Problems with new Laser Filament Monitor

-

@madhunm said in Problems with new Laser Filament Monitor:

What about somehting like this: https://www.thingiverse.com/thing:3091625

the part in that thing is just an interposer... but, the skelestruder project has the other parts.

sensing off of a rotating bearing kinda sorta makes sense to me.Fantastic idea

-

@3dmntbighker I am working on a modified version of my casing with this purpose

-

@brunofporto said in Problems with new Laser Filament Monitor:

@3dmntbighker I am working on a modified version of my casing with this purpose

When I print your current version I find the PTFE clamping is marginal at best. I have had to drill deeper into the housing to find some purchase for the tube. My printer is partially to blame. While you are at the redesign can I suggest a longer surface area for clamping the PTFE tube. I am using Capricorn tubing now. Actually I may switch to cheap PTFE tube because in this application the Capricorn is actually a detriment. It's more particular about out of tolerance filament and it's not as if it's a bowden tube.

-

@3dmntbighker Actually a short piece of Capricorn tube was recommended coming into and going out the sensor housing because this will better constrain the filament passing over the center of the sensor. But it is hard to use only a short amount if you need longer distances.

Reg. fixing the tube inside the housing the approach used in this housing by @punamenon might be very interesting. @brunofporto what do you think?

-

@wilriker said in Problems with new Laser Filament Monitor:

@3dmntbighker Actually a short piece of Capricorn tube was recommended coming into and going out the sensor housing because this will better constrain the filament passing over the center of the sensor. But it is hard to use only a short amount if you need longer distances.

Reg. fixing the tube inside the housing the approach used in this housing by @punamenon might be very interesting. @brunofporto what do you think?

Thanks, I'll stick with the Capricorn. I'm fortunate I don't need a long section. I think I have no more than 20mm on either end.

Yeah, that looks like a much better way to capture the tube. I actually don't have issues with the tube coming out, but it's very poorly held in place now.

-

@wilriker said in Problems with new Laser Filament Monitor:

@brunofporto what do you think?

Nice idea!

An M4 nut may hold that nicely!

An M4 nut may hold that nicely! -

@3dmntbighker said in Problems with new Laser Filament Monitor:

@brunofporto said in Problems with new Laser Filament Monitor:

@3dmntbighker I am working on a modified version of my casing with this purpose

When I print your current version I find the PTFE clamping is marginal at best. I have had to drill deeper into the housing to find some purchase for the tube. My printer is partially to blame. While you are at the redesign can I suggest a longer surface area for clamping the PTFE tube. I am using Capricorn tubing now. Actually I may switch to cheap PTFE tube because in this application the Capricorn is actually a detriment. It's more particular about out of tolerance filament and it's not as if it's a bowden tube.

I have the same issue... It keeps falling when I am messing with it sometimes. Thank you! I'll increase the length of the hold and also make it tighter a little.

Besides the centering the Capricorn tube is also opaque and prevents the light to interfere with the sensor.

But If I use the bearing solution there is no problem as the sensor will be shielded by the bearing.

-

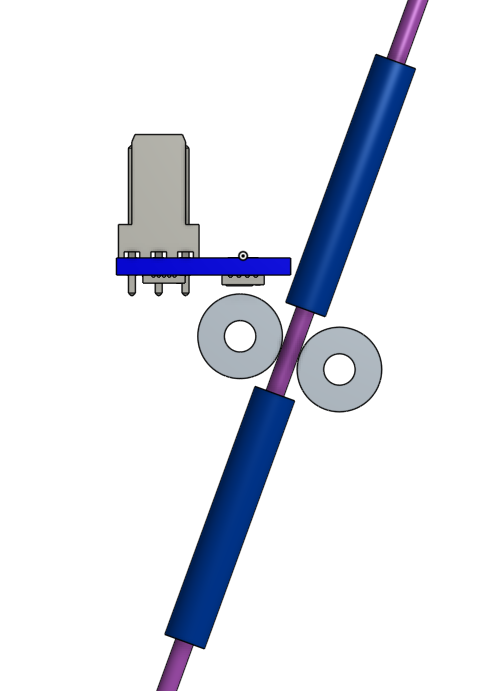

Something like this

Now I need to think the thing around the concept

-

That Prusa one on Thingy manages with one bearing. And weirdly it seems to read the side of the bearing instead of the circumference. Presumably you will want some kind of weak spring in there somewhere keeping tension on the filament without wearing out the tubing.

-

@3dmntbighker yes... I'll leave the "reading" bearing fixed and the second bearing will press against the filament with some type of spring system - like the one used with bmtech extruders.

-

would lightly sanding the bearing also help with the sensor pickup more light?

-

@nikker Not needed for the sensor as it is perfect for the type of surface the bearing offers. What concerns me is the possibility of the filament slipping the bearing somehow. If this starts happening then the sanding will help.

-

What about some knock off Bondtech gears?

-

@nikker said in Problems with new Laser Filament Monitor:

What about some knock off Bondtech gears?

I don't think you want to distort the filament that much before it reaches the real extruder.

-

good point... I would really like to get a filament sensor. It seems like the magnetic version worked a lot better from what i remember reading however i guess its the laser version that is only available. I have some time to tinker between my current build. I haven't read this whole thread but do we think we can get it to work reliably with some community effort? If so I'll place an order to buy one. My current build has the extruder temporarily mounted on the outside and is wired up and already calibrated so seems like a good time to help? Would be nice if I could contribute to the community after lurking for so long...

-

Where do I find the STL for the Bondtech? Can't seem to locate it anywhere

-

@cabal2000 I have recently put a spring loaded version of the indirect monitor housing on thingiverse (3717158). It seems to work well, especially recording total filament use very accurately.