Voron 0 + Duet 3 Mini

-

@pkos Great!

-

@fma I am building another V0 but the V0.1

I have been toying with the SKR, cheaper if you get it shipped from China, but I think after seeing this post has made up my mind, Duet Mini !

Just need to look at the backpack for the SKR and LRS-100 and move the heatsets so the Duet mini can be mounted on the Underneath.I am also thinking about WiFi Version, but would have to hook in with a USB to set the WiFi connection up each time, wherever I might take it.

Decisions decisions!Already have a 220V heater so will keep that as part of the build.

-

@paulhew Forgot to say that I will use a 24V heat bed. I don' like having LV here, as this printer will be used by children...

-

The cult of Voron seems to catch significant momentum recently, with vendors offerings kits and products that target vorons (LDO frames, Fsyetc Spider, Funssor metal parts, etc).

I am working on my V2.4 sourcing, most parts already arrived, black Misumi extrusions will take a little bit longer to arrive.

So far Klipper seems to be recommended and most common firmware and Spyder seems to be the upcoming recommended controller.

Next they will expand, I think, to desktop CNC machines but yet to be seen.

-

@fma said in Voron 0 + Duet 3 Mini:

Forgot to say that I will use a 24V heat bed

Do you have room for the larger power supply? I heard that the V0 design is very tight.

-

@zapta said in Voron 0 + Duet 3 Mini:

@fma said in Voron 0 + Duet 3 Mini:

Forgot to say that I will use a 24V heat bed

Do you have room for the larger power supply? I heard that the V0 design is very tight.

As I drop the Bowden extruder and the Rpi, yes, no problem. The Duet3 Mini fits behind the Z axis, and the power supply fits below.

And a 120x120mm heatbed does not need a lot of current... -

@fma Is there an available mount for the Mini that fits on the 15x15

I looked in voron users but I cannot find one.P.

-

@paulhew I don't own a Duet 3 Mini yet, so didn't look for a mount. But I was thinking to make holes in the rear panel, and mount the Duet with spacers...

-

@paulhew said in Voron 0 + Duet 3 Mini:

@fma Is there an available mount for the Mini that fits on the 15x15

I looked in voron users but I cannot find one.P.

It has the same hole spacing as the Maestro, so if there is a mount for that it should work.

-

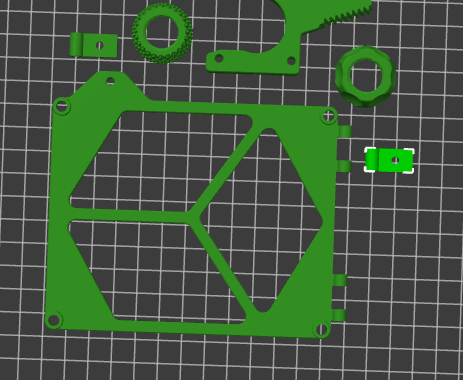

@phaedrux Friend just designed one for me.

He is good with F360

Just need to buy the board.

-

@phaedrux Sorry, my manners. That is good info, thank you. I will look for it so I can share.

-

@paulhew said in Voron 0 + Duet 3 Mini:

He is good with F360

That's a skill that worth the learning time IMO.

-

I'm just wondering,if someone has a config.g to get the required esteps as reference. I'm just configuring my V0.1.

-

@danjunior Which extruder exactly?

-

@phaedrux The V0.1 is a DirectDrive unit, BMG internals and the LDO Pancake stepper.

Mine V0.1 is offline at the moment as I am going to have to rebuild the DD unit

even at 350ma it cooked again.

The rating is suitable for High Temp applications..... So I and possibly like others think that it is suitable for an enclosure, which it is

What I did not realise that the motor will heat itself up also, more than any of the OMC's I have been running with no problems @80% of their rating.Slightly disappointed that this info is not displayed clearly when looking at general info on the motor......

-

@paulhew depending on your microsteps, it'll be 345 or 690 steps/mm on the LDO pancake stepper meant for the Orbiter.

-

This is what I have on my V0.1 + Duet 3 Mini 5+, with OMC steppers. No guarantees it's correct, still tuning in and adjusting, but it's printing things reasonably so should be a good starting point at least. Also, critique welcome

; Configuration file for Duet 3 Mini 5+ (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Fri Jun 04 2021 16:03:31 GMT+0100 (British Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"voronzero" ; set printer name M669 K1 ; select CoreXY mode ; Drives M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M569 P0.4 S0 ; physical drive 0.4 goes backwards M569 P0.3 S1 ; physical drive 0.3 goes forwards M584 X0.1 Y0.2 Z0.4 E0.3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E1370.00 ; set steps per mm M566 X1080.00 Y1080.00 Z90.00 E150.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z1200.00 E9000.00 ; set maximum speeds (mm/min) M201 X4000.00 Y4000.00 Z450.00 E6000.00 ; set accelerations (mm/s^2) M906 X1250 Y1250 Z400 E800 I25 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X120 Y120 Z120 S0 ; set axis maxima ; Endstops M574 X2 S1 P"io3.in" ; configure active-high endstop for high end on X via pin io3.in M574 Y2 S1 P"io5.in" ; configure active-high endstop for high end on Y via pin io5.in M574 Z1 S1 P"io6.in" ; configure active-high endstop for low end on Z via pin io6.in ; Z-Probe M558 P0 H5 F120 T3000 ; disable Z probe but set dive height, probe speed and travel speed ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out6" Q75 ; create fan 0 on pin out6 and set its frequency M106 P0 C"Cooling" H1 T45 B0.5 ; set fan 0 name and value. Thermostatic control is turned on M950 F1 C"out5" Q75 ; create fan 1 on pin out5 and set its frequency M106 P1 C"Part" H-1 B0.5 ; set fan 1 name and value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings ; DHT22 Temperature Sensor M308 S10 P"io4.out+io4.in" Y"dht22" A"Chamber Temp" M308 S11 P"S10.1" Y"dhthumidity" A"Chamber Hum[%]" ; Set bed screw positions for true bed leveling M671 X60:5:115 Y5:115:115 P0.5 ; Laser filament monitor with over the top R values M591 D0 P6 C"io1.in" R0:200 E3.0 S1 ; ST7567 12864 display M918 P2 E2 ; enable ST7567-based 12864 display M150 X2 R32 U255 B32 S3 ; set all 3 LEDs to white ; M955 P0 C"io0.out+io0.in" ; Miscellaneous M501 ; load saved parameters from non-volatile memory T0 ; select first tool -

@keyz182 What OMC have you got on the Extruder?

- I am interested

- I pray you do not suffer my fate where the LDO motor destroyed my DD plastics.

I was running 800ma, later to find that was too high and should be about 350ish

P.

-

@paulhew https://www.omc-stepperonline.com/round-nema-14-bipolar-1-8deg-9-ncm-12-75-oz-in-1-0a-f36x17-5mm-4-wires.html

That's the one. Yeah, it's a bit high, as I said, still tuning. Put probably a roll of filament through at that amperage though and so far it looks fine (had the extruder disassembled yesterday).

-

@keyz182 Thanks for the info.

Going to steal some of your config!My LDO even @450ma was hot enough to burn my fingers.

Might get one of those steppers, not trusting the LDO at the moment....

Thanks again

P.