NPN Inductive Z Probe

-

Thank you for your kind words and support, and your efforts as English isn't your native language. I don't know if this was lost in translation;

@norder said in NPN Inductive Z Probe:

If you got along well with Marlin then RepRap won't cause you any big problems.

I've never used Marlin only the Tronxy firmware, which (if I'm correct regarding the translation) is very cryptic, using mm's per step for example rather than steps per mm.

The Gcode reference dictionary page is always in an open tab, along with the wiring page and many more, as is to be expected with a duet novice.

Homez, So would home Z look like this;

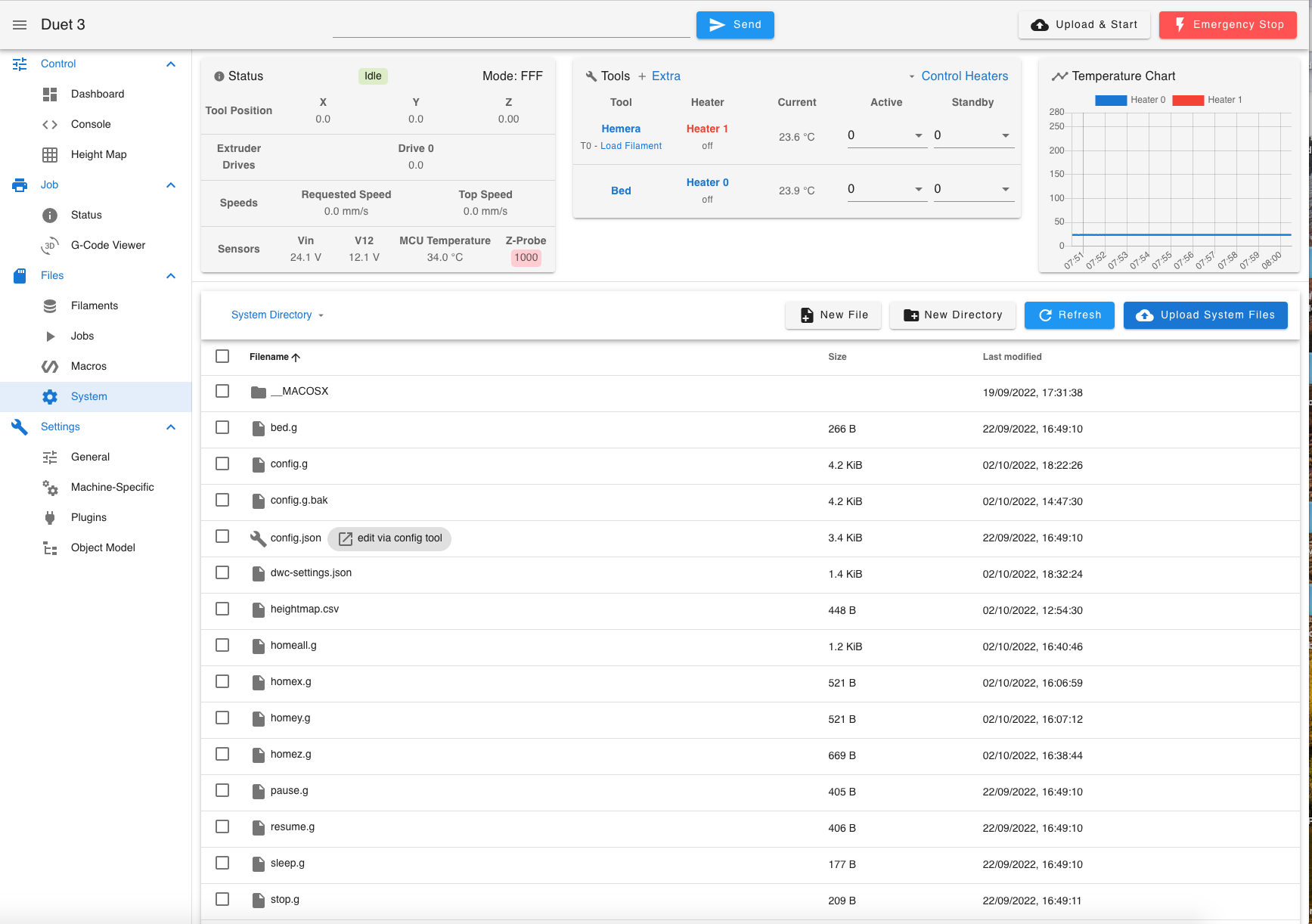

G91 G30Config-override.g, I'm using RRF 3.4.2, but don't see this file listed anywhere?

It's not in __MACOSX, as soon as I click on that, it disappears?

Thank you again for your help.

-

@dizzwold said in NPN Inductive Z Probe:

don't know if this was lost in translation

Unfortunately, this happens very often because Google translates the words well, but the grammar often falls by the wayside.

... using mm's per step for example rather than steps per mm.

You always have to pay attention to that, because RRF uses both.

In config.g, for example, the maximum axis speed is specified in mm/min and the speeds are displayed in mm/s in the DWC.

Always keep an eye on it when you change something in the settings!My cascaded printer's homez.g file looks like this:

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Sun Mar 20 2022 22:36:03 GMT+0100 (Mitteleuropäische Normalzeit) G91 ; relative positioning G1 H2 Z8 F6000 ; lift Z relative to current position G1 H1 Z-9999 F77 ; move Z down until the endstop is triggered G4 P500 ; 500stel Sekunde Pause G92 Z0 ; set Z position to axis minimum (you may want to adjust this)Don't take over 1:1, because I have an end stop for each spindle for the Z-axis and don't use a probe for positioning like you do.

My homez.g has changed. Normally, a fast ride is made first, followed by a second, slower ride. This doesn't happen with me in homez.g but only in the homeall.g file.If you don't have the config-override.g file in your system directory, then run the M500 command once... now refresh the displayed system folder contents and then you should see the config-override.g.

Google Translate

-- Original Text --don't know if this was lost in translation

Das passiert leider sehr oft da Google zwar die Wörter gut übersetzt aber die Gramatik oft auf der Strecke bleibt.

... using mm's per step for example rather than steps per mm.

Da musst Du immer drauf achten, denn RRF benutzt beides.

In der config.g wird zB die maximale Achsgeschwindigkeit in mm/min angegeben und im DWC werden die Geschwindigkeiten in mm/s angezeigt.

Habe da immer ein Auge drauf wenn Du etwas an den Einstellungen änderst !Die homez.g Datei meines kaskadischen Druckers sieht so aus:

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Sun Mar 20 2022 22:36:03 GMT+0100 (Mitteleuropäische Normalzeit) G91 ; relative positioning G1 H2 Z8 F6000 ; lift Z relative to current position G1 H1 Z-9999 F77 ; move Z down until the endstop is triggered G4 P500 ; 500stel Sekunde Pause G92 Z0 ; set Z position to axis minimum (you may want to adjust this)Nicht 1:1 übernehmen, da ich für die Z-Achse je Spindel einen Endstop habe und nicht so wie Du eine Sonde zur Positionierung nutze.

Meine homez.g ist geändert. Normalerweise wird erst eine schnelle Fahrt gemacht und eine zweite langsamere Fahrt hinterher. Das passiert bei mir nicht in der homez.g sondern nur in der homeall.g Datei.Wenn Du die Datei config-override.g nicht in Deinem System Verzeichnis hast, dann führe einmal den Befehl M500 aus... jetzt aktualisiere den angezeigten System Ordner Inhalt und dann sollte die config-override.g zu sehen sein.

-

@dizzwold said in NPN Inductive Z Probe:

Config-override.g, I'm using RRF 3.4.2, but don't see this file listed anywhere?

That file is only created on the first use of M500 to save the things it tracks.

@dizzwold said in NPN Inductive Z Probe:

Homez, So would home Z look like this;

G91 G30It could, but a G30 by itself will start probing at whatever location the print head is currently at. So you may want to add a G1 XY move before the G30 to specify a safe location to probe. Or you may not. It depends how you want to use G28 Z.

-

I'm back again, and sorry to be a real pest.

Firstly thank you again for your input and comments.

I'm starting to get the hang of things now, or at least I thought I was.

Nothing major& I now know I can work around it, it's just bugging the heck out off me as to why?

I've moved on to the next stage of calibrating, Bed Plane levelling via means of MBLA

M671,

But the X axis/carriage crashes into the back of the frame. I believe I've allowed for the Z probe offset, and I've typedM999after any changes made.My previous z probe offsets (x-41 y-17), have changed slightly as these were first calculated more-or-less to the centre of the z probe. So now with my current z probe offset of (x-46 y20), the probe is fully allowed for.

My X axis from home has a full 327mm before crashing into the frame. So my bed.g in the X axis is set to 279 allowing 2mm spare. 327 -46 (-46 offset)=281.

My Y axis from home has a full 333m before crashing into the back of the frame. So my bed.g in the Y axis is set to 310 allowing 3mm spare. 333 -20 (-20 offset)=310.I can't spot a mistake?

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Mon Sep 19 2022 16:04:20 GMT+0100 (British Summer Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M669 K1 ; select CoreXY mode ; Bed Adjustment Screw Positions M671 X5:279:279:5 Y5:5:310:310 P0.5 ; front left, front right, back right, back left ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S1 M569 P0.4 S1 ; physical drive 0.3 goes forwards M584 X0.0 Y0.1 Z0.2 Z0.3 E0.4 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E330.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X900 Y900 Z900 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-2 Y-8 Z0 S1 ; set axis minima M208 X330 Y330 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin !io1.in M574 Y1 S1 P"!io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin !io2.in ; Z-Probe M574 Z1 Z1 S2 ; set endstops controlled be probe M558 P5 C"^!io3.in" H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X-46 Y-20 Z1.45 ; set Z probe trigger value, offset and trigger height M557 X46:325 Y20:330 P5 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.187 K0.192:0.000 D1.89 E1.35 S1.00 B0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 R2.498 K0.275:0.349 D6.79 E1.35 S1.00 B0 V24.0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out7" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 C"Part Cooling" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"out8" Q500 ; create fan 1 on pin out5 and set its frequency M106 P1 C"Extruder Cooling" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on ; Tools M563 P0 S"Hemera" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Emergency Stop M950 J1 C"io4.in" M851 P1 T0 S0 R0 ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Mon Sep 19 2022 16:04:20 GMT+0100 (British Summer Time) ;M561 ; clear any bed transform ;G29 ; probe the bed and enable compensation G28 ; home M401 ; deploy Z probe G30 P0 X5 Y5 Z-9999 G30 P1 X279 Y5 Z-9999 G30 P2 X279 Y310 Z-999 G30 P3 X5 Y310 Z-9999 S3 M402; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Mon Sep 19 2022 16:04:20 GMT+0100 (British Summer Time) G91 ; relative positioning G1 H2 Z10 F6000 ; lift Z relative to current position G1 H1 X-337 Y-343 F3000 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X-337 ; home X axis G1 H1 Y-343 ; home Y axis G1 X5 Y5 F6000 ; go back a few mm G1 H1 X-337 F360 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-343 ; then move slowly to Y axis endstop ;G1 H2 X202.5 F1500 ; move X & Y to centre of bed before Z home ;G1 H2 Y175.5 F1500 ; move Y to centre of bed before Z home ;G1 H1 Z-405 F360 ; move Z down stopping at the endstop ;G90 ; absolute positioning ;G92 Z0 ; set Z position to axis minimum (you may want to adjust this) G1 X202.5 Y175.5 F3000 ; move X & Y to centre of bed before Z home G30 ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Mon Sep 19 2022 16:04:20 GMT+0100 (British Summer Time) G91 ; relative positioning G1 H2 Z10 F6000 ; lift Z relative to current position G1 H1 X-337 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 X5 F6000 ; go back a few mm G1 H1 X-337 F360 ; move slowly to X axis endstop once more (second pass) G1 H2 Z-10 F6000 ; lower Z again G90 ; absolute positioning; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Mon Sep 19 2022 16:04:20 GMT+0100 (British Summer Time) G91 ; relative positioning G1 H2 Z10 F6000 ; lift Z relative to current position G1 H1 Y-343 F3000 ; move quickly to Y axis endstop and stop there (first pass) G1 Y5 F6000 ; go back a few mm G1 H1 Y-343 F360 ; move slowly to Y axis endstop once more (second pass) G1 H2 Z-10 F6000 ; lower Z again G90 ; absolute positioning; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Mon Sep 19 2022 16:04:20 GMT+0100 (British Summer Time) ;G91 ; relative positioning ;G1 H2 Z10 F6000 ; lift Z relative to current position ;G1 X202.5 Y175.5 F1500 ; move X & Y to centre of bed before Z home ;G30 ;G1 H1 Z-405 F1800 ; move Z down until the endstop is triggered ;G92 Z0 ; set Z position to axis minimum (you may want to adjust this) ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning G91 ; relative positioning G1 H2 Z10 F6000 ; lift Z relative to current position G1 H1 X-337 Y-343 F3000 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X-337 ; home X axis G1 H1 Y-343 ; home Y axis G1 X5 Y5 F6000 ; go back a few mm G1 H1 X-337 F360 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-343 ; then move slowly to Y axis endstop G1 X46 Y20 F3000 ; move X & Y to front left, home Z at front left G30Sorry for all the unneeded stuff in the files, but as I still unsure of myself, I've left some in there.

I've also tried and failed to extrude afterM302 P1, and get the error "attempting to extrude with no tool selected". I've tried changing tool number in the tool part of the config.g lines 64, 65 & 66 fromP0toP1and the drive fromD0toD4, but no luck. -

@dizzwold said in NPN Inductive Z Probe:

I have a quick answer to the last question.

I'll watch the rest later because I have work to do.I'm back again, and sorry to be a real pest.

Yes, that's really bad with you.

(fun)

(fun)error "attempting to extrude with no tool selected".

At the end in config.g you have to enter T0.

This activates tool #0.See you later.

-

First the homeall.g... I edited it to include the sample offset from the X-46 / Y20.

If you start this modified homeall.g with you, be ready to press the emergency stop quickly.

But I think your homeall.g should look like this.

Nevertheless the hint !!! No guarantee !!!Feel free to wait for an OK from another experienced user here on the forum if you need a second opinion.

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Mon Sep 19 2022 16:04:20 GMT+0100 (British Summer Time) ; X Y homing section G91 ; relative positioning G1 H2 Z10 F6000 ; lift Z relative to current position G1 H1 X-337 Y-343 F3000 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X-337 ; home X axis G1 H1 Y-343 ; home Y axis G1 H2 X5 Y5 F6000 ; go back a few mm G1 H1 X-337 F360 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-343 ; move slowly to Y axis endstop once more (second pass) ; Z homing section G1 X119 Y185 F3000 ; move probe X & Y to centre of bed (Probe offset X-46 Y20 included) G30 ; probe z G90 ; absolute positioning G92 Z0 ; set Z position to axis minimum (you may want to adjust this) G1 Z10 ; lift z 10mm G1 X0 Y0 ; move to home (X0 Y0 Z10)My previous z probe offsets (x-41 y-17), have changed slightly as these were first calculated more-or-less to the centre of the z probe. So now with my current z probe offset of (x-46 y20), the probe is fully allowed for.

But the offset of the probe has changed drastically, not just a little bit.

Make a mark somewhere on the print bed (but preferably in the middle) with an Edding or a glued-on dot or similar, and after homing, move the nozzle tip exactly over this mark. Use the DWC to move the print head.

Now note down the coordinates that are displayed in the DWC.

Now drive the probe exactly over this marking and also note down the coordinates.

Now calculate the difference between the two coordinates.

This is the exact offset of the probe.bed.g and M671...

I have misused my bed.g and use it for my second probe (BLTouch), which I use when I put on another pressure plate with which my first probe (IR probe) has problems, such as PEI, glass or similar surfaces.

So I just don't have a way to compare.I would also have to deal with the M671 command first, since I do not use this command.

I have written special macros for the manual setting of the level wheels that support me with the setting.Edit homeall.g Content 5.Oktober 12:30

The reason for editing: I accidentally assumed a cascading printer, but this is about a CoreXYGoogle Translate

-- Original Text --Erst einmal die homeall.g... ich habe sie so bearbeitet das dort der Probe-Offset von X-46 / Y20 mit einbezogen ist.

Wenn Du diese geänderte homeall.g bei Dir startest, halte Dich bereit den NotAus schnell drücken zu können.

Aber ich denke so müsste Deine homeall.g aussehen.

Trotzdem der Hinweis !!! Ohne Gewähr !!!

(homeall.g Inhalt siehe oben)My previous z probe offsets (x-41 y-17), have changed slightly as these were first calculated more-or-less to the centre of the z probe. So now with my current z probe offset of (x-46 y20), the probe is fully allowed for.

Der Offset der Sonde hat sich aber extrem geändert, nicht nur ein bisschen.

Mache irgendwo (am besten aber in etwa der Mitte) auf dem Druckbett eine Markierung mit einem Edding oder einen aufgeklebten Punkt o.ä., und fahre nach dem Homing mit der Düsenspitze genau über diese Markierung. Nutze dazu das DWC um den Druckkopf zu bewegen.

Notiere Dir jetzt die Koordinaten die im DWC angezeigt werden.

Jetzt fahre genau mit der Sonde über diese Markierung und notiere Dir ebenfalls die Koordinaten.

Jetzt rechne die Differenz der beiden Koordinaten aus.

Das ist der exakte Offset der Sonde.bed.g und M671...

Meine bed.g habe ich zweckentfremdet und nutze sie für meine zweite Sonde (BLTouch) die ich nutze wenn ich eine andere Druckplatte auflege mit der meine erste Sonde (IR-Probe) Probleme hat wie zB PEI, Glas oder ähnliche Oberflächen.

Daher fehlt mir gerade die Vergleichsmöglichkeit.Auch mit dem Befehl M671 müsste ich mich erst einmal beschäftigen, da ich diesen Befehl nicht nutze.

Ich habe mir für das manuelle einstellen der Levelräder spezielle Makros geschrieben die mich bei dem einstellen unterstützen.Inhalt der homeall.g editiert 5.Oktober 12:30

Der Grund zum editieren: Ich bin versehentlich von einem kaskadischen Drucker ausgegangen, aber hier geht es ja um ein CoreXY -

@dizzwold said in NPN Inductive Z Probe:

My X axis from home has a full 327mm before crashing into the frame.

I don't understand that now... You have a 330mm x 330mm print bed ?

Why does the print head hit the frame at 327mm ?It might have been because you commented out the G90 (absolute positioning) command in homeall.g ?

Please test it again with my edited homeall.g if you have tested it and it works as it should.Google Translate

-- Original Text --Das verstehe ich jetzt nicht... Du hast doch ein 330mm x 330mm Druckbett ?

Warum stößt der Druckkopf schon bei 327mm an den Rahmen ?Es könnte ggf daran gelegen haben das Du den G90 (absolute Position) Befehl in der homeall.g auskommentiert gehabt hast ?

Teste es bitte noch einmal mit der editierten homeall.g von mir, wenn Du sie getestet hast und sie funktioniert wie sie soll. -

Editing homez.g

Nevertheless the hint !!! No guarantee !!!; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Mon Sep 19 2022 16:04:20 GMT+0100 (British Summer Time) G91 ; relative positioning G1 H2 Z10 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X119 Y185 F3000 ; move probe X & Y to centre of bed (Probe offset X-46 Y20 included) G30 ; probe ZEdit File Content 5.Oktober 12:10

-

Thank you for your detailed guidance. I've tinkered with your example code, but not had a good chance to test it (I've got a lot on at the minuet).

I have had to omit theG92 Z0in the homez as this resets the the settings previously entered for the trigger height in config.g.

I appreciate you have different z probes, and what you've sent above is an example. Thank you, It does help a lot.I'll try and get time to test/tinker/play tomorrow, but it may be at the weekend until I get good chance to do so.

Dizzwold.

-

@dizzwold said in NPN Inductive Z Probe:

I appreciate you have different z probes

If you will, there are 4 pieces.

(fun)

(fun)

Two self-made Z-endstops with HAL-Sensors that react to a magnet that I can adjust steplessly.

The magnets move with the X-axis and the HAL-Sensors are firmly mounted at the bottom of the boom.

This way I can level the X-axis and don't have to loosen and move the whole endstop. With the adjustable magnets, this is more convenient and precise.Then the right probes, the IR-Probe which I use for the most part and the BLTouch is for printing surfaces that are rough or permeable to IR light (glass, PC and PEI).

G29 makes an MBL with the IR-Probe.

G32 makes an MBL with the BLTouch, so my bed.g is misused.Four different printers are then set up in the slicer, although I only have this one printer.

One to start printing with the BLTouch and the other starts with the IR-Probe which brings the MBL to the right height just before printing.

The whole then for 0.4mm nozzle and for a 0.2mm nozzle.The worst thing about two probes is comparing them to each other. You must probe the exact same point where the z-offset of the two probes was queried.

It took days to get it right, because the different repeatability of the two probes sometimes makes you despair.

But now it works great and every first layer of 0.1mm is printed perfectly.

Baby steps are not often necessary.If it wasn't a hobby and I only needed the printer for work, I wouldn't have done these things to myself.

Google Translate

-- Original Text --Wenn man so will sind es 4 Stück.

Zwei selbst gebaute Z-Endstops mit HAL-Sensoren die auf einen Magneten reagieren die ich stufenlos einstellen kann.

Die Magnete fahren mit der X-Achse mit und die HAL-Sensoren sind unten am Galgen fest montiert.

So kann ich die X-Achse nivellieren und muss dazu nicht den ganzen Endstop lösen und verschieben. Mit den einstellbaren Magneten geht das konfortabler und genauer.Dann die richtigen Probes, einmal den IR-Probe den ich zum größten Teil nutze und den BLTouch ist für Druckoberflächen die rau oder durchlässig für das IR Licht sind (Glas, PC und PEI).

G29 macht ein MBL mit dem IR-Probe.

G32 macht ein MBL mit dem BLTouch, daher ist meine bed.g zweckentfremdet.Im Slicer sind dann vier verschiedene Drucker eingerichtet, obwohl ich nur diesen einen Drucker besitze.

Einmal um den Druck mit dem BLTouch zu starten und der andere startet mit dem IR-Probe der kurz vor dem Drucken das MBL auf die richtige Höhe bringt.

Das ganze dann für 0,4mm Düse und für eine 0,2mm Düse.Das schlimmste an zwei Probes ist, diese aufeinander abzugleichen. Sie müssen exakt den gleichen Punkt sondieren wo auch das Z-Offset der beiden Probes abgefragt wurde.

Es hat Tage gedauert bis es stimmte, denn die unterschiedliche Wiederholgenauigkeit beider Probes lässt einem manches mal verzweifeln.

Aber jetzt funktioniert es super und jeder erste Layer von 0,1mm wird ideal gedruckt.

Babystepps sind nicht oft nötig.Wenn es nicht ein Hobby wäre sondern ich den Drucker nur zur Arbeit bräuchte, hätte ich mir diese sachen nicht angetan.