ST3Di Modelsmart 280 - Duet Maestro repair/upgrade

-

Hello, I wanted to start a thread where I can hopefully gain advice from the knowledgeable people on here. I have a ST3Di printer I picked up cheap a couple of years back. I fried the control board through my own stupidity and therefore bought a Duet 2 Maestro in the hope of upgrading the printer and bringing it back to life.

Original thread asking advice

https://forum.duet3d.com/topic/10915/fried-my-printer-can-i-upgrade-to-duet/18I'm reasonably well versed in the principles of 3D printers. My strengths are more in the software world and not in electronics. However I'm keen to learn and see how I go.

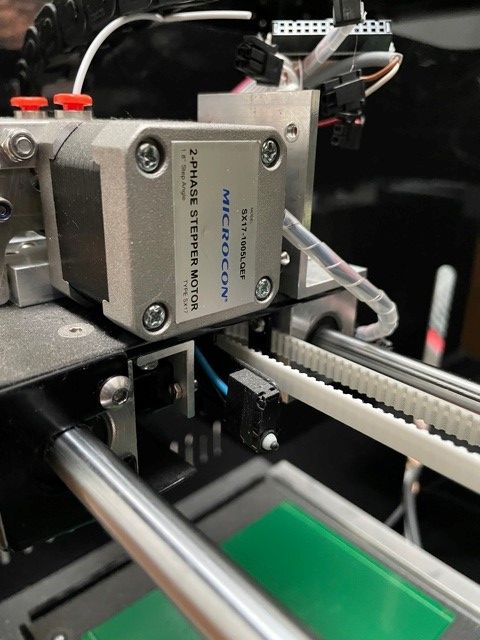

This is the machine in question.

I have already started a couple of threads asking question but it makes sense to have everything in one place.

https://forum.duet3d.com/topic/20663/how-to-work-out-what-goes-where-ribbon-from-print-heads/7

https://forum.duet3d.com/topic/20688/heated-bed-wiring/6

I am still trying to work out if I can use the feeds from the ribbon and connect to the Duet. I will post a photo later of my crude diagram where I'm seeing which pins are connected to the board on the print heads.

I would like advice on this as to the best way to proceed. Keeping the existing wiring seems the easiest in terms of getting it working however I am wondering if I am better removing the ribbon and replacing it with a wiring loom. That way at least I know which part connects to where on the board.

I have updated the board to 3.1.1 with the same version web interface. That's it as far as the board goes for now. I have printed a case for it.

Thanks in advance for any help/advice. I hope I have the understanding and skills to get this printer back working.

-

@Blacksheep99 said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

I am wondering if I am better removing the ribbon and replacing it with a wiring loom. That way at least I know which part connects to where on the board.

I would think so. But looking at your other thread on the ribbon cable it looks like there is a PCB that should be fairly easy to figure out with a multimeter and some patience.

-

@Phaedrux said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

@Blacksheep99 said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

I am wondering if I am better removing the ribbon and replacing it with a wiring loom. That way at least I know which part connects to where on the board.

I would think so. But looking at your other thread on the ribbon cable it looks like there is a PCB that should be fairly easy to figure out with a multimeter and some patience.

Thanks for the feedback. I attempted that yesterday. Forgive my rudimentary diagram. I was just trying to trace the pins. I expected a pin to a pin but as you can see that wasn't the case at all. This just adds to my confusion.

-

Some of the pins may be power or ground and may be shared between several things. Data/signal pins would be unique. This may be a problem if for instance they share a ground pin between fans and heaters which won't work with the Duet since the PWM signal is switched on the negative side.

-

Thanks for the info.

Any recommendations of where to buy suitable components to create a new loom from the print head? I'm wondering about using the existing connectors or best to remove all that and crimp wires to wires?

-

Its probably more a question of identifying the parts in use than where to buy; could look like molex microfit, so maybe something like https://www.molex.com/molex/products/part-detail/crimp_housings/0430200200 for the loose connector to the top

rightleft.however you might spend less time re-crimping it all than to identifying them with 100% certainty when its not a goal in itself to create compatibility. i've had a bias towards making sure my conversion was reversible, but when the original hardware is "nfg" then whatever is easiest might be better option.

-

@bearer

not quite. the number on the connector is 43025

its https://www.molex.com/molex/products/part-detail/crimp_housings/0430250200edit: sorry i see you posted the female part

-

@bearer I figure that the printer would be either thrown or sold for next to nothing as spares or repair. As such all I'm interested in is getting it functioning again and learning along the way. This is my first foray in to Duet and any form or modifying a printer. It doesn't really owe me anything. Thanks for the pointer with the connectors.

-

I'm favouring a rewire so will be researching that. Going this route then I will need to have a separate bed level probe. Any recommendations?

My plan would be to use the current probe/end stop purely as an end stop.

-

depends on your surface.

there is the dc42 ir probe

or a good capacitive sensor. -

It's currently a glass bed. Thanks, I'll check out those options.

-

@Blacksheep99

glass is not good with either of those.i think with glass your best choice is a bltouch.

or the one i prefer https://www.thingiverse.com/thing:3303618 -

I've just been reading up on the options, came to that conclusion that the glass bed would provide some issues. I'm aware of the BL touch. I'll look at those options, thanks.

-

I made some progress last night. Having updated the Duet to 3.2 I wanted to create a base config and see if I could get the printer to at least power up. I was able to connect the X,Y & Z motors, plus two end stops (the X end stop is the servo controlled probe. I was able to home Y and Z and control them via the web interface. I then connected the heated bed and ran the autotune. It completed and the bed was holding temp which is good.

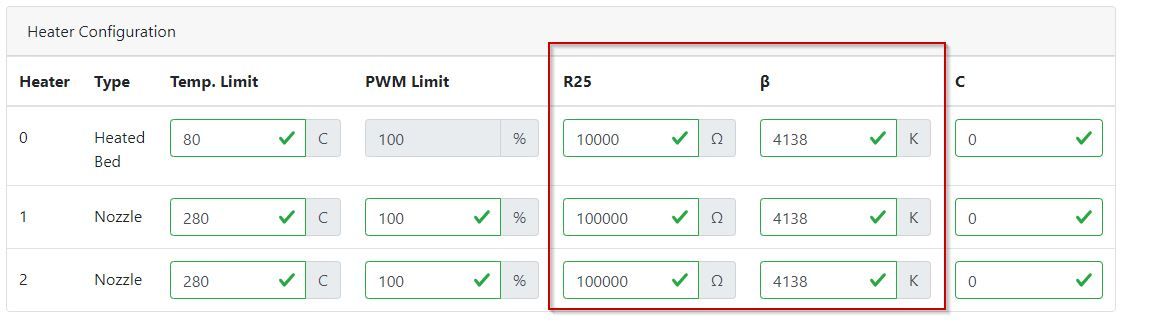

I don't fully understand the config setup using the webtool, if someone can explain it in simple terms to me that could be helpful.

So all in all good progress, well I felt happy. I keep avoiding how to connect up the print heads and associated components. Advice on this area would be welcome. What seems easiest is if I can reuse the existing wiring from the components with the ribbon and then connect from the ribbon to the Duet. I have some Dupont cables which can connect to the ribbon. My issue remains how things were connected. It seems multiple components are taking power from the same pins. Using my crude schematic I identified those pins with a single feed and traced it to the respective component. See the highlighted paths.

-

-

multiple power from the same pin is fine as all the mosfets switch to ground.

Main thing to think about is the total amount of power being drawn of the appropriate output is used.

What bits are you confused with with the config tool? It won't be able to cover all setup requirements and is really only used as a base for configuration.

-

So the motors have a pin to pin mapping. The probe\end stop has one but shared power circuits, the servo has a single feed to one pin with shared power, the hot ends have a single pin but share power also. This seems to make things complicated if I try to map this to the Duet. So I'm thinking I can use the spare wires in the ribbon plus an additional one if required and then wire back to the Duet at the other end. This way all the power circuits are kept seperate..

-

@jay_s_uk said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

multiple power from the same pin is fine as all the mosfets switch to ground.

Main thing to think about is the total amount of power being drawn of the appropriate output is used.

What bits are you confused with with the config tool? It won't be able to cover all setup requirements and is really only used as a base for configuration.

Thanks, that's helpful to know. This is the area I do not understand currently....

-

what software does the printer originally run?

-

thats the difficult part.

is there any way you can get documentation as to what the exact model number is of the thermistor?