post to include the config.g instead -

X/Y axis not homing after new configposted in General Discussion

I did a direct drive mod for my Ender 3 and needed to modify the bed size so I opened up the RRF Configurator Tool with the config file I was using, changed the bed size, and got the latest firmware (I was on 1.21 going to 2.03). After that, the X and Y axis would not home correctly. It was making an awful sound as it hit the min stop switch and continued driving the motor. I haven't been able to test the Z axis homing because I have a BLtouch and it needs the other axes homed first.

Here are the things I have tried:

-The end stop type was set to 'sensorless'/stall detection so I instead tried both 'active high' (which didn't move, but showed as homed, and made the motors whine) and 'active low' (which again caused the issue of hitting the end stop, but continuing as if it hadn't).

-I downgraded the firmware and repeated the above tests.The Ender 3 endstop type is 'active low', right??

Any help, direction, or info is greatly appreciated.

-Alec

; Configuration file for Duet Maestro (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Sun Jan 24 2021 22:51:12 GMT-0700 (Mountain Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"MaestroPro" ; set printer name ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E93.00 ; set steps per mm M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z300.00 E1500.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X400 Y400 Z400 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S300 ; Set idle timeout ; Axis Limits M208 X-5.5 Y-10 Z0 S1 ; set axis minima M208 X258.5 Y246 Z260 S0 ; set axis maxima ; Endstops M574 X1 Y1 S0 ; set active low and disabled endstops M574 Z1 S2 ; set endstops controlled by probe ; Z-Probe M558 P9 H2.5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P25 X-31 Y0 Z0.6 ; set Z probe trigger value, offset and trigger height M557 X20:215 Y20:215 S20 ; define mesh grid ; Heaters M305 P0 T98801 B4185 R2200 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T98801 B4185 R2200 ; set thermistor + ADC parameters for heater 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 S1 I0 F500 H0:1 T45 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Sun Jan 24 2021 22:51:12 GMT-0700 (Mountain Standard Time) G91 ; relative positioning G1 S2 Z2.5 F6000 ; lift Z relative to current position G1 S1 X-269 F1800 ; move quickly to X axis endstop and stop there (first pass) G1 S2 X5 F6000 ; go back a few mm G1 S1 X-269 F360 ; move slowly to X axis endstop once more (second pass) G1 S2 Z-2.5 F6000 ; lower Z again G90 ; absolute positioning; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Sun Jan 24 2021 22:51:12 GMT-0700 (Mountain Standard Time) G91 ; relative positioning G1 S2 Z2.5 F6000 ; lift Z relative to current position G1 S1 Y-261 F1800 ; move quickly to Y axis endstop and stop there (first pass) G1 S2 Y5 F6000 ; go back a few mm G1 S1 Y-261 F360 ; move slowly to Y axis endstop once more (second pass) G1 S2 Z-2.5 F6000 ; lower Z again G90 ; absolute positioning; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Sun Jan 24 2021 22:51:12 GMT-0700 (Mountain Standard Time) G91 ; relative positioning G1 S2 Z2.5 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X51 Y20 F6000 ; go to first probe point G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z2.5 F100 ; lift Z relative to current position ;G90 ; absolute positioning