Inconsistent results with optical encoder wheel filament sensor

-

@JohnOCFII AH! I tool another look at a larger zoom level and I do see that the LED is connected between positive voltage and the output signal.

-

Progress!

I manually moved the filament back and forth a few times, just to see if I was capture what I expected to capture. Other than the fact that the signal seems inverted -- it definitely looks like the Channel 1 signal is a cleaned up version of Channel 3.

Spacing seems somewhat different too, but I can't imagine that matters in this case. I'll do a test print next.

Here's the very tiny Saleae log file: https://1drv.ms/u/s!ApuOkxTDmZEzgoHeOopsvsFwqzJ2Eck?e=6bpojT

-

Yeah, maybe that inversion does matter. The LED on the optical sensor now is behaving opposite to the sensor on the DUET e1stop.

Of course, I did buy a Schmitt trigger -inverter-...

-

OK - test print complete. I inverted the endstop in my config:

M591 D0 P7 C"!^e1stop" S0 R30:1500 L04.0 E5 A1Once again, this was just a slow vase mode test, but it looked pretty consistent. Now to do a more varied test print.

Pulse-type filament monitor on pin !e1stop, disabled, sensitivity 4.000mm/pulse, allowed movement 30% to 1500%, check every 5.0mm, measured sensitivity 4.048mm/pulse, measured minimum 92%, maximum 107% over 275.3mmHere's the Saleae capture: https://1drv.ms/u/s!ApuOkxTDmZEzgoHgcZ3MG-VMfmaWuDk?e=LBB2Ue

John

-

A "normal" print with varying movement types and speeds up to 120 mm/sec. Results were pretty stable. Very similar to the vase mode print.

Pulse-type filament monitor on pin !e1stop, disabled, sensitivity 4.000mm/pulse, allowed movement 30% to 1500%, check every 5.0mm, measured sensitivity 4.016mm/pulse, measured minimum 91%, maximum 109% over 851.3mmThat's enough for today.

-

@JohnOCFII brilliant results that is a huge improvement

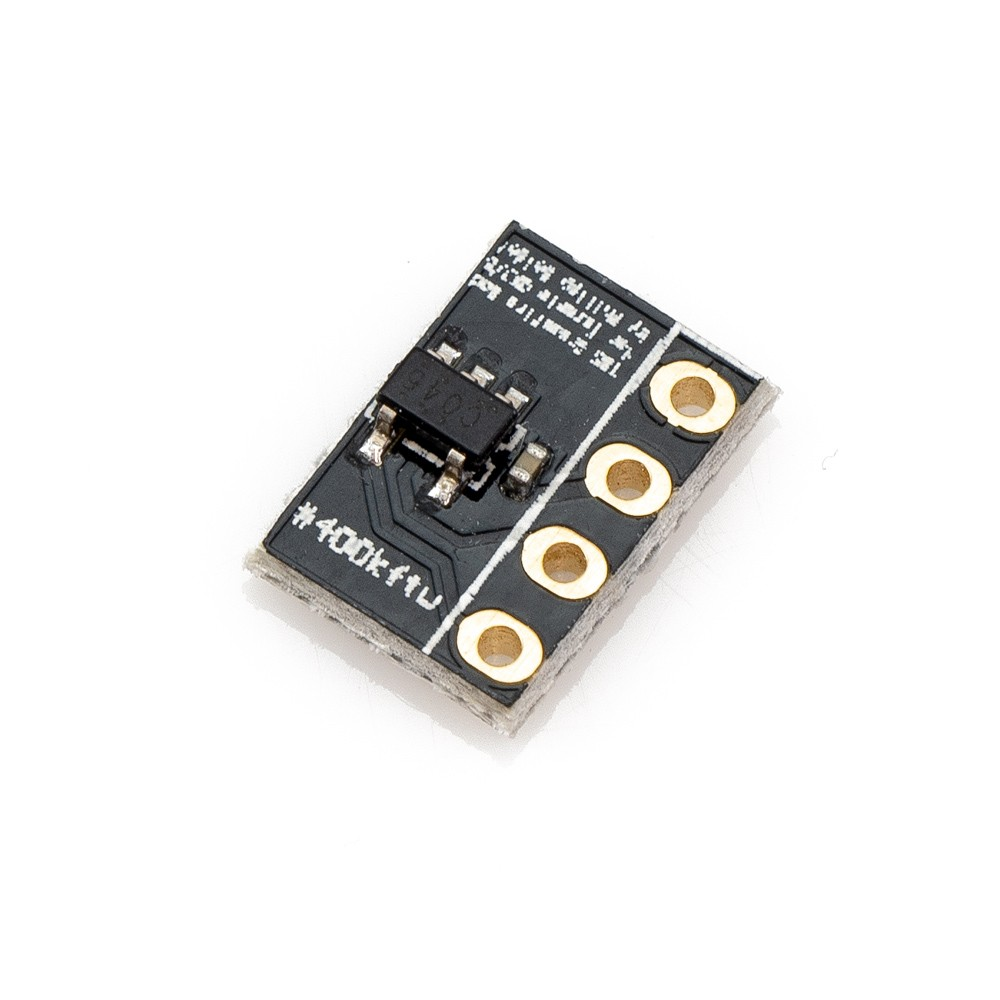

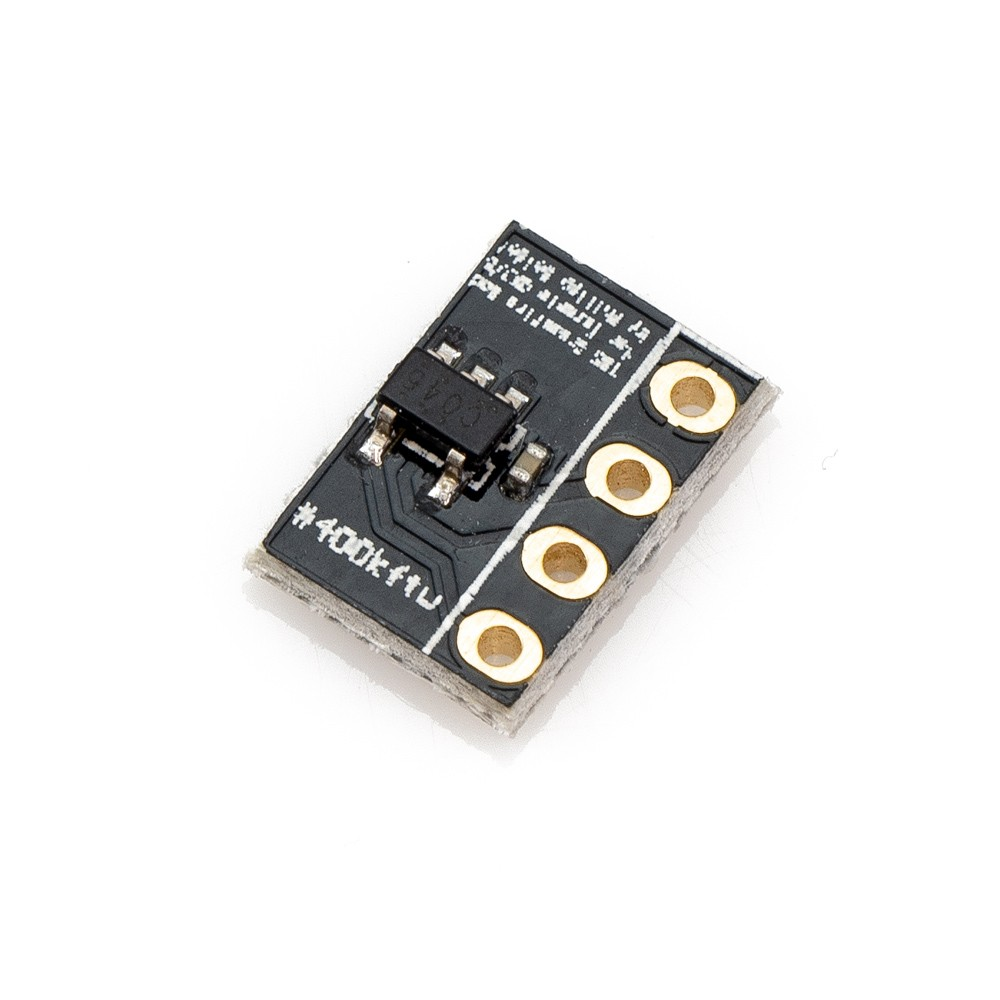

I actually have a C045 single inverter from my TBS Crossfire mod lol; might give it a shot

-

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

minimum 91%, maximum 109%

awesome

so would be cool if @dc42 can implement sometimes in future Schottky input on the MCU for endstop inputs as it is supported from what I see in the datasheet.

-

Thanks -- my next step is to re-test with the higher resolution encoder wheel. Right now I'm on the "middle" wheel.

-

@fractalengineer said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII brilliant results that is a huge improvement

I actually have a C045 single inverter from my TBS Crossfire mod lol; might give it a shot

Does that have the Schmitt trigger in it?

-

@JohnOCFII ah right, it doesn't.

I've found some in the same package though; might work on making a custom pcb with sensor and trigger included

https://lcsc.com/product-detail/74-Series_ON-Semiconductor-ON-M74VHC1G132DFT1G_C233567.html

-

@fractalengineer said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII ah right, it doesn't.

I've found some in the same package though; might work on making a custom pcb with sensor and trigger included

Cool idea! I was just thinking, "well, it looks like I've got a usable solution -- now how am I going to package up this mess..."

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

minimum 91%, maximum 109%

awesome

so would be cool if @dc42 can implement sometimes in future Schottky input on the MCU for endstop inputs as it is supported from what I see in the datasheet.

Yeah, it would be. And based on my testing so far, I wish I had known that the CONN_LCD input apparently does have the same input filter (or something) as the e0 and e1stop. I certainly got less wacky results once I switched from CONN_LCD to e1stop.

-

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

The LED on the optical sensor now is behaving opposite to the sensor on the DUET e1stop.

Yes, it's inverted, but it makes ZERO difference since you are not using it as an endstop, but rather as a pulse for the filament monitor.

If you care to have the lights be the same, just wire two of the inverters in series and it will invert twice and make it not-inverted anymore!

Pin 1 input from sensor

Pin 2 connect to pin 3

Pin 4 connect to Duet. -

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

If you care to have the lights be the same, just wire two of the inverters in series and it will invert twice and make it not-inverted anymore!

Pin 1 input from sensor

Pin 2 connect to pin 3

Pin 4 connect to Duet.Oooh! I might try that. Thanks!

-

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

Spacing seems somewhat different too, but I can't imagine that matters in this case.

The timing difference between the Saleae edge and the Schmitt trigger inverter edge is all caused by the difference in "threshold" voltages between the two and the VVVVEEEERRRRYYY SSSSLLLLOOOOOOOOWWWWLLLLYYY changing signal from your optical interruptor.

The Saleae trace you posted shows the Schmitt trigger working PERFECTLY!!!

You're only getting one transition for each fuzzy/mushy/multiple-edge-bouncing-ball transition you see in the optical-interrupter output Saleae signal.

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

The Saleae trace you posted shows the Schmitt trigger working PERFECTLY!!!

That is fantastic to hear!

I went ahead and passed the signal through the adjacent inverter. I don't know why, but it makes me smile.

-

Another test before I swap encoder wheels. Very consistent results. This was a 3D Benchy.

Pulse-type filament monitor on pin !e1stop, disabled, sensitivity 4.000mm/pulse, allowed movement 30% to 1500%, check every 5.0mm, measured sensitivity 4.034mm/pulse, measured minimum 91%, maximum 109% over 871.3mm -

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

Very consistent results.

That looks really great!

The pulse-type monitor already has some filtering in the code, so I really should learn how to build the code and see if I can implement a delay-based debouncer in there with a setting so it can be configured for zero to a LOT of debouncing.

-

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

check every 5.0mm, measured sensitivity 4.034mm/pulse

I wonder if you should be checking less often.

Checking every 5mm when you only get one pulse every 4mm means the checking mechanism basically gets 0 or 1 pulse to go by.

Maybe check every 20mm? Would that make too big a mess when you DO run out of filament?

Hey, can you do some tests where you cut the filament mid-print a few times and show how nice the restart looks?

(I can do that also, but I'm in the middle of a paid job that will keep my printer running 24/7 through mid December)

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII said in Inconsistent results with optical encoder wheel filament sensor:

check every 5.0mm, measured sensitivity 4.034mm/pulse

I wonder if you should be checking less often.

Checking every 5mm when you only get one pulse every 4mm means the checking mechanism basically gets 0 or 1 pulse to go by.

One thing I plan to do is try the encoder wheel with more "spokes." This should give me a pulse closer to every 2.4mm. I can then also increase the distance. I know that @fractalengineer was checking at a much longer distance.

Maybe check every 20mm? Would that make too big a mess when you DO run out of filament?

Hey, can you do some tests where you cut the filament mid-print a few times and show how nice the restart looks?

Oh yes, once I try the other wheel, my next plan is to actually test what happens by both cutting the filament before it gets to the wheel and then changing/restarting to see then impact, as well as to cut the filament after it has passed through the encoder wheel (to replicate a non-moving, or jammed state), and then to restart from that.

John