Watercooled Smart Effector In Larger Effector || 4th Axis Design

-

@denke said in Mounting a smart effector in larger effector - watercooled:

This is a cool idea, so I'm really hoping to be wrong ... But I have some questions:

- How much extra weight does this add?

- If I see it correctly you grinded down the radiator to be square, and added the blocks to the sides you got this way. But, for me it seems that this adds a distance between the heatbreak and the heater block which are only about 50% connected to the system (the original radiator is not solid)

I have seen an idea somewhere earlyer, when someone printed a large tube around the radiator, sealed the upper and lower most ring of the radiator to it, and circulated the water in this tube making the original radiator the inner part of the water block. This way seems better because:

- All extra parts are printable

- It seems to be lighter

- The water is closer to the heat source and also has a larger contact surfice

Again, the idea is great, and I really hope that I'm wrong and your approach works flawlessly!!

-

I plan to weigh the complete hotend once it is all finished up.

-

The original radiator was indeed ground down to be squarish. And you are right this is not optimal in terms of contact surface.

-

I have seen a couple of designs like the one you mention. The main problem with a printed heat block/sleeve is leaks. I am fairly certain my current plan will not leak at all. With a printed sleeve, you always have the issue of making it water tight. I might experiment with it in the future though.

I think all your points are quite valid. I am just experimenting around for now I guess.

-

@nxt-1

Thanx for explaining your reasoning, please let me know how it goes! -

Ever thought about putting all the hardware on top, just the tubes running down, so more clearance around the nozzle, using the 3 holes around the centerhole for mounting the hardware, keeping the balls at the designated spots?

In theory, you can also use this then to add a direct drive instead of using a bowden

-

@denke I believe you remember https://well-engineered.net/index.php/en/86-community-water-cooling

I do have the water cooling block at home, but it is waiting for a later time when I finished off my current ones.

-

@crynool said in Mounting a smart effector in larger effector - watercooled:

Ever thought about putting all the hardware on top, just the tubes running down, so more clearance around the nozzle, using the 3 holes around the centerhole for mounting the hardware, keeping the balls at the designated spots?

In theory, you can also use this then to add a direct drive instead of using a bowden

I do not see how moving the two black water splitter block up will increase clearance around the nozzle, please elaborate. As far I know, the 3 holes around the center hole are not a good spot for mounting anything with any mass. These holes are just about in the strain gauge area of the board and will influence measurements if constrained. Furthermore, I am not using the usual mag ball's so I cannot keep the balls at the usual spots even if I wanted to.

A direct drive can be added to this whether or not I move things around (it would be harder with more stuff moved upwards actually). I have printed with a direct drive Bondtech BMG mounted on a custom effector I designed for over a year I believe. While the direct-y-ness is a bliss, the added mass is not at all. The BMG+(pancake)stepper add quite a bit of weight to the moving effector, resulting a significant ringing at corners in the print.

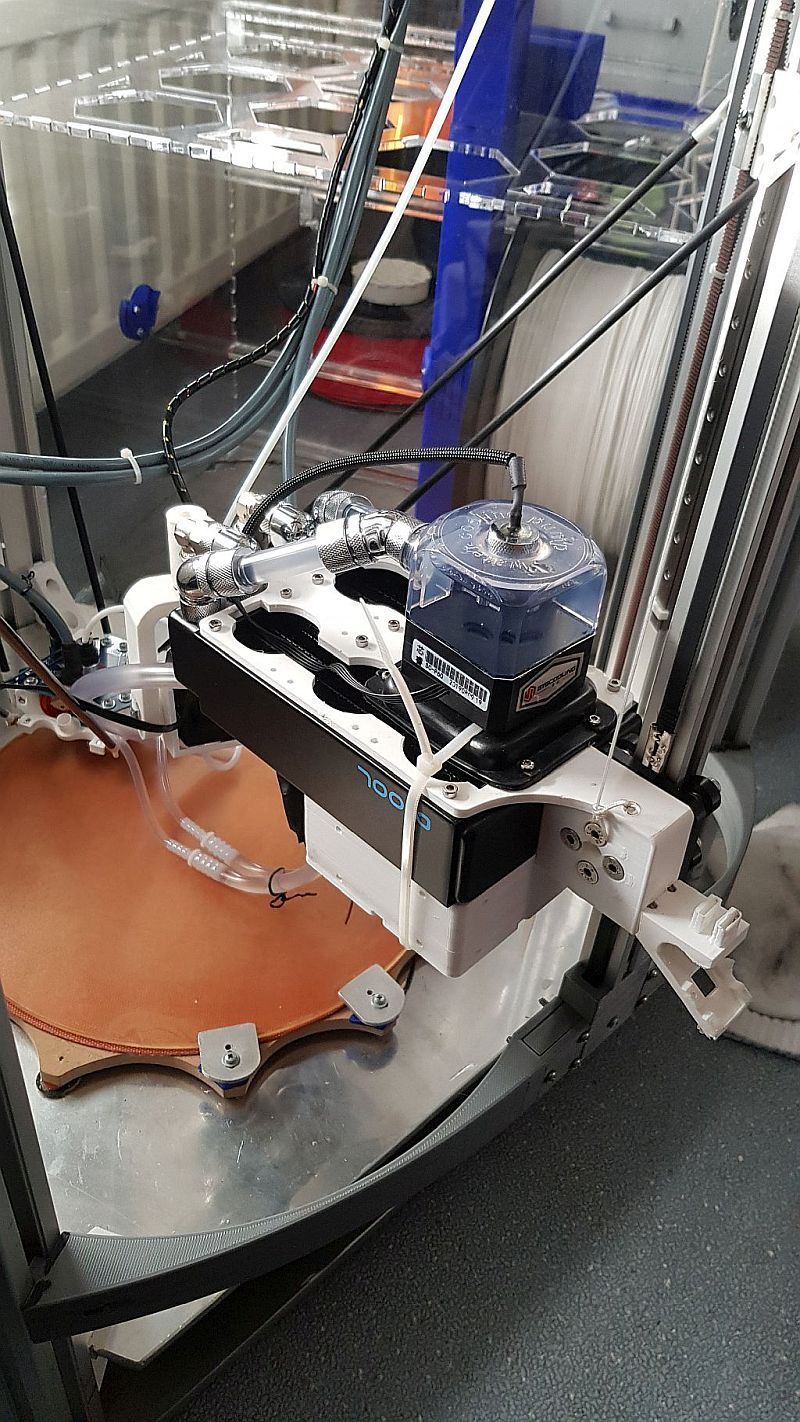

Recently I have moved the extruder to a separate 4th axis, Leaving me with a lighter effector and shortish bowden tube (170mm I believe).

-

@oliof said in Mounting a smart effector in larger effector - watercooled:

@denke I believe you remember https://well-engineered.net/index.php/en/86-community-water-cooling

I do have the water cooling block at home, but it is waiting for a later time when I finished off my current ones.

I that block was available with a M12 threaded mount instead of a groove mount, I would throw my ideas in the bin right way most likely

I sadly do not have access to metal shaping machines to make my own either.

I sadly do not have access to metal shaping machines to make my own either. -

Sorry to put a dampener on your work but I don't think it will work, With the feed tube/blocks where they are I don't think you will have anywhere near enough clearance for the arms so your print radius is going to be severely limited and should you go beyond that limit you are likely to get an arm disconnection. I hope I am wrong but I would attempt to mount it and see before you go much farther. Also you might like to Check out the Zesty Kryo

-

@dougal1957 said in Mounting a smart effector in larger effector - watercooled:

Sorry to put a dampener on your work but I don't think it will work, With the feed tube/blocks where they are I don't think you will have anywhere near enough clearance for the arms so your print radius is going to be severely limited and should you go beyond that limit you are likely to get an arm disconnection. I hope I am wrong but I would attempt to mount it and see before you go much farther. Also you might like to Check out the Zesty Kryo

No worries about damping

, I have been thinking the same about clearance. In the current design, I have placed the ball joint connections at close to the edge of the smart effector pcb as I physically possible. If clearance issues arise, I can move them outwards or increase the spacing between the rods.

, I have been thinking the same about clearance. In the current design, I have placed the ball joint connections at close to the edge of the smart effector pcb as I physically possible. If clearance issues arise, I can move them outwards or increase the spacing between the rods.On terms of the Zesty Kryo, holy crap. That seems just about what I was looking for. I have to interest into getting the rest of the Nimble ecosystem but I will definitely look at the Kryo. One issue, did Zesty discontinue the Kryo. I cannot find a source for it.

-

Also, check out https://hackaday.io/project/158650-folds-and-hinges-technology-to-make-mechanisms/log/147838-ultra-light-extrusion-toward-the-graal for a very interesting and simple water cooling design.

-

@oliof said in Mounting a smart effector in larger effector - watercooled:

Also, check out https://hackaday.io/project/158650-folds-and-hinges-technology-to-make-mechanisms/log/147838-ultra-light-extrusion-toward-the-graal for a very interesting and simple water cooling design.

I saw that design when they released it but I do not think it is direct compatible with the E3D ecosystem that I use. Futhermore, it does not seem to be a likely fit for a smart effector.

-

@nxt-1 agreed on the extruder and it definitely is not a simple E3D drop-in. That said, the hotend/cooling part might fit. I heard mixed opinions on the ceramic heater with the thermistor in the nozzle though ...

-

This post is deleted! -

@nxt-1 said in Mounting a smart effector in larger effector - watercooled:

@dougal1957 said in Mounting a smart effector in larger effector - watercooled:

Sorry to put a dampener on your work but I don't think it will work, With the feed tube/blocks where they are I don't think you will have anywhere near enough clearance for the arms so your print radius is going to be severely limited and should you go beyond that limit you are likely to get an arm disconnection. I hope I am wrong but I would attempt to mount it and see before you go much farther. Also you might like to Check out the Zesty Kryo

No worries about damping

, I have been thinking the same about clearance. In the current design, I have placed the ball joint connections at close to the edge of the smart effector pcb as I physically possible. If clearance issues arise, I can move them outwards or increase the spacing between the rods.

, I have been thinking the same about clearance. In the current design, I have placed the ball joint connections at close to the edge of the smart effector pcb as I physically possible. If clearance issues arise, I can move them outwards or increase the spacing between the rods.On terms of the Zesty Kryo, holy crap. That seems just about what I was looking for. I have to interest into getting the rest of the Nimble ecosystem but I will definitely look at the Kryo. One issue, did Zesty discontinue the Kryo. I cannot find a source for it.

Comming back to the Kryo, I just heard back from Zesty directly and it seems that some users reported leakages appearing after a while. The guys over at Zesty make the right call and pulled the Kryo from sales until they can release a re-engineered version.

-

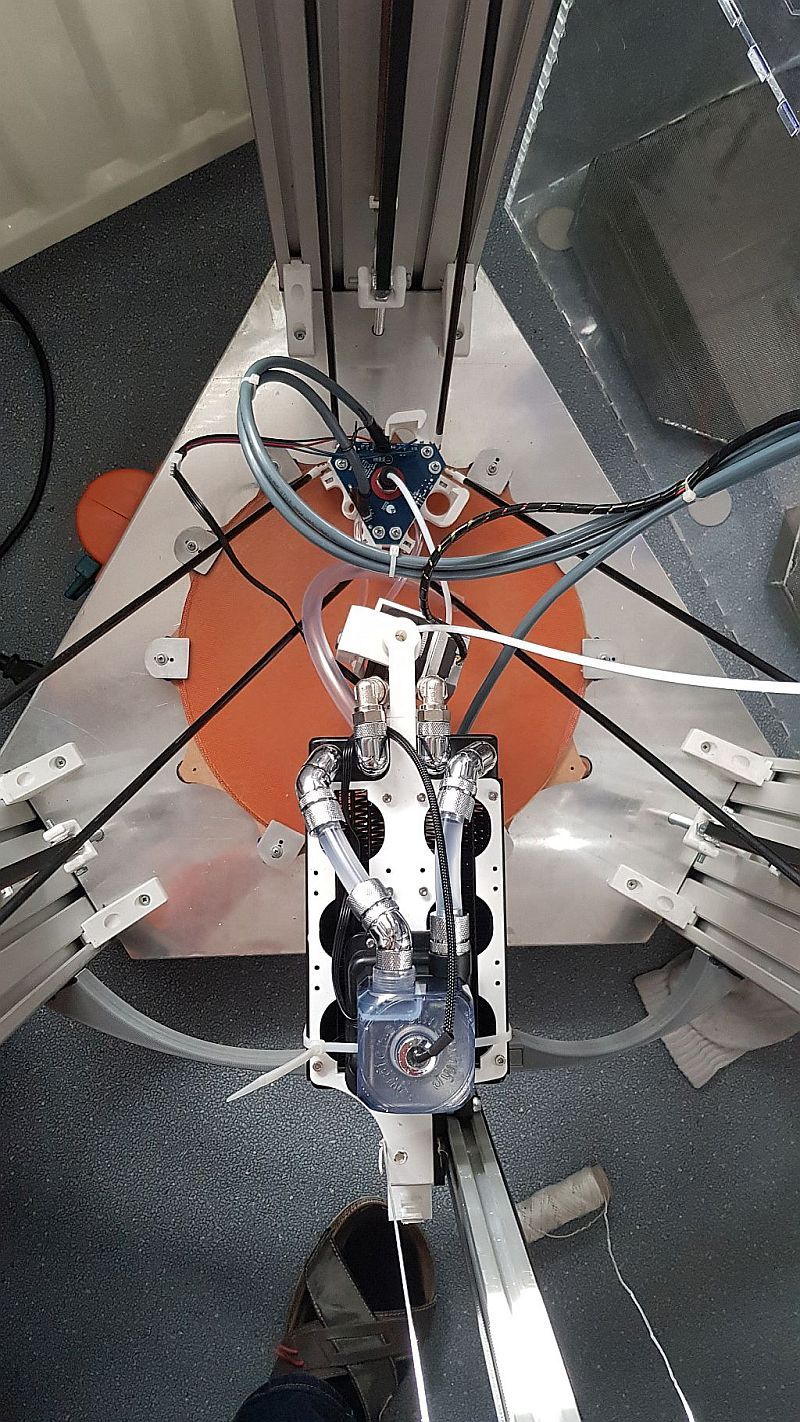

I've been continuing the work on this project. I've had a few failed print due to clogging, I assume from the heatbreak overheating. The last couple of print are doing fine however. I measured some temps with a thermocouple and the water rises to 30-35°C and the copper waterblocks themselves to around 44°C.

-

There is also a thread concerning monitoring the water temps with a 10K thermistor here.

And a thread about getting the part fan to work here.I have also decided to go full blow and mount some radiators on the 4th axis arm. Furthermore, I ordered an off-the-shelf water cooled heatsink from Germany. I plan to turn down the groovemount down to 12mm on a lathe and thread it to M12 myself. Not only is probably a better solution cooling wise but also way less tubes down at the effector. I feel the short tube in tight corners are in a way constraining the Z-probe action of a smart effector.

-

As described in a separate thread I now use a different way of mounting (the new) water cooled heatsink. This makes tubing a lot neater and should give better performance. I will keep this thread updated with the results once I find the time to properly do some testing.

-

@Nxt-1 Here is a quick status update. I am currently figuring out how I am going to implement the counterweight for the 2-2.5kg that the 4th axis weighs. The current plan is to cut a stack of disk out of lead sheet, so I can stack more weights as needed.

-

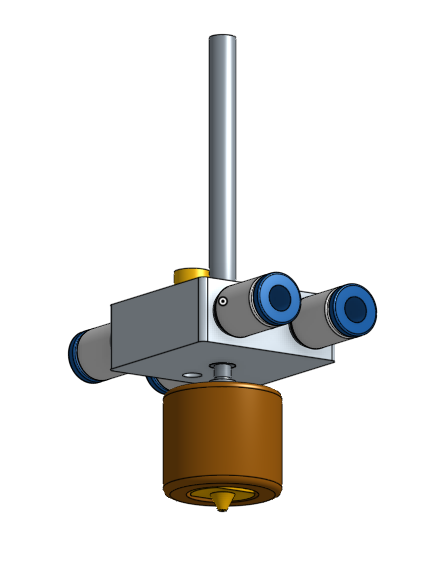

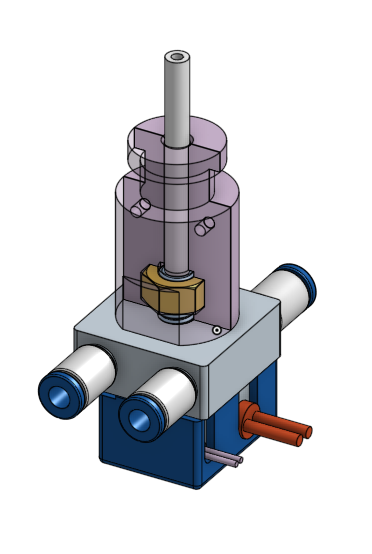

I'm using a FNU (http://reprapuniverse.com/catalog/store.php?cPath=44_155_157), and made a water-cooled block with a simple piece of aluminium (25x25x10), and a few holes:

It works fine. It does not require much water flow; my previous pump died, and I'm about to buy a peristaltic one.

I also made a version for a E3D-v6, for friends:

but for now, nobody tried it... It requires a new thermal heat-break, which can be found on ebay (M6 thread on full-length)

-

@fma I never heard of the FNU style nozzle/hotends, looks interesting. As for your waterblock, looks nice, clean and effective. I assume there are four fittings to avoid needing a channel machined in there and simplify the manufacturing process?

-

@Nxt-1 said in Mounting a smart effector in larger effector - watercooled:

@fma I never heard of the FNU style nozzle/hotends, looks interesting.

Note that I broke one while doing 5 axis printing (forgot to lift up Z at the end of the print, and it collided with the part

). On the second one, I cut the tip of the nozzle, and only let the threaded part. This way, I can use any nozzle I want (like the Zatsit one, I'm still waiting for).

). On the second one, I cut the tip of the nozzle, and only let the threaded part. This way, I can use any nozzle I want (like the Zatsit one, I'm still waiting for).As for your waterblock, looks nice, clean and effective. I assume there are four fittings to avoid needing a channel machined in there and simplify the manufacturing process?

Exactly: just through all holes! I put a shunt tube on one side, so I only need 2 tubes for the water supply.