What useful things have you printed on a 3D printer?

-

Apart from sundry brackets, housings etc around the house, most of my efforts are devoted to custome skirted lure designs for marlin fishing.

"Traditional" lures have a head cast from resin. Shaping the face creates a swimming action and having holes through it helps create a bubble trail to help attract the fish.

It's a big ocean out there, so anything out of the ordinary for a predator gets attention and hopefully an "I wonder if I can eat that" moment.I don't try to replicate traditional lures. We all know they work and resin being heavier has different properties.

I try to design things that have never been tried before.

Flexibility of design and fast prototyping allow me to create weird shapes to see what they do to the action as different areas grab the water.

Easy creation of complex air pathways allow differing bubble trails.

I can combine tings like bibs (normally only used on non game fishing lures) and add pivoting sections.Some designs work, others are abject failures , but it's all fun.

Unfortunately I don't own a game boat, so usually only do one trip a year chasing marlin.A few designs

Checking out theaction and bubble trail

A marlin checking out the spread.

Underwater camera towed in the lure spread shows fish come for a look but often don't strike.

-

I printed wire spools.

Something not useful, but fun, I printed some wind turbines -- for me, this is the driven reason to buy a 3d printer.

I plan to print some stacking boxes to use corner spaces around furniture, but have not started yet.

-

on my workplace i use FDM Printed parts quite frequently for Workholding Jigs.

either on a CMM or on a Mill to get oddly shaped SLM Printed parts to behave.Printed stuff like a Door Dampener out of 60A TPU to prevent a door to slam shut during the summer months when i have a window open

also for a family member a guideblock for a Circular saw because of poor Manufacturing tolerances the included one had way to much play -

@dc42 I bought my 1st 3D printer 10 years ago, a Fabtotum.

I bought 2 years later a Big Box from E3D.

In the mean time, I manufactured countless parts

Special hinges for mosquito net to equip my 12 windows

Various supports for phone, pc

Dozens of RPI enclosures, including caméras rpi0

Repair parts for a dishwashing machine.

Fixtures for connecting various feather boards with test pins.

Complete Fabtotum rework, including 6 new print heads with various extruders, last one is a orbiter with piezo packed in 42mm square envelope...

Big Box rework, some new parts, including duet2 supports, panel due box, cleaning system

Letters for my grand child's

Different lamps, including a pair of candle imitated neopixel ones

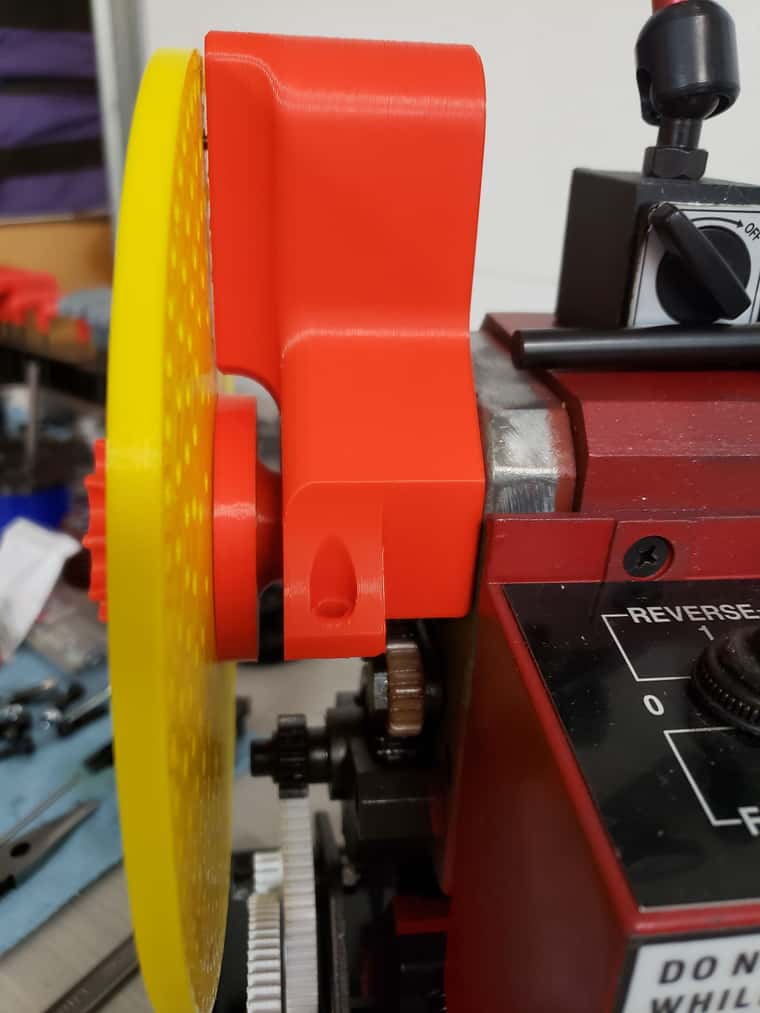

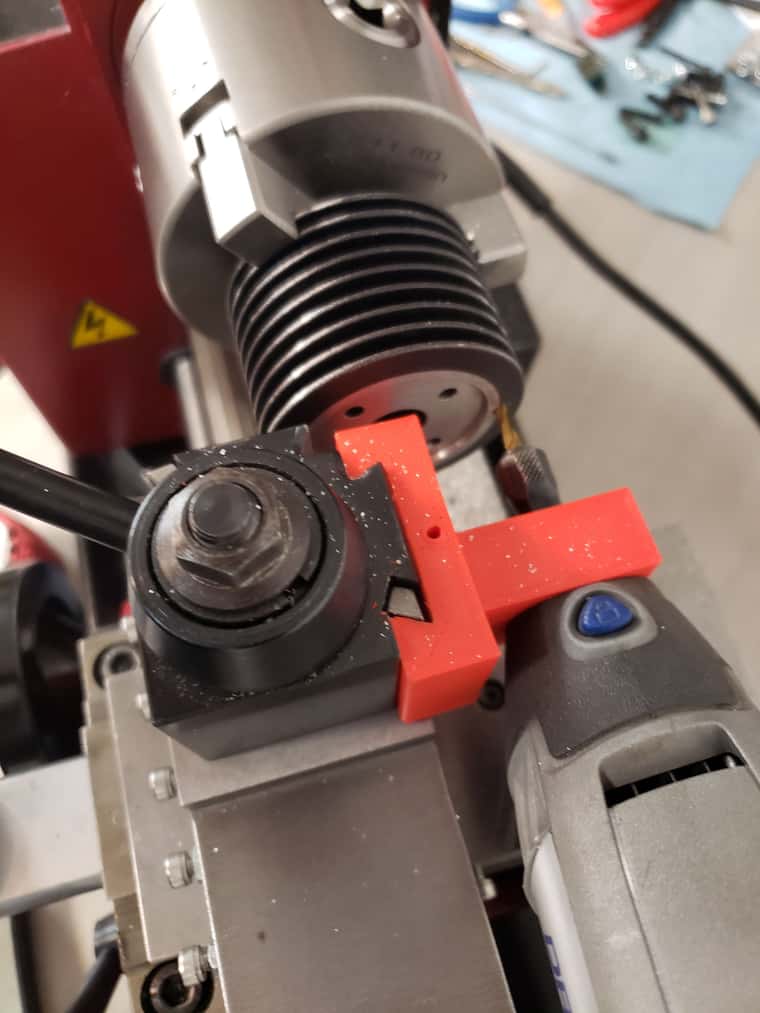

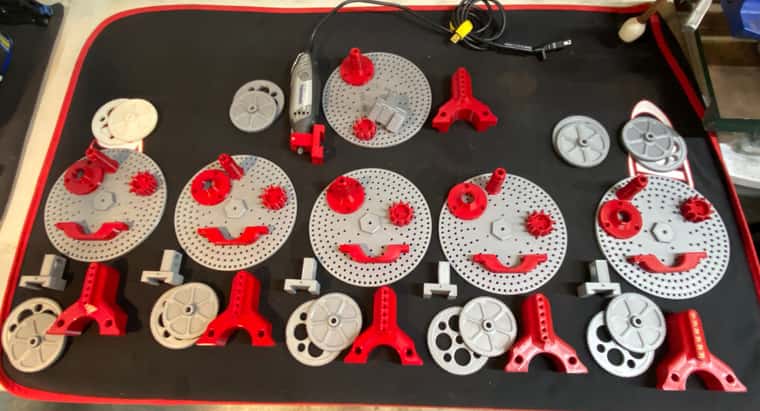

Currently refurbishing a milling machine with multiple 3d parts: display, supports, panels....Looking for buy/build a new printer and discard old one.

-

@dc42 I print hand drums to play Plena music from Puerto Rico. The drum is 3d printed and I cut, form, weld and paint the metal hardware and the lugs myself. Mainly use goat skin but also some cow , buffalo and camel skin are used. I have an LED version where when you hit it the leds change color. For that I use an adafruit feather RP2040. I also make the guiros to play Plena music.

Edit:

I mainly use a custom 24x24x24inches printer I built with duet. The drums are mainly printed on PETG some are PLA and the guiros are PLA

-