@dc42

Ok, thanks a lot for your help. If I get it working, I'll post it on the forum for anyone who might be interested.

Posts made by amimafe

-

RE: Modify job.filePosition valueposted in Gcode meta commands

-

RE: Modify job.filePosition valueposted in Gcode meta commands

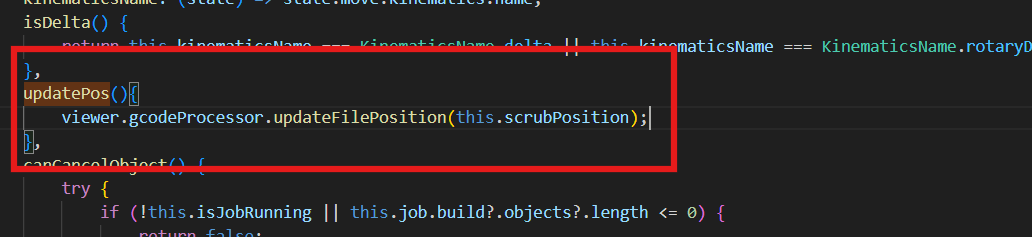

I have been able to add a button in the Gcodeviewer Plugin and what I would like is to be able to save the value of ScrubPosition (the position of the gcode where the mouse points), in a variable that I can read in duet, when I press this button. I thought I could do it in the job.filePosition object, but I can't do it.

I have added the following function but it doesn't work. I apologize because I don't have a lot of programming knowledge and I'm trying to learn little by little:

On the other hand I have a problem when resuming a printout with the command M26 S{job.filePosition}. I must enter before G92 Ennn with the corresponding extrusion value of the code line where it is going to start or it is not strictly necessary?

-

RE: Modify job.filePosition valueposted in Gcode meta commands

M26 works perfectly.

What I want to achieve is that when I press a button in gcodeviewer it stores the scrubPosition value directly in a variable that I can use in M26 and I don't have to enter it manually.

Unfortunately I have not found any variable in the source code that I can work with later in duet.

I thought about using job.filePosition, but it does not allow me to modify its value, only to read it. -

Modify job.filePosition valueposted in Gcode meta commands

Hi,

Is it possible to assign a value to job.filePosition if a gcode is not running? I would like to take advantage of the value in the GcodeViewer (scrubPosition), to restart a print from that point.

Thank you!

-

RE: Manually updating resurrect.g without having to pause the print?posted in General Discussion

@Alva I'm sorry but I don't know how I can help you with your problem. If it helps you, I am working to create a macro that allows me to save the current line that is being executed from the gcode in a global variable and allows me to restart the layer if something goes wrong.

When I have it if you think it can be interesting I can share it with you.Best regards!

-

RE: Manually updating resurrect.g without having to pause the print?posted in General Discussion

@Alva for me, the power failure recovery (M916) works correctly, but what I would like is to be able to save the G60 position in the resurrect.g so I can continue printing from that point.

-

RE: Manually updating resurrect.g without having to pause the print?posted in General Discussion

@Phaedrux Pedí algunas tapas para ver si eso ayuda con el problema. Sin embargo, me gustaría poder guardar manualmente la posición también, en caso de que la pérdida de energía no funcione o algo que no sea un bajo voltaje haga que la placa se reinicie. ¿Quizás algo como G60? Pero no parece que la posición de restauración de G60 se guarde después de un reinicio.

I'm also interested in this. I've tested it with G60, as you said it's not suitable for that use.

Were you able to find out anything? -

RE: Read Gcode File backwardsposted in Firmware wishlist

I have been testing with the G60 command and have obtained good results.

Now I have the following problem:

With G60 I go back to a saved position and manage to go back, but when I run resume.g the printer returns to the coordinates where it paused and not at the G60 position.

I have checked both in the Gcode commands and in the Object model to see if there is any option to update the coordinates before executing resume.g but I have not found anything.Any ideas or suggestions on this?

Thanks

-

RE: G2/G3 arc slow downposted in Tuning and tweaking

Wow, it's certainly very interesting and I think it might be just what I needed. I will study it well and give an answer.

Thank you very much

-

RE: G2/G3 arc slow downposted in Tuning and tweaking

Hi @gloomyandy ,

The problem I see is that if I increase the jerk to improve the speed of the arcs, when the printer makes a corner it will make a very strong jerk.

Is there no way to make the printer perform a constant movement as if it were performing a straight line? -

G2/G3 arc slow downposted in Tuning and tweaking

Hi,

I am performing various tests and configurations on a clay printer. I have noticed that when I generate the gcode with the instructions G2/G3 it reduces the speed to half when I make the movement of an arc.

Do you know what could be the cause of this. I have checked the Gcode and I don't see any Fxxxx command before the arcs.

Do you know if it could be a config.g parameter or is it something in the firmware?Thank you.

-

RE: Read Gcode File backwardsposted in Firmware wishlist

Hi @marzubus

Thank you for your help.

I'm going to look into the G60 instruction to see if it can be of any help to me.Thanks again

-

RE: Read Gcode File backwardsposted in Firmware wishlist

Sorry @OwenD ,

Yes, I hadn't mentioned that. It is a clay printer. I'm going to check what you told me about the G60 and see if this could be solved, although I think it is not exactly the initial idea.

Gracias.

-

RE: Read Gcode File backwardsposted in Firmware wishlist

Hi @oliof ,

What I want is that if at some point the 3D printer stops extruding I can pause, go back to the gcode position where the failure occurred and continue printing.

The material I print with is not plastic and I need that the correction can be done quickly without the need to modify the gcode.

With industrial PLC it can be implemented more easily, but I would like to know if it could be done with duet or object language.Thank you.

-

Read Gcode File backwardsposted in Firmware wishlist

Hi,

I want to make a macro for Duet2 that allows me to read the lines of a gcode file in reverse.

I have seen that with the M110 command you can know and establish the gcode line, but I don't know how I could implement it.

Any idea how I could do it?Thank you!

-

RE: Layer change detection job.layerposted in Gcode meta commands

The slicers we use add a comment on the layer changes that DUET2 recognizes.

-

RE: Layer change detection job.layerposted in Gcode meta commands

Hi @dc42 ,

I read the postRe: Job.Layer not working anymore with 3.3rc2 and wanted to do something similar. Execute a command at each layer change. Entering the layer change comment with the laminator would not be a problem.

Is there still an option? I tried to do it with creating a variable and assigning it the job.layer value to compare with its current values but it doesn't work.

The idea was to make everything more compact with the duet firmware.Thanks again

-

RE: Layer change detection job.layerposted in Gcode meta commands

Hi @fcwilt ,

Yes, that's the other option I had thought of, but I preferred to do it by daemon.g and if a third party manages the machine, everything is integrated with the firmware.

Thank you.