RRF3.2Beta4.1 Heightmap vs. Spindle/Driver Mapping

-

Console output of 3 point Leveling:

G32 Leadscrew adjustments made: 0.810 0.762 0.377, points used 3, (mean, deviation) before (0.623, 0.151) after (-0.000, 0.000) Leadscrew adjustments made: 0.013 0.161 -0.115, points used 3, (mean, deviation) before (-0.012, 0.105) after (-0.000, 0.000) Height map loaded from file heightmap.csvafter i edited the standard BLtouch Line to:

´´´

H4 F60 T6000 A10 S0.005 B1 it got from around 0.xx1 values to 0.0xx values at the second round probing with F120 i never saw values like that. if i change the value S0.005 to 0.003 i got an Error Message: unconsistend Z Values.... i also tried to play sith the setscrew on top of the bltouch and generated makro Files for Selftest and Error Reset. after i send these 2 Makkros the sensor is working again without touching the cabling . so i think thats probably a setting /software issue.i try to make some photos for reference

Head at Endstops = X0 Y0

Nozzle Tip is at

-

what a timing, the last Time i posted a question about trigger heigt Problems i ordered a few shottky diodes bat 43 -do35:

Bauform DO-35

Elektrische Werte

URRM 30 V

UF 0,33 V

IF(AV) 0,2 A

IFSM 4 A

IR 0,5 µAI have an unsused inductive Probe here thats working witht 24 V .

could i connect it with that diode savely to an unused IOpin only for testing purposes , if there is a hardware error or other problem on the bltouch ? -

For the BLtouch try this command

M558 P9 H4 F60 T6000 A10 B1 R0.5

Don't specify S at all, let it use the default.

Now if you do a test of G30 S-1 several times in a row, how consistent are the results?

Why do you think there is a problem with the BLTouch?

Error Message: unconsistend Z Values

That will happen if you use too tight a tolerance in S.

-

@Frederik

It looks like the second pass is better then the first.

If your setting are not prefect it may take several more rounds depending on the tolerance you want.This is my output and it starts out much closer then your first attempt. I only have two Z motors instead of three hence only two probe points. As @Phaedrux said I also use the default S value and it works fine.

Leadscrew adjustments made: 0.005 0.005, points used 2, (mean, deviation) before (0.005, 0.000) after (-0.000, 0.000) Leadscrew adjustments made: -0.007 0.016, points used 2, (mean, deviation) before (0.004, 0.004) after (0.000, 0.000) Leadscrew adjustments made: -0.012 0.026, points used 2, (mean, deviation) before (0.006, 0.006) after (-0.000, 0.000) Leadscrew adjustments made: -0.014 0.047, points used 2, (mean, deviation) before (0.015, 0.010) after (0.000, 0.000) Leadscrew adjustments made: -0.080 0.095, points used 2, (mean, deviation) before (0.004, 0.029) after (-0.000, 0.000) Leadscrew adjustments made: -0.098 0.245, points used 2, (mean, deviation) before (0.066, 0.056) after (0.000, 0.000) -

@Phaedrux I was reading on the antclabs web page that the v3. 1 is measuring within 0.005 mm and the results im getting are different every time I generate a Heightmap

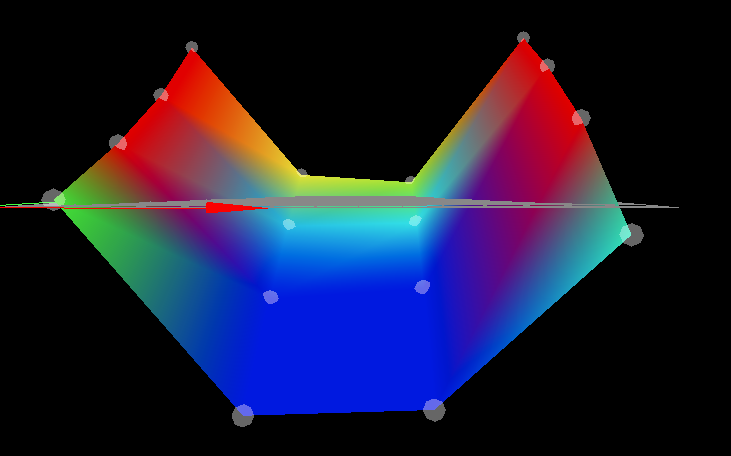

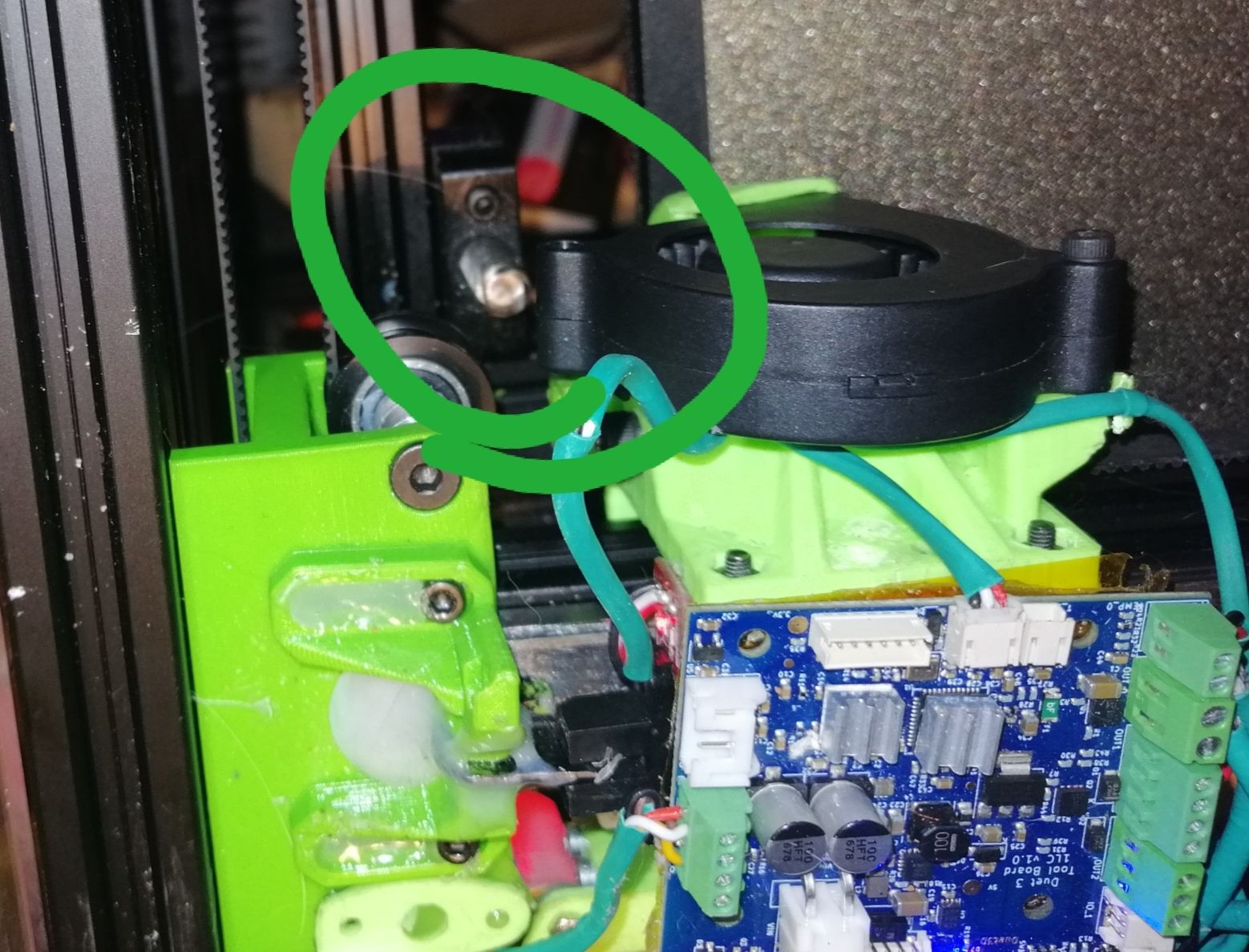

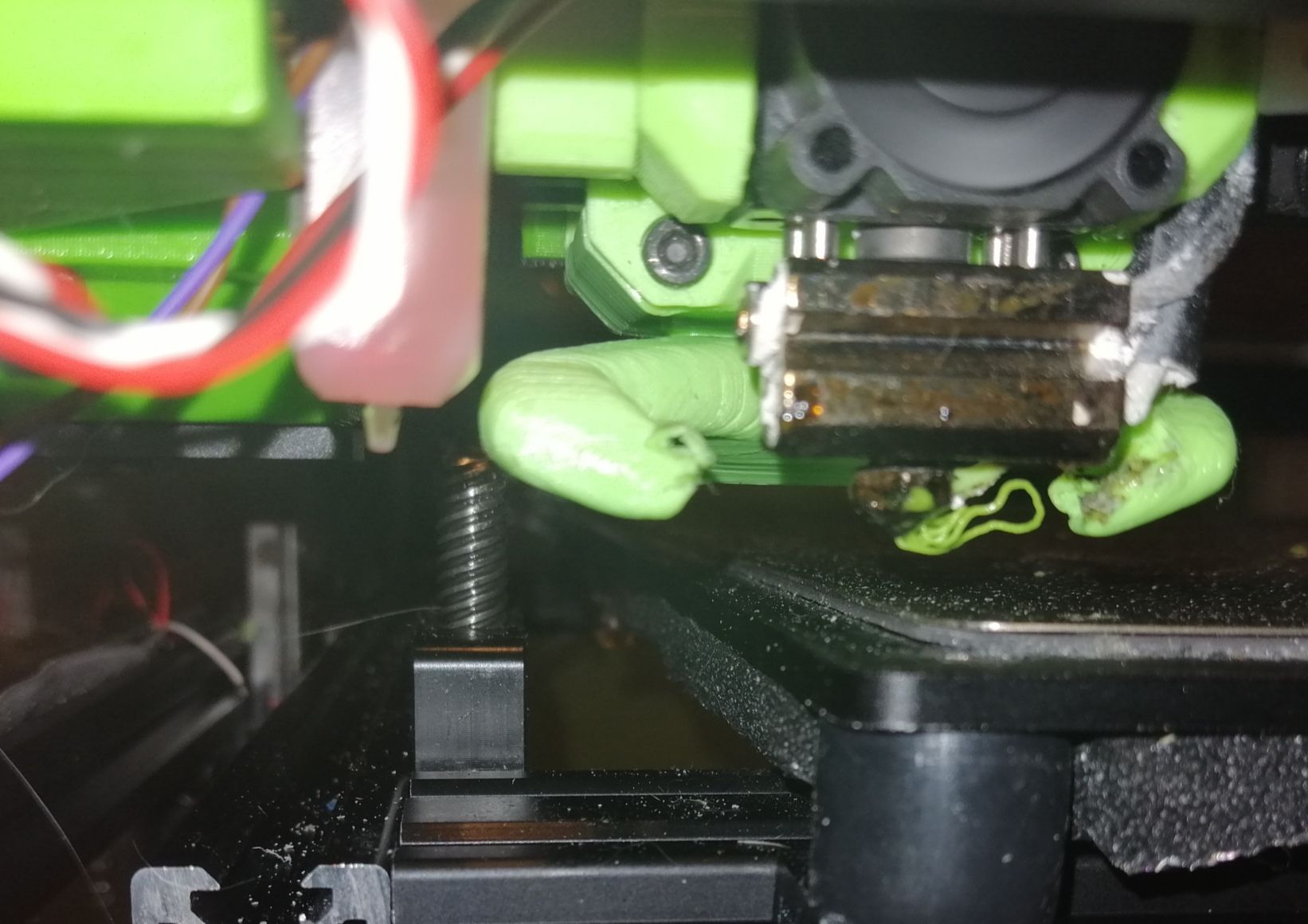

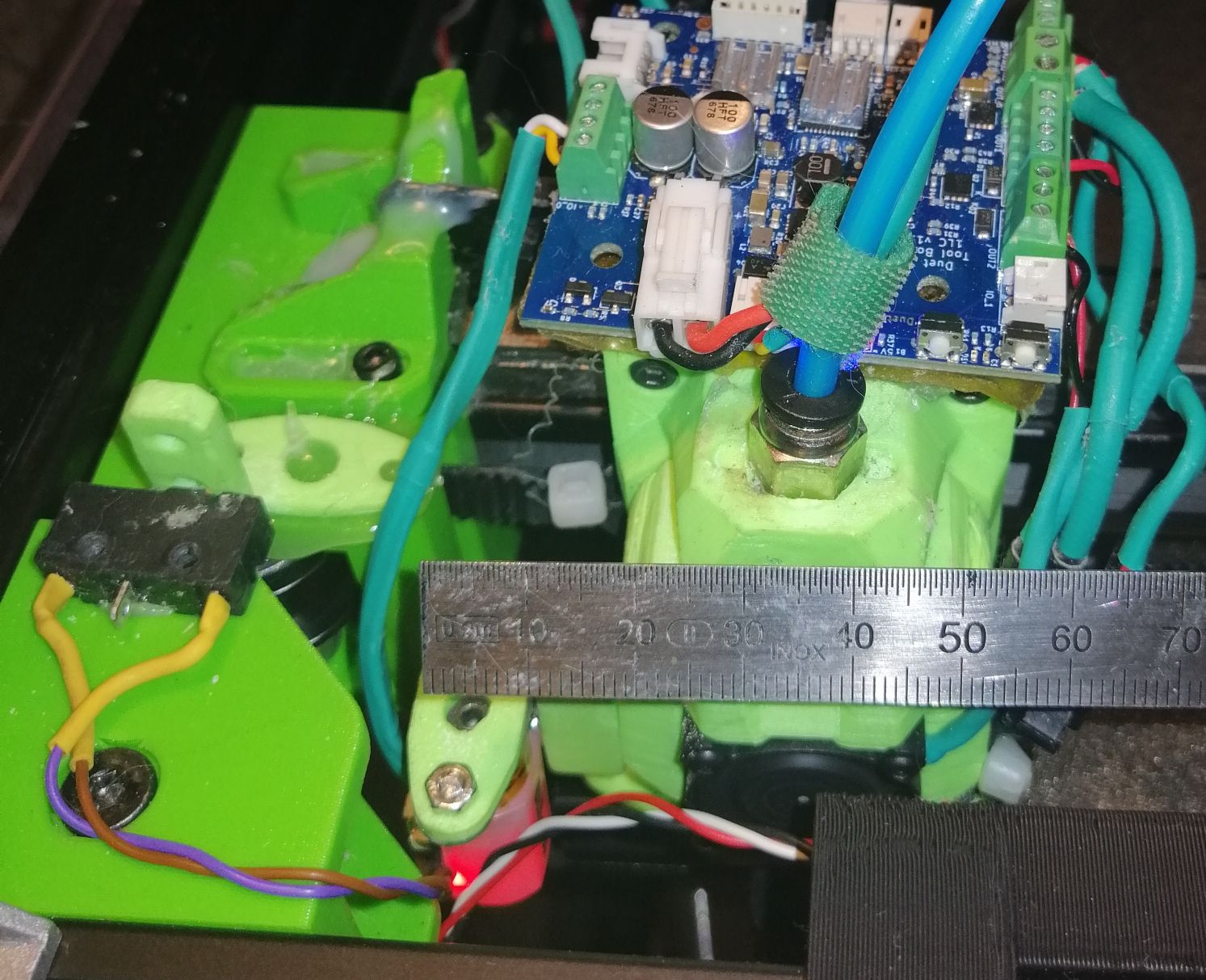

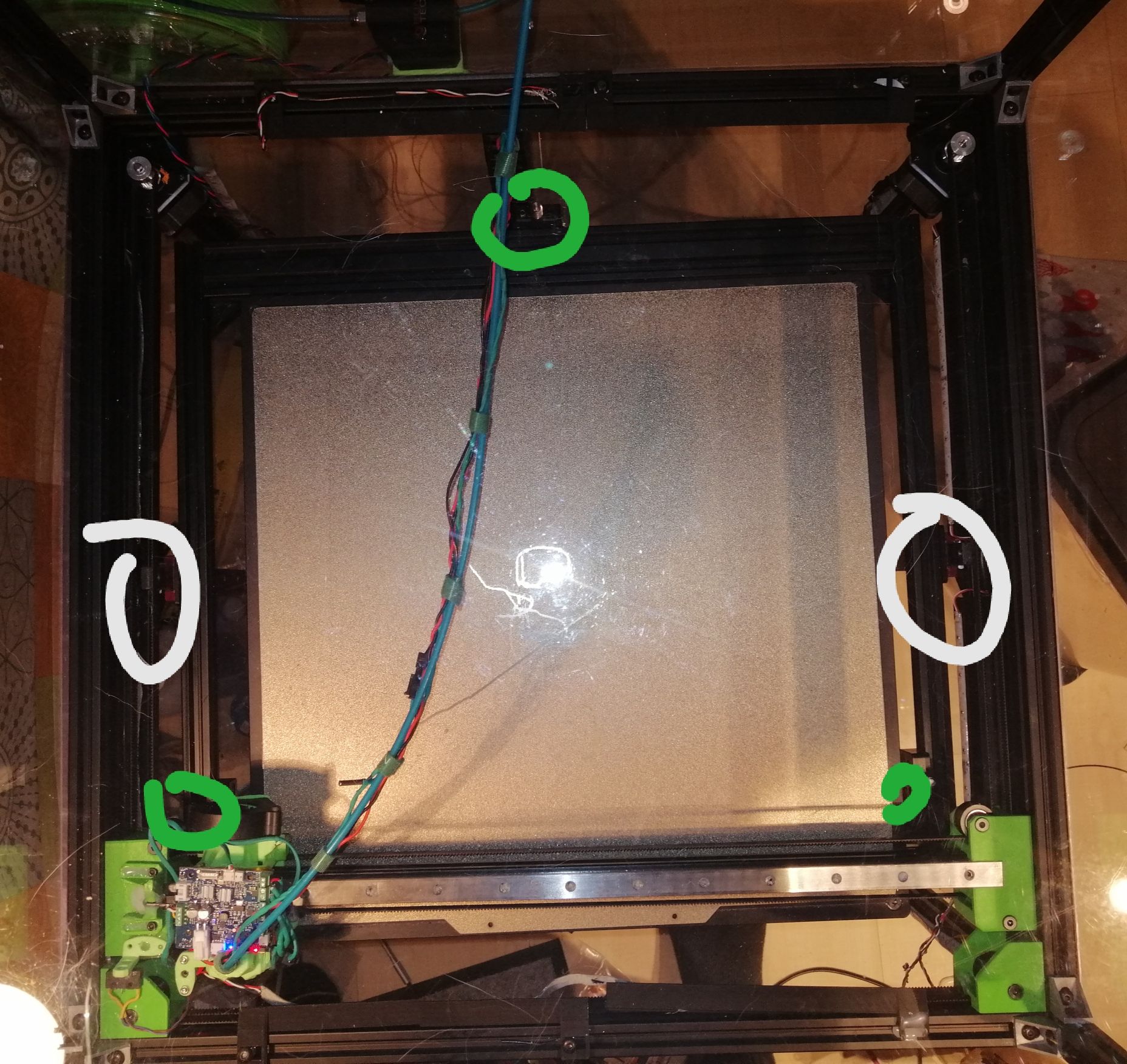

Here are the pictures of my head and in green the position of my spindles and white the position of mgn15 rails to eliminate any z wobble

-

-

@Frederik The different Heightmaps is because your Leadscrew deviation is not 0 before you generate the Heightmap.

-

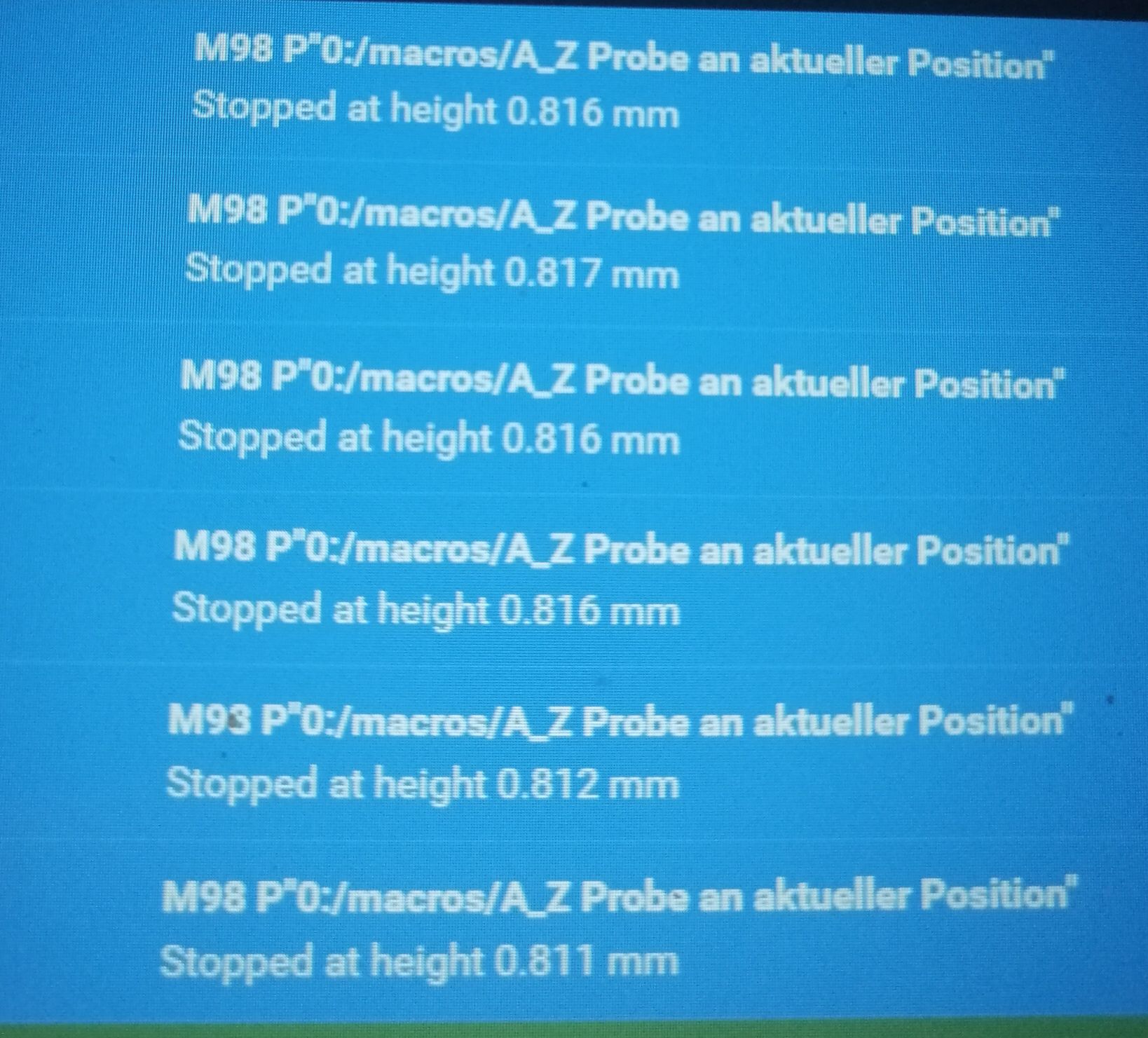

@Phaedrux one moment. I probing single spots and checking the values before and after the z probe code change

-

@3dML I delete the Heightmap and compensation bevor generating a new mesh.

Is that wrong?

And after startup only a g32 - 3 point level +loading of Heightmap.csv (bed.g)

-

@3dML the showed Heightmap was generated at room temperature. To have a baseline when starting test at different standard bed temperatures. Like 60, 90, 100 etc

How Lo g would you give the bed before starting the measurements, so that the temp is as evenly as possible

-

If you run the 3point calibration multiple time it should return a smaller deviation each time hence the reason I use a while loop and an if statement to check the deviation value. It will continue to run until it passes the tolerance set by the if statement.

You could put this code in a macro and run it multiple time to see how small you can get the deviation.

G30 P0 X40 Y80 Z-99999 ; Probe near the front left lead-screw G30 P1 X215 Y395 Z-99999 ; Probe near the rear lead screw G30 P2 X415 Y80 Z-99999 S3 ; Probe near the front right lead-screw -

-

@Frederik said in RRF3.2Beta4.1 Heightmap vs. Spindle/Driver Mapping:

And after startup only a g32 - 3 point level +loading of Heightmap.csv (bed.g)

generate a Heightmap

If you can do a 3point calibration the a deviation of 0 or as close as you can get it you should not have to generate a new Heightmap every time you do a 3point calibration.

The time to temp all depends on your setup.

I have a 750w heater that covers the entire 300mm bed with a temp sensor to control the heat in a slot cutout of the magnet for the flex sheet so very close to the top of the bed. I also have a temp sensor on the heater pad itself so once they both stabilize its good to go. If you are only measuring temp at the heater pad it will take a while for the top of the bed to reach an even temp unless the bed is very thin.

@Frederik said in RRF3.2Beta4.1 Heightmap vs. Spindle/Driver Mapping:

Changed bltouch config to H3 F60 T6000 A10 B1 R0.5

What was the max Z speed for this test? The last 4 readings look good. Too high of a Z speed can cause the shift between the second and third reading.

-

@3dML Z Probing speed F60 normal in the RRF config tool was F120

-

@Frederik said in RRF3.2Beta4.1 Heightmap vs. Spindle/Driver Mapping:

@3dML Z Probing speed F60 normal in the RRF config tool was F120

Yes that is used for Z- speed when probing but M203 sets the max speed which is used for Z+. Too high of max speed will cause higher deviations when probing but not enough to notice when printing.

I have found that slowing down the maximum Z speed can help with tolerance. Try adding a M203 Z100 before any bed probing moves and M203 Z1000 after the bed probing is finished to restore the speed back to your config settings. You may be able to push the speed a little higher Z100.

-

@3dML its probing with 1mm/s. is that slow enough ?

The Last G32 after changing the settings

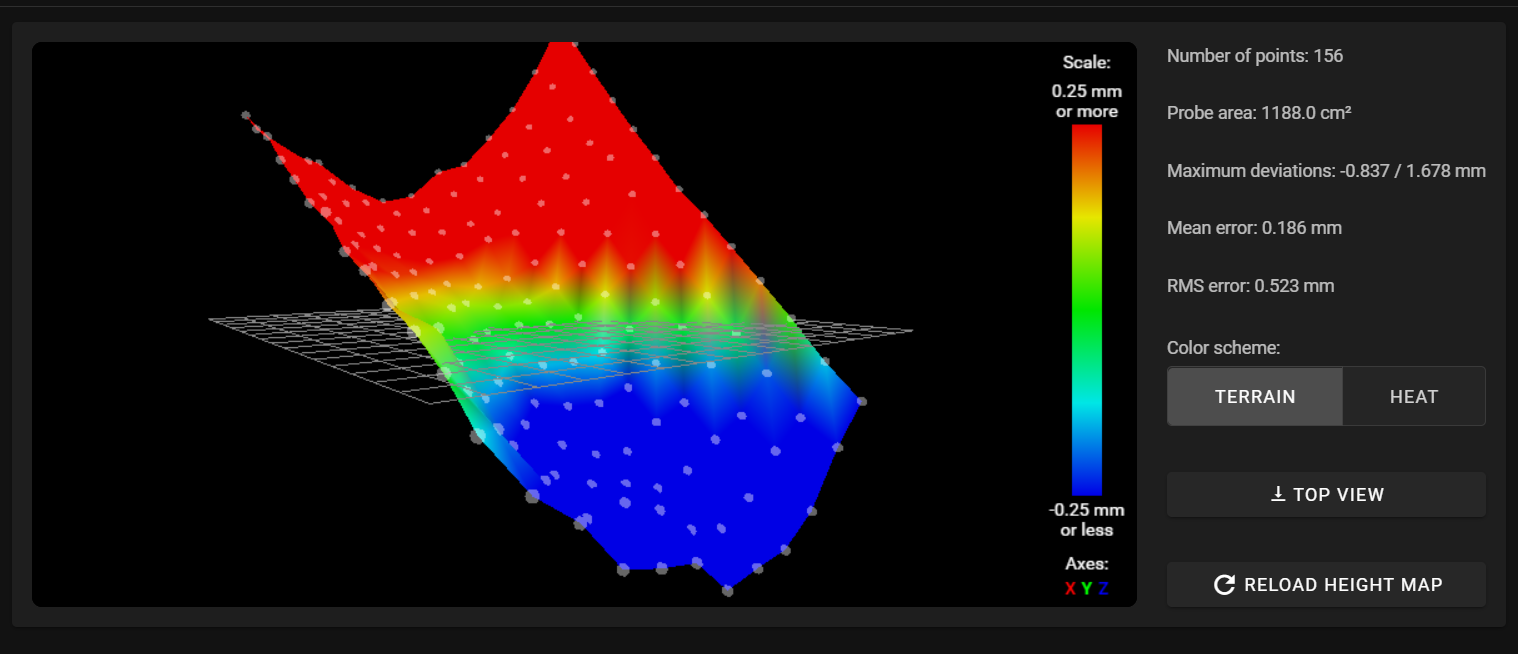

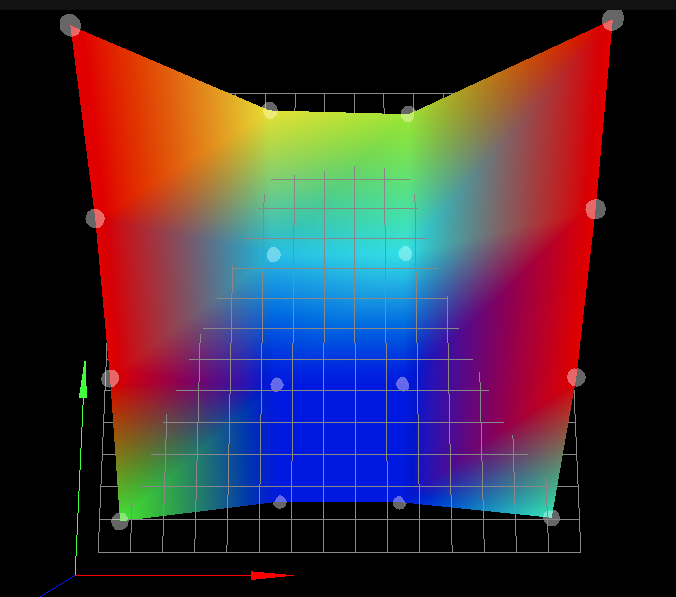

Leadscrew adjustments made: 0.380 0.168 0.089, points used 3, (mean, deviation) before (0.244, 0.085) after (0.000, 0.000) Leadscrew adjustments made: 0.064 -0.009 -0.213, points used 3, (mean, deviation) before (-0.044, 0.083) after (0.000, 0.000) Leadscrew adjustments made: 0.215 0.207 -0.272, points used 3, (mean, deviation) before (0.044, 0.169) after (0.000, 0.000) Leadscrew adjustments made: 0.011 0.098 -0.100, points used 3, (mean, deviation) before (-0.013, 0.066) after (0.000, 0.000) Leadscrew adjustments made: -0.087 0.158 0.672, points used 3, (mean, deviation) before (0.216, 0.222) after (-0.000, 0.000) Leadscrew adjustments made: -0.018 -0.124 0.255, points used 3, (mean, deviation) before (0.060, 0.126) after (-0.000, 0.000) Leadscrew adjustments made: 0.305 0.199 0.353, points used 3, (mean, deviation) before (0.304, 0.054) after (-0.000, 0.000) Leadscrew adjustments made: 0.017 -0.064 0.012, points used 3, (mean, deviation) before (0.002, 0.031) after (0.000, 0.000) Leadscrew adjustments made: 0.278 0.250 0.293, points used 3, (mean, deviation) before (0.279, 0.015) after (0.000, 0.000) Leadscrew adjustments made: 0.012 -0.013 -0.004, points used 3, (mean, deviation) before (0.003, 0.008) after (0.000, 0.000) Leadscrew adjustments made: 0.264 0.270 0.289, points used 3, (mean, deviation) before (0.274, 0.008) after (0.000, 0.000) Leadscrew adjustments made: 0.011 -0.011 -0.009, points used 3, (mean, deviation) before (0.000, 0.007) after (0.000, 0.000)G29 81 points probed, min error -0.806, max error 0.757, mean -0.124, deviation 0.338 Height map saved to file heightmap.csvxmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum 50.00,400.00,50.00,390.00,-1.00,38.90,37.80,9,9 -0.028, -0.333, -0.536, -0.719, -0.794, -0.806, -0.694, -0.498, -0.213 0.086, -0.210, -0.423, -0.591, -0.686, -0.655, -0.535, -0.386, -0.109 0.123, -0.133, -0.348, -0.498, -0.593, -0.561, -0.411, -0.277, -0.096 0.277, -0.020, -0.213, -0.400, -0.465, -0.453, -0.370, -0.169, 0.052 0.300, 0.019, -0.156, -0.299, -0.374, -0.309, -0.263, -0.114, 0.103 0.395, 0.137, -0.045, -0.197, -0.278, -0.281, -0.146, -0.010, 0.215 0.523, 0.232, 0.018, -0.110, -0.236, -0.192, -0.128, 0.062, 0.233 0.651, 0.365, 0.130, -0.022, -0.146, -0.135, -0.048, 0.122, 0.346 0.757, 0.547, 0.280, 0.062, -0.042, -0.017, 0.075, 0.206, 0.420RepRapFirmware height map file v2 generated at 2020-12-23 01:13 xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum 45.00,410.00,40.00,390.00,-1.00,365.00,350.00,2,2 0.423, 0.344 1.333, 1.363th last is a heightmap on the 4 corners as far out as possible

-

@Frederik

Yes if multipleG30 S-1in the same spot return a very small variation these results mean the config is not correct.If this is your only G31 this may be your problem. I just notice you have no X or Y offset for your BLTouch.

G31 P1000 X0 Y0 Z0.81 -

@3dML is the offset measured from the nozzle or always from x0 y0 ?

-

@Frederik

G31 is the probe offset from the nozzle. If you position the nozzle at x0 y0 the G31 offset would be the position of the BLTouch. -

@3dML when my printhead is homed at x0 y0 (left front corner) the bltouch is around x-3 y-2

the nozzle x35 y8this is are the values for another test with 4:4 Probing Points

xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum 45.00,410.00,40.00,390.00,-1.00,121.67,116.67,4,4 0.020, -0.735, -0.706, -0.097 0.252, -0.427, -0.378, 0.354 0.536, -0.148, -0.128, 0.676 0.903, 0.127, 0.082, 0.945