Advanced nozzle design

-

@plasticfactory A little late, but small update for today. The machining is finished on the new nozzle, and started another one for a proper cross section (quality check that will ultimately make a good photo). I feel confident previous issues are resolved after putting it on our inspection setup. Now that its in my hands I should be able to start doing actual prints! More updates and photos to come throughout the week.

If there are any tests in particular anyone would like me to do, please share!

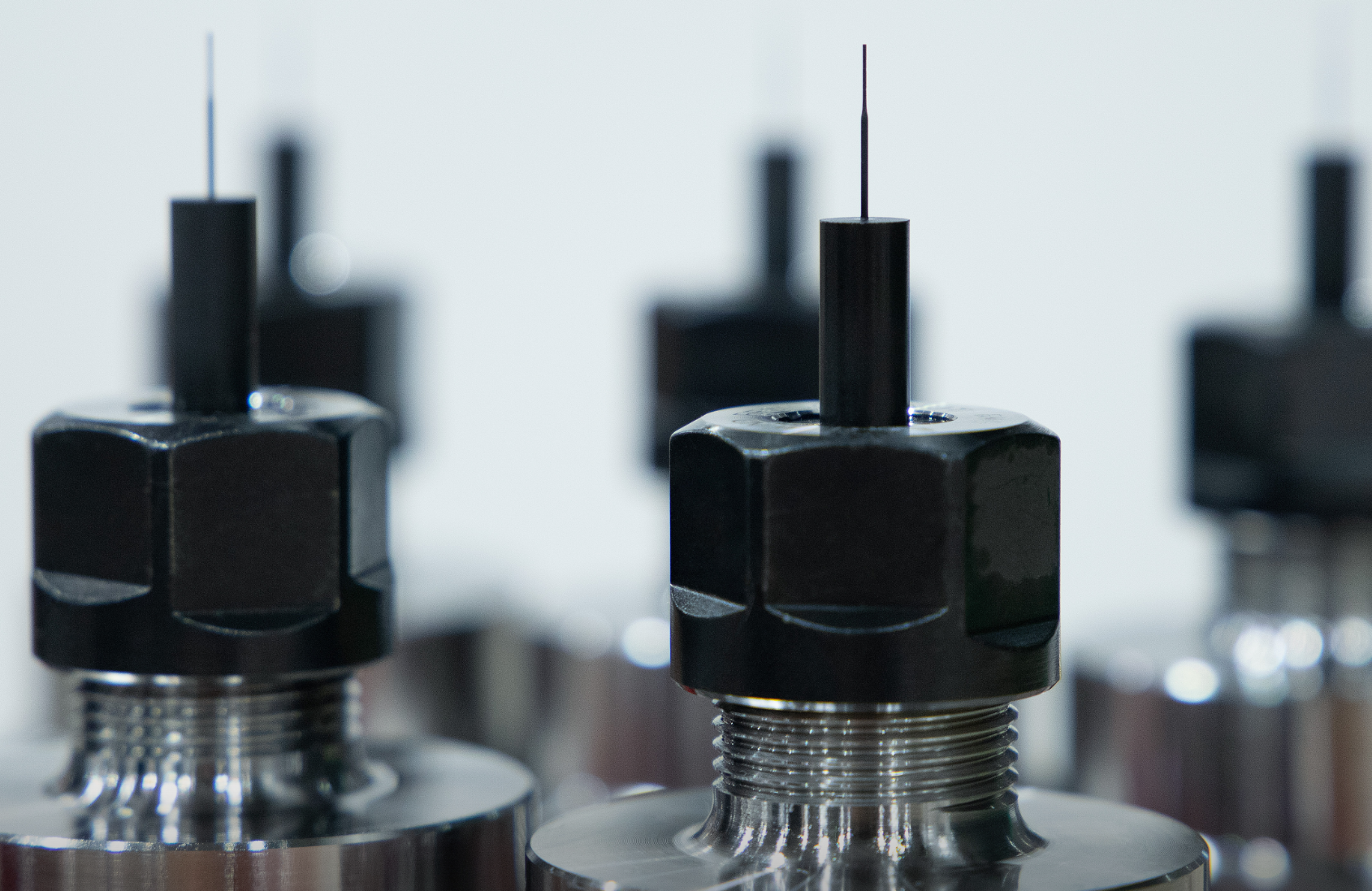

As for the pictures, the "C" shaped steel is a very simple fixture made to screw a nozzle into and machine from. The black piece is the finishing electrode that reflects the shape of the machined area (the bulbous areas are fluid buildup).

-

@plasticfactory

Jingle tools !!!

-

@plasticfactory, what does it take to generate an electrode that fine that by all rights should disintegrate when you look at it ?

Thanks for that picture! Amazing! -

@jens55 We use a high speed mill designed for cutting graphite. It utilizes high cutting speeds, lower forces and a flushing system specifically for removing graphite dust. A proper graphite setup really is the difference between being able to do general EDM work, and to be able to do something like this (not to say it couldn't be done without).

It's definitely a difficult part to make; the last nozzle came out better but we are running one more through, but breaking the electrodes up into 2 -- one for the major ID, and one for the minor. This should help things out quite a bit. Just part of the development process! Once the process is validated it will be highly repeatable.

-

Quick update -- had some improvement on the last samples, but in doing so identified areas for further improvement. We are breaking the electrode up into 2 pieces and sampling again early next week. I'm optimistic this will be one worth sharing!

EDIT: rather than bumping this thread further I'll use this as an update. Currently, our EDM department is backlogged after receiving a wave of production demand. We have electrodes cut, but no EDM machining will take place for ~3 weeks. To anyone particularly intrigued by this project, do not worry -- it is line one for our AM prototype development.

-

@plasticfactory your thread is so interesting, that I bought a book about micro EDM (from Sidpara/Malayath), please continue, I am curious to see where this goes!

-

@joergs5 Considering the stage this project is in it makes me exceedingly happy it inspired someone to learn more about these machining techniques. Feel free to private message me if you have any questions.

That book is in our small technical library, but I have not personally read it.

Here is another great place to start, because it covers the basics without over simplifying anything:

https://reliableedm.com/handbook.phpEDIT: and so much for me not bumping the thread, lol

-

@plasticfactory said in Advanced nozzle design:

another great place to start, be

thank you, I'll look into it, and thank you for your offer!

-

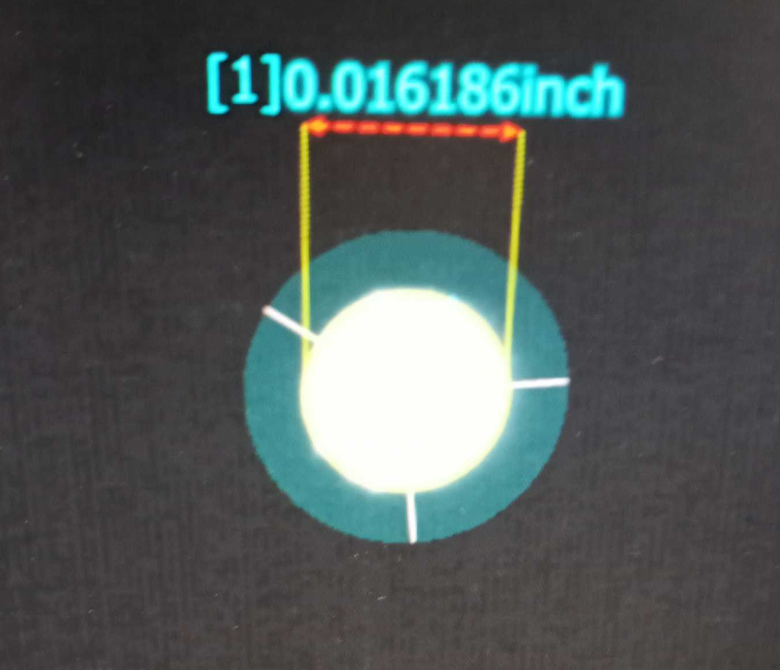

Finally, an update. After finding some machine time, we were able to complete the first nozzle. We inspected the orifice with a Keyence IM inspection system, and compared it to 5 leading brands who also make nozzles (to get an idea of how close to nominal we realistically need to be). We wound up at 0.410mm, which is almost exactly as close to nominal as the best commercially available nozzles inspected. We will definitely make more, as electrode sizing is why we aren't as close to .400 as I'd like. Realistically, +/- .001mm should be achievable. However, testing can finally commence. As an aside, the most "premium" (re. expensive) nozzles inspected were the worst, dipping down as low as .35mm ID.

Attached is a photo of the electrodes used, and inspection of the EDM machined nozzle. Testing is next, then I will cut more cross sections to share. These should be much, much cleaner on the inside than what is in OP.

-

Very cool. We have an IM at our shop, with a rotary axis as well.

-

First, apologies for the lack of updates. I started doing testing today, and have reached out to various content creators hoping for some assistance with this side of things. Time to do testing has just not been on my side.

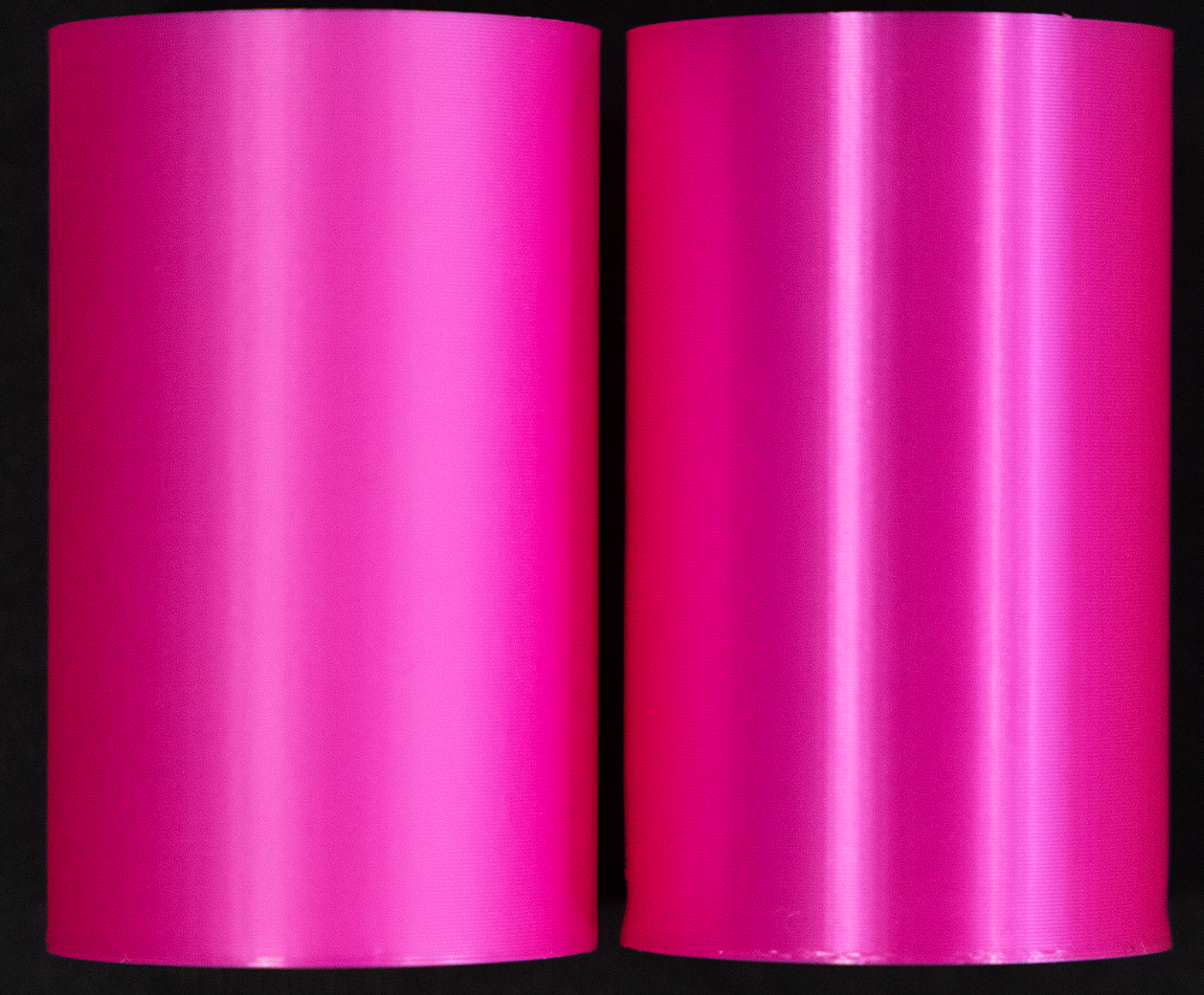

Today I did some very simple vase mode prints to check two things:

- potential change in surface finish

- ability to take objective measurements of layer width

The prints were done on an E3D toolchanger, using a Hemera extruder and Copper V6 block. Both prints were done with the exact same hardware, only the nozzle being different. I used a hardened steel E3D V6 nozzle as the control. The material was the same spool of Prusament PLA, fed closed loop from a material dryer.

First impression: the ADV nozzle produces a significantly more matte finish. Though "improvement" is completely subjective, it objectively hides layer lines more than the gloss, especially in person. The photo posted was spliced together as both parts were taken under identical lighting conditions.

The next step is to use our IM to take measurements of wall thickness and layer width, to determine if there is any significant difference in extrusion consistency (visually, I'm not expecting much difference).

Anecdotally, the ADV nozzle oozes considerably less than the V6. The next steps will be various retraction prints, sans retraction, to evaluate stringing/oozing.

Finally, I had some mushrooming at the bottom of the V6 print. This is obviously not a fault of the nozzle.

I'm not expecting too much enthusiasm over the initial results, but I'm happy so far and am very excited to get to the retraction tests. My first reaction is that will be the area most improved.

ADV left, E3D right

-

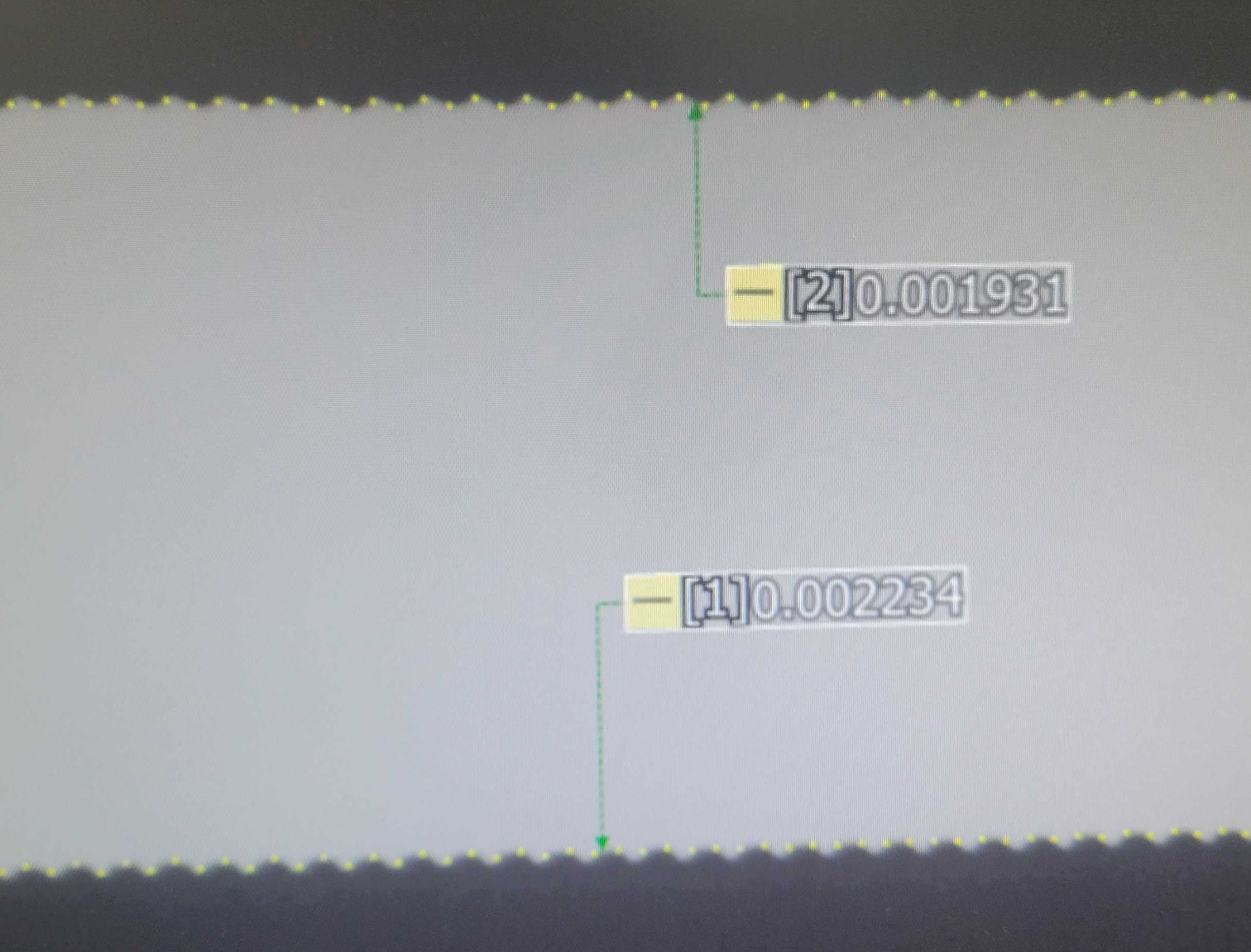

@plasticfactory Last quick update before Monday. From our QE: "the ADV nozzle is more consistent with layer width, but I will do more inspections Monday and generate a proper report".

I will of course share said report, with data, here. This will include how the inspection was conducted. But that was a nice message to cap off the week.

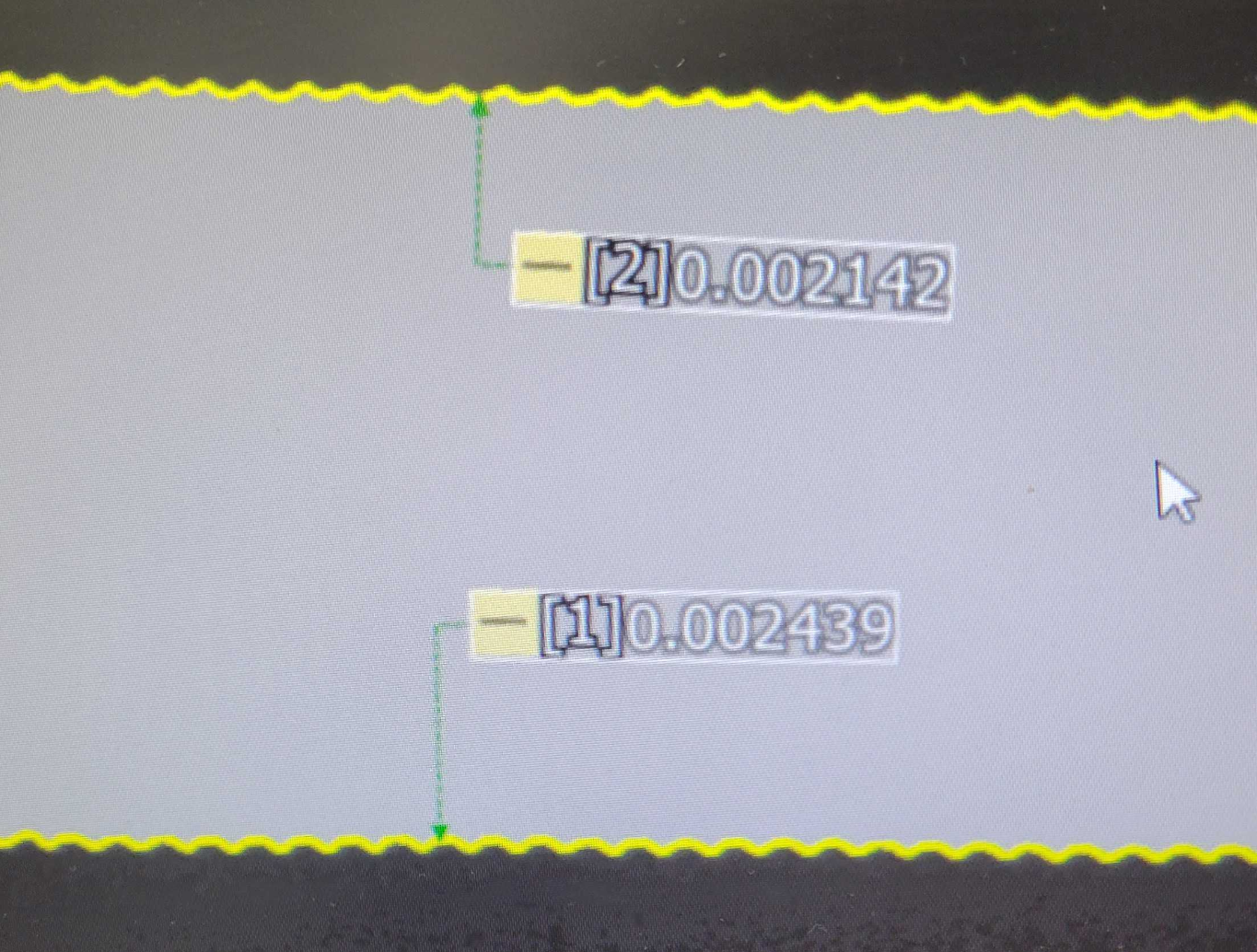

EDIT: This probably doesn't mean much right now as it was a "first guess" way to check this, but here is the image I was provided:

Top is ADV, bottom V6

This is an overall straightness measurement. So it doesn't account for the exact deviation from each layer line, but would indicate that overall it is less "wavy" (ie, more consistent extrusion width).

I'm open to suggestions on what types of measurements to take, or prints to use to take said measurements.

EDIT 2: I was also sent some inspections comparing actual individual layer lines. I will share those images and preliminary findings shortly. Similar conclusion -- ADV is more consistent. Is it an appreciable improvement? Maybe not, but it appears to be an improvement. I hope to have real conclusions by the middle of next week (but if you have kept up with this thread, it could be in 2023...)

-

The point snapping on the ADV is better synchronized to the peaks and valleys of the layer lines. It falls out of sync on the V6 nozzle, which may be hiding straightness error.

I should throw a print on our IM sometime.

-

@ccs86 Yeah, I definitely see that -- good eye. I probably got too excited with the last post, but the other images, coupled with this, are promising. I will refrain from making conclusions until we get a proper inspection next week.

-

Disclaimer: A sample size of 1 is not enough to draw distinct conclusions. Everything I am sharing are simply preliminary results and I will do many prints/inspections before making any clear statements of capability.

Based on user CCS86's suggestion, we performed another straightness test with more data points:

Slight reduction, but ~12% "straighter". Eventually we will do more thorough inspections on this. I was considering using our extrusion measurement systems to test it not on a print, but in line (like a normal plastic extruder).

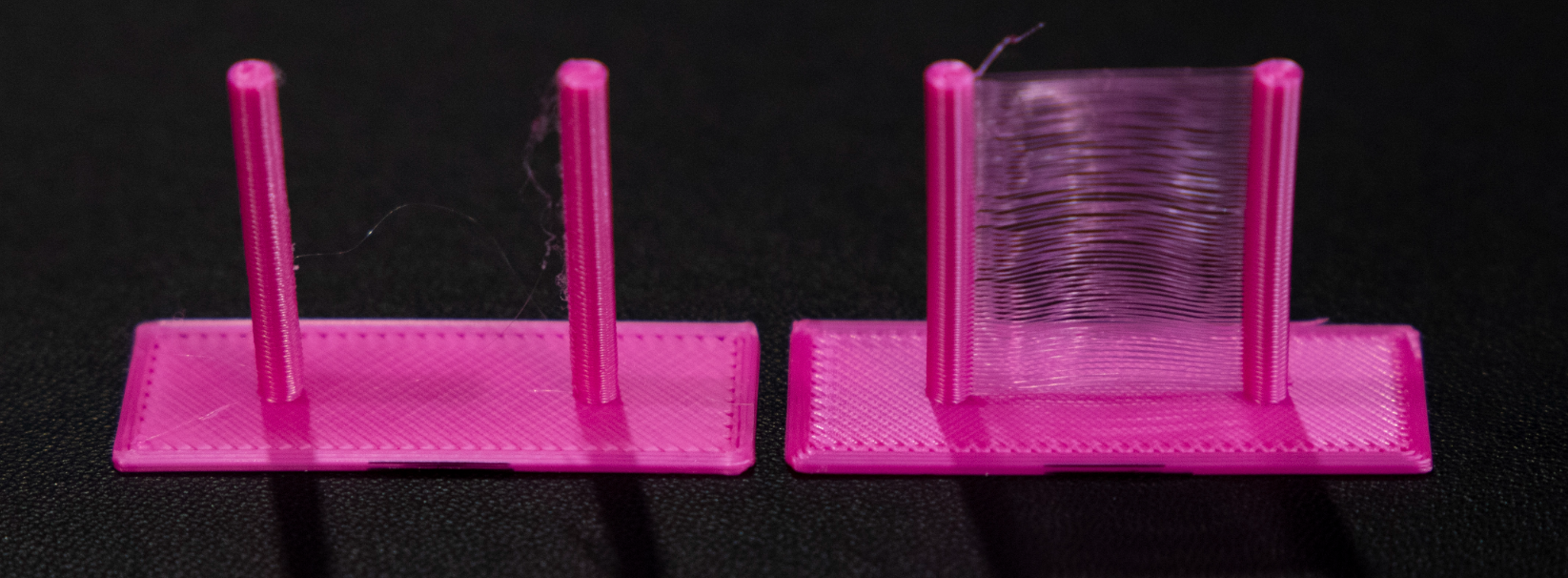

Next up are simple stringing tests, pictured here:

ADV Left, V6 Right

These prints were done on the same hardware, with same the same Gcode file. Both prints were done with no retraction. Prusament PLA, 200*, 15mm/s print, 180mm/s travel.

Clearly, the ADV oozes considerably less, almost none at all. I do notice "fuzz" on the edges, and what appears to be occasional heat dissipation issues from the ADV nozzle. I suspect this is due to the end taper geometry not being correct for a V6 0.4 orifice nozzle (as mentioned by another user earlier in the thread). The next step is to EDM or surface grind this taper to the correct geometry to eliminate this as a variable. Nozzle taper comparison below:

I very much welcome feedback!

-

This post is deleted! -

@plasticfactory the base of the stringing test with the ADV nozzle appears much smoother/flatter than the other one. Is it just the picture or can you see a difference as well? On a side note, earlier in the thread you said you have a toolchanger, how has that turned out? It seems like a very solid system to base a printer on.

Edit: I has a other idea for a test you could run, idk if this is what you mean in an earlier post, but I will ask anyway. When you calibrate linear advance on Marlin it extrudes multiple lines with varying speed, teaching tech has an excellent video on how it works if you don't know what I mean (though I would guess you do, you seem quite experienced with 3d printing), but I wonder if the ADV nozzle would offer improved properties in this 'test'. I could see the flow properties allowing changes in speed that should be synced with the extruder (I think firmware does this but I'm not sure) to require less compensation in this test. Another example of this sort of test is the Bambu Labs X1 auto/self calibration function.

Edit 2: I think the larger diameter of the nozzle tip would unnecesarily heat the plastic, requiring aditional cooling to compensate. All of the cheap nozzles I have also have larger tip diameters and seem to perform worse it that area.

-

Very interesting and pretty cool tools you got there!

What about maximum flow comparison between both nozzles? -

@mrdui I'm curious about this too. I wonder if the longer orifice creates significantly more pressure loss due to friction compared to a standard V6.

-

@hebigt said in Advanced nozzle design:

@mrdui I'm curious about this too. I wonder if the longer orifice creates significantly more pressure loss due to friction compared to a standard V6.

I would say that's highly likely (although not necessary just due to friction). Based on my own exploits into multi-input hot ends, something like a Diamond which has about 2mm final orifice length needs an immense amount of pressure advance compensation but has very little tendency to ooze and requires only a little retraction length on top of the PA compensation. But my own design which uses "standard" M6 threaded nozzles and thus a much shorter final orifice length, requires hardly any pressure advance compensation but has a much higher tendency to ooze and requires much higher retraction length values. The nozzle diameter, filament and temperature in both cases being the same.