Anybody wants a stepper motor analyzer?

-

@ccs86 said in Anybody wants a stepper motor analyzer?:

The small sine wave like pattern on the step chart indicates the circles, and the magnitude represents the radius.

-

@zapta cant believe you've not linked to this vid on YT.

https://www.youtube.com/watch?v=4iII25DGIdA

I'm interested from a learning perspective but currently have no use for it. I'd actually like to know what people will use this for? To test drivers and steppers I assume but to what extent?

-

If you are still taking orders, I would be interested in one. I was looking at building my own but don't have the necessary tools to make it easy.

-

@zapta If it's not too late, I would like one of your stepper motor analysers when you next do a run .

-

The last batch of 9 units is ready to be shipped to the people listed below. If there is no X near your name please send me your name and shipping address via chat.

Once it will be shipped, I will let you know and ask you to purchase and send me a gift card from www.amazon.com (not from local amazon website), $40 if you are in the US and $45 international.

@lbi X

@Sindarius

@skrotz

@GeorgeM X

@1ri

@Egon.net

@coseng

@DeadNewbie X

@agmeadows@appjaws, the last batch is already allocated so you are at the top of the waiting list, in case somebody from the list above will not provide their shipping address.

-

I would like one from your next batch--do you have an ETA?

-

hi, i sent my address and t’he amazon code via chat, i think.

I don't know if you received it or not, I don't get along with chatsVia GoogleTranslator

-

@1ri, got your message. Replied via chat. Sorry for my late response.

-

@agmeadows, please send me your shipping name and address via chat.

@tenaja, I am sorry but all the planed units are claimed. I hope that somebody will pick the idea and will make them available in larger quantities (the design is in public domain with no strings attached whatsoever).

-

I am planning to make a few but I've been delayed by a few weeks. I may decide to just place a big order once I'm done with the first, I'll post here when I do. If you're interested send me a message and I'll direct my communication to those people interested.

-

@th0mpy said in Anybody wants a stepper motor analyzer?:

I am planning to make a few

Hi @Th0mpy, that's a great initiative. Thanks. Please remember that the license is public domain (CC0) and allows commercial use, which make the availability of analyzers more sustainable. Can also be a great kickstarter.

I suggest to use files from released versions (firmware, electronic, and mechanical) rather than latest, it's safe this way. https://github.com/zapta/simple_stepper_motor_analyzer/releases

Also, I used JLCP to provide and solder all the SMD components in their inventory, which includes the heavy lifting of soldering the two FPC 0.5mm pitch connectors. Just had to solder myself the current sensors, stepper connector (remember to cut the pins using the 3D printed jig) and the Pico.

The mechanical design and TFT are based on Dustin's Watts ESP32 Touchdown (but is ~2mm longer). https://www.youtube.com/channel/UCYPmdetwhvFeRkgXhIWq_eg . He uses PCBWay to assembled his board (potentially they can solder all of the components) and had a few vidoes about it. He is also very approachable on his Discord forum so you can ask him for manufacturing advise. https://youtu.be/YHzU_GXCIkQ

https://www.tindie.com/products/dustinwattsnl/esp32-touchdown/

Please let me know if you have any question, here or on github, and if you want I can add to my github repository a link to your store.

BTW, the last unit from my 30 units batch went out today and I don't plan to make another batch.

-

@zapta Cool thank you! I appreciate the feedback and the offer. Once I get mine done I'll give you a holler.

-

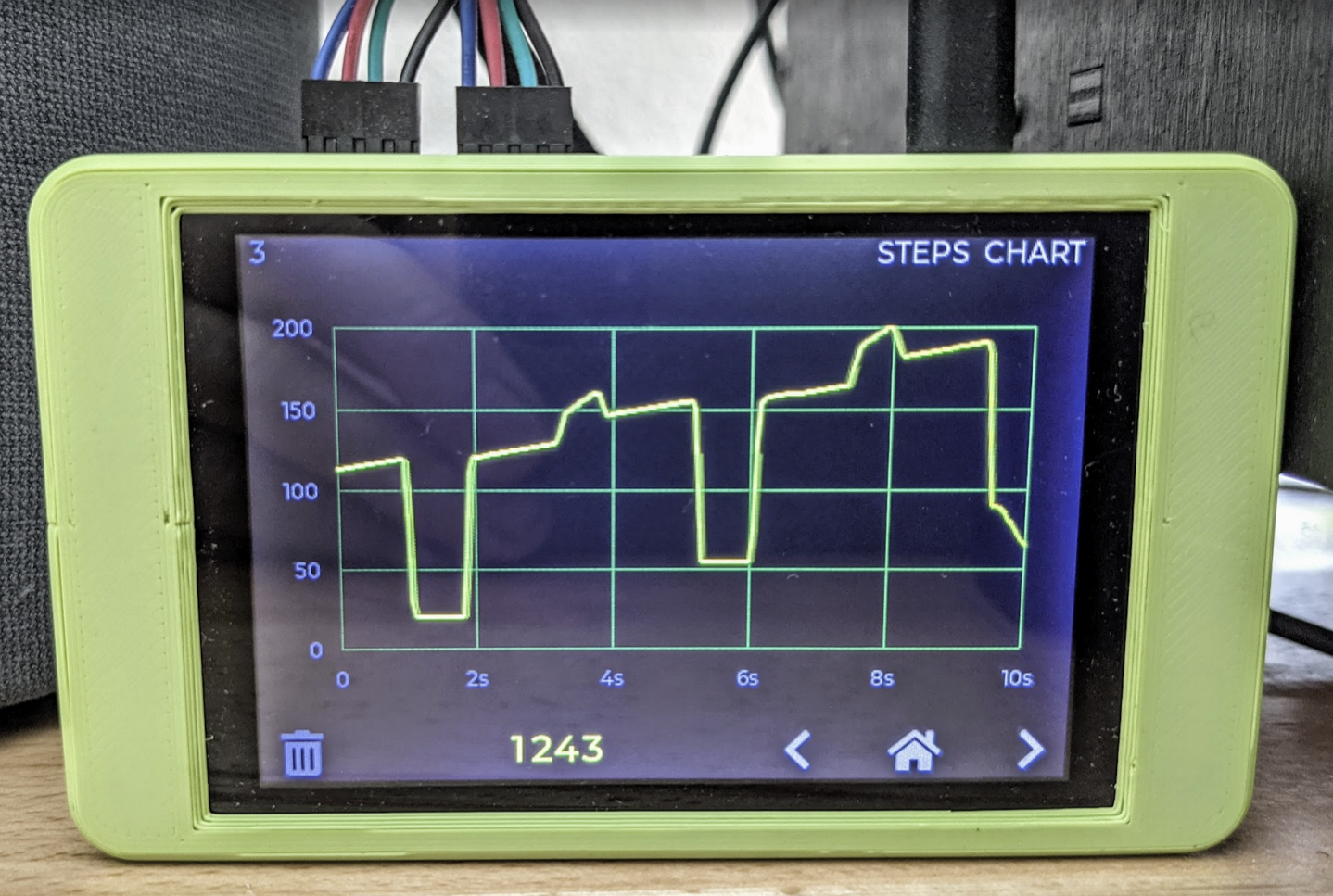

Hey @Zapta, after using it for a while now, I would love to change at least one configuration aspect: A lower scale screen for the steps chart.

When I have it hooked up to my extruder motor, even at the higher end of my print speeds, I only use about 600 of the 1k step scale, with the current time scaling.

For really looking at how linear advance is (or is not) working, a much tighter scale would be awesome. Maybe a [300 step / 10 sec] screen, or even [150 step / 5 sec]

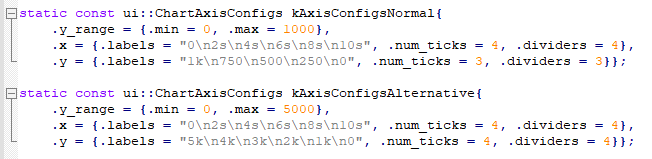

It looks like steps_chart_screen.cpp handles this:

But while Y scale might be set here (and labeling), it looks like the X time scale is defined elsewhere.

Questions:

- Is there a memory limit that would prevent adding say 2 more chart axis configs to this screen?

- Would you be interested in kicking out a new firmware revision that added these?

- If not, could you offer any guidance on which files need to be changed, and any thing else about compiling and uploading that is important?

Thanks!

-

Hi @ccs86, thanks for the feedback.

I created a release candidate with that include a third scale 0-200 steps. Please try to flash to your device and see if it works.

To flash, disconnect the usb connector, press and hold the button at the back (through the hole) and connect to your computer. This should add a new disk drive to your computer. Download and copy APPLICATION.uf2 from the link below to that disk, wait a second or two until it completes and you are doen.

https://github.com/zapta/simple_stepper_motor_analyzer/blob/main/temp/APPLICATION.uf2

If it will work, I will make it an official release.

As for the time scale, how important is it to have it faster (e.g. 5 secs)? This change is slightly more involved if different Y scales need different time scale but doable.

EDIT: this is how the scale definitions looks now. If you have change suggestion for the other two scales please let me know.

-

@zapta said in Anybody wants a stepper motor analyzer?:

Hi @ccs86, thanks for the feedback.

I created a release candidate with that include a third scale 0-200 steps. Please try to flash to your device and see if it works.

To flash, disconnect the usb connector, press and hold the button at the back (through the hole) and connect to your computer. This should add a new disk drive to your computer. Download and copy APPLICATION.uf2 from the link below to that disk, wait a second or two until it completes and you are doen.

https://github.com/zapta/simple_stepper_motor_analyzer/blob/main/temp/APPLICATION.uf2

If it will work, I will make it an official release.

As for the time scale, how important is it to have it faster (e.g. 5 secs)? This change is slightly more involved if different Y scales need different time scale but doable.

EDIT: this is how the scale definitions looks now. If you have change suggestion for the other two scales please let me know.

@zapta Thanks my man!

It works great!

The shorter times scale (I think) would be cool, but if it's a big pain don't worry about it. Here is a simple pressure advance test, 20 - 80 mm/s, 3mm retracts.

Going to first off an actual print to see how that looks.

-

@ccs86, I published a new release with this change https://github.com/zapta/simple_stepper_motor_analyzer/releases/tag/F1.0.4

The graph looks interesting. If I understand it correctly the pressure advance doesn't start immediate after the retraction/traction, and it extrudes a little bit before it increases slope. is it so?

-

@zapta said in Anybody wants a stepper motor analyzer?:

@ccs86, I published a new release with this change https://github.com/zapta/simple_stepper_motor_analyzer/releases/tag/F1.0.4

The graph looks interesting. If I understand it correctly the pressure advance doesn't start immediate after the retraction/traction, and it extrudes a little bit before it increases slope. is it so?

I think you have it right.

Here is a video that will probably illustrate it much better than I can explain.

It starts with some alignment marks, then does a pass with no pressure advance, then PA turns on and increases for each line, and then off again for the last line.

-

@ccs86, the link didn't work for me.

-

@zapta said in Anybody wants a stepper motor analyzer?:

@ccs86, the link didn't work for me.

Link updated. Try again.

-

@ccs86, very interesting. Those PA 'pulses' is not how I imagined PA.

It explains the extreme noises I got at the time when I tried high PA values with a 600mm bowden printer. The stepper was so erratic that I had to install it on RC rubber dumpers. Eventually I switched to a direct drive and the problem solved.

I wonder if PA has one 'natural' profile or if different firmware developers come with different profiles. There are many degrees of freedom in shaping the profile which we reduce to a single number.