Toolboard Heater Tuning and Fan Error

-

@Frederik said in Toolboard Heater Tuning and Fan Error:

how can i delete a used thermistor pin ?

dont define it the in the config.

-

@Veti i deleted it already, my heated bed is ok. the thermistor has 100.8k resistance , but i cant get them to wrok after the config change

-

post the changes you made

-

@Veti i removed the chamber heater

; Heaters M308 S0 P"temp0" Y"thermistor" T10000 B4100 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limitd ; map heated bed to heater 0 M143 H0 S150 M308 S1 P"121.temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S500but i get -273°C

-

eeven if i conmect a brand new e3d thermistor i get the -273 reading

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.10 on Sat Dec 19 2020 18:27:02 GMT+0100 (Mitteleuropäische Normalzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"vcore" ; set printer name M669 K1 ; select CoreXY mode ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.5 goes forwards M569 P0.4 S0 ; physical drive 0.5 goes forwards M569 P0.5 S0 ; physical drive 0.5 goes forwards M584 X0.0 Y0.1 Z0.2:0.3:0.4 E0.5 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z800.00 E830.00 ; set steps per mm M566 X3000.00 Y3000.00 Z60.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E250.00 ; set accelerations (mm/s^2) M906 X1900 Y1900 Z1900 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M671 X0:200:400 Y50:385:50 S10 ; Position of Leadscrews ;Duet Laser Filament Monitor ;M591 D0 P5 C"io3.in" R30:130 E3.0 S0 ; Tolerance 30 to 130%, 3mm comparison length, diabled ; Pressure Advance Tuning ;M572 D0 S0.1 ; Extruder pressure advance ; Cancel Ringing at the defined Freuquenzy ;M593 F40.5 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X410 Y385 Z390 S0 ; set axis maxima ; Endstops M574 X1 S1 P"121.io2.in" ; configure active-high endstop for low end on X via pin 121.io2.in M574 Y1 S1 P"io0.in" ; configure active-high endstop for low end on Y via pin io0.in M574 Z2 S2 ; configure Z-probe endstop for high end on Z ; Z-Probe M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"^121.io0.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z0 ; set Z probe trigger value, offset and trigger height M557 X38:410 Y15:385 S40 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T10000 B4100 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limitd ; map heated bed to heater 0 M143 H0 S150 M308 S1 P"121.temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S500 ; Fans M950 F0 C"121.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency M106 P0 C"Düse" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"121.out1" Q500 ; create fan 1 on pin 121.out1 and set its frequency M106 P1 C"Bauteil" S0 H-1 ; set fan 1 name and value. Thermostatic control is turned off ; Tools M563 P0 S"Mosquito Magnum" H1 F0:1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M912 P0 S-14.8 ; MCU Temperature Calibration ; Miscellaneous ;M501 ; load saved parameters from non-volatile memory ;M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select first tool ;M280 P0 S60 ; BLtouch - toggle switch mode ;G4 P1000 ; wait 1 second ;M280 P0 S120 ; BLtouch toggle self-test -

this was the config before

; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4100 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"121.temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S500 ; set temperature limit for heater 1 to 500C M308 S2 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp2 M950 H2 C"out1" T2 ; create chamber heater output on out1 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for the E3D Volcano and set PWM limit M141 H2 ; map chamber to heater 2 M143 H2 S250 ; set temperature limit for heater 2 to 200C ;M308 S3 P"temp2" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 3 as thermistor on pin temp3 ;M950 H3 C"out2" T3 ; create chamber heater output on out2 and map it to sensor 3 ;M307 H3 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit ;M141 H3 ; map chamber to heater 3 ;M143 H3 S250 ; set temperature limit for heater 3 to 250C ; Heater Model Parameters M307 H0 R0.641 C945.3 D3.18 S1.00 V24.1 ; PID Parameters Heated Bed M307 H1 R2.770 C158.7 D5.63 S1.00 V24.0 ; PID Parameter Mosquito Magnum M307 H2 A202.7 C76.2 D3.1 S1.0 V24.0 B0 ; PID Parameters E3D Volcano ; PID Parameters BuildChamber -

@Frederik said in Toolboard Heater Tuning and Fan Error:

eeven if i conmect a brand new e3d thermistor i get the -273 reading

273 means open circuit. so its not making connection.

also see

https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitationsEndstop switches and Z probes connected to the main board cannot control motors on an expansion board. This is planned to be fixed in release 3.3.0.

If you use a Z probe then the Z motors must be connected to the main board. This is planned to be fixed in release 3.3.0. -

@Veti but befor the change it worked, and i didn´t touch the cabling.

how can there be an open circuit?

the faulty device is my keenovo heated bed that is connected over an ssr.

both are on the mainboard. on thte toolboard is only the thermistor and heater for the mosquito

-

what exactly did you change in the config?

-

only from this heater config :

; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4100 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"121.temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S500 ; set temperature limit for heater 1 to 500C M308 S2 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp2 M950 H2 C"out1" T2 ; create chamber heater output on out1 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for the E3D Volcano and set PWM limit M141 H2 ; map chamber to heater 2 M143 H2 S250 ; set temperature limit for heater 2 to 200C ;M308 S3 P"temp2" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 3 as thermistor on pin temp3 ;M950 H3 C"out2" T3 ; create chamber heater output on out2 and map it to sensor 3 ;M307 H3 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit ;M141 H3 ; map chamber to heater 3 ;M143 H3 S250to this:

; Heaters M308 S0 P"temp0" Y"thermistor" T10000 B4100 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limitd ; map heated bed to heater 0 M143 H0 S150 M308 S1 P"121.temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S500and now i get the open circuit message

-

i don´t know what happend, but i generated a new config.g with the RRF Config Tool and the problem was gone...

how can such things happen ?

-

@veti

it is s crazy, one problem is gone, the next one is here

I want to print as test a Calicat,

but while the extruder is priming, the print pauses and I got the following message:

Printing paused

Extruder 0 reported 'noDataReceived'what.... ?!?

i am using Driver 5 on the mainboard, not on the toolboard.

-

post the M122 for main and toolboard after this happens

-

it happens now every time i start a print

19.12.2020, 22:18:50 m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.2-beta4.1 running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-956BA-NA3TN-6J9DL-3S46S-99AUT Used output buffers: 1 of 40 (10 max) === RTOS === Static ram: 123292 Dynamic ram: 138756 of which 88 recycled Never used RAM 130056, free system stack 126 words Tasks: Linux(ready,83) HEAT(blocked,297) CanReceiv(blocked,831) CanSender(blocked,348) CanClock(blocked,352) TMC(blocked,20) MAIN(running,669) IDLE(ready,19) Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:36:36 ago, cause: software Last software reset at 2020-12-19 21:42, reason: User, GCodes spinning, available RAM 130216, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0xffffffff Task Linu Error status: 0x00 MCU temperature: min 29.8, current 32.6, max 44.8 Supply voltage: min 23.8, current 24.0, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.1, max 12.2, under voltage events: 0 Driver 0: position 0, standstill, reads 23239, writes 31 timeouts 0, SG min/max 0/246 Driver 1: position 0, standstill, reads 23239, writes 31 timeouts 0, SG min/max 0/245 Driver 2: position 11388, standstill, reads 23238, writes 33 timeouts 0, SG min/max 0/795 Driver 3: position 0, standstill, reads 23239, writes 33 timeouts 0, SG min/max 0/1023 Driver 4: position 0, standstill, reads 23240, writes 33 timeouts 0, SG min/max 0/1023 Driver 5: position 0, standstill, reads 23248, writes 25 timeouts 0, SG min/max 0/316 Date/time: 2020-12-19 22:18:49 Slowest loop: 226.34ms; fastest: 0.07ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === FreeDm 375 (min 359), maxWait 99384ms, bed compensation in use: mesh, comp offset -0.670 === MainDDARing === Scheduled moves 6, completed moves 6, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 15], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = 2 -1 -1 -1 Heater 0 is on, I-accum = 0.2 Heater 1 is on, I-accum = 0.0 Heater 2 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File* is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue* is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause* is idle in state(s) 0 Code queue is empty. === Filament sensors === Extruder 0: no data received === CAN === Messages queued 9636, send timeouts 0, received 27395, lost 0, longest wait 2ms for reply type 6049, free buffers 47 === SBC interface === State: 0, failed transfers: 0 Last transfer: 19ms ago RX/TX seq numbers: 12458/12459 SPI underruns 0, overruns 0 Number of disconnects: 0, IAP RAM available 0x2098c Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.2.0-beta4 Code buffer space: 4096 Configured SPI speed: 8000000 Hz Full transfers per second: 35.64 File /opt/dsf/sd/gcodes/CFFFP_20mm_calibration_cube.gcode is selected, paused 19.12.2020, 22:18:28 Printing paused at X0.0 Y0.0 Z10.0 19.12.2020, 22:18:11 M32 "0:/gcodes/CFFFP_20mm_calibration_cube.gcode" File 0:/gcodes/CFFFP_20mm_calibration_cube.gcode selected for printingtoolboard:

m122 b121 Diagnostics for board 121: Duet TOOL1LC firmware version 3.2-beta4.1 (2020-12-03) Bootloader ID: SAMC21 bootloader version 2.1 (2020-11-03b2) Never used RAM 4180, free system stack 72 words HEAT 50 CanAsync 85 CanRecv 83 TMC 54 MAIN 216 AIN 64 Last reset 00:39:01 ago, cause: software Last software reset data not available Driver 0: position 0, 830.0 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 1, ifcnt 32, reads 56493, writes 12, timeouts 0, DMA errors 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0 No step interrupt scheduled VIN: 23.9V MCU temperature: min 34.5C, current 46.9C, max 51.0C Ticks since heat task active 19, ADC conversions started 2331952, completed 2331951, timed out 0 Last sensors broadcast 0x00000002 found 1 24 ticks ago, loop time 0 CAN messages queued 29030, send timeouts 0, received 21901, lost 0, free buffers 36config.g :

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"vcore" ; set printer name M669 K1 ; select CoreXY mode ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.5 goes forwards M569 P0.4 S0 ; physical drive 0.5 goes forwards M569 P0.5 S0 ; physical drive 0.5 goes forwards M584 X0.0 Y0.1 Z0.2:0.3:0.4 E0.5 ; set drive mapping ; configure microstepping without interpolation M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z800.00 E830.00 ; set steps per mm M566 X3000.00 Y3000.00 Z60.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E250.00 ; set accelerations (mm/s^2) M906 X1900 Y1900 Z1900 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M671 X0:200:400 Y50:385:50 S10 ; Position of Leadscrews ;Duet Laser Filament Monitor ;M591 D0 P5 C"io3.in" R30:130 E3.0 S0 ; Tolerance 30 to 130%, 3mm comparison length, diabled ; Pressure Advance Tuning ;M572 D0 S0.1 ; Extruder pressure advance ; Cancel Ringing at the defined Freuquenzy ;M593 F40.5 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X410 Y385 Z390 S0 ; set axis maxima ; Endstops M574 X1 S1 P"121.io2.in" ; configure active-high endstop for low end on X via pin 121.io2.in M574 Y1 S1 P"io0.in" ; configure active-high endstop for low end on Y via pin io1.in M574 Z2 S2 ; configure Z-probe endstop for high end on Z ; Z-Probe M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"121.io0.in" H8 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z0 ; set Z probe trigger value, offset and trigger height M557 X38:410 Y15:385 S75 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"121.temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S500 ; set temperature limit for heater 1 to 500C M308 S2 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp1 M950 H2 C"out1" T2 ; create chamber heater output on out1 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit M141 H2 ; map chamber to heater 2 M143 H2 S120 ; set temperature limit for heater 2 to 120C ; Heater Model Parameters M307 H0 R0.641 C945.3 D3.18 S1.00 V24.1 ; PID Parameters Heated Bed M307 H1 R2.770 C158.7 D5.63 S1.00 V24.0 ; PID Parameter Mosquito Magnum M307 H2 A202.7 C76.2 D3.1 S1.0 V24.0 B0 ; PID Parameters Build Chamber ; Fans M950 F0 C"121.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"121.out1" Q500 ; create fan 1 on pin 121.out1 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 S"mosquito magnum" D0 H1 F0:1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M912 P0 S-14.8 ; Miscellaneous T0 ; select first tool ;M280 P0 S60 ; BLtouch - toggle switch mode ;G4 P1000 ; wait 1 second ;M280 P0 S120 ; BLtouch toggle self-test -

can you move the extruder connection to the expansion board?

-

@Veti i think that message was generated by the interpolation settings.

I changed yesterday only the following line:

M350 X16 Y16 Z16 E16 I1to

M350 X16 Y16 Z16 I1 M350 E16 I0after that change, the message was gone.

i could try it as a test, but I don't have printed the motor mount for the direct drive setup

-

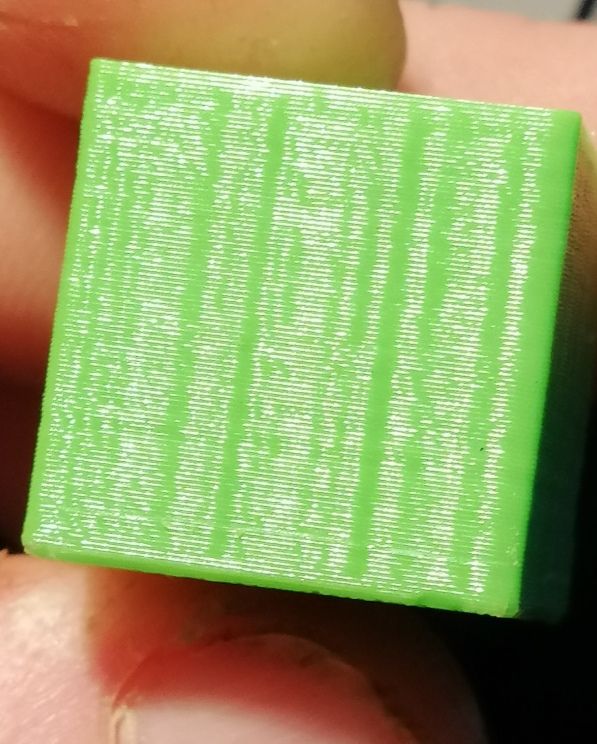

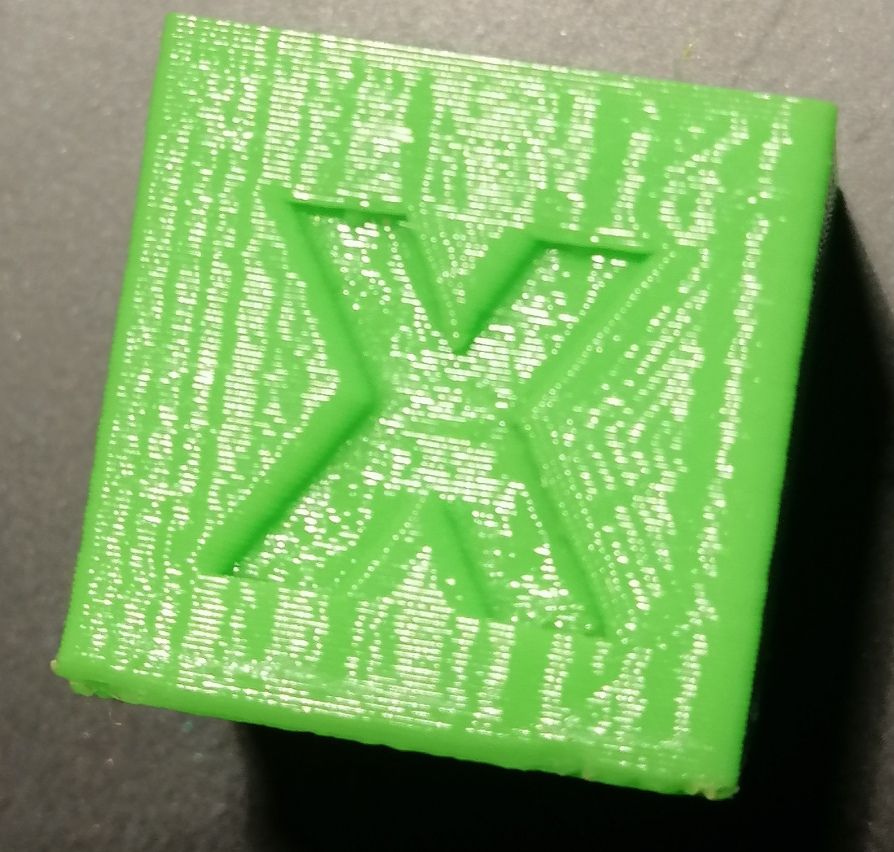

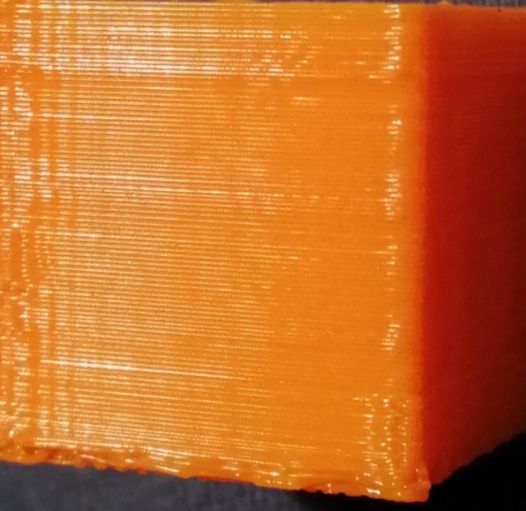

I printed a test cube to see if now everything is work g as it should,

This is my second or third print with petg.

What could cause these stripes?

Max instantaneous speed change x+y=1000

Max acceleration x+y=750

I played a little bit with the settings, but I think it isn't speed related? Perhaps some small mechanical problems? But I can't find them

-

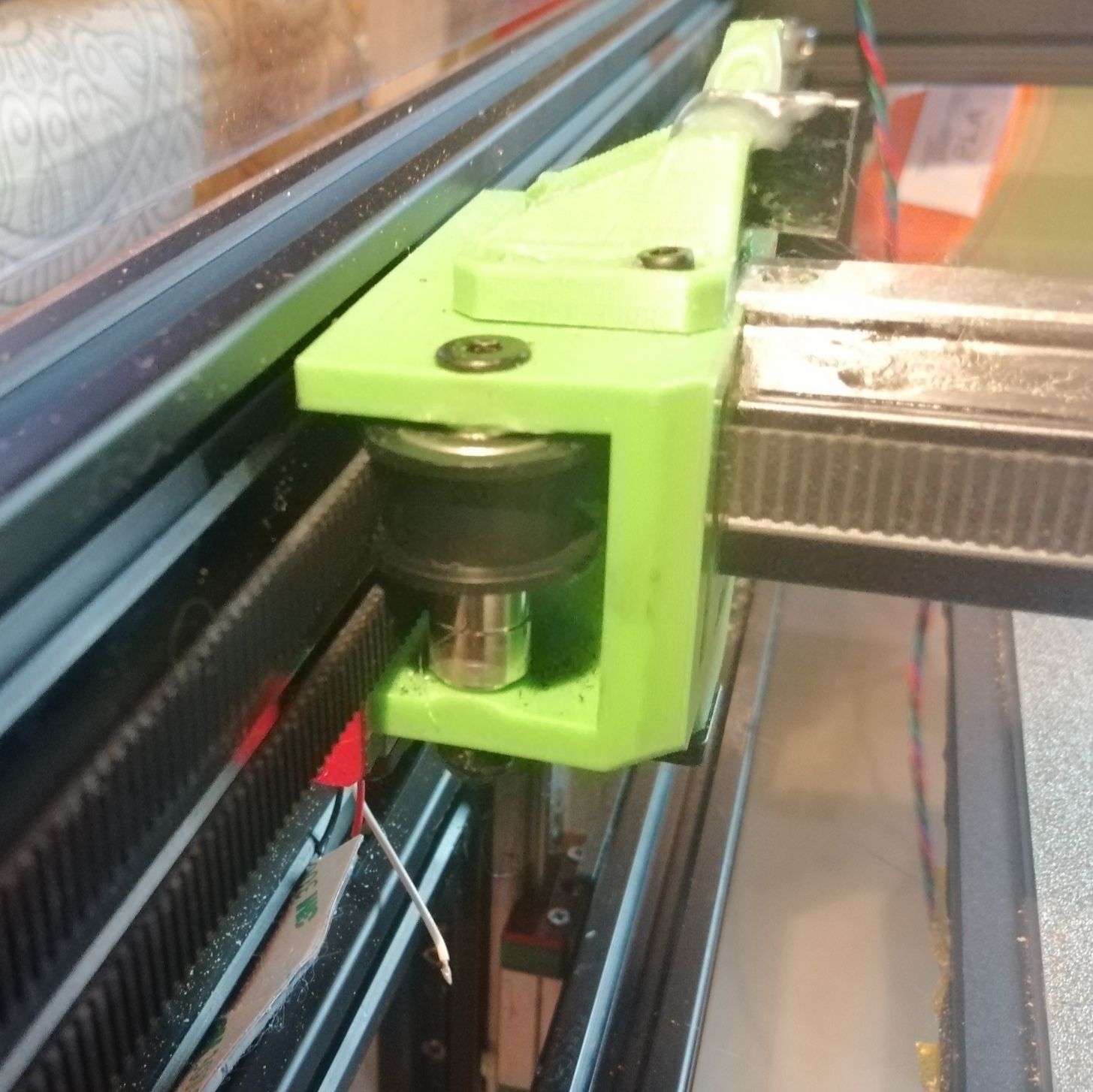

could be belt on smooth pulley

damaged bearing

1.8 stepper artefacthard to tell

-

@Veti right now I have only 0.9 degree steppers on the machine. I have 2 flat pullys on the teethed belt side. But the kit was shipped like that

Do you think that is the problem ?

I checked the bearings. They are all good. The Machine has printed perhaps 15 hours after I finished the build

Could be the belt tension also play a role?

What do you think is a good starting point?Ive read somewhere that ok a CoreXY it should sound a little bit like a low guitar string. Around 60-80 hz?

I tested now with pla and the same speed settings, but switched from cura 4.8 to prusa slicer.

It looks a lot better. Perhaps the slicer profile has wrong settings or other config issue

-

try changing the belt tension and see if that changes the pattern