Aluminium plate for heat bed what alloy type ?

-

@percar said in Aluminium plate for heat bed what alloy type ?:

mrehorstdmd

You are incorrect with the kinematic mount. What will happen is that the outer edge will always be cooler than the mid area of the plate unless you have chamber heat that will equalize the plate temperature. This is what will cause warpage...do the math.

The thermal images that @mrehorstdmd posted disprove your hypothesis. Far from suggesting that he "do the math", I would suggest that you take a look at the actual, real world data that has been presented.

-

@percar The Taz came with a glass bed that was 4 or 5 mm thick, as I recall. It broke when someone was trying to remove a print that stuck too well after they slathered the plate with glue -to try to get their print to stick.

The kinematic mount has nothing to do with heat distribution in the bed plate. It simply allows the aluminum plate to expand laterally without putting any force on the mounting/leveling screws. If the plate expands when it heats up and you don't use a kinematic mount, there will be a lot of lateral force applied somewhere, usually to the leveling screws in most plate mounting schemes. That will cause something to flex- maybe the bed supports, maybe the bed plate- it depends on how it is built.

In theory, a glass bed would not expand much at all, so a kinematic mount should not be needed if you glue the heater directly to the glass. I suppose that if glass is thick enough it might allow even heat distribution, eventually. The bed plate also acts as a heatsink for the heater. The heaters don't heat evenly- some areas are hotter than others, and a thermally conductive plate helps even the heater temperature out as well as providing an evenly heated surface on which to print.

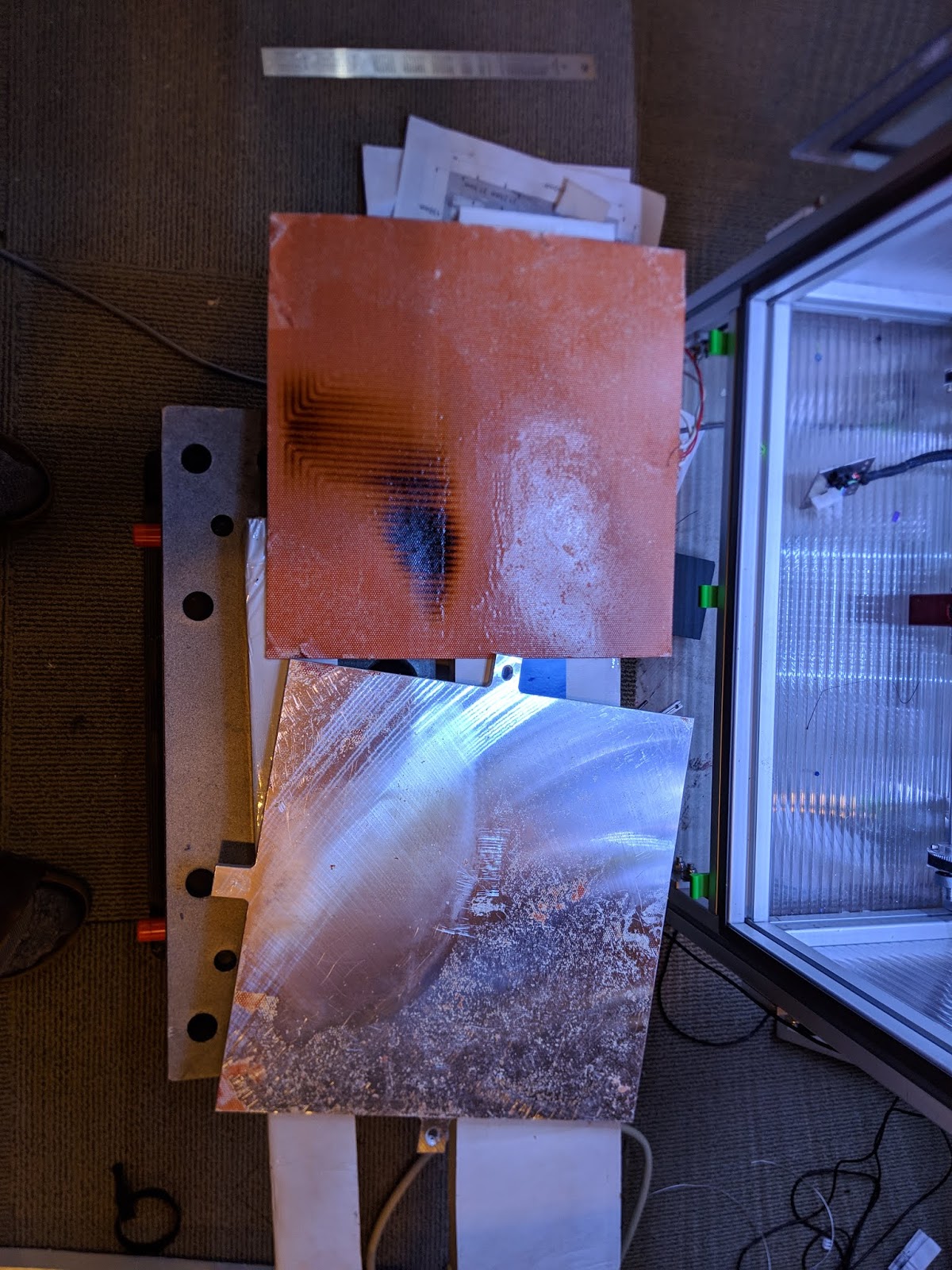

You're using a LOT of power to get that thick glass to heat up. It would be interesting to see thermal images of your heater and the bed surface. I'd be concerned about exceeding the maximum temperature rating of the heater (or the adhesive holding it to the glass) when you first start up the bed heating process. I had the self-stick adhesive fail in my printer after a couple years of almost daily temperature cycling. It allowed air bubbles to form between the heater and the plate. The result was the heater was scorched in those areas:

This was a 5.2W/sq. in. heater, which is normally regarded as a LOT of power density. You're using 3x that power. Yikes! I sure hope you have at least one TCO stuck to the heater...

When I replaced the heater I used high temperature silicone to bond it to the plate instead of the self-adhesive stuff that usually comes on the heaters. I'm hoping that will never let go. I think it's been about 2 years now and it appears to be OK.

The thick glass you're using will respond to heat input very slowly which I think would make it more difficult to control its temperature. Maybe the higher heater power you're using would compensate for that. Where is the bed temperature sensor in your machine?

If you use an aluminum heat spreader under the glass, it's still a good idea to use a kinematic mount. I think it's obvious that a piece of aluminum foil wouldn't make a good heat spreader. So how thick does the heat spreader need to be? I don't know. You wouldn't want to go too thin because the plate needs to support its own weight in addition to spreading the heat. For a 300x300 mm bed, 1/4" plate works fine. I've used 1/4" plate and 8 mm plate and both work fine. I haven't run into cast tooling plate less than 1/4" thick, but maybe someone in the civilized world supplies it in thinner pieces, like maybe 5 mm or so.

-

I am using high temperature silicon for the adessive. I had this under a press during curing so that there were no voids. I am using 2 heating pads each with their own controls and scr. Each pad has its own safety to prevent over heating. Each pad has type K thermocouple. Heater control is commercial heater control with an analog input so that Duet and control temperatures. The controller has safety cutoff if it runs outside of the set range plus the safety switches. I have been using this for a few years without issue. Thickness of the glass is important as the thicker glass gives more stable temperatures.