A heater fault occurs on the LC1 board.

-

A heater fault occurs on the LC1 board at a frequency of about 70%.

Environment

- firmware version: 3.2

- temperature sensor: PT1000

- heating block: Volcano

Symptom

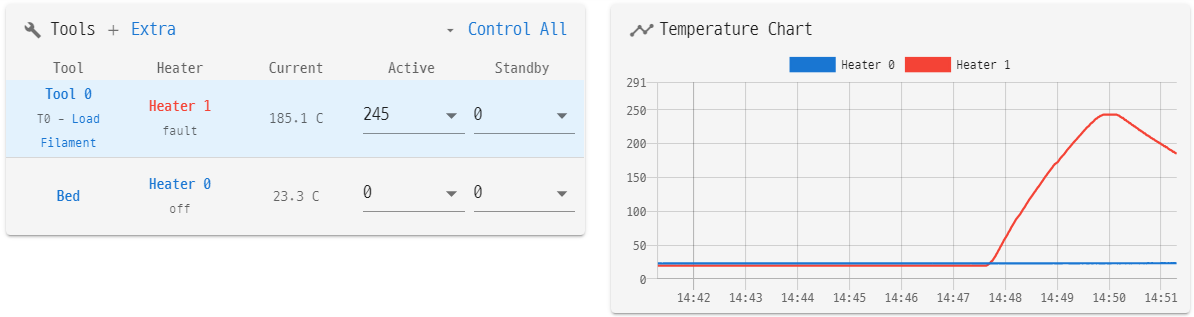

When the temperature is set, the set temperature is normally reached.

After 10~20 seconds, the heater turns off due to a fault.

There is no error message in the console.

M122 B121 Diagnostics for board 121: Duet TOOL1LC firmware version 3.2 (2021-01-05) Bootloader ID: not available Never used RAM 4100, free system stack 50 words HEAT 86 CanAsync 85 CanRecv 83 TMC 54 MAIN 216 AIN 64 Last reset 00:45:37 ago, cause: software Last software reset data not available Driver 0: position 540589, 420.0 steps/mm, standstill, SG min/max 0/270, read errors 0, write errors 0, ifcnt 31, reads 4878, writes 10, timeouts 0, DMA errors 0 Moves scheduled 2213, completed 2213, in progress 0, hiccups 2553 No step interrupt scheduled VIN: 24.0V MCU temperature: min 36.5C, current 43.1C, max 48.2C Ticks since heat task active 71, ADC conversions started 2732191, completed 2732190, timed out 0 Last sensors broadcast 0x00000002 found 1 75 ticks ago, loop time 0 CAN messages queued 27429, send timeouts 0, received 22560, lost 0, free buffers 36Here is my full config.sys file

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;;; Sys-config for Duet3 + 1LC ;;; ;;;; 1LC CAN Address = 121 ;;; ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ; /sys/config.g ;;;;; Ethernet networking ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M550 P"Voron300" ; Machine name and Netbios name (can be anything you like) ;M551 P"tmddms" ; Machine password (used for FTP) ;M540 P0xBE:0xEF:0xDE:0xAD:0xFE:0xED ; MAC Address M552 P192.168.0.230 S1 ; IP address ;M553 P255.255.255.0 ; Netmask ;M554 P192.168.0.254 ; Gateway M586 P0 S1 ; HTTP S0:Disable, S1:Enable M586 P1 S0 ; FTP S0:Disable, S1:Enable M586 P2 S0 ; Telnet S0:Disable, S1:Enable ;;;;; Kinematics ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M669 K1 X-1:-1:0 Y1:-1:0 Z0:0:1 ;Core XY ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves ;;;; Z Axis motor Location ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ; ; Z1 Z2 ; ; ; Z0 Z3 ;;;;; Drives & Axis ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;; Para. : P for driver No. S for Direction (0 = backward, 1 = forward) M569 P0.0 S1 ; A of XY M569 P0.1 S1 ; B of XY M569 P0.2 S0 ; Z0 M569 P0.3 S1 ; Z1 M569 P0.4 S0 ; Z2 M569 P0.5 S1 ; Z3 M569 P121.0 S1 ; Extruder ;;;;; Z Gear Ratio = 5.181818... M584 X0.0 Y0.1 Z2:3:4:5 E121.0 ; set drive mapping M92 X80 Y80 Z414.545454 E420 ; steps/mm @ 16-micro-stepping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M566 X1200 Y1200 Z2400 E2200 ; set maximum instantaneous speed changes (mm/min) M203 X24000 Y24000 Z4800 E2200 ; set maximum speeds (mm/min) M201 X5000 Y5000 Z2000 E3000 ; set Max accelerations (mm/s^2) M906 X1600 Y1600 Z1200 E600 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ;;;;; Axis Limits = Working Area ;;;;;;;;;;;;;; M208 X-140 Y-150 Z0 S1 ; set axis minima M208 X140 Y150 Z250 S0 ; set axis maxima ;;;; 4-Motor-Z-Axis define M671 X-200:-200:200:200 Y-200:170:170:-200 S10.0; S>Maximum correction to apply to each leadscrew in mm ;;;;; Endstops ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M574 X1 S1 P"!^io0.in" ; configure active-low endstop for low end on X via M574 Y2 S1 P"!^io1.in" ; configure active-low endstop for low end on Y via M574 Z1 S2 ; configure Z-probe endstop for low end on Z ;;;;; Z-Probe ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M558 P8 C"121.io0.in" H5 F120 T12000 ; Liquid Head G31 P500 X0 Y0 Z-0.3 ; Liquid Head M950 S0 C"121.io0.out" ; create servo/gpio 0 (for BL Touch) M280 P0 S160 ; BL Touch Reset (servo-0) M280 P0 S10 ; BL Touch Pin Down (servo-0) ;;;;; Mesh Grid M557 X-130:130 Y-130:130 P5:5 ; define mesh grid, NOT nozzle co-orditnate, PROBE point!!! ;G29 S1 ; load height map G29 S2 ; Clear height map ;;;;; Extruder ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M302 S140 R110 ; Allow extrusion starting from 140°C and retractions already from 110°C ;;;;; Bed Heaters ;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M308 S0 P"temp0" Y"thermistor" ; T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"out0" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ;M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M570 S60 ; Heater timeout 60 seconds ;;;;; Hot-End Heaters ;;;;;;;;;;;;;;;;;;;;;;;;; M308 S1 P"121.temp0" Y"pt1000" ; Sensor no.1 on temp0, PT-1000 M950 H1 C"121.out0" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S291 ; set temperature limit for heater 1 to 280C M307 H1 A1077.7 C574.8 D5.6 S1.00 V23.9 B0 ; Auto tune result - Super volcano ;;;; Super Volcano auto tune ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;;; M303 H1 S250 ;;;; Auto tuning heater 1 using target temperature 250.0°C and PWM 1.00 - do not leave printer unattended ;;;; ;;;; M307 H1 ;;;; Heater 1 model: gain 1077.7, time constant 574.8, dead time 5.6, max PWM 1.00, calibration voltage 23.9, mode PID ;;;; Computed PID parameters for setpoint change: P17.0, I0.299, D66.6 ;;;; Computed PID parameters for load change: P17.0, I0.835, D66.6 ;;;;; Fans ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M950 F0 C"121.out2" Q100 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ;;;;; Tools ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ;;;;; Custom settings are not defined ;;;;;;;;; ;M555 P2 ; Set output to look like Marlin ;;;;; Miscellaneous ;;;;;;;;;;;;;;;;;;;;;;;;;;; T0 ; select first tool ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;;;; Advanced Option ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;;;; Firmware Retraction M207 S1.0 R0.05 F9999 Z0.1 ; Retraction Setting: 1.0mm +0.1mm, Feedrate=9999mm/min, Z-hopping=0.2mm ;;;;; Pressure advance M572 D0 S0.1 ; Extruder0 0.1sec advance ;;;;; Dynamic Acceleration Adjustment ;;;;;;;;;;;;;;;;;;;;;; M593 F39.7 ; cancel ringing at 40.5Hz

-

@psyblue said in A heater fault occurs on the LC1 board.:

M308 S0 P"temp0" Y"thermistor" ; T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

this is missing a T and B value

Bootloader ID: not available

you need to update the bootloader for the bltouch to work correctly at startup.

G31 P500 X0 Y0 Z-0.3 ; Liquid Head

this is missing x and y offset

M307 H1 A1077.7 C574.8 D5.6 S1.00 V23.9 B0 ; Auto tune result - Super volcano

this is the old pid tuning that does not take into account the fan. that could cause problems when the fan turns on

-

This post is deleted! -

Thank you for your interest in my writing.

I have a few questions in your relpy.

How to update the bootloader? Is it different from the firmware update?

How did you know it was old PID tunning just by looking at the result? Fortunately, I don't use a fan.

Thanks again. -

see

https://duet3d.dozuki.com/Wiki/Updating_the_bootloader_on_Duet_3_expansion_and_tool_boardsthe new tuning has a different format

M307 H1 R2.670 C256.7:158.3 D9.93 S1.00 V23.8 -

@Veti

Great thanks!!!I'll update the boot-loader & tuning values.

-

The cause was old auto tuning value.

I commented the M307 line and using the default value, the fault situation disappeared.Thanks Veti !!

-

there is a beta of 3.3 that allows you to do tuning on the toolboard