Toolboard Mounting (RatRig 500 V-Core) LGX/Magnum

-

Hello everyone. So I am building a RatRig 500 V-Core. Unlike 99% of builders I am electing to go with Duet RepRap FW.

Here's my question. So I am running a RPi, on a Duet 3 Mainboard, and while preparing I came across the benefits of using the Toolboard 1LC V1.1. Especially for the Accelerometer and only running 4 wires back to the board. But I am trying to see anyone who has actually mounted the tool board besides the Toolchanger.

Is the bolt patter on the Toolboard the same as a Stepper bolt pattern? Can it be mounted to the back of a Stepper? or is there some other suggested way? All the documentation says how to mount it to a Hemera, but I don't have one, nor do I want one.

Can anyone show me some examples of where they mounted theirs? again no Hemera...

I would appreciate any ideas or help. Thanks.

-

The bolt pattern is the same as the hemeras - 34x34mm square. Any design that you'd like has this will be fine. Nema 17 screws are 31x31mm, so they won't fit.

You could sink 2-3x heat inserts into plastic holes and then just bolt it in anywhere you'd like.

I use klipper CAN toolboards and i just mount them above/around the tool. I can provide pictures if you'd like.

-

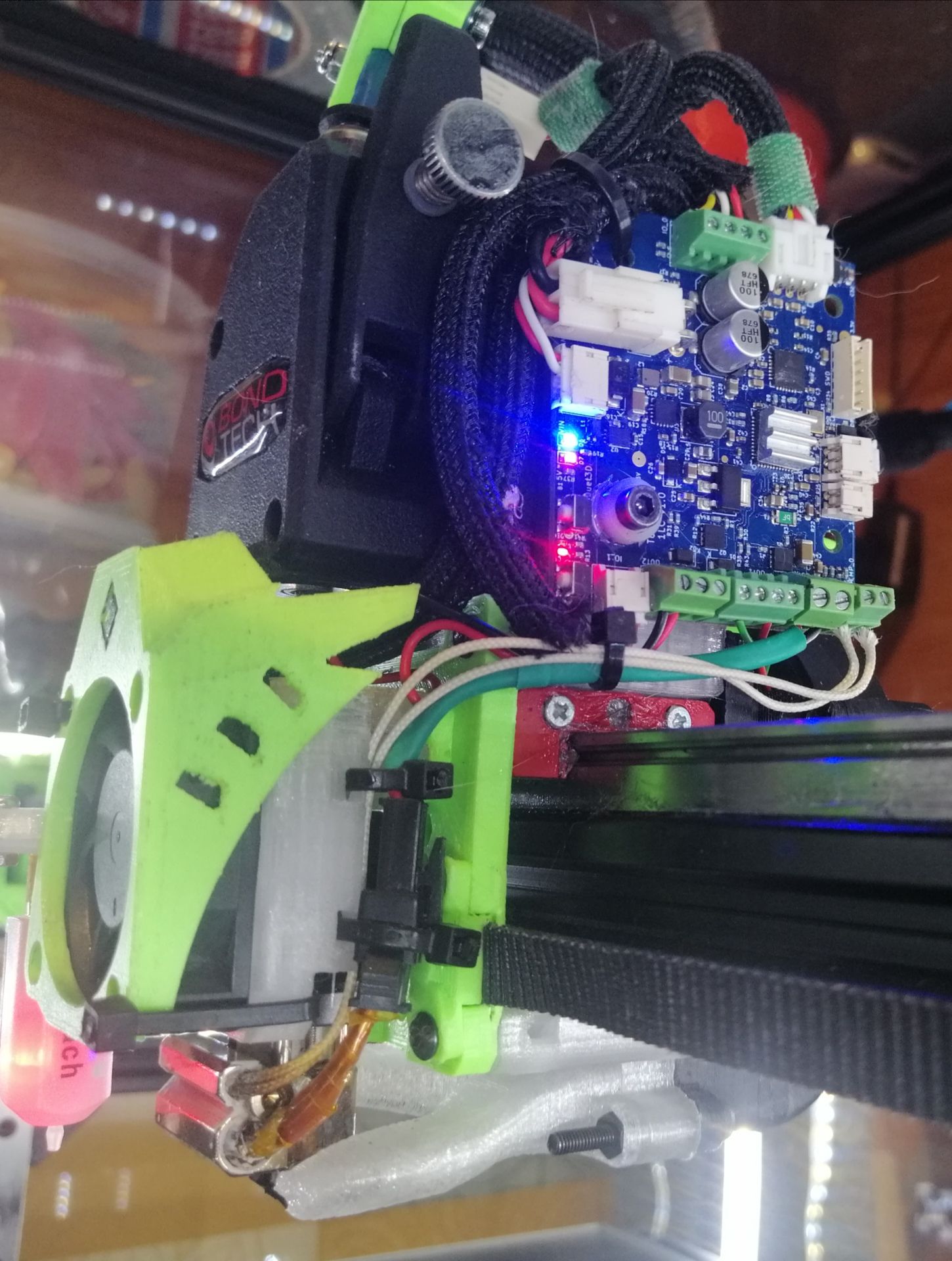

@thelightspeed I did on my newly built big coreXY.

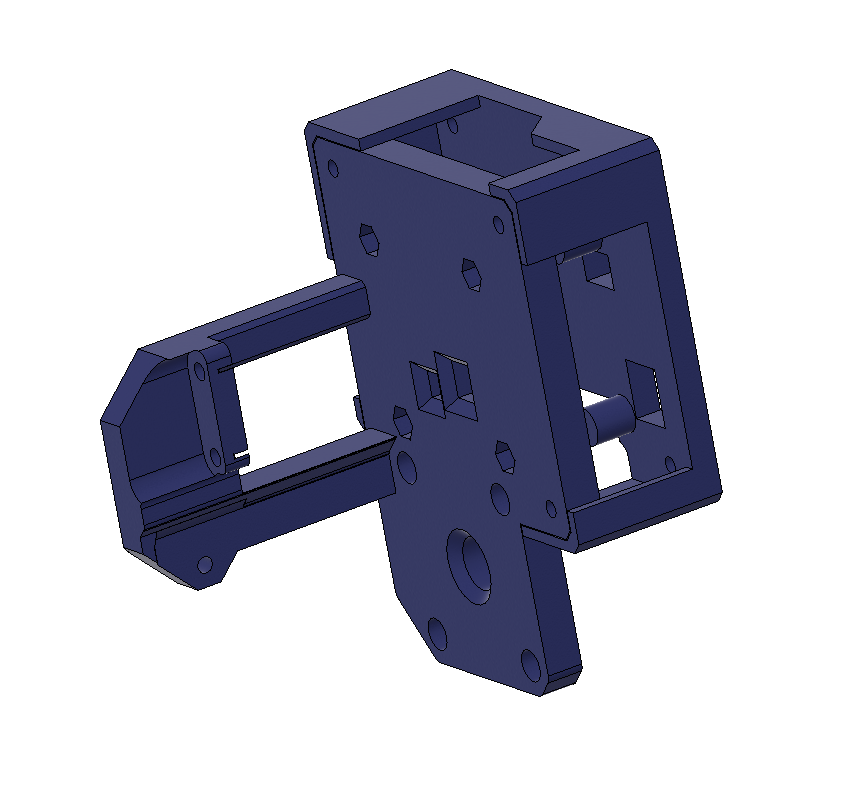

Runing Duet3 with toolboard 1.1 and hemera with superpinda on the toolboard. It is runing 24/7 for the last few weeks in 55+ dg C enclosure. The only drawback that I find is that I have to wire my BTT encoder filament sensor to the toolboard as far extruder is there. Runing 3.3 rc3. Did not update yet to 3.3 final as far my orders are urgent and the printer is running fine. I did not check for back of a stepper, just downloaded stp file from duet, put it in my assembly and designed a simple bracket to hold the board and work as a strain relief , printed in ABS, second itteration was good so it is on the printer now -

Hi, I did a very basic mount for mine which includes a mounting point for the Duet Magnetic Filament Sensor as well. I've been using it since a month now without any issue.

-

Picture with v1.0, v1.1 is mounted exactly the same

Frederik

-

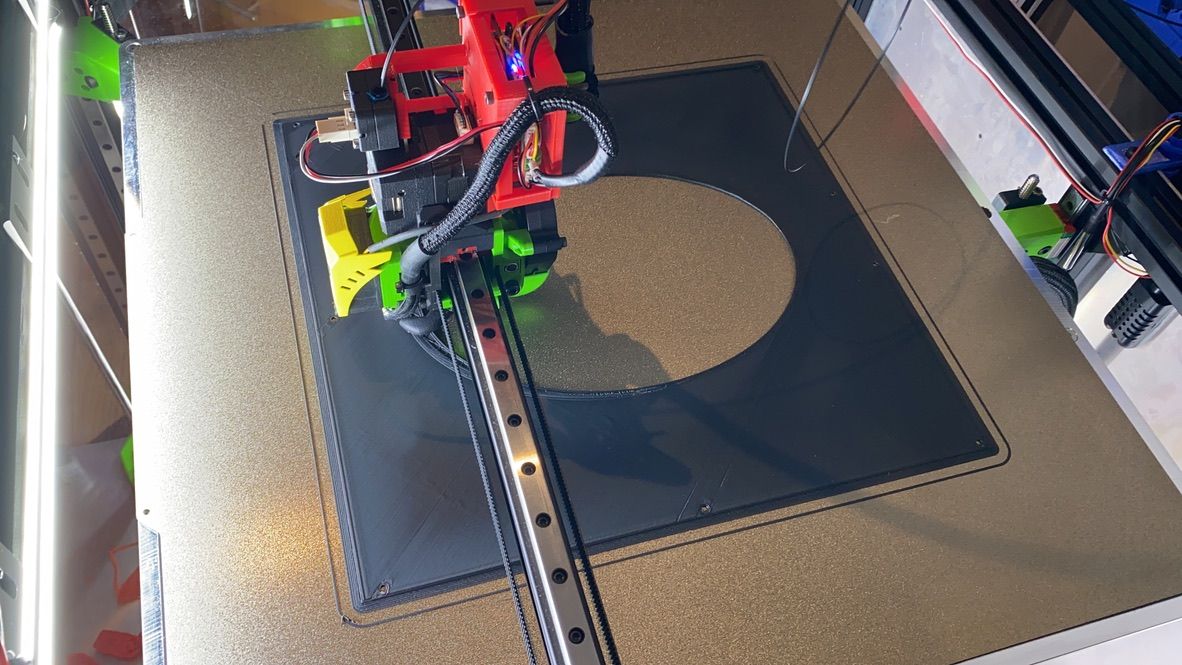

I am running similar (just regular Mosquito), I put together a design (https://www.thingiverse.com/thing:4925085) toolboard attaches between the cooling fan and the extruder, right where EVA cable relief arm mounts. Keeps the toolhead setup as compact and as tucked together as possible. The arm is relocated to the side - original cable relief bracket from EVA can be reused, or the one I added which is smaller since toolboard only requires 4 wires. The bracket has provisioning for a lid, but it felt as unnecessary weight (and would restrict board cooling) and I never ended up finishing it.

-

@martin7404 How did you wire up the super pinda to your toolboard? Are you happy with it? I am considering switching from BL-Touch to superpinda as the BLTouch is often acting up on me and feels not as reliable as magnetic probes