Issue with X and Y both moving on HomeX

-

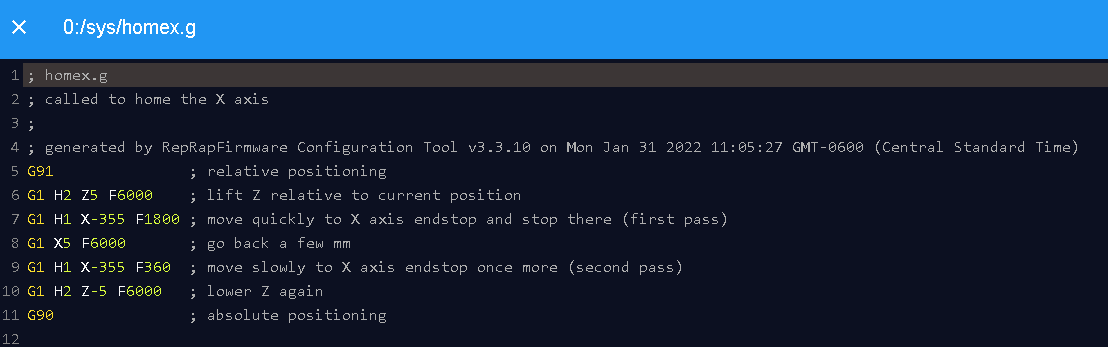

Having an issue with setting up the Duet 3 Mini 5+ where if I enter in G1 H1 X-355 F1800 command I end up with movement in both X and Y directions. I am using prefab cables so no leads have been swapped on accident. The X-axis is on stepper drive 0 and Y is on 1. This is going to an Ender 5 plus Running the latest firmware.

-

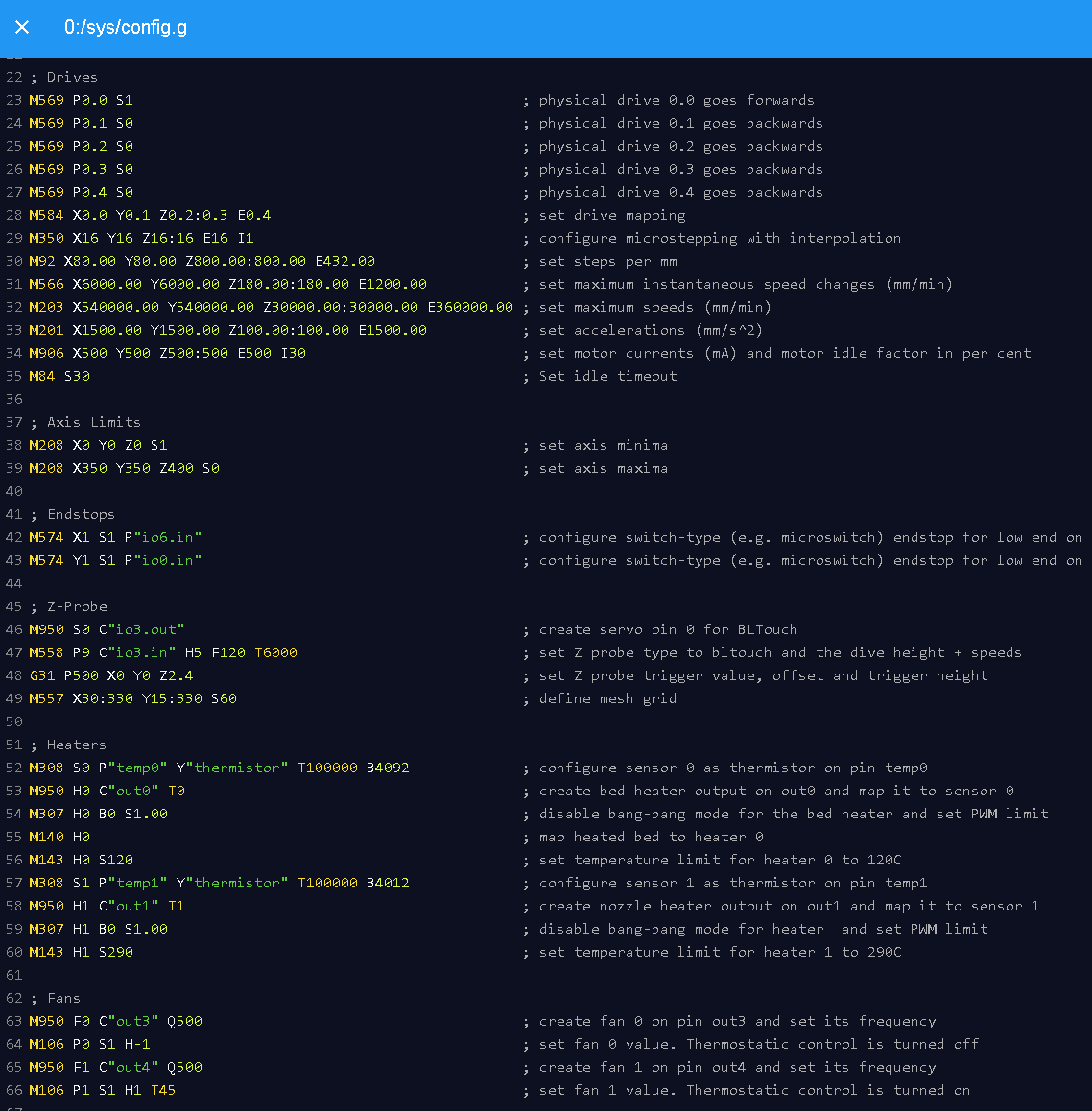

If you post your complete config.g, we can see what you have your kinematics set for.

Hit the button that looks like </> and then paste in your config.g

It will come out

Looking nice like this! -

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Mon Jan 31 2022 11:05:27 GMT-0600 (Central Standard Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K1 ; select CoreXY mode M918 P1 E4 F2000000 ; configure direct-connect display ; Network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M569 P0.3 S0 ; physical drive 0.3 goes backwards M569 P0.4 S0 ; physical drive 0.4 goes backwards M584 X0.0 Y0.1 Z0.2:0.3 E0.4 ; set drive mapping M350 X16 Y16 Z16:16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00:800.00 E432.00 ; set steps per mm M566 X6000.00 Y6000.00 Z180.00:180.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X540000.00 Y540000.00 Z30000.00:30000.00 E360000.00 ; set maximum speeds (mm/min) M201 X1500.00 Y1500.00 Z100.00:100.00 E1500.00 ; set accelerations (mm/s^2) M906 X500 Y500 Z500:500 E500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X350 Y350 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io6.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io6.in M574 Y1 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io0.in ; Z-Probe M950 S0 C"io3.out" ; create servo pin 0 for BLTouch M558 P9 C"io3.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.4 ; set Z probe trigger value, offset and trigger height M557 X30:330 Y15:330 S60 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4012 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S290 ; set temperature limit for heater 1 to 290C ; Fans M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P1 S"Extruder" D0 H1 F0 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@pre This line:

M669 K1 ; select CoreXY mode

Selects CoreXY mode, which would move both motors on a single axis move. So, operating as instructed...

-

@elmoret

That was it, Thanks! -

@pre Awesome!

I'm glad you got it sorted.

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved