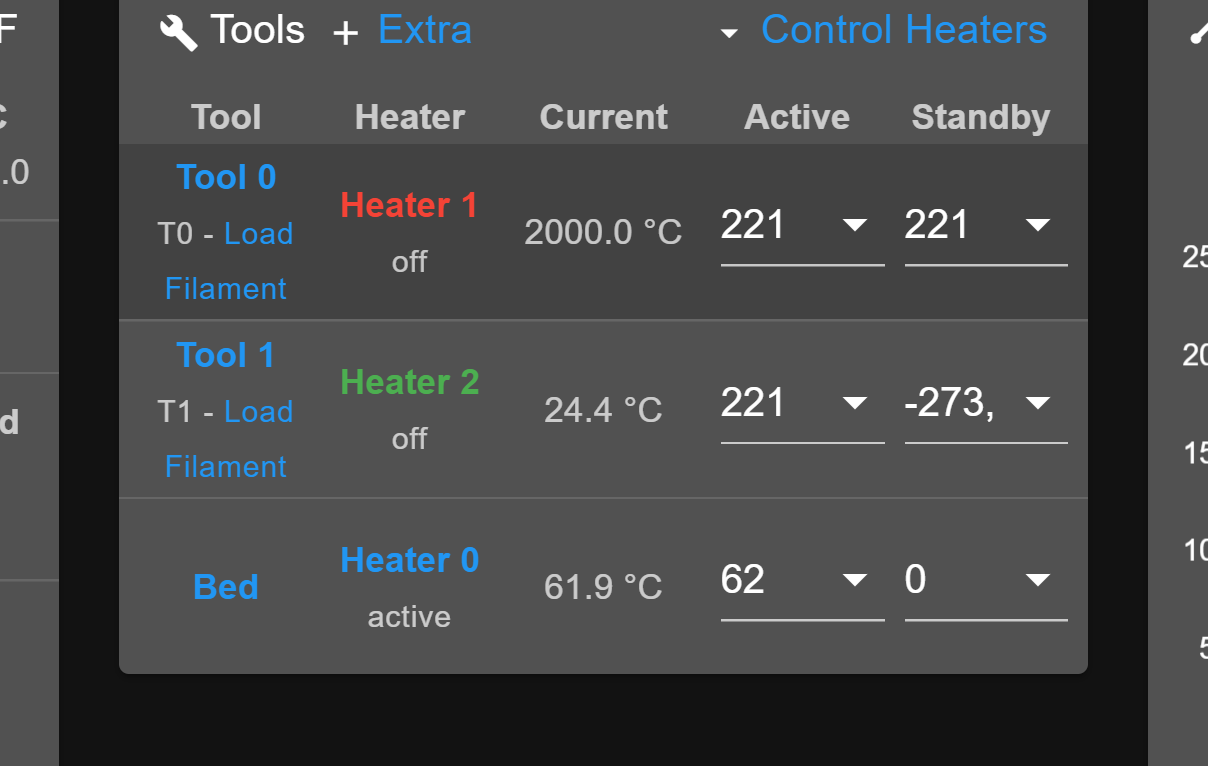

PT1000 on Toolboard v1.2 shows 2000C on RRF 3.4RC2

-

Hi,

I have a 6HC + 1LC Tool board configuration for a Voron 2.4 printer. The extruder motor, hotend heater, hotend/part fans, and hotend temperature sensor (PT1000) are connected to the tool board.

The PT1000 sensor returns the correct temperature in RRF 3.3. However, when I upgrade both the 6HC and 1LC's firmware to 3.4RC2, the PT1000 sensor always return 2000C. Is this a known bug?

Here's my config.g:

; Configuration file for Duet 3 (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Wed Mar 02 2022 23:23:46 GMT-0500 (Eastern Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Voron2" ; set printer name M669 K1 ; select CoreXY mode ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.4 S1 ; X motor direction (B motor) M569 P0.5 S1 ; Y motor direction (A motor) M569 P0.0 S1 ; Z0 motor direction M569 P0.1 S0 ; Z1 motor direction M569 P0.2 S1 ; Z2 motor direction M569 P0.3 S0 ; Z3 motor direction M569 P121.0 S0 ; E motor direction ; Motor remapping for dual Z and axis Limits M584 X0.4 Y0.5 Z0.0:0.1:0.2:0.3 E121.0 ; set drive mapping M671 X-65:-65:365:365 Y-20:380:380:-20 S20 ; Define Z belts locations (Front_Left, Back_Left, Back_Right, Front_Right) M557 X25:275 Y25:275 S25 ; Define bed mesh grid (inductive probe, positions include the Z offset!) ; Microstepping and Speed M350 X256 Y256 E32 Z256 I0 ; Configure microstepping with interpolation M92 X1280.00 Y1280.00 E800.00 z6400.00 ; Set steps per mm 1.8 motors ; Speeds, Acceleration and Jerk M566 X300.00 Y300.00 Z60.00 E600.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X120000.00 Y120000.00 Z4000.00 E1200.00 ; Set maximum speeds (mm/min) M201 X9000.00 Y9000.00 Z1600.00 E5000.00 ; Set accelerations (mm/s^2) ; Motor currents M906 X1200.00 Y1200.00 Z1200.00 E513.757 I60 ; Set motor currents (mA) and motor idle factor in percent M84 S600 ; Set idle timeout ; Endstops for each Axis M574 X2 S1 P"!0.io0.in" ; Set X endstop controlled by switch M574 Y2 S1 P"!0.io1.in" ; Set Y endstop controlled by switch M574 Z1 S1 P"0.io3.in" ; Set Z endstop ; Stallgaurd Sensitivy (maybe use to pause print after crash) M915 X S2 F0 H200 R0 ; Set X axis Sensitivity 1.8 motors M915 Y S2 F0 H200 R0 ; Set y axis Sensitivity 1.8 motors ; Mesh Grid M557 X5:280 Y30:250 P4 ; ; Z Probe Offset (Probe behind Afterburner) G31 P1000 X0 Y25 Z1.367 ; Axis Limits M208 X0 Y-2 Z0 S1 ; set axis minima M208 X300 Y301 Z260 S0 ; set axis maxima ; Heatbed Heaters and Thermistor Bed M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S116 ; set temperature limit for heater 0 to 115C ; Fans Electronic compartment & Exhaust ; M950 F1 C"out3" Q100 ; Creates Case Fan 1 ; M106 P1 T40 S150 H0 ; Case Fan 1 Settings (Turns on at 60°C tool temp) at low speed ; M950 F2 C"out4" Q100 ; Creates Case Fan 2 ; M106 P2 T40 S150 H0 ; Case Fan 2 Settings (Turns on at 60°C tool temp) at low speed ; M950 F5 C"out2" Q100 ; Creates Case Fan 2 ; M106 P5 T95 S50 H0 ; Exhaust fan ; Filament Runout sensor ;M950 J4 C"io5.in" ; Input 4 filament sensor ;M581 P4 T2 S1 R1 ; Filament Sensor P4 triggers inactive-to-active edge (S1) tigger2.g (T2) only when printing (R1) ;M591 D0 P1 C"io5.in" S1 ; Filament Sensor ; Tool 0 ; HotEnd Heaters and Thermistor HotEnd M308 S1 P"121.temp0" Y"pt1000" ; define E0 temperature sensor M950 H1 C"121.out0" T1 Q100 ; Create HotEnd Heater M307 H1 B0 R2.310 C158.7:115.4 D5.24 S1.00 V24.5 ; PID M143 H1 S315 ; Set temperature limit for heater 1 to 285C HotEnd M302 S185 R185 ; Select inductive probe, OMRON TL-Q5MC2-Z ; P4: connected to Zmin SIG and GND ; I0: P4 expects NC, TL-Q5MC2-Z is also NC ; T18000: Move to probe points at 300mm/s ; F1200: Probing Speed: 20mm/s ; H5: Dive height: 5mm ; A5 S0.01: Perform up to 5 touches until change is below 0.01mm ; B1: Turn off heaters while probing M400 M98 P"/macros/Home/use_z_probe.g" G31 T8 P500 X0 Y25 Z3.45 ; inductive probe offset, not critical, only used for coarse homing G4 P200 ; Accelerometer M955 P121.0 I20 ; Fans Hotend + Part M950 F1 C"121.out1" Q100 ; Creates HOTEND Fan M106 P1 T45 S0.8 H1 ; HOTEND Fan Settings M950 F0 C"121.out2" Q100 ; Creates PARTS COOLING FAN M106 P0 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off PARTS COOLING FAN M563 P0 S"Tool 0" D0 H1 F0 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M501 ; Load overrides -

I had the same problem... after a while it was gone without changing something.

don´t know what was wrong there..I also have the problem that I have no temperatur on heater 0 after switching can adress. It´s the second time in 1 month. Have you something similar?

EDIT:

minutes after I wrote you, this happened and destroyed my print. help to duet!!!! pleaase answer this time

-

@gruna-studio Not sure if it helps - everything is okay in RRF 3.3. So I just revert the firmware on both boards back to 3.3 then it runs well.

-

-

@gruna-studio It would probably help DC42 if you provide more information for him to work with. I think the following would be of help...

- Your config.g file

- The output from M122 when everything is OK and ideally again when your PT1000 is not working and the same for M122 B<xxx> but replace <xxx> with the CAN board number for your toolboard.

3 Can you provide more details of what you mean by "when I change the tool can , it stays with the same toolboard" what did you change, what happened and what did you expect to happen? - It looks like you have multiple tools? Are both tools using a toolboard? Do they both have a PT1000? Do you have problems on both boards or just on one?

- Can you provide more details about the problem you describe as "I also have the problem that I have no temperatur on heater 0 after switching can adress". It looks like heater 0 is your bed heater, did that really stop working when you changed the CAN address of your toolboard? Can you provide details of what exactly you did and what heppened?

-

I just want to report that when I flash the firmware again on both boards, everything seems normal now. I will update here again if I see anything out of order.

Just in case you need my M122:

m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.4.0rc2 (2022-02-22 17:04:17) running on Duet 3 MB6HC v1.01 or later (standalone mode) Board ID: 08DJM-956BA-NA3TJ-6JTDD-3SD6L-KA9UT Used output buffers: 1 of 40 (26 max) === RTOS === Static ram: 150984 Dynamic ram: 96080 of which 140 recycled Never used RAM 100468, free system stack 129 words Tasks: NETWORK(ready,23.9%,207) ETHERNET(notifyWait,0.2%,168) HEAT(notifyWait,0.0%,321) Move(notifyWait,0.0%,269) CanReceiv(notifyWait,0.0%,793) CanSender(notifyWait,0.0%,356) CanClock(delaying,0.0%,339) TMC(notifyWait,9.7%,58) MAIN(running,66.1%,925) IDLE(ready,0.0%,30), total 100.0% Owned mutexes: === Platform === Last reset 00:03:14 ago, cause: software Last software reset at 2022-03-10 10:17, reason: User, GCodes spinning, available RAM 103468, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Step timer max interval 138 MCU temperature: min 47.7, current 48.5, max 48.5 Supply voltage: min 24.0, current 24.1, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.0, current 12.1, max 12.1, under voltage events: 0 Heap OK, handles allocated/used 99/1, heap memory allocated/used/recyclable 2048/700/690, gc cycles 0 Events: 0 queued, 0 completed Driver 0: pos 384000, standstill, SG min 0, mspos 74, reads 40263, writes 15 timeouts 0 Driver 1: pos 0, standstill, SG min 0, mspos 808, reads 40263, writes 15 timeouts 0 Driver 2: pos 64000, standstill, SG min 0, mspos 568, reads 40263, writes 15 timeouts 0 Driver 3: pos 0, standstill, SG min 0, mspos 401, reads 40264, writes 15 timeouts 0 Driver 4: pos 0, standstill, SG min 0, mspos 618, reads 40276, writes 3 timeouts 0 Driver 5: pos 0, standstill, SG min 0, mspos 947, reads 40275, writes 3 timeouts 0 Date/time: 2022-03-10 10:20:51 Slowest loop: 11.28ms; fastest: 0.05ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 2.1ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 6, maxWait 81202ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 91, completed 91, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === CAN === Messages queued 1227, received 3694, lost 0, boc 0 Longest wait 2ms for reply type 6013, peak Tx sync delay 18, free buffers 50 (min 49), ts 635/635/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 24.33ms; fastest: 0.02ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions HTTP sessions: 1 of 8 - Ethernet - State: active Error counts: 0 0 0 0 0 Socket states: 5 2 2 2 2 2 0 0M122 B121

m122 b121 Diagnostics for board 121: Duet TOOL1LC rev 1.1 or later firmware version 3.4.0rc2 (2022-02-22 10:15:02) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) All averaging filters OK Never used RAM 2624, free system stack 62 words Tasks: Move(notifyWait,0.0%,153) HEAT(notifyWait,0.2%,115) CanAsync(notifyWait,0.0%,59) CanRecv(notifyWait,0.0%,76) CanClock(notifyWait,0.0%,65) ACCEL(notifyWait,0.0%,61) TMC(notifyWait,3.0%,57) MAIN(running,91.9%,335) IDLE(ready,0.0%,26) AIN(delaying,4.9%,142), total 100.0% Last reset 00:03:48 ago, cause: software Last software reset data not available Driver 0: pos 0, 800.0 steps/mm,standstill, SG min 6, read errors 0, write errors 1, ifcnt 232, reads 48769, writes 12, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter 3/7, peak Rx sync delay 213, resyncs 0/0, no step interrupt scheduled VIN voltage: min 23.9, current 23.9, max 23.9 MCU temperature: min 43.7C, current 43.8C, max 44.2C Last sensors broadcast 0x00000002 found 1 172 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 4723, send timeouts 0, received 2159, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer: LIS3DH, status: 00 I2C bus errors 0, naks 3, other errors 0