@phaedrux said in So close...Extruder connected to Toolboard won't budge.:

M98 P"config.g"

M122

M122 B121

1/20/2022, 2:53:05 PM M122 B121

Diagnostics for board 121:

Duet TOOL1LC firmware version 3.3 (2021-06-15 16:12:58)

Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1)

Never used RAM 2912, free system stack 2789 words

Tasks: Move(notifyWait,0.1%,147) HEAT(delaying,2.1%,117) CanAsync(notifyWait,0.0%,65) CanRecv(notifyWait,0.6%,76) CanClock(notifyWait,0.9%,65) ACCEL(notifyWait,0.0%,61) TLast software reset data not available

Driver 0: position 0, 80.0 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 0, ifcnt 12, reads 28120, writes 12, timeouts 0, DMA errors 0, steps req 0 done 0

Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0

Peak sync jitter 0/0, peak Rx sync delay 199, resyncs 0/0, no step interrupt scheduled

VIN: 24.5V

MCU temperature: min 17.4C, cuLast sensors broadcast 0x00000000 found 0 12 ticks ago, loop time 0

CAN messages queued 653435, send timeouts 0, received 1470240, lost 0, free buffers 37, min 37, error reg 110000

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0

Accelerometer detected: yes, status: 00

I2C bus errors 0, naks 0, other errors 0

1/20/2022, 2:52:52 PM M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.01-RC9 running on Duet 3 MB6HC v1.01 or later

Board ID: 08DJM-956BA-NA3TN-6J1F6-3S46K-TBAASUsed output buffers: 1 of 40 (13 max)

=== RTOS ===

Static ram: 154572

Dynamic ram: 162220 of which 464 recycled

Exception stack ram used: 332

Never used ram: 75628

Tasks: ETHERNET(blocked,804) NETWORK(ready,2076) HEAT(blocked,1084) CanReceiv(suspended,3412) CanSender(suspended,1432) CanClock(blocked,1432) TMC(blocked,216) MAIN(running,4404) IDLE(ready,80)

Owned mutexes:

=== Platform ===

Last reset 45:22:34 ago, cause: power up

Last software reset at 2022-01-10 04:03, reason: User, spinning module LinuxInterface, available RAM 75656 bytes (slot 0)

Software reset code 0x0010 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0444a000 BFAR 0x00000000 SP 0xffffffff Task 0x4e49414d

Error status: 0

Free file entries: 10

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest block write time: 0.0ms, max retries 0

MCU temperature: min 38.2, current 38.4, max 38.5

Supply voltage: min 24.1, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 11.8, current 12.3, max 12.9, under voltage events: 0

Driver 0: standstill, reads 19216, writes 8 timeouts 0, SG min/max not available

Driver 1: standstill, reads 19216, writes 8 timeouts 0, SG min/max not available

Driver 2: standstill, reads 19216, writes 8 timeouts 0, SG min/max not available

Driver 3: standstill, reads 19216, writes 8 timeouts 0, SG min/max not available

Driver 4: standstill, reads 19216, writes 8 timeouts 0, SG min/max not available

Driver 5: standstill, reads 19224, writes 0 timeouts 0, SG min/max not available

Date/time: 2022-01-20 20:52:50

Slowest loop: 4.55ms; fastest: 0.21ms

=== Move ===

Hiccups: 0(0), FreeDm: 375, MinFreeDm: 375, MaxWait: 0ms

Bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves: 3, completed moves: 3, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== AuxDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== Heat ===

Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

Heater 1 is on, I-accum = 0.0

Heater 2 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP* is ready with "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon* is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 0.48ms; fastest: 0.03ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0)

HTTP sessions: 0 of 8

- Ethernet -

State: establishingLink

Error counts: 0 0 0 0 0

Socket states: 0 0 0 0 0 0 0 0

=== CAN ===

Messages sent 200, longest wait 1ms for type 6017

=== Linux interface ===

State: 0, failed transfers: 0

Last transfer: 23ms ago

RX/TX seq numbers: 52946/52947

SPI underruns 0, overruns 0

Number of disconnects: 0

Buffer RX/TX: 0/0-0

=== Duet Control Server ===

Duet Control Server v3.1.1

Code buffer space: 4096

Configured SPI speed: 8000000 Hz

Full transfers per second: 31.46

1/20/2022, 2:52:39 PM M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

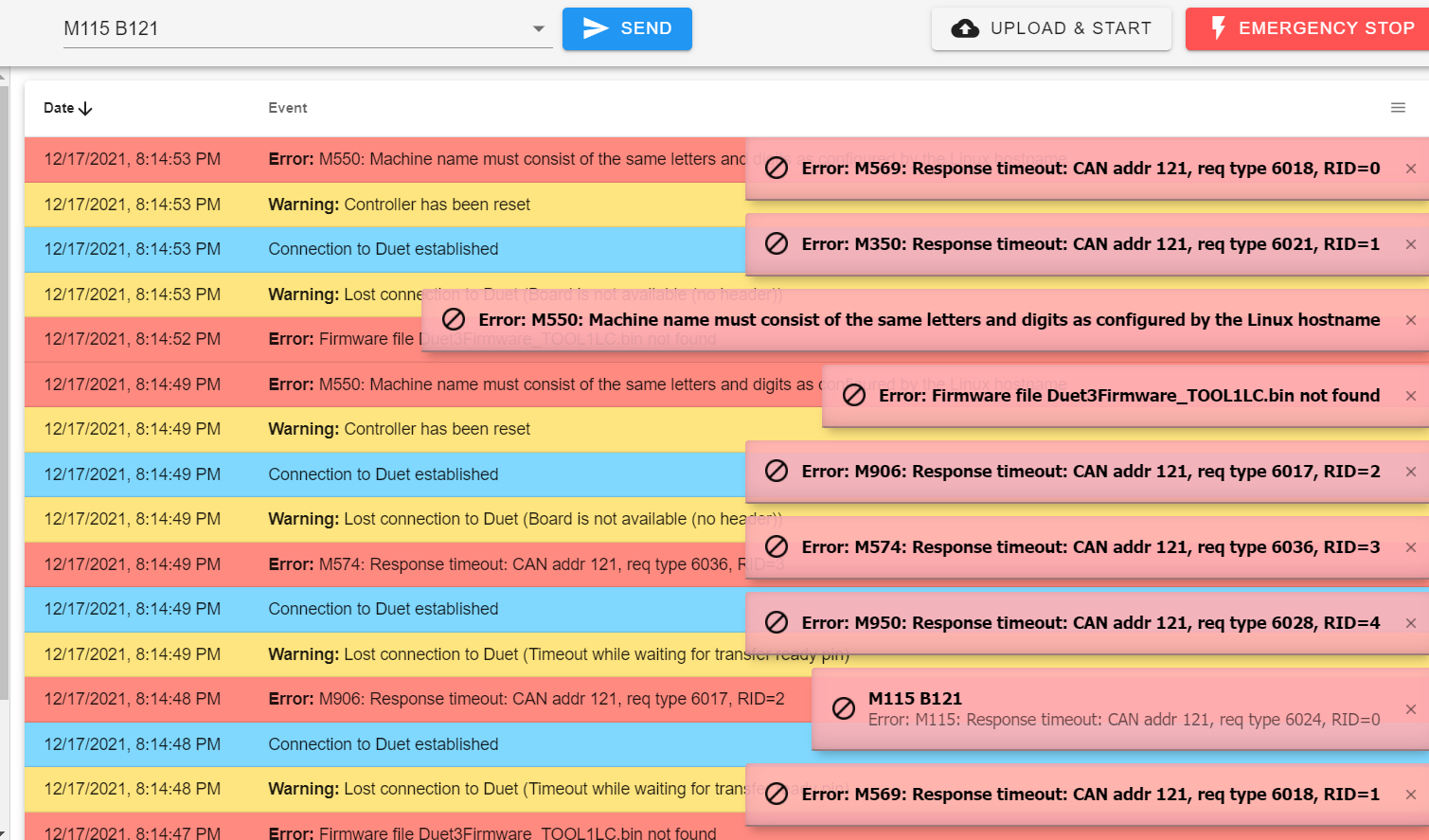

Error: M350: Board 121 received unknown msg type 6021

Error: M906: Board 121 received unknown msg type 6017

Warning: M307: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 365C

Warning: M955: Command is not supported

Error: M591: Remote ports not yet supported by this command

1/20/2022, 2:52:16 PM M98 P"config.g" M122 M122 B121

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.01-RC9 running on Duet 3 MB6HC v1.01 or later

Board ID: 08DJM-956BA-NA3TN-6J1F6-3S46K-TBAASUsed output buffers: 1 of 40 (10 max)

=== RTOS ===

Static ram: 154572

Dynamic ram: 162220 of which 464 recycled

Exception stack ram used: 332

Never used ram: 75628

Tasks: ETHERNET(blocked,804) NETWORK(ready,2076) HEAT(blocked,1084) CanReceiv(suspended,3412) CanSender(suspended,1432) CanClock(blocked,1432) TMC(blocked,216) MAIN(running,4764) IDLE(ready,80)

Owned mutexes:

=== Platform ===

Last reset 45:21:51 ago, cause: power up

Last software reset at 2022-01-10 04:03, reason: User, spinning module LinuxInterface, available RAM 75656 bytes (slot 0)

Software reset code 0x0010 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0444a000 BFAR 0x00000000 SP 0xffffffff Task 0x4e49414d

Error status: 0

Free file entries: 10

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest block write time: 0.0ms, max retries 0

MCU temperature: min 15.2, current 38.3, max 40.7

Supply voltage: min 24.1, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 11.4, current 12.4, max 12.9, under voltage events: 0

Driver 0: standstill, reads 36868, writes 15 timeouts 0, SG min/max 0/0

Driver 1: standstill, reads 36869, writes 15 timeouts 0, SG min/max 0/0

Driver 2: standstill, reads 36869, writes 15 timeouts 0, SG min/max 0/0

Driver 3: standstill, reads 36870, writes 15 timeouts 0, SG min/max 0/0

Driver 4: standstill, reads 36870, writes 15 timeouts 0, SG min/max 0/0

Driver 5: standstill, reads 36875, writes 11 timeouts 0, SG min/max 0/0

Date/time: 2022-01-20 20:52:06

Slowest loop: 4.63ms; fastest: 0.14ms

=== Move ===

Hiccups: 0(0), FreeDm: 375, MinFreeDm: 375, MaxWait: 3240065ms

Bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves: 3, completed moves: 3, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== AuxDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== Heat ===

Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

Heater 1 is on, I-accum = 0.0

Heater 2 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP* is ready with "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon* is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 1.68ms; fastest: 0.01ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0)

HTTP sessions: 0 of 8

- Ethernet -

State: establishingLink

Error counts: 0 0 0 0 0

Socket states: 0 0 0 0 0 0 0 0

=== CAN ===

Messages sent 653144, longest wait 1ms for type 6018

=== Linux interface ===

State: 0, failed transfers: 0

Last transfer: 18ms ago

RX/TX seq numbers: 51574/51575

SPI underruns 0, overruns 0

Number of disconnects: 0

Buffer RX/TX: 0/0-0

=== Duet Control Server ===

Duet Control Server v3.1.1

Code buffer space: 4096

Configured SPI speed: 8000000 Hz

Full transfers per second: 10.46

Error: M122: Board 121 received unknown msg type 50

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

Error: M569: Board 121 received unknown msg type 50

Error: M350: Board 121 received unknown msg type 50

Error: M906: Discarded msg src=121 typ=4510 RID=11 exp 14

Discarded msg src=121 typ=4510 RID=11 exp 14

Discarded msg src=121 typ=4510 RID=12 exp 14

Board 121 received unknown msg type 6021

Discarded msg src=121 typ=4510 RID=15 exp 16

Warning: M307: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 365C

Warning: M955: Command is not supported

Error: M591: Remote ports not yet supported by this command