Heated bed recommendation in UK please

-

@razrudy said in Heated bed recommendation in UK please:

400x400 silicone heater.

thats to big, you need space on the sides for the screws.

-

@Veti said in Heated bed recommendation in UK please:

@razrudy said in Heated bed recommendation in UK please:

400x400 silicone heater.

thats to big, you need space on the sides for the screws.

With such a big heatplate I would rather go with 3 independent z-axis spindles with the newer independent z-levelling algorithm. Therfor you rest the bed on 3 magnetic balls (just like those delta-printers did with their toolboards) because then the heatplate can freely be levelled

-> Just my suggestion... It is sunday so maybe too much time to dream around

-

you misunderstood me, you need to attach the bed somehow to a carriage or the frame.

when all is taken up by the heater, you can not attach it -

@LB said in Heated bed recommendation in UK please:

it is only (currently) max 300x300 but sure it has raw power:

https://e3d-online.com/collections/printer-parts-electrical/products/high-temperature-heated-bedsor you buy 4* of the 200x200

i'm using e3d high temp bed . its great , but as you said max size is 300x300 .

i also think its a bit overkill , unless you need to print with the bed at 200c .did anyone consider sticking silicone heater directly to borosilicate glass ? if you're printing just pla , i think it can be the cheapest option .

-

of course, just wanted to spin it further

-

@Veti

The heater is 400x400 and the build plate 406x406....this will work or I will need more clearance?

This is what I have in my mind at this point and 99.99% I will go coreXY just need to decide if I will have the bed moving down or the Z moving up......I saw at one of the users here ( can't remember his username)

Silicone heater

Flexplate

Standard Surface

PETG Surface -

thats 3mm per side. so no it will not work..

as i written above the right size would be 350x350 for the heater.

-

@LB definitely minimum 3 axis if I will move the bed up and down

By any chance can you please post a link with that magnetic balls?

-

@GTech What thickness on the aluminium plate please?

I can find minimum 5mm only for cast type. Then 6 , 8 and 10mm. -

@razrudy I normally use 8mm at the size we are talking it is already quite a chunck of metal. You might be able to get away with 6mm anything below that makes no sense in my mind.

10mm will work as well, its just heavier and has more thermal mass aka. needs longer to heat and cool. Depends on what you can get you hands on.As others mentioned mounting that thing is the challange, at 400x400 you will need to somehow compensate for thermal expansion or it will warp no matter how thick the plate is.

Take a look at the HeVORT printer, the guy is on the forum here as well, I think he has a nice way of mounting the bed ... it is just bit overkill

. Also take a look at the Jubilee nice bed mounting as well.

. Also take a look at the Jubilee nice bed mounting as well.On eBay and some stores you can also find silicone blocks and spacers intended for moutng printer beds. They are flexible enough to allow the bed to expand and act as a heat break between the bed and the frame at the same time ... not my first choice but apparently people use them succesfully.

Couple of related notes; You can get silicone heaters with holes in them so you can do the mounting directly under the bed and maximize the print area.

Forget about the Cartisan, 8mm 400x400 should weight something in the 3-4kg range(?) accelerating and decelerating that quickly without loosing steps is a whole different discussion. If you want to go Cartisian your only option is a PCB heater ... Chinese clone of the Prusa Mk42 most likely?

FYI I am just dialing in my new build, bit smaller then yours (300x300 build plate on a 8mm cast aluminium tool plate ~380x350) and with propper mounting there is next to no warping.

I disabled mesh bed compensation, active leveling with three Z screws is enough and I can print right up to the edge with a nice and even first layer. -

I would also recommend filafarm

As for the Hevort it has already been concluded that, that is an abortion of a design that merely looks pretty, one that relies far too heavily on the wasteful use of supports and the fact that on the "wobble wings" the only thing retaining the bed structure to the ball screw is magnets, as an abortive attempt to overcome ball screws which are not straight, when the correct engineering solution would be it either straighten the ball screws or buy ones from a reputable source...

-

@CaLviNx

Still waiting for the UK and Europe to clear "the after Brexit custom things". Most of my orders from Europe it says that can't be delivered yet because of the new custom rules between UK and Europe. I will check from tomorrow onwards when most shops will open again after holidays to check what are the updates about. -

@razrudy said in Heated bed recommendation in UK please:

@CaLviNx

Still waiting for the UK and Europe to clear "the after Brexit custom things". Most of my orders from Europe it says that can't be delivered yet because of the new custom rules between UK and Europe. I will check from tomorrow onwards when most shops will open again after holidays to check what are the updates about.That's because most resellers do not wish to endure the headache of filling out the extra customs paperwork, as the UK is now considered a "third" country in the eyes of the EU.

So In effect the British government has gotten its wish, and made Britain into "little Britain" and pushed the UK back around 50 years a very very sad state of affairs

-

@CaLviNx

Tell me about......but honestly I don't want to talk about this on the forum. It's a "complicated" situation and I know that the things will settle soon and everything will be like before.Just my opinion........

-

@razrudy said in Heated bed recommendation in UK please:

@LB definitely minimum 3 axis if I will move the bed up and down

By any chance can you please post a link with that magnetic balls?

-> I like the way projects like HeVORT and or Jubilee are exploring, also I would rather pull on the thin z-spindle(s) instead of pushing it together for accuracy and of course You would need a stable flat-milled e.g. aluplate of around 6+mm for ca. 350x350 better go 8mm for 400x400 where you attach at the bottom your silicone heater or e3d-heater and on top a FR4-plate or similar. THERE WAS A POST on this forum where somebody had calculated the inherent sag of given metal with FE, just search in the forum for it if you have need, you might ask him politely I am sure he will calc you the correct thickness related to where you place the 3 spheres (for star-centering free-floating of that plate) If I think about it they do not even need to be magnetic if the opposite parts are out of plastic. (I have been buying stuff here for years https://www.reprap.me/ (I am not affiliated to them by any means) but sadly for you at the moment also EU).

Just my 5 cents - do what you understand and makes you happy

For most people in a forum like this, something in that ballpark should be accurate enough for 2021 if you do it right

For most people in a forum like this, something in that ballpark should be accurate enough for 2021 if you do it right

-

After many searches I found that I will need " Aluminium Tooling Plate " is this the right one?

Based on the space I have I decided to go with a 500X500mm ( outer frame 620x640mm ) plate and 400 X 400mm silicone heater. What thickness should I choose? I know...It will be a big challenge going that big...but if I am rebuilding my budget printer at least I am doing something for long run. -

my 500 x 500 is 10mm thick

-

@hackinistrator said in Heated bed recommendation in UK please:

did anyone consider sticking silicone heater directly to borosilicate glass ? if you're printing just pla , i think it can be the cheapest option .

The Taz printers used to be set up that way. It was awful. Glass is not a good thermal conductor so the bed had hot and cool spots randomly distributed over its surface. It was very difficult to get prints to stick to it.

This will calculate bed heat-up time based on construction and power input. It seems to be pretty accurate, at least for aluminum plate beds.

468MP adhesive is commonly used to stick silicone heaters (and PEI sheets) to bed plates. Keenovo recommends sealing the edges of the heater with high temperature silicone. Without doing that the adhesive will start to let go in about 2 years (my experience). I don't know if sealing the edges with silicone will increase the life of the adhesive. I think it's best to get a heater that has no adhesive and stick it to the plate using high temperature silicone. That should stay stuck permanently- I'll let you know for sure in a few more years. At about 1 year so far I don't see any signs of it letting go.

If you get a high powered heater, there is no need to insulate the underside of the bed plate unless there is stuff under there that you're trying to protect from the heat. Even then it would probably be better to insulate the other stuff that's at a much lower temperature than to try to stick insulation to the much hotter bed plate. With a high powered heater you'll have no trouble quickly reaching the target temperature, so insulating the underside of the heater mostly just increases the cool-down time.

If you're enclosing the printer and maybe heating the enclosure to allow printing ABS, the heat "lost" from the underside of the bed plate contributes to warming the chamber, so it isn't really lost at all.

As a point of reference, the uninsulated 300x300x8mm, cast aluminum plate in my printer gets to 105C to print ABS in about 4 minutes with a 300x300 mm 750W line powered heater. Here's the performance with the heater set to 105C:

I routinely print right to the edges of the plate without any print curling or detachment from the bed.

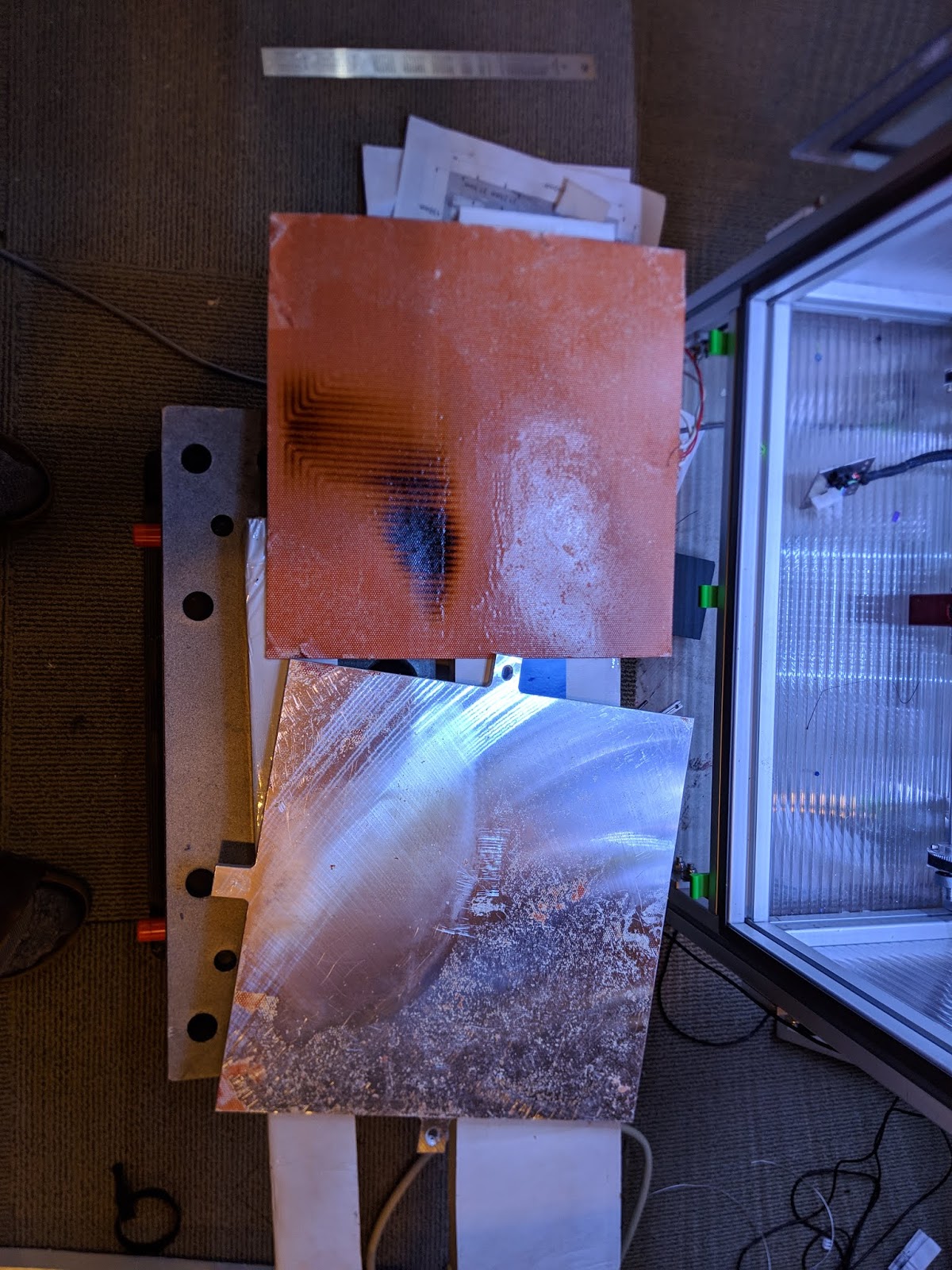

Here's what happens to the heater when the 468MP adhesive starts to let go:

-

@razrudy said in Heated bed recommendation in UK please:

After many searches I found that I will need " Aluminium Tooling Plate " is this the right one?

Based on the space I have I decided to go with a 500X500mm ( outer frame 620x640mm ) plate and 400 X 400mm silicone heater. What thickness should I choose? I know...It will be a big challenge going that big...but if I am rebuilding my budget printer at least I am doing something for long run.You need "end hard aluminum" (I am german: "Endfestes/ausgehärtetes Aluminium"), search for "flat milled"/"fine milled" on at least 1 of the sides to have something flat to print on

-

This is what I found and looks like what I need

PlateAnd this is the answer I got from them

" They are cast, Machined top and bottom, & coated too "

The coated too may be a small problem but think I can easily trough a glass on top until coating will be gone