@jay_s_uk

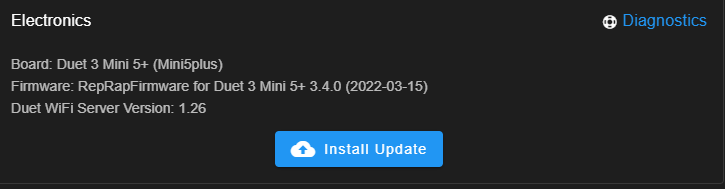

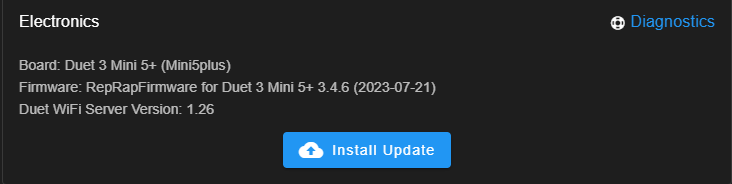

I will upgrade as soon as the printing is finished on Duet Printer 2

Posts made by Aleksander Cane

-

RE: Duet 3 mini5+ nightly restarts 3.5.2posted in Beta Firmware

-

RE: Duet 3 mini5+ nightly restarts 3.5.2posted in Beta Firmware

Duet Printer 2

M122

M122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.4.0 (2022-03-15 18:59:15) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: D3XWJ-AN6KL-K65J0-409NL-JPW1Z-ZGHMG Used output buffers: 9 of 40 (40 max) === RTOS === Static ram: 103684 Dynamic ram: 110780 of which 24 recycled Never used RAM 23336, free system stack 118 words Tasks: NETWORK(ready,96.3%,202) HEAT(notifyWait,0.2%,338) Move(notifyWait,15.6%,267) CanReceiv(notifyWait,0.0%,942) CanSender(notifyWait,0.0%,356) CanClock(delaying,0.1%,337) TMC(notifyWait,9.3%,71) MAIN(running,120.7%,428) IDLE(ready,0.1%,29) AIN(delaying,6.3%,264), total 248.6% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 07:25:59 ago, cause: power up Last software reset at 2024-06-16 10:56, reason: User, GCodes spinning, available RAM 27008, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x04 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 26760958, completed 26760958, timed out 0, errs 0 Step timer max interval 912 MCU temperature: min 34.2, current 39.5, max 41.2 Supply voltage: min 23.6, current 23.9, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/1, heap memory allocated/used/recyclable 2048/26/0, gc cycles 0 Events: 1 queued, 1 completed Driver 0: standstill, SG min 0, read errors 0, write errors 0, ifcnt 11, reads 7577, writes 11, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 0, ifcnt 11, reads 7576, writes 11, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 0, read errors 0, write errors 0, ifcnt 11, reads 7576, writes 11, timeouts 0, DMA errors 0, CC errors 0 Driver 3: ok, SG min 0, read errors 0, write errors 0, ifcnt 11, reads 7575, writes 11, timeouts 1, DMA errors 0, CC errors 0, failedOp 0x6a Driver 4: ok, SG min 0, read errors 0, write errors 0, ifcnt 11, reads 7577, writes 11, timeouts 0, DMA errors 0, CC errors 0 Driver 5: ok, SG min 0, read errors 0, write errors 0, ifcnt 11, reads 7576, writes 11, timeouts 0, DMA errors 0, CC errors 0 Driver 6: standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 7578, writes 9, timeouts 0, DMA errors 0, CC errors 0 Date/time: 2024-06-17 15:21:50 Cache data hit count 4294967295 Slowest loop: 60.25ms; fastest: 0.09ms === Storage === Free file entries: 9 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 2.1ms, write time 7.8ms, max retries 0 === Move === DMs created 83, segments created 43, maxWait 1393453ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 662178, completed 662138, hiccups 0, stepErrors 0, LaErrors 0, Underruns [136, 0, 0], CDDA state 3 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.7 === GCodes === Segments left: 1 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is doing "G1 X362.183 Y193.699 E1554.25171" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Filament sensors === Extruder 0: pos 80.86, errs: frame 33 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 240831, received 0, lost 0, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 18 (min 18), ts 133796/0/0 Tx timeouts 0,0,133795,0,0,107034 last cancelled message type 30 dest 127 === Network === Slowest loop: 71.89ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.26 WiFi MAC address e8:68:e7:e1:50:99 WiFi Vcc 3.38, reset reason Power up WiFi flash size 2097152, free heap 25592 WiFi IP address 172.16.1.11 WiFi signal strength -49dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0config.g

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"RatRig_2" ; set printer name M669 K1 ; CoreXY G21 ; Set Units to Millimeters ; Configurazione della connessione Wi-Fi M587 S"*****" P"******" ; Salva il nome e la password della rete Wi-Fi M552 S1 ; Abilita la connessione Wi-Fi M586 P0 S1 ; enable HTTP M586 P1 S0 ; enable FTP M586 P2 S0 ; enable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes forwards M569 P0.1 S0 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S1 ; physical drive 0.3 goes forwards M569 P0.4 S1 ; physical drive 0.4 goes forwards M569 P0.5 S1 ; physical drive 0.5 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E0.5 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 ; set steps per mm M906 X1600 Y1600 Z1600 I30 ; set motor currents (mA) and motor idle factor in per cent -- safe for Duet 3 mini 5+ M84 S30 ; Set idle timeout ; M566 X400.00 Y400.00 Z6.00 E120.00 P1 ; set maximum instantaneous speed changes (mm/min) ; M203 X10800.00 Y10800.00 Z1000.00 E5000.00 ; set maximum speeds (mm/min) ; M201 X3000.00 Y3000.00 Z100.00 E3600.00 ; set accelerations (mm/s^2) M566 X800.00 Y800.00 Z12.00 E240.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 X24000.00 Y24000.00 Z3000.00 E15000.00 ; set maximum speeds (mm/min) M201 X9000.00 Y9000.00 Z300.00 E6000.00 ; set accelerations (mm/s^2) ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io3.in" ; configure active high endstops M574 Y2 S1 P"io1.in" ; configure active high endstops M671 X-4.5:150:304.5 Y-4.52:305:-4.52 S5 ; define positions of Z leadscrews or bed levelling screws M557 X20:280 Y20:280 P5 ; define 5x5 mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 Q11 ; create bed heater output on out5 and map it to sensor 0, lower switching frequency to 11Hz M307 H0 B0 S3.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C ;; Run Bed PID Tune!! Below is an example for a 300x300 bed ;; M307 H0 A303.1 C356.7 D1.4 S1.00 V24.0 B0 ; Fans ;M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency ;M106 P0 C"Layer Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off ; 4-wire PWM fan and tacho M950 F0 C"!out4+out4.tach" ; Definisce la ventola 3 con controllo PWM su io4.out e tachimetro su io4.in M106 P0 C"Layer Fan" S0 ; set fan 1 name and value. Thermostatic control turned on for Hotend M950 F1 C"out3" Q500 ; create fan 1 on pin out3 and set its frequency M106 P1 C"Hotend Fan" S0 H1 T45 ; set fan 1 name and value. Thermostatic control turned on for Hotend M950 F2 C"out5" Q500 ; create fan 2 on pin out5 and set its frequency M106 P2 C"Electronics Fan" S1 H-1 ; set fan 2 name and value. Thermostatic control turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M950 H1 C"out1" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set the maximum temperature in C for heater ; EVA 2 / BMG / E3D V6 M92 E400 ; set extruder steps per mm, 0.9 angle/step (LGX BONDTECH) M906 E600 ; set extruder motor current (mA) and idle factor in per cent M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.060000e-8 A"Hotend" ;; Run Heater PID Tune!! ;; M307 H1 A751.5 C196.6 D4.7 S1.00 V23.9 B0 ; Z-Probe ;; Inductive Probe ; M558 P5 C"!io3.in" H5 F400 T5000 ; set Z probe type to unmodulated and the dive height + speeds ; G31 P500 X-30 Y-15 Z0.20 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ;; BLTouch M950 S0 C"io2.out" ; Create a servo pin on io2 M558 P9 C"io2.in" H5 F240 T10800 A5 ; set Z probe type to unmodulated and the dive height + speeds G31 P25 X-28.00 Y-13.00 Z3.5 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ; Select default tool T0 ; Pressure Advance M572 D0 S0.10 ; Panel Due 7i M575 P1 B57600 S1 ; Avvia communicazione seriale ; Sensore fillamento M591 D0.5 P3 C"io5.in" R0:99999 S0; E22.0; filament monitor connected to E0_stop M591 D0.5 ; display filament sensor parameters for extruder drive 0 -

RE: Duet 3 mini5+ nightly restarts 3.5.2posted in Beta Firmware

Hi Ian,

I am using the boards for 3D printers in standalone mode and they are not connected to any non-standard boards. Below, I have provided the requested information for both boards.

The machines were not running the same Gcode. However, I have never encountered this problem with Duet Printer 1, while I am continuously experiencing it with Duet Printer 2.

If it can be helpful, several times after the board (Duet Printer 2) restarted, the layer cooling fan remained on, the motors were disabled, and one of the three Z-axis drivers was not working when I requested the Z-axis homing. To restart them, I had to reboot the printer.If you need any additional information/actions, please let me know.

Duet Printer 1

M122

M122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.4.6 (2023-07-21 14:09:13) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: R5GU7-D296U-D65J0-40KMJ-L903Z-7T0FN Used output buffers: 1 of 40 (28 max) === RTOS === Static ram: 103712 Dynamic ram: 110476 of which 36 recycled Never used RAM 27488, free system stack 192 words Tasks: NETWORK(notifyWait,57.7%,250) HEAT(notifyWait,0.1%,340) Move(notifyWait,0.0%,363) CanReceiv(notifyWait,0.0%,941) CanSender(notifyWait,0.0%,335) CanClock(delaying,0.1%,342) TMC(notifyWait,4.8%,115) MAIN(running,33.9%,425) IDLE(ready,0.0%,30) AIN(delaying,3.4%,263), total 100.0% Owned mutexes: === Platform === Last reset 07:02:37 ago, cause: software Last software reset at 2024-06-17 08:06, reason: User, GCodes spinning, available RAM 23240, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 25357202, completed 25357201, timed out 0, errs 0 Step timer max interval 1487 MCU temperature: min 32.5, current 33.2, max 34.7 Supply voltage: min 24.2, current 24.3, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 2, read errors 0, write errors 0, ifcnt 40, reads 44553, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 0, ifcnt 44, reads 44553, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 0, read errors 0, write errors 0, ifcnt 44, reads 44553, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 0, ifcnt 46, reads 44552, writes 0, timeouts 1, DMA errors 0, CC errors 0, failedOp 0x6f Driver 4: standstill, SG min 0, read errors 0, write errors 0, ifcnt 46, reads 44553, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 5: standstill, SG min 0, read errors 0, write errors 0, ifcnt 37, reads 44553, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 6: standstill, SG min 0, read errors 0, write errors 0, ifcnt 29, reads 44553, writes 0, timeouts 0, DMA errors 0, CC errors 0 Date/time: 2024-06-17 15:08:57 Cache data hit count 4294967295 Slowest loop: 6.44ms; fastest: 0.13ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 3.4ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Filament sensors === Extruder 0 sensor: no data received === CAN === Messages queued 205540, received 0, lost 0, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 18 (min 18), ts 114189/0/0 Tx timeouts 0,0,114189,0,0,91351 last cancelled message type 30 dest 127 === Network === Slowest loop: 100.72ms; fastest: 0.06ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 = WiFi = Interface state: active Module is connected to access point Failed messages: pending 0, notready 0, noresp 2 WiFi firmware version 1.26 WiFi MAC address f0:08:d1:03:80:e0 WiFi Vcc 3.44, reset reason Power up WiFi flash size 2097152, free heap 25208 WiFi IP address 172.16.1.10 WiFi signal strength -40dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0Config.g

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"RatRig_1" ; set printer name M669 K1 ; CoreXY G21 ; Set Units to Millimeters ; Configurazione della connessione Wi-Fi M587 S"******" P"******" ; Salva il nome e la password della rete Wi-Fi M552 S1 ; Abilita la connessione Wi-Fi M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S1 ; physical drive 0.3 goes forwards M569 P0.4 S1 ; physical drive 0.4 goes forwards M569 P0.5 S1 ; physical drive 0.5 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E0.5 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 ; set steps per mm M906 X1600 Y1600 Z1600 I30 ; set motor currents (mA) and motor idle factor in per cent -- safe for Duet 3 mini 5+ M84 S30 ; Set idle timeout ; M566 X400.00 Y400.00 Z6.00 E120.00 P1 ; set maximum instantaneous speed changes (mm/min) ; M203 X10800.00 Y10800.00 Z1000.00 E5000.00 ; set maximum speeds (mm/min) ; M201 X3000.00 Y3000.00 Z100.00 E3600.00 ; set accelerations (mm/s^2) M566 X800.00 Y800.00 Z12.00 E240.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 X24000.00 Y24000.00 Z3000.00 E15000.00 ; set maximum speeds (mm/min) M201 X9000.00 Y9000.00 Z300.00 E6000.00 ; set accelerations (mm/s^2) ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X475 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io3.in" ; configure active high endstops M574 Y2 S1 P"io1.in" ; configure active high endstops M671 X-4.5:150:304.5 Y-4.52:305:-4.52 S5 ; define positions of Z leadscrews or bed levelling screws M557 X20:280 Y20:280 P5 ; define 5x5 mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 Q11 ; create bed heater output on out5 and map it to sensor 0, lower switching frequency to 11Hz M307 H0 B0 S3.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C ;; Run Bed PID Tune!! Below is an example for a 300x300 bed ;; M307 H0 A303.1 C356.7 D1.4 S1.00 V24.0 B0 ; Fans ;M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency ;M106 P0 C"Layer Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off ; 4-wire PWM fan and tacho M950 F0 C"!out4+out4.tach" ; Definisce la ventola 3 con controllo PWM su io4.out e tachimetro su io4.in M106 P0 C"Layer Fan" S0 ; set fan 1 name and value. Thermostatic control turned on for Hotend M950 F1 C"out3" Q500 ; create fan 1 on pin out3 and set its frequency M106 P1 C"Hotend Fan" S0 H1 T45 ; set fan 1 name and value. Thermostatic control turned on for Hotend M950 F2 C"out6" Q500 ; create fan 2 on pin out5 and set its frequency M106 P2 C"Electronics Fan" S1 H-1 ; set fan 2 name and value. Thermostatic control turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M950 H1 C"out1" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set the maximum temperature in C for heater ; EVA 2 / BMG / E3D V6 M92 E400 ; set extruder steps per mm, 0.9 angle/step (LGX BONDTECH) M906 E600 ; set extruder motor current (mA) and idle factor in per cent M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.060000e-8 A"Hotend" ;; Run Heater PID Tune!! M307 H1 R2.796 K1.398:0.000 D8.59 E1.35 S1.00 B0 V24.2 M570 H1 P30 T30 ; Imposta un tempo di tolleranza di 30 secondi (P30) e un tempo di monitoraggio di 30 minuti (T30) per Heater 1 ; Z-Probe ;; Inductive Probe ; M558 P5 C"!io3.in" H5 F400 T5000 ; set Z probe type to unmodulated and the dive height + speeds ; G31 P500 X-30 Y-15 Z0.20 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ;; BLTouch M950 S0 C"io2.out" ; Create a servo pin on io2 M558 P9 C"io2.in" H5 F240 T10800 A5 ; set Z probe type to unmodulated and the dive height + speeds G31 P25 X-28.00 Y-13.00 Z3.8 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ; Select default tool T0 ; Pressure Advance M572 D0 S0.08 ; Panel Due 7i M575 P1 B57600 S1 ; Avvia communicazione seriale ; Sensore fillamento ;M591 D0.5 P7 C"io5.in" S1 F30:200 ; Dichiara pulse generating sensore di filamento M591 D0.5 P7 L6.5 E20 C"io5.in" S0 R1:99999 ; -

RE: Duet 3 mini5+ nightly restarts 3.5.2posted in Beta Firmware

Hello!

I am experiencing the same problem with my Duet 3 Mini 5+ Wi-Fi board. After weeks of unsuccessful prints, I see on the forum that I am not the only one with the same issue.

I have two printers with Duet 3 Mini 5+ boards, and on Friday I started a two-day print on both printers. The older board completed the print without any problems. The second one, however, reset itself three times, and this morning I restarted it, expecting it to happen again. At least, I hope so, as I can then provide you with some data or log files from the second board.

If you need any information from board 2 or both boards to compare them, please let me know.

Thank you, Alex

-

RE: Board arrived with a damaged componentposted in Other control boards

Hi @oliof,

Thank you for your note on the matter. I'm not sure exactly what the damaged component is for, so thank you for specifying it. However, as I also explained in the title of this post, the board arrived already damaged, and I didn't even have the satisfaction of turning it on as it doesn't power up.

-

RE: Board arrived with a damaged componentposted in Other control boards

Hi @T3P3Tony,

Thank you very much for your response. I've already sent an email to "sales@Duet3d.com", and they have already replied. They are working with RatRig to resolve the issue. If necessary, I can also send it to "info@duet3d.com".

Thanks again!

-

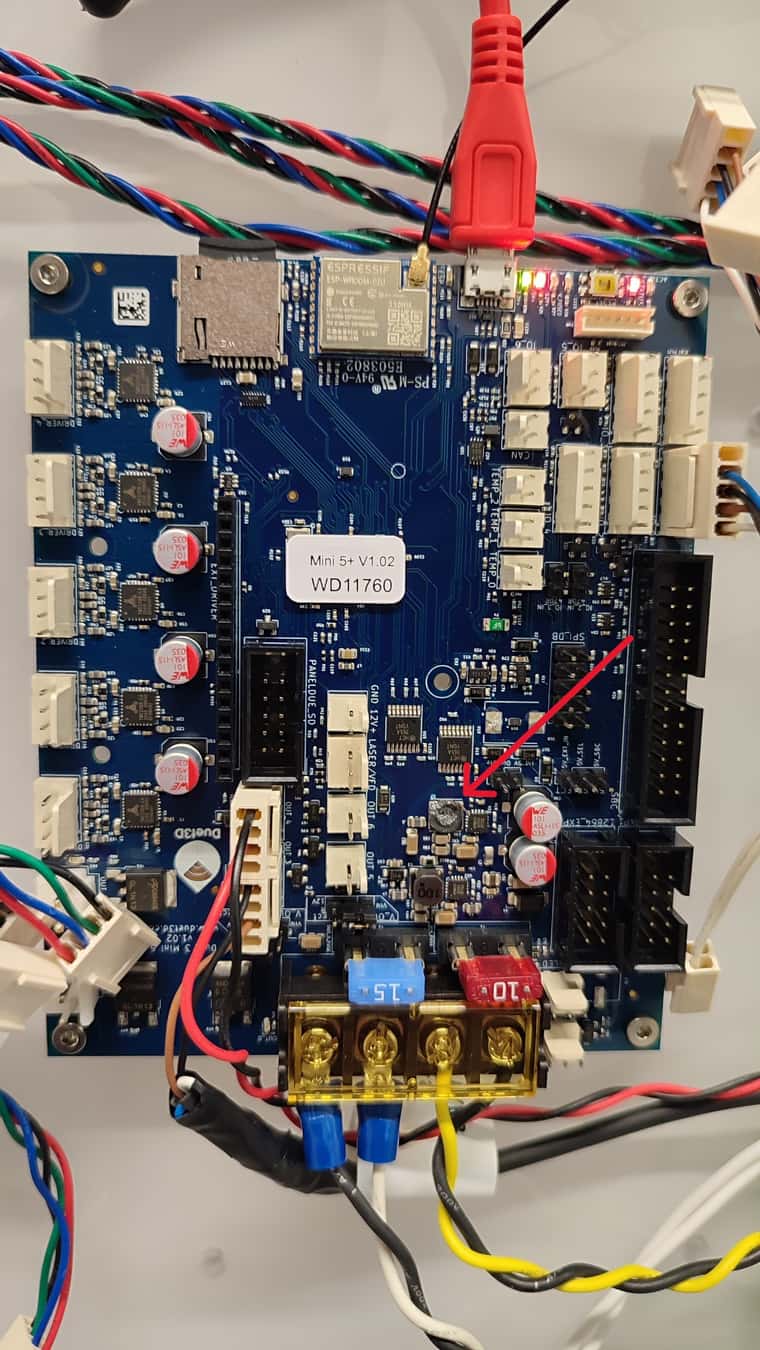

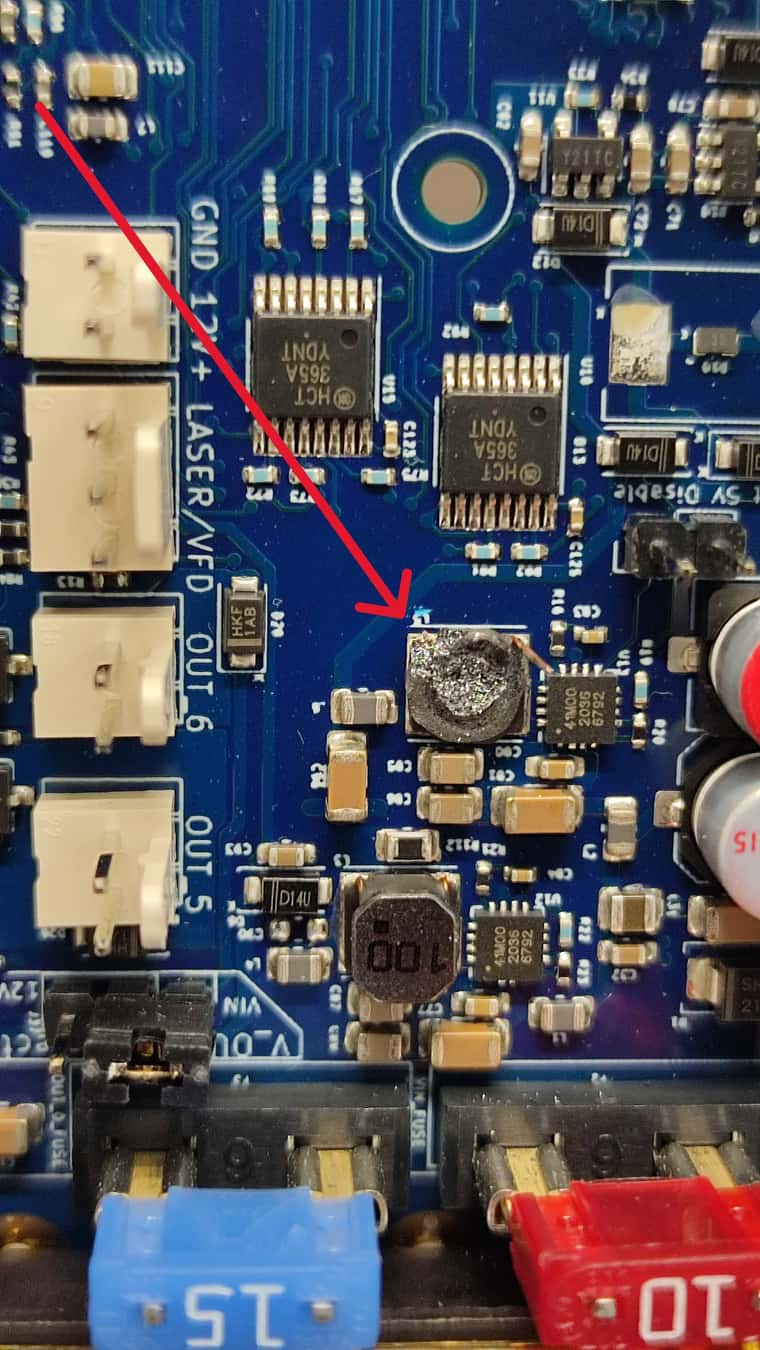

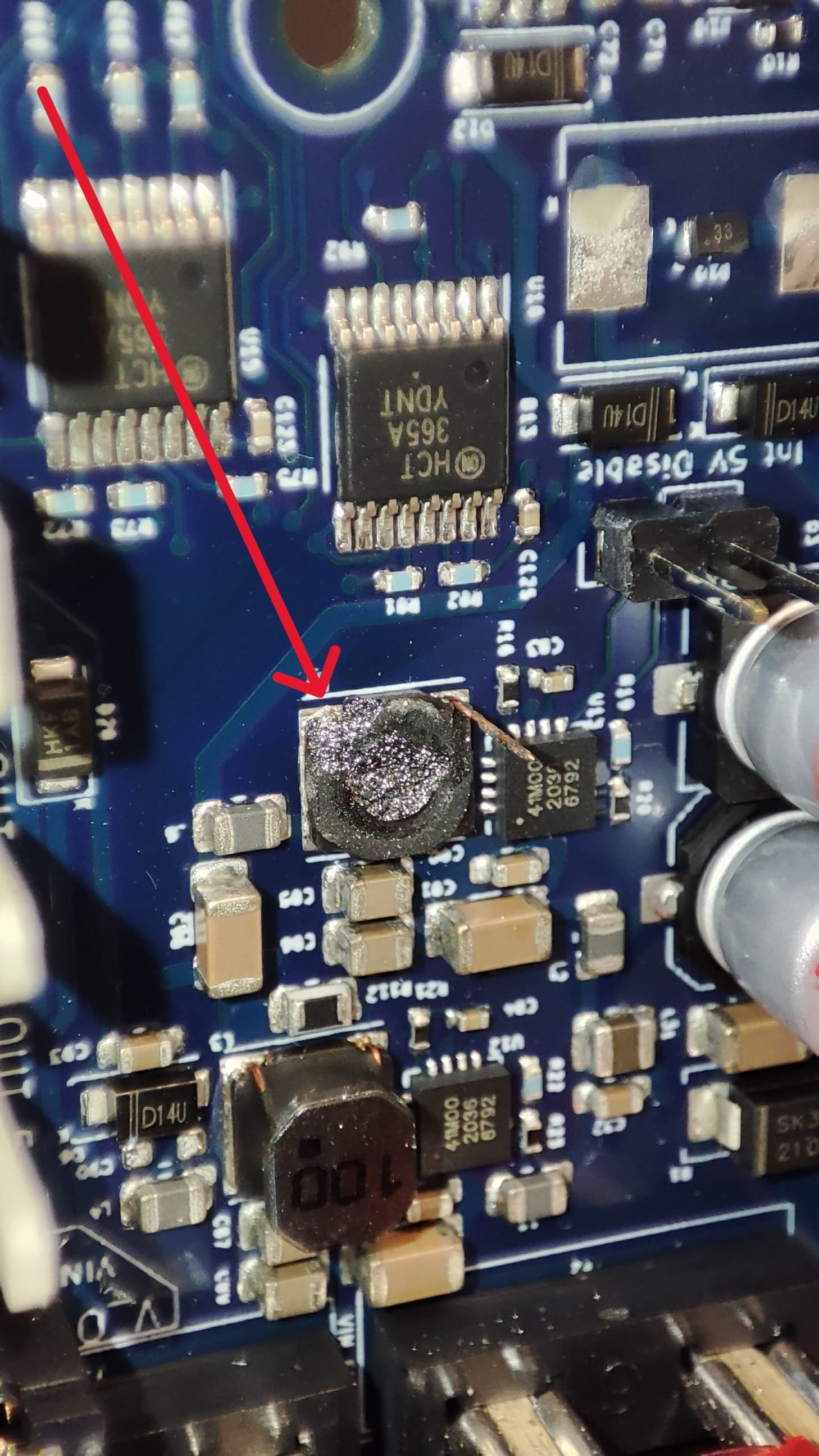

Board arrived with a damaged componentposted in Other control boards

Good morning Duet Team,

I ordered a 3D printer from RatRig (https://ratrig.com/) with a Duet 3 Mini 5+ Wi-Fi board. Upon assembly and powering it on, nothing turned on. After examining the components, I noticed that one of them was damaged.

I contacted RatRig, and they directed me to this forum without much explanation. It's evident that the board needs to be replaced as it's not functioning.

I look forward to your prompt response.

Best regards,

-

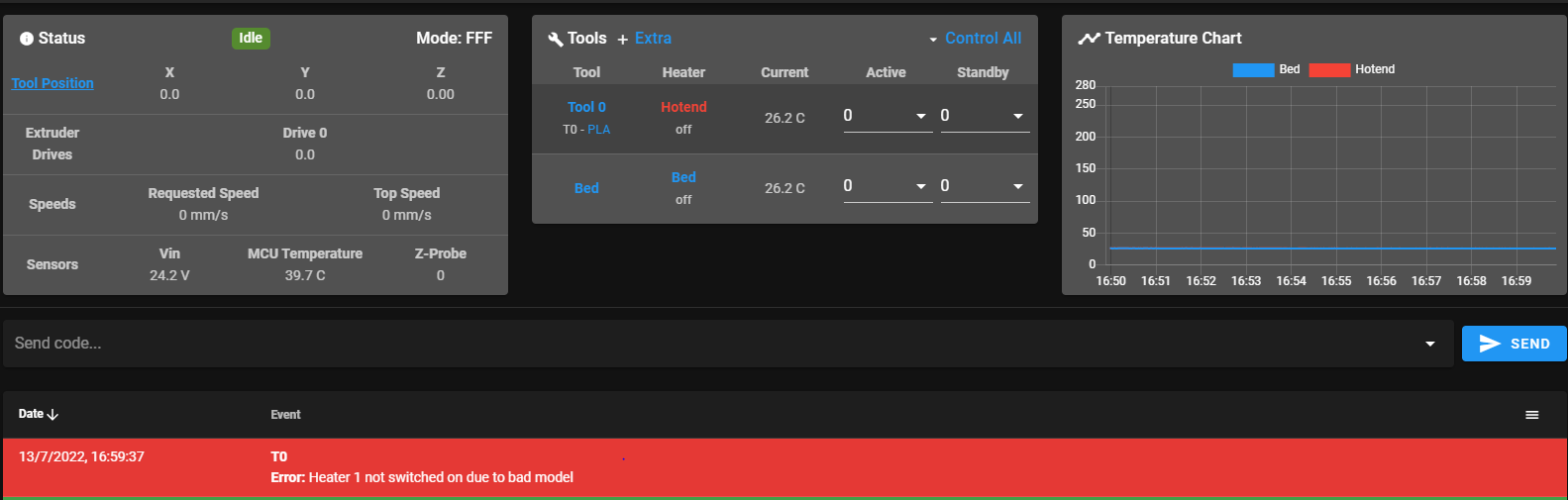

T0 Error: Heater 1 not switched on due to bad modelposted in Duet Hardware and wiring

hello everyone!

I just finished assembling my printer but I'm having this problem when I try to heat the nozzle.

has anyone ever had the same problem?; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"RatRig_3D_Printer" ; set printer name M669 K1 ; CoreXY G21 ; Set Units to Millimeters ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S1 ; physical drive 0.3 goes forwards M569 P0.4 S1 ; physical drive 0.4 goes forwards M569 P0.5 S0 ; physical drive 0.5 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E0.5 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 ; set steps per mm M906 X1600 Y1600 Z1600 I30 ; set motor currents (mA) and motor idle factor in per cent -- safe for Duet 3 mini 5+ M84 S30 ; Set idle timeout M566 X400.00 Y400.00 Z6.00 E120.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 X10800.00 Y10800.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E3600.00 ; set accelerations (mm/s^2) ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io0.in" ; configure active high endstops M574 Y2 S1 P"io1.in" ; configure active high endstops M671 X-4.5:150:304.5 Y-4.52:305:-4.52 S5 ; define positions of Z leadscrews or bed levelling screws M557 X20:280 Y20:280 P5 ; define 5x5 mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 Q11 ; create bed heater output on out0 and map it to sensor 0, lower switching frequency to 11Hz M307 H0 B0 S5.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C ;; Run Bed PID Tune!! Below is an example for a 300x300 bed M307 H0 A303.1 C356.7 D1.4 S5.00 V24.0 B0 ; Fans M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 C"Layer Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"out3" Q500 ; create fan 1 on pin out3 and set its frequency M106 P1 C"Hotend Fan" S0 H1 T45 ; set fan 1 name and value. Thermostatic control turned on for Hotend ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S2.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set the maximum temperature in C for heater ; EVA 2 / BMG / E3D V6 M92 E830 ; set extruder steps per mm, 0.9 angle/step (LDO Pancake) M906 E800 ; set extruder motor current (mA) and idle factor in per cent M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.060000e-8 A"Hotend" ;; Run Heater PID Tune!! ;; M307 H1 A751.5 C196.6 D4.7 S5.00 V23.9 B0 Z-Probe ;; Inductive Probe ; M558 P5 C"!io3.in" H5 F400 T5000 ; set Z probe type to unmodulated and the dive height + speeds ; G31 P500 X-30 Y-15 Z0.20 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed BLTouch M950 S0 C"io2.out" ; Create a servo pin on io7 M558 P9 C"io2.in" H5 F240 T10800 A5 ; set Z probe type to unmodulated and the dive height + speeds G31 P25 X-28.00 Y-13.00 Z0.90 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ; Select default tool T0 ; Pressure Advance ; M572 D0 S0.10