Remove filament-sensor and extruder motor same board requirement

-

Per https://docs.duet3d.com/en/User_manual/Connecting_hardware/Sensors_filament#connecting-to-the-duet

Important! If you are using a Duet 3 or 3 Mini with tool or expansion boards, then the filament monitor must be connected to the same board as the motor for the extruder that it is monitoring. Filament monitors connected to tool and expansion boards are supported in RepRapFirmware 3.2beta4 and later.

However, my installations will not ever place the filament sensor at the extruder, they are all installed near the spool (pulsed sensor). Logically speaking, there is little reason any kind filament sensor needs to be placed at the toolhead itself. Detecting a runout a meter away would be the same either way.

As a result, if I want to use a toolboard on my print head, I would need to run wires off the toolhead to the location of the runout sensor mounted elsewhere on the printer and nullifying the point of minimizing wires to the toolboard.

Additionally, I've found hyper-sensitive filament-sensing to be unreliable anyway, and I have to add false-positive handling into my filament-error handlers.

It would be great if the filament sensor can be decoupled from being plugged into the same board as the E motor.

-

@pfn Filament monitors (as opposed to presence sensors) need to be close to the hot end in order to detect a possible jam. If you only want to detect filament presence or run out, then you can do so with a simple switch. In which case, you could mount it anywhere and hook it up to any spare io pin and use an external trigger to take action or generate an alert.

-

@deckingman said in Remove filament-sensor and extruder motor same board requirement:

@pfn Filament monitors (as opposed to presence sensors) need to be close to the hot end in order to detect a possible jam. If you only want to detect filament presence or run out, then you can do so with a simple switch. In which case, you could mount it anywhere and hook it up to any spare io pin and use an external trigger to take action or generate an alert.

This is rather false, I use a monitor far away from the extruder, it detects jams fine. It might not be immediate due to bowden slack, but jams are detected nonetheless.

I have 4 filament monitors installed at the spool (Up to 1meter away from the print head and extruder) across 4 printers.

-

@pfn Not sure I understand how this is possible but maybe you have a different arrangement on your printer. For me, as the print head moves away from the reel, it'll pulls out the amount of filament roughly equal to the distance that the print head is away from the reel, plus whatever the hot end is consuming. Then as the print head moves back towards the reel, the excess filament forms a loop so no more filament is pulled off the reel until the slack within the loop is taken up. I'd have thought that a filament sensor close to the reel would detect this lack of movement as a jam

I'd be interested to know how you have managed to decouple the filament consumed by the hot end, from the filament that is pulled off the reel (or not) due to the relative position of the hot end from the reel.

-

@deckingman I think he may be using a reverse bowden setup (so the filament between the sensor and the print head is inside a ptfe tube).

-

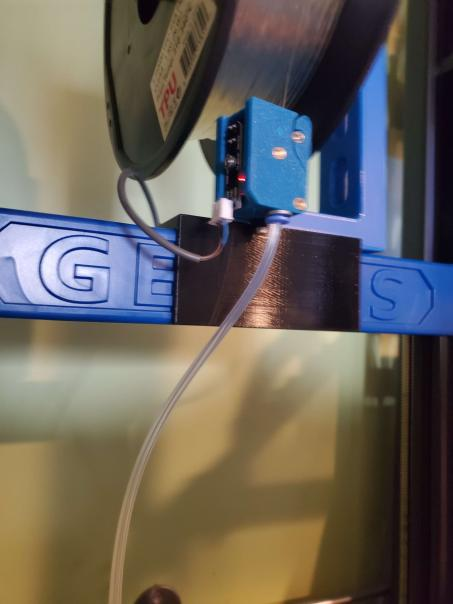

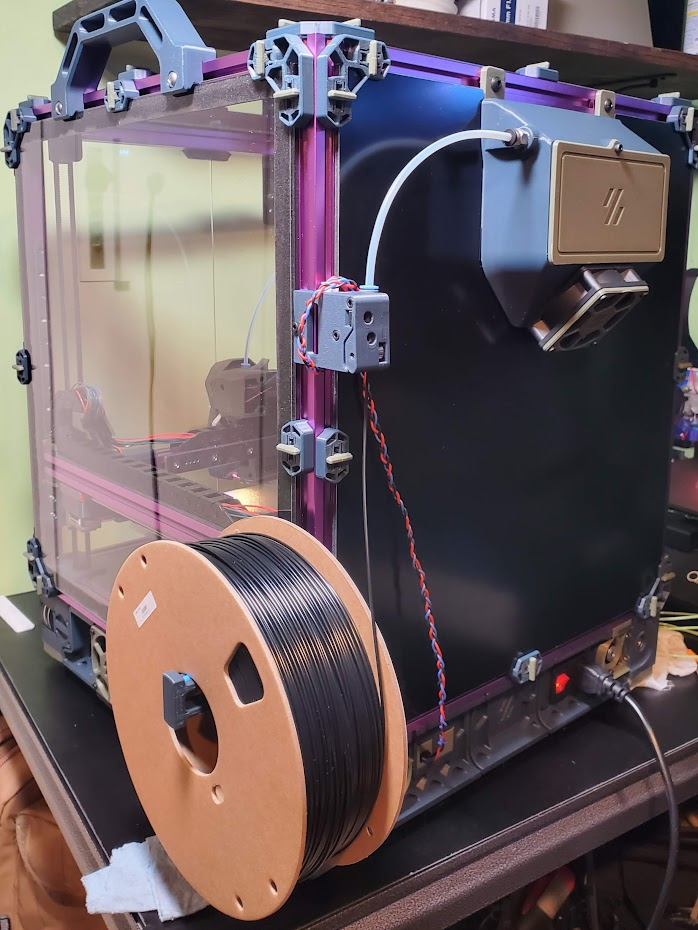

@deckingman gloomyandy has it right, I use reverse bowden tubes. in my experience, except in the straightest filament runs, skipping a reverse bowden will often result in tangles.

Some examples:

-

i'm interested in removing a similar limit from Duet which blocks using the temperature sensor and hotend heater on 2 different boards.

basically i want to use a Type K thermocouple daughter board in combination with my toolboard 1LC. i dont quite understand the safety concerns with this setup.

how feasible is it for me to compile my own firmware and flash it for a custom setup? hoping i could use VS Code.

-

@RogerPodacter said in Remove filament-sensor and extruder motor same board requirement:

i'm interested in removing a similar limit from Duet which blocks using the temperature sensor and hotend heater on 2 different boards.

basically i want to use a Type K thermocouple daughter board in combination with my toolboard 1LC. i dont quite understand the safety concerns with this setup.

how feasible is it for me to compile my own firmware and flash it for a custom setup? hoping i could use VS Code.

This is less likely to be possible as the realtime nature of PID loop handling probably won't play nicely with not co-locating the temp sensor & heater. This would come at the expense of temperature consistency