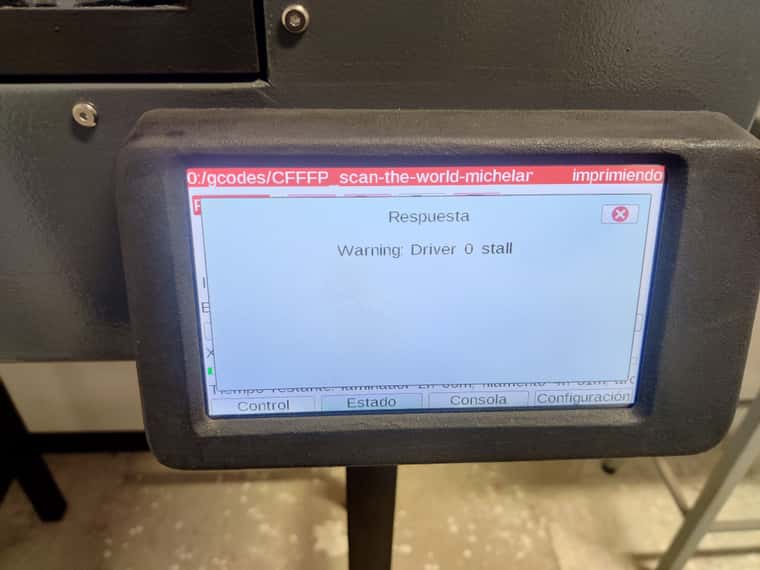

"Warning: Driver 0 stall"

-

Hello everyone.

After a lot of work I managed to finish the 3D printer. And everything works correctly, and the prints come out well. The only problem that persists is a message that continually appears on the screen. "Warning: Driver 0 stall"

This message appears with both driver 0 and driver 1, both motors are the extruders found in the print head.

This message appears when it has been running for a while.

Please note that I have heated the chamber.

Could you please tell me what this message is about?On the other hand, could you tell me how I can at least remove the message from the screen? It comes up so many times in a row that I can't use the screen when the message is on the screen.

Another message that I would like to remove from the screen or make it appear less often is the one that tells me that it is not connected to Wi-Fi.

Do you know how I can solve this problem?Thank you very much for the help.

-

@Juan-Estanislao

Nice build! Sorry, can't help with the question. -

@Juan-Estanislao I guess you enabled stall detect on the machine and you get stall messages, which might come from Pressure Advance, Retracts, or filament change macros.

To help sort out what this is, please share your configuration files.

-

@jens55 Thank you very much for your comment.

-

@oliof

Thank you very much for your answer. Right now I don't have the files, but as soon as I have them I'll buy them without a problem.Thank you very much in advance.

-

@oliof I am very sorry that it took me so long to respond to you, but I have not been able to access the printer until today.

As you requested, I will show you the configuration file.Thank you very much for the help.

; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.15 on Thu Nov 24 2022 23:03:50 GMT+0100 (hora estándar de Europa central); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Estanisleitor 2P" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X239.65 Y240.15 Z2402.00 E427.9:427.9 ; set steps per mm

M566 X900.00 Y900.00 Z400.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z400.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X200.00 Y200.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1700 Y1700 Z1700 E1100:1100 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-39 Y0 Z0 S1 ; set axis minima

M208 X462 Y378 Z419 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop:Z-Probe

M950 S0 C"exp.heater3"

M558 P9 C"^zprobe.in" H3 F300 T6000 ; FW v3 BLTouch connected to Z probe IN pin

G31 P500 X61.2 Y8.4 Z0.64 ; Set Z probe trigger value, offset and trigger height Incrementar el valor = acercar la mesa de impresión.

M557 X24:460 Y11:376 S60 ; Define mesh grid

M915 X Y S5 R2

M950 H6 C"nil" ; Disable heaters H3-H7 to free up pins; Heaters

M308 S0 P"e0temp" Y"pt1000" ; configure sensor 0 as PT1000 on pin e0temp

M950 H0 C"e0heat" T0 ; create nozzle heater output on e0heat and map it to sensor 0

M570 H0 P400 T400

M307 H0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H0 S420 ; set temperature limit for heater 0 to 450C

M308 S1 P"e1temp" Y"pt1000" ; configure sensor 1 as PT1000 on pin e1temp

M950 H1 C"e1heat" T1 ; create nozzle heater output on e1heat and map it to sensor 1

M570 H1 P400 T400

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S420 ; set temperature limit for heater 1 to 450C

M308 S2 P"bedtemp" Y"pt1000" R4700 ; configure sensor 2 as PT1000 on pin bedtemp

M950 H2 C"bedheat" T2 ; create bed heater output on bedheat and map it to sensor 2

M307 H2 B0 S1.00; disable bang-bang mode for the bed heater and set PWM limit

M570 H2 P1200 T90 ; comando añadido porque tarda mucho en calentar la cama y daba error

M140 H2 ; map heated bed to heater 2

M143 H2 S130 ; set temperature limit for heater 2 to 180CCámara

M308 S3 P"e3temp" Y"pt1000" R4700 ; configure sensor 3 as PT1000 on pin duex.e2temp

M950 H4 C"exp.heater4" T3 ; create chamber heater output on duex.e3heat and map it to sensor 3

M307 H4 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit

M570 H4 P4200 T110

M141 H4 ; map chamber to heater 3

M143 H4 S70 ; set temperature limit for heater 3 to 90CVentiladores

Ventilador de pieza

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"Ventilador De Pieza" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned offBomba de agua y ventilador radiador

M308 S4 P"e4temp" Y"pt1000" R4700 ; configure sensor 4 as PT1000 on pin duex.e5temp

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"Ventilador De Cabezal" T60 H4 X1 ; set fan 1 name and value. Thermostatic control is turned onVentilador Filtro Cámara

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 C"Ventilador De Cámara" T60 H3 X1 ; set fan 2 name and value. Thermostatic control is turned onVentilador Cabezal soplador

M308 S5 P"e5temp" Y"pt1000" R4700 ; configure sensor 5 as PT1000 on pin duex.e6temp

M308 S6 P"e6temp" Y"pt1000" R4700 ; configure sensor 6 as PT1000 on pin duex.e7temp

M950 F3 C"exp.heater7" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P3 C"Soplador Cabezal" T40 H5:6 X1 ; set fan 1 name and value. Thermostatic control is turned onBomba Aire MotorY

M308 S7 P"e2temp" Y"pt1000" R4700 ; configure sensor 6 as PT1000 on pin duex.e7temp

M950 F4 C"exp.heater5" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P4 C"Bomba Aire MotorY" T50 H7 X1 ; set fan 1 name and value. Thermostatic control is turned on; Tools

M563 P0 S"Material Base" D0 H0 F1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Soporte" D1 H1 F1 ; define tool 1

G10 P1 X38 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings are not defined

M591 D0 P2 C"e0stop" S1 ; Final de Filamento extrusor 0

M591 D0 P2 C"e1stop" S1 ; Final de Filamento extrusor 1; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tool

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings are not defined