Duet 2 Wifi Dual Z issue after increasing esteps

-

@slabstations said in Duet 2 Wifi Dual Z issue after increasing esteps:

M906 X800 Y800 Z2500 E1000 I50 ; set motor currents (mA) and motor idle factor in per cent

Then the last and I think the most important step to solve your problem would be to edit the mA for Z.

The 2500mA (Z2500) is important, they are much too high and could cause irreparable damage in the long run.

Here 800mA (Z800) should be entered for the beginning.

My stepper motors are also designed for 800mA, but I have set them to 1000mA and constantly monitored the temperatures and made sure that the motors do not get hotter than 60°C. Without housing or closed pressure room.Motors behave exactly like in the video when they are allocated too much mA.

Google Translate

-- Original Text --Dann wäre der letzte und ich denke es ist der wichtigste Schritt um Dein Problem zu lösen, die mA für Z zu editieren.

Wichtig ist die 2500mA (Z2500), die sind viel zu hoch und könnten auf Dauer einen irreperablen Schaden verursachen.

Hier sollten 800mA (Z800) für den Anfang eingetragen werden.

Meine Stepper Motoren sind auch für 800mA ausgelegt, ich habe sie aber auf 1000mA eingestellt und die Temperaturen ständig überwacht und darauf geachtet das die Motoren nicht über 60°C heiß werden. Ohne Umhausung oder geschlossenen Druckraum.Motoren verhalten sich genau so wie in dem Video wenn sie zu viel mA zugeteilt bekommen.

-

@norder I change the mA back down to 800mA and change the esteps to 400 but now it doesnt move the correct amount of mm. Back to where it seems as if it needs more esteps.

-

@slabstations

But the two Z motors are now both running normally again, so not like in the video where only one moved normally and the other stuttered?

After what you wrote what kind of engines you have, 400 steps should be correct.

But maybe they are 0.9° motors or the spindles have a different pitch?

You can easily adjust the steps, but the mA should be in the range of 800mA to about 1000mA without the temperatures being too high.

At 2500mA, the motors can overheat, but so can the stepper driver chips on the Duet board.First of all, it is important that the motors run evenly with 800mA.

Can you measure how far the z-axis moves if you enter 100mm, for example.

If the axis then only moves 50mm, you probably have 0.9° motors, because they need twice as many steps (800 instead of 400).Google Translate

-- Original Text --Aber die beiden Z-Motoren laufen jetzt beide wieder normal, also nicht mehr so wie im Video wo sich nur einer normal bewegt hat und der andere stotterte ?

Nachdem was Du geschrieben hast was für Motoren Du hast, sollten 400 Steps richtig sein.

Aber vielleicht sind es doch 0,9° Motoren oder die Spindeln haben eine andere Steigung ?

Die Steps kannst Du problemlos anpassen aber die mA sollten so im Bereich von 800mA bis etwa 1000mA liegen ohne das zu hohe Temperaturen entstehen können.

Bei 2500mA können die Motoren überhitzen aber auch die Chips der Stepper Treiber auf dem Duet Board.Wichtig ist erst einmal dass die Motoren mit 800mA gleichmäßig laufen.

Kannst Du mal messen wie weit die z-Achse verfährt wenn Du zB 100mm eingibst.

Sollte sich die Achse dann nur 50mm bewegen, hast Du vermutlich 0,9° Motoren, denn die brauchen doppelt so viele Steps (800 statt 400). -

@slabstations

I just watched your video again.

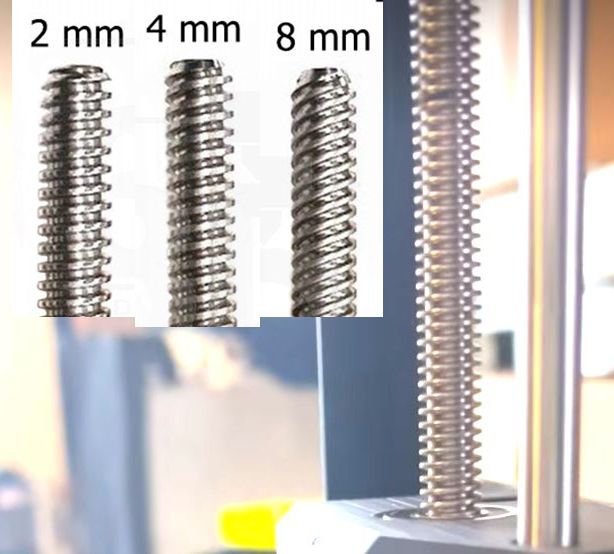

Most 3D printers have a spindle with 8mm Lead per revolution and thus 400 steps with a 1.8° motor and 800 steps with a 0.9° motor.When I look at the lead of your spindle, it looks more like a 2mm lead.

If your information about your Z motors is correct, then you would have to enter 1600 steps (Z1600) for your Z axis.

Google Translate

-- Original Text --Ich habe mir gerade noch einmal Dein Video angesehen.

Die meisten 3D-Drucker haben eine Spindel mit 8mm Steigung (Lead) pro Umdrehung und somit 400 Steps bei einem 1,8° Motor und 800 Steps bei einem 0,9° Motor.Wenn ich mir die Steigung Deiner Spindel so ansehe, sieht es eher nach einer Steigung von 2mm aus.

Wenn Deine Angaben zu Deinen Z-Motoren richtig sind, dann müsstest Du 1600 Steps (Z1600) für Deine Z-Achse eintragen. -

@norder You can't tell what the lead if a screw is by looking at the side. The reason being that lead screws are often multi-start. Also, don't confuse pitch with lead. Pitch is the distance between thread peaks (or troughs) while lead is how far a nut will travel in one revolution. So a two start screw might have a pitch of 2mm but the lead will be 4mm.

-

@deckingman

You're right, I mistakenly put pitch and lead together.

I already know what the meaning is.

But I am of the opinion that since threaded spindles in commercially available 3D printers almost always have a multi-start thread, which can be roughly recognized by the angle of the thread path to the longitudinal axis, that the threaded spindle is not a threaded spindle with 8mm lead per revolution, even though I can't see the front end.

The lead screw in the video has less than 8mm lead per revolution, don't you think?I correct my previous comments on pitch and lead !

Not that anyone is misled.P.S.:

I only had to correct the text translated by Google.

The German word "Steigung" was translated as "Pitch", which is incorrect.

"Steigung" or "Verfahrweg" is the German term for the English "lead".

Google is to blame.

Google Translate

-- Original Text --Da gebe ich Dir Recht, ich habe Pitch und Lead irrtümlich zusammengebracht.

Ich weiß schon was die Bedeutung ist.

Aber ich bin der Meinung, da Gewindespindeln bei handelsüblichen 3D Druckern so gut wie immer eine mehrgängiges Gewinde haben, das man anhand des Winkels der Gewindebahn zur Längsachse grob erkennen kann das es sich bei der Gewindespindel nicht um eine Gewindespindel mit 8mm Lead pro Umdrehung handelt, auch wenn ich die Stirnseite nicht sehen kann.

Die Gewindespindel in dem Video hat weniger wie 8mm Lead pro Umdrehung, oder glaubst Du etwa nicht ?Ich korrigiere meine vorherigen Kommentare zum Thema Pitch und Lead !

Nicht das jemand in die irre geführt wird.P.S.:

Ich musste nur den von Google übersetzen Text korrigieren.

Das deutsche Wort "Steigung" wurde als Pitch übersetzt, was falsch ist.

Steigung oder Verfahrweg ist der deutsche Befriff für das englische lead.

Google hat Schuld.

-

@norder Yea I had bumped the esteps up to 1600 and thats why the motors would stall out like they did in the video. They both move and stutter out, with one side tending to move a little bit more then the other.

-

@norder

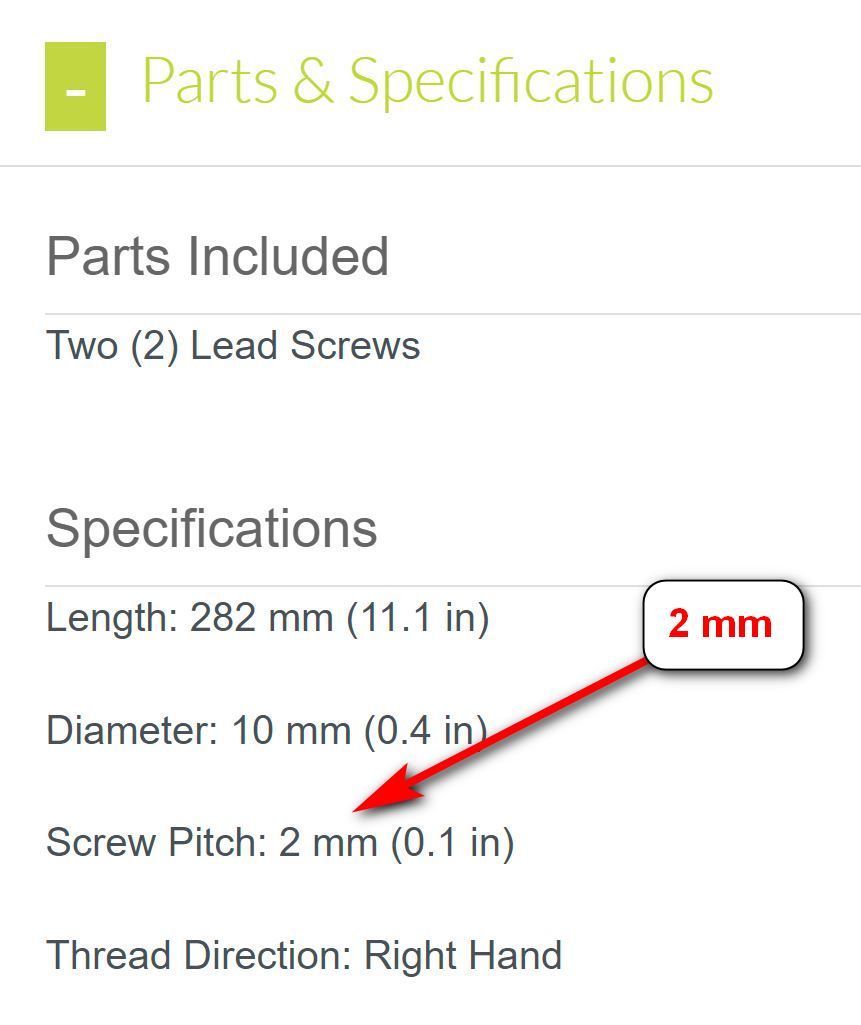

Here is the leadscrews used on the lulzbot mini if that helps!

Here is the leadscrews used on the lulzbot mini if that helps! -

@norder I also had the same issue when I was running the stock stepper motors. 400 esteps it would move fine but if I commanded 10mm it would give me 1-2mm, I though something could be wrong with the motors since they are older and thats when I tried the new creality ones and same issue.

-

@slabstations You refer to Z steppers in the plural yet your configuration only has one Z stepper defined. So I assume that you have wired the two motors in series to a single driver. IIRC on the Duet 2, that means connecting one motor to ZA and the other the ZB. Is that what you'd done? If so, have you remembered to remove the jumpers?

-

@slabstations said in Duet 2 Wifi Dual Z issue after increasing esteps:

@norder I have removed the D3 V40 and commented out the M575 and M918 lines. I have not gotten far enough for me to setup the probe offset yet, ran into this problem and have been messing with it since. I do one highend mounted endstop connected to the board. The motors are connected in the Z spot, I removed the jumpers in the second Z spot to plug in the second motor. I had it at 400 esteps originally but when I asked it to move 10mm, it would only move 1-2mm so that is why I bumped them up. But once I added the addition esteps, it started to do what its doing in the video.

@deckingman I've already asked him that.

-

@slabstations

Recently there was a similar problem here, the motors must be identical, otherwise problems arose when Z1 and Z2, i.e. one driver for both steppers, were used.If both spindles each have an endstop, or you have a second endstop to spare, then you could set up a Dual-Z so that each Z motor has its own driver. E1 should still be free!?

My printer also runs Dual-Z. It has the advantage that the X-axis can be leveled.

I have self-made HAL sensor endstops, each with an adjustable magnet.Would Dual-Z be conceivable for you?

Google Translate

-- Original Text --Letztens gab es hier ein ähnliches Problem, die Motoren müssen identisch sein sonst kam es zu Problemen wenn Z1 und Z2, also ein Treiber für beide Stepper, genutzt wurden.

Wenn beide Spindeln je einen Endstop haben oder Du einen zweiten Endstop übrig hast, dann könntest Du ein Dual-Z einrichten so das jeder Z-Motor seinen eigenen Treiber hat. E1 sollte doch noch frei sein !?

Bei meinem Drucker läuft auch Dual-Z. Es hat den Vorteil das die X-Achse nivelliert werden kann.

Ich habe selbst gebaute HAL-Sensoren Endstops mit je einem justierbaren Magneten.Wäre Dual-Z für Dich denkbar ?

-

So 1600 steps are correct.

-

@slabstations said in Duet 2 Wifi Dual Z issue after increasing esteps:

@norder Yea I had bumped the esteps up to 1600 and thats why the motors would stall out like they did in the video. They both move and stutter out, with one side tending to move a little bit more then the other.

So that I understand this correctly... After you set 800mA for the motors, you tried to let these 800mA run with 1600 steps, so not earlier but now ?

To be on the safe side, please post your current config.g with which you started the last attempt !

-

@deckingman No I just plugged the second motor into the second port on the board. I did the same thing on an ender 3 and it worked just fine. The only jumpers I removed were the ones in the second z port.

-

@norder Yes I tried with 800mA and 1600esteps and same result as in the video.

-

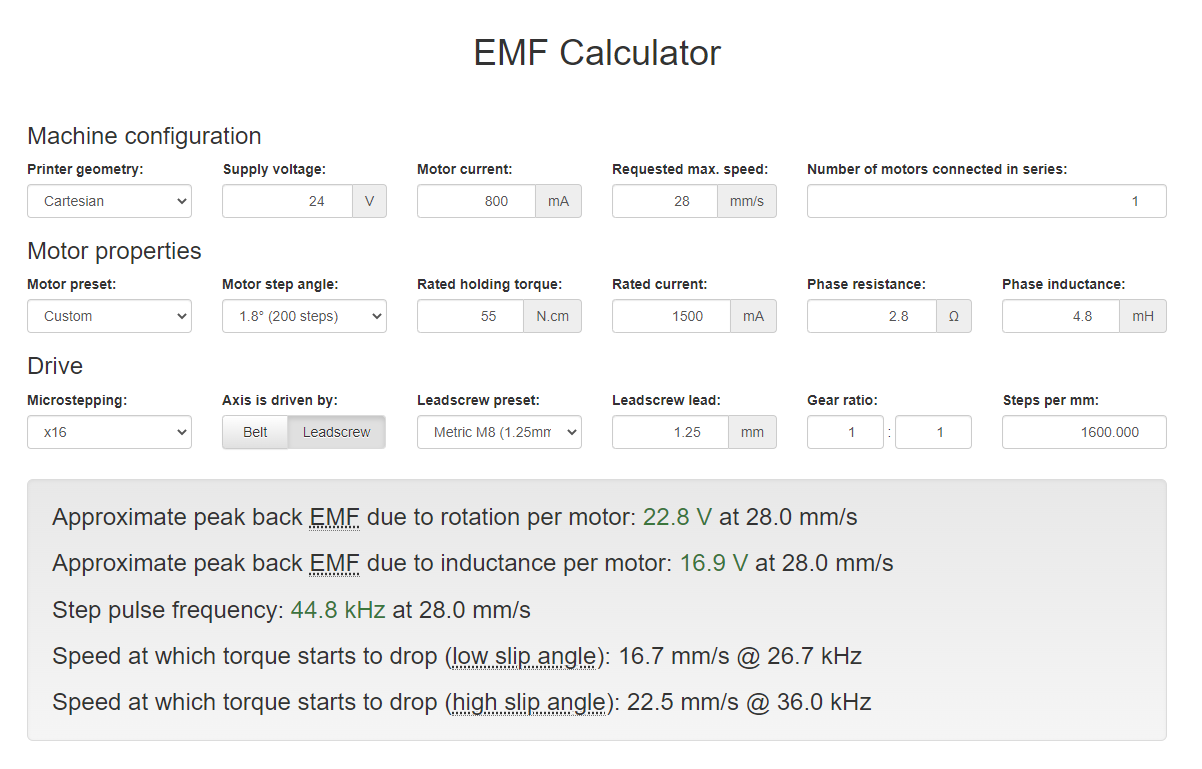

@slabstations what voltage are you running at?

-

@jay_s_uk 24v. It even says it on the dashboard, that was one of the first things I checked.

-

@slabstations how fast are you trying to move the motors?

max speed you can really run them at before generating too much EMF is 28mm/s (F1680)

-

@jay_s_uk Honestly I am not sure, whatever the default is when you control it through the web interface. I started with the creality ender 3 base config in the configurator. I have gotten an ender 3 pro up and running, so I just copied the config and change printer size to fit the lulzbot. Only thing I did different was add a bl touch to the lulzbot, which seems to be working properly, have only gotten as far as retracting and dropping it.