I would like to have auto-scaling of temperatures graph - would make tracking lower temps easier.

Perhaps it would be also nice to have dual-scale - left scale for tools (usually higher range), right scale to heatbed/chamber (usualy lower range).

I would like to have auto-scaling of temperatures graph - would make tracking lower temps easier.

Perhaps it would be also nice to have dual-scale - left scale for tools (usually higher range), right scale to heatbed/chamber (usualy lower range).

@phaedrux I bought it from Hobbystore, around IX.2020

I have 2 of them, and can swap to check if this issue is still there.

In fact I have no idea why I did not do that already.

I will test 2 cases:

It would be nice to have recursive delete for non empty directories.

I think that viable solution would be to use NFC tags and a spool holder with reader. With new spool just put a nfc sticker (can be bought easily) and set a filament length when spool used for a first time.

Then each time spool in put on spoolholder read the tag, and update legth when print finished/tool change/ etc

Easy to implement - nfc readers are available with many intercaes, tags can be bought without problems.

If state.gpOut[3].pwm==0

M42 P3 S1

else state.gpOut[3].pwm==1

M42 P3 S0

condition in else is obsolete, and more "elegant" way is

If state.gpOut[3].pwm != 0

M42 P3 S0

else

M42 P3 S1

I am wondering how this "community repairs" idea is woking out.

Are there any stats how many community repairs been done so far?

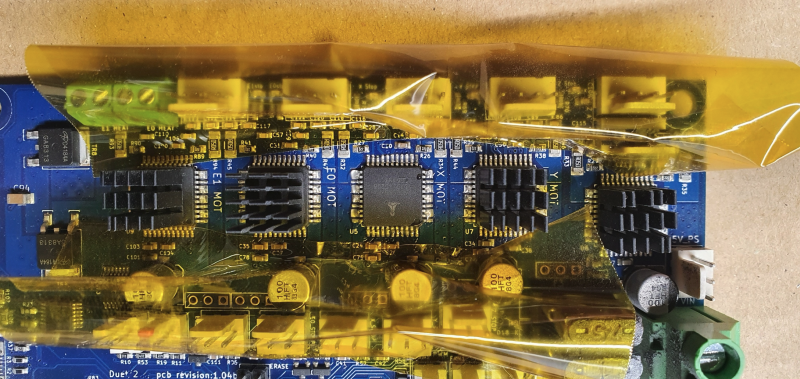

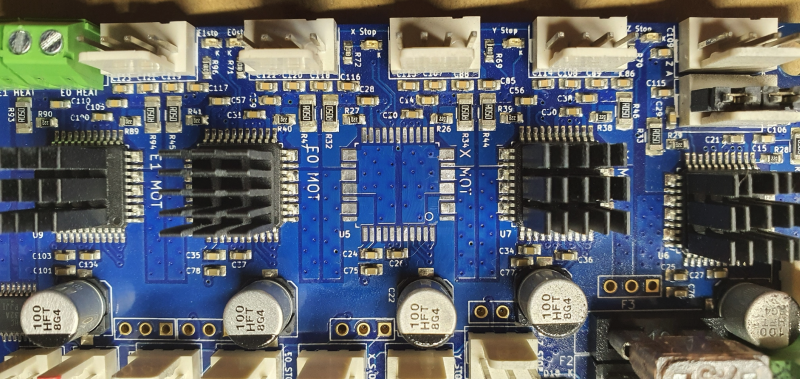

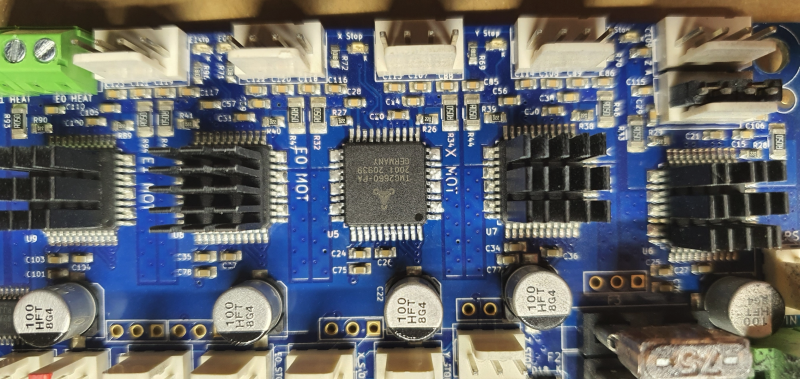

I recently replaced one of the stepper drivers in duet2.

Here are some pics from the process:

@dom I think latest paneldue will not work properly with 2.05.1 firmware. Update Duet firmware to 3.2.2

Probing twice the same point?

G30 P0 X26 Y226 Z-99999 ; probe near an adjusting screw

G30 P1 X26 Y226 Z-99999 ; probe near an adjusting screw

@wieman01 Y range is limited only from one side. Y=0 coordinates can be reached by bltouch - it just moves nozzle to position Y=36, and then proble is at Y=0.

But.. if nozzle can go only to Y=350, then probe can reach only points with Y <= 350-36.

So M557 would have Y range Y0:314, as any higher Y is out of reach of probe tip.

@chrishamm Duet 3 MB6HC,

And I have found part of uploaded file thas is corrupted... seems some issue with uploading? Looks like part of HTTP header found it's way to became part of file

;WIPE_START

G1 F8640.000

G1 X123.480 Y109.004 E-0.10336

G1 X123.276 Y108.556 E-0.11374

G1 X123.884 Y108.812 E-0.15251

;WIPE_END

G1 E-0.430.204

User-Agent: Mozilla/5.0 (Windows NT 10.0; Win64; x64; rv:92.0) Gecko/20100101 Firefox/92.0

Accept: */*

Accept-Language: pl,en-US;q=0.7,en;q=0.3

Accept-Encoding: gzip, deflate

Content-Type: application/json

X-Requested-With: XMLHttpRequest

Connection: keep-alive

Referer: http://192.168.0.204/

ؽþ 2 X121.725 Y107.215 I1.405 J-0.346 E-0.16829

;WIPE_END

G1 E-0.40387 F2100.000

G1 Z9.000 F10800.000

G1 X121.068 Y104.629

G1 Z8.600

G1 E0.80000 F2100.000

M204 S800

I am getting popcorn

This is getting ridiculous.

It is so hard to understand, that older hardware is not capable of handling new features?

https://forum.duet3d.com/topic/28401/g-code-for-only-filament-extrusion-without-moving-nozzle

Same question in 2 places, and 3 minutes between posting them... damn I thought I am the impatient guy

G30 P0 X28.8 Y24 Z-99999 ; hinten rechts

G30 P1 X198.8 Y24 Z-99999 ; hinten links

G30 P2 X198 Y194 Z-99999 ; vorne links

G30 P3 X28.8 Y194 Z-99999 S4 ; vorne rechts and report adjustments needed

You missed P1

@MartinNYHC M208 X0 Y0 Z0 S1 instead of M208 X77 Y84 Z0 S1

OK. This seems to be coincidence. Printer pauses for a few seconds in random places even without panel connected.

Out of pure curiosity, I just checked on my printer (Duet3, standalone, 3.2-b1), and seems to be just fine.

@Frederik And cleanup You config. Seems

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z2560.00 E837.02 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z1800.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z30.00 E250.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z1000 E1200 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X400 Y400 Z400 S0 ; set axis maxima

; Endstops

M574 X2 S1 P"!io1.in" ; configure active-high endstop for high end on X via pin !io1.in

M574 Y1 S1 P"!io0.in" ; configure active-high endstop for low end on Y via pin !io0.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

is duplicated

M107 - works, so nothing to overcome (at least for now)

Setting temperatures

If You add into custom gcode

M104 S0 Tx

then prusa slicer is not adding it at the beginning and You can set it later when You need it. Downside is that prusa slicer will use later M104 if You have different temp for first and next layers.

My startup code:

G90 ; use absolute coordinates

M83 ; extruder relative mode

T-1

M104 S0 T0

; M104 S0 T1

M144 S1

M140 S[first_layer_bed_temperature] ; set bed temp

G10 P0 R120 S[first_layer_temperature_0]

; G10 P1 R120 S[first_layer_temperature_1]

M116

G28 ; home all without mesh bed level

G32 ; mesh bed leveling

M404 N1.75 D0.4

G1 X0.0 Y-4.0 Z[first_layer_height] F1000.0 ; go outside print area

T0

M116

G92 E0.0

G1 E4.0 F300.0

G92 E0.0

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.5 F1000.0 ; intro line

G92 E0.0

@Phaedrux Same results with XY active - moving head diagonally 0,0 to 200,200 and back to 0,0

at 4000mm/min 0 hiccups

And for completness: gcode file I am printing: gravitrax_dual_0.2mm_PETG_MK3S_52m.gcode