Strategy for PID tuning multiple heat zones

-

@nhfoley That's a tricky one. In my case I have a heat break between the two zones so although there is some transfer from one zone to the other, it isn't enough to prevent one zone from cooling sufficiently when the heater turns off.

I'd have thought that, where there is significant transfer between the two zones, then the best strategy would be to treat the hot end as a single heat zone. So maybe connect both heaters in parallel and simply use a single sensor.

-

Yes, I may do that, but keep the second sensor wired & reporting to DWC for monitoring purposes.

-

Almost accomplished this with the new RRF 3.4 multi-pin heater syntax! But held back on the upgrade to stay on production FW. Nonetheless, meatspace wiring of the two heaters in parallel is now correctly holding a temp +/-.02C, which is the noise floor of my sensor reading, anyway. With the other thermistor still wired in place, I can see that there is a roughly consistent 1C difference on the non-control side. Not perfect, but much better than what I was seeing before.

-

@nhfoley A mere 1 Deg difference between sensors means that it's effectively just a single zone so treating as such must be the best way to do the PID tuning. In my case, I can easily get 100 Deg C separation between the heat zones which is what I need for printing multiple filaments with a single nozzle. Do Slice engineering say why they use two sensors?

-

What we really need to do is start heating one heater at the same time as starting the tuning cycle for the other.

@deckingman, what is more important to you, the behavior during the initial heating or the stability once things are got to their target temperatures?

If it's the latter, then it maybe it's more representative to let two sides reaching roughly their target temperature and then tune them independently.

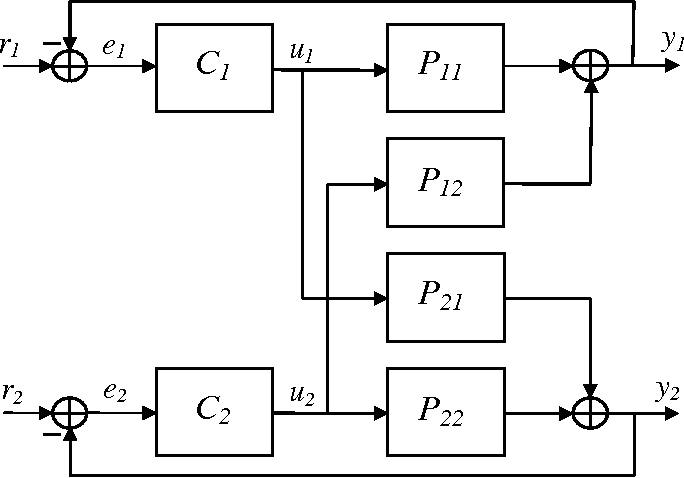

BTW, apparently, multivariable PID is a thing. Maybe you can convince @dc42 to support it, or just buy an of the shelf controller.

-

@zapta You clearly haven't read my opening post when I started this thread - please do so and you will see that I have developed a strategy to enable PID tuning of multiple heaters which works well for me.

The reason it didn't work for the other user is that he has a single heat zone so either heater will heat both parts of the hot end. In my case, I have two heat zones separated by a heat break giving more than 100 degC separation between the two zones.

The strategy I use gives me accurate, stable and repeatable temperature control of both zones and I don't need any advice on how you think it should be done thank you.

-

@deckingman said in Strategy for PID tuning multiple heat zones:

I don't need any advice on how you think it should be done thank you

@deckingman, it was not advice, it was guidance.

-

@deckingman said in Strategy for PID tuning multiple heat zones:

If anyone can figure out how to automatically turn off the other heater after the tuning cycle completes, post the answer in this thread.

T0 P0 ; select tool and suppress tool change macros G10 P0 S0:190 R0:190 ; set secondary heater to 190 active and standby M303 T0 S290 ; tune primary heater as tool while heat.heaters[0].state = "tuning" G4 S1 M568 P0 S0 R0 A0 ; turn off heaters associated with tool zero -

@owend said in Strategy for PID tuning multiple heat zones:

while heat.heaters[0].state = "tuning"

G4 S1

M568 P0 S0 R0 A0 ; turn off heaters associated with tool zeroBrilliant! I'm currently the other side of the world from my printer but I'll give it a go when I get back. Thanks.

-

undefined jay_s_uk referenced this topic

undefined jay_s_uk referenced this topic

-

This post is deleted!