I see no effect of microstepping on torque

-

Hello,

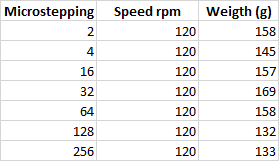

I wanted to see the effect of microstepping on stepper motor torque as I already saw tables that show 10% of nominal torque at 16x microstepping.

I took a Duet3 6CH and made a small test bench where I lift a glass with the stepper. I increase the weigth by putting large screws in the glass. The results I have are a bit strange ;

I see no real evolution when I change the microstepping parameter.Here is my config for the test (I changed the M350 command) :

; GENERAL PREFERENCES M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P2 ; Set firmware compatibility to look like Marlin M667 S0 ; Select Cartesian mode ; NETWORK M550 P"Duet3_2" ; Set machine name M552 S1 ; start Wifi module M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; DRIVE DIRECTION M569 P0 S0 ; Drive 0 X M584 X0 ; Apply custom drive mapping M208 X-35:328.5 ; Set axis maxima & minima M92 X17.76 S16 ; Set steps per mm assuming x16 microstepping M350 X4 I0 ; Configure microstepping with interpolation M566 X400000 ; Set maximum instantaneous speed changes (mm/min) M203 X400000 ; Set maximum speeds (mm/min) M201 X600000 ; Set accelerations (mm/s^2) M906 X1680 ; Idle motion motorsI used a Nema 17 stepper and made it move at 120rpm with this command :

G1 X180 F43200If I understand correctly the torque should be very different at 2x microstepping or 128x microstepping and that's not what I see here. Am I doing something wrong ?

-

@e4d yeah.... it's not the total torque that changes, it's the torque per step. So simplified you got two coils and we are looking at two teeth on the rotor. Coil A is at full current so it's pulling the full torque into that position on tooth A which is a full step position. A half step will put half current on each coil so you only have half the torque pulling into the middle of the two teeth. Continue to put full current on coil B, and zero on coil A and you get full torque to move you from the mid position between Teeth A and B to the full step position of B.

Whether you microstep or not you go through full current on a coil in the full step positions so your total torque is the same over a distance, but how well you constantly and repetively hit a microstep outside that full step position decreases as you increase the number of positions between full steps. TLDR; the tiny changes in current may not actually move you that tiny amount between the teeth, but when it comes to the tooth being fully lined up it's all the same.

-

You would need to measure the actual position of the shaft and the commanded position of the shaft to see the lack of torque during microstepping.

From the Faulhaber site:

What Does It Mean? The consequence is that if the load torque plus the motor’s friction and detent torque is greater than the incremental torque of a microstep, successive microsteps will have to be realized until the accumulated torque exceeds the load torque plus the motor’s friction and detent torque. Simply stated, taking a microstep does not mean the motor will actually move.In summary, although Microstepping gives the designer more resolution, improved accuracy is not realized. Reduction in mechanical and electromagnetically induced noise is, however, a real benefit. -

undefined alankilian referenced this topic

undefined alankilian referenced this topic