Vibrations, resonance, stealhshop and emf calculator

-

Hello. I have another post similar to my issue regarding vibrations: https://forum.duet3d.com/topic/36540/vibration-on-motors-at-low-speed?_=1726668381705

My specs: cartesian printer, nema23 ballscrew motors, 1 in Y 2 for moving X connected in seriedReading others posts, documentation, I would say my "issue" is what @dc42 tld me about mid band resonance, most probably I can say after looking more deep into this. Mechanical reason are completly confirmed out of the scope

I decided after some reding to give a try to stealthchop2. My drivers are configured so far to be all the time on spreadcycle

I have some question if possible @dc42 can clarify because on some of his past answers some info is not clear to me (not an electronic guy here)

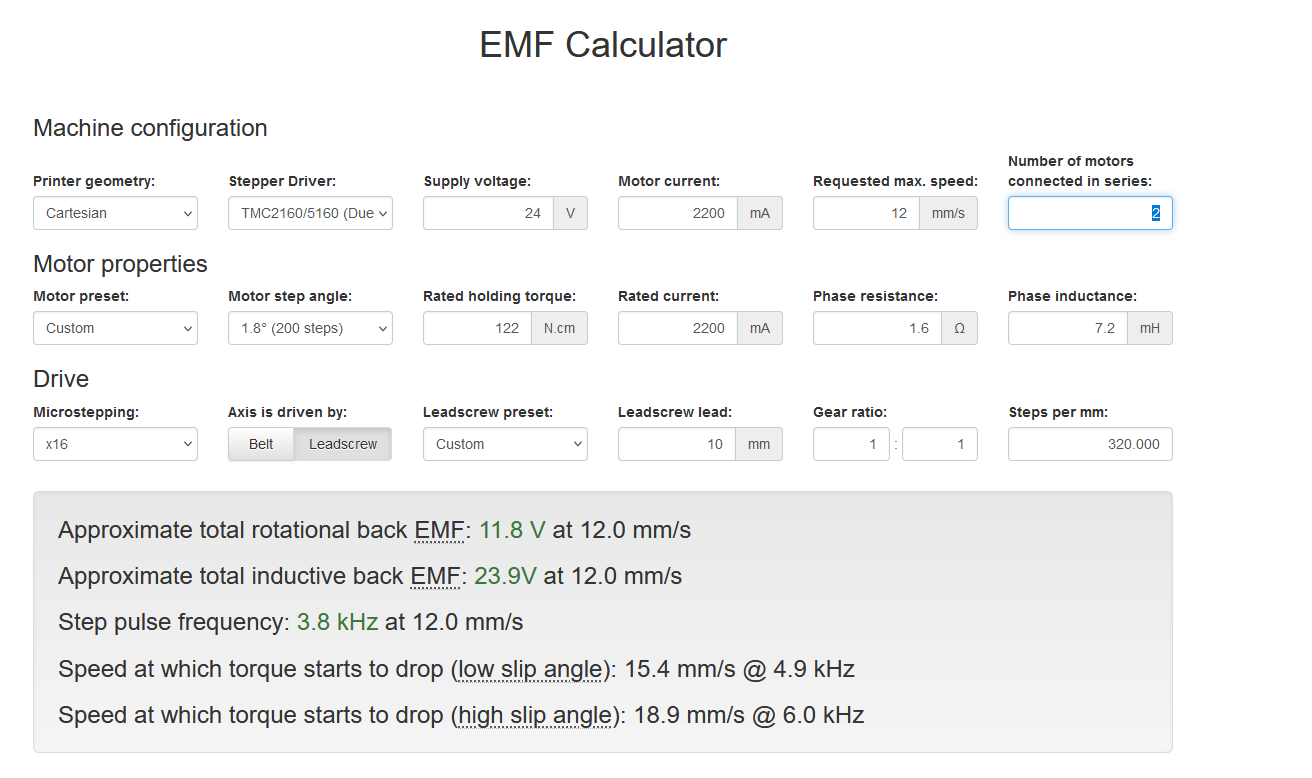

1.- Used the emf calculator and here it is a screenshot ; (My serious doubt there is how my X mmotors are connected, they are both connected to the same driver, but I dont know if it is a parallel connection or they are in series, help on this?)

. Stealshchop is not reliable if enough voltage is not supplied. So acording to me screenshot a switch speed limit of 12 mm/s is my limit, if I go up I start to get ugly numbers like for example if I go for 20 mm/s I get:

. Stealshchop is not reliable if enough voltage is not supplied. So acording to me screenshot a switch speed limit of 12 mm/s is my limit, if I go up I start to get ugly numbers like for example if I go for 20 mm/s I get:

Approximate total rotational back EMF: 19.7 V at 20.0 mm/s

Approximate total inductive back EMF: 39.8V at 20.0 mm/s

So those 39.8 V tells me that I would need to get a PSU capable of supplying the duet3 board with 40 Volts?2.- The values of the emf calculaor only applies to stealhschop? because on spreadcycle I have no problems running at speeds of real 200 mm/s (my issue is onlky vibration of the motors on the range between 10 mm/s and 18 mm/s)

3.- I did a test M569 P0 H196 V196 These values removed almost all vibrations on the X motors and M569 P1 H196 V196 on Y. I also used

M915 P0 T196

M915 P1 T196But in my case I dont use stall detection, so is it necesary? Because those commands are intended for coolstep, withh these have any effect on my config?

4.- I have created a small macro in order to activate stealchop during my tests, is this ok?

silence.gM18 G28 X0 Y0 M569 P0 H196 V196 M915 P0 T196 M569 P0 H196 V196 M915 P1 T196 M17 X Y G4 S0.5 G91 G1 X1 F500 G1 Y1 F500 G904.- As I said, printing not at 12 mm/s using this config eliminated vibrations but even Im not loosing steps, all changing directions movements, like small zigzag infill, are done very noise with a "clak", Im not losing steps, I already printed test cubes. That noize comen in every direction change id it looks like every of thise movements are done purely using jerk speed (200 mm/min in my case on both axis), like there is no acceleration being used, but I know that is not correct. Ideas on this?

Thank you very much for the info I can use to learn and the help you can provide me.