Return to position gcode

-

@OwenD

So I added that and it looks like it is moving xyz to the 0,0 position every tool change. -

@Jered

Z is also going to zero. -

@Jered

Please post the firmware version you're using and the macro you are calling the tool changes from.

Also your tpre*.g tfree*.g tpost*.g files for the two tools -

@OwenD

firmware version 3.3

Original macro is:

G1 E-5 F5000

G91

G1 Z2 F1000

G90

G1 X328 Y306 F6000

G1 E10 F300

G1 E-30 F5000

G1 E-50 F500

G1 E-175 F5000

{IF NEWTOOL=0}T0

{IF NEWTOOL=1}T1

{IF NEWTOOL=2}T2

{IF NEWTOOL=3}T3

{IF NEWTOOL=4}T4

{IF NEWTOOL=5}T5

{IF NEWTOOL=6}T6

G1 E200 F5000

G1 E60 F1500

G91

G1 Y100 E50 F1000

G1 Y-100 F3000

G1 Z-2 F1000

G1 E3 F5000

G90I am not using any of the Tool.g files currently. I am using simplify3d's tool change tab to add this to my gcode files. I added the command you sent me to the end of my tool change code to see what would happen.

To test the command G1 R command I added an extra 10 to the Z movement at the top of the macro to see if it would return back to the correct Z height. It does not. Just keeps adding.

-

@Jered

Firmware now 3.4.5Just upgraded.

-

@Jered

I really don't know anything about S3D or what happens if you don't use the tool change files, but...

Try this

Note: I don't know if you're using a tool changer so I don't know what you have to do to safely move to and from the pickup pointG60 S3 ; save position to slot 3 G1 E-5 F5000 G91 G1 Z2 F1000 G90 G1 X328 Y306 F6000 G1 E10 F300 G1 E-30 F5000 G1 E-50 F500 G1 E-175 F5000 {IF NEWTOOL=0}T0 {IF NEWTOOL=1}T1 {IF NEWTOOL=2}T2 {IF NEWTOOL=3}T3 {IF NEWTOOL=4}T4 {IF NEWTOOL=5}T5 {IF NEWTOOL=6}T6 G1 E200 F5000 G1 E60 F1500 G91 G1 Y100 E50 F1000 G1 Y-100 F3000 G1 Z-2 F1000 G1 E3 F5000 G90 G1 R3 X0 Y0 Z0 ; move back to slot 3 position -

Ok,

So when I use:

G1 R3 X0 Y0 Z0

I think it is causing it to go to 0,0,0 However, when I use:

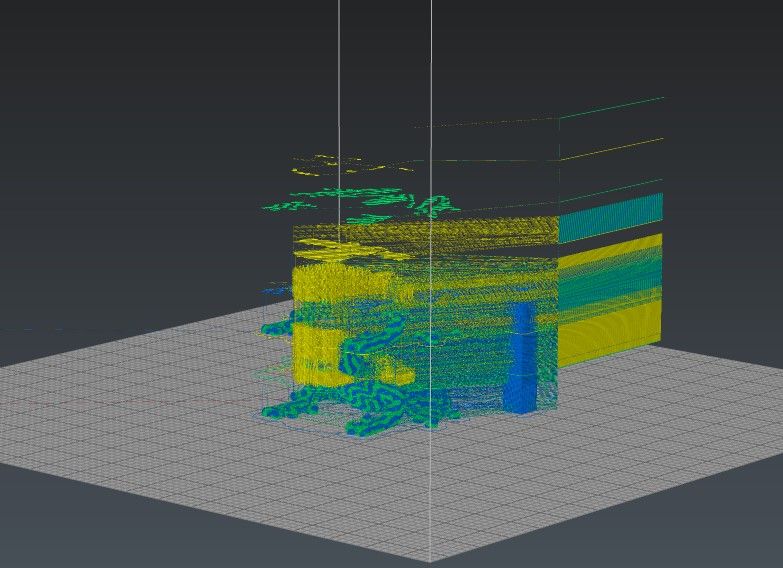

G1 R3 X Y Z (I used your G60 S3 at the top) is seems to work!That being said, the picture of the slicer generates is all kinds of F'd up. See pic bellow:

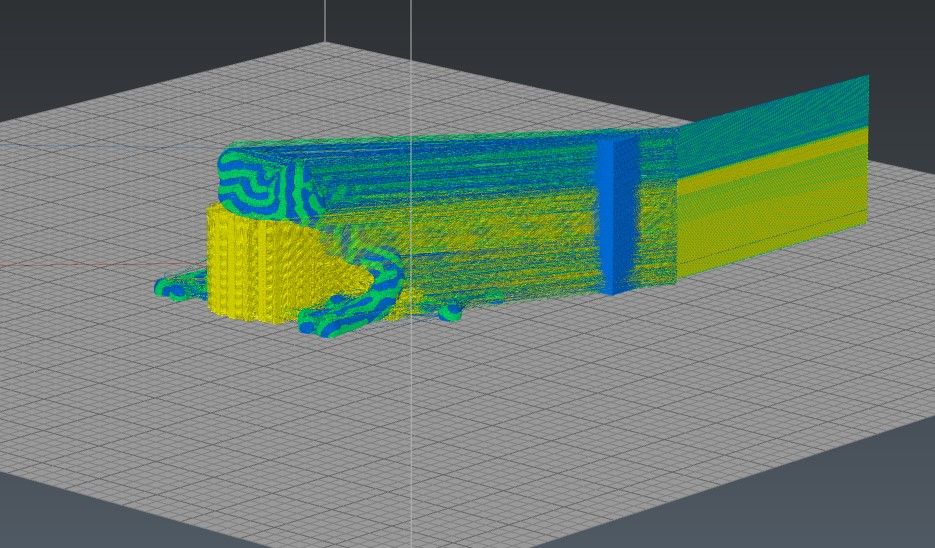

Should look like this:

I decided to run this anyway, with no filament and with a Z offset from the bed (don't want a crash) and it looks right. The slicer doesn't know how to handle the code apparently.

I also waited for the layer height to change before sending this.

I did have this tool change process in the tool.g files, and it works fine, however, if there is a problem, such as a filament jam, it makes it a pain to recover from. Everytime I click on a different tool, it runs the process. If there was a software switch to turn off the tool.g files for recovering a failed print or jam, then I would move this tool change process to the tool.g files.

Anyway, let me test this for a while and get back to you. Seems good though!

Ultimate goal is to add a purge/dump area to the printer.

I may make a video about this so that you can see more details if needed later. -

-

@OwenD

Thanks,I guess I can write a macro for turning them on and off.

-

@Jered

You don't "turn it off"

You need to use the P0 parameter on every tool change where you don't want to run the tool change macros.

If you did this ....

T1 P0 ; select tool 1 but don't run the tool change macros

T0 ; select tool zero and run tool change macros

T-1 ; deselect all tools and run tool change macros

T0 P0 ; select tool 0 but don't run tool change macros -

I understand. I think this can be closed. I get it now.

I really appreciate your help!

You guys are the best!

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved