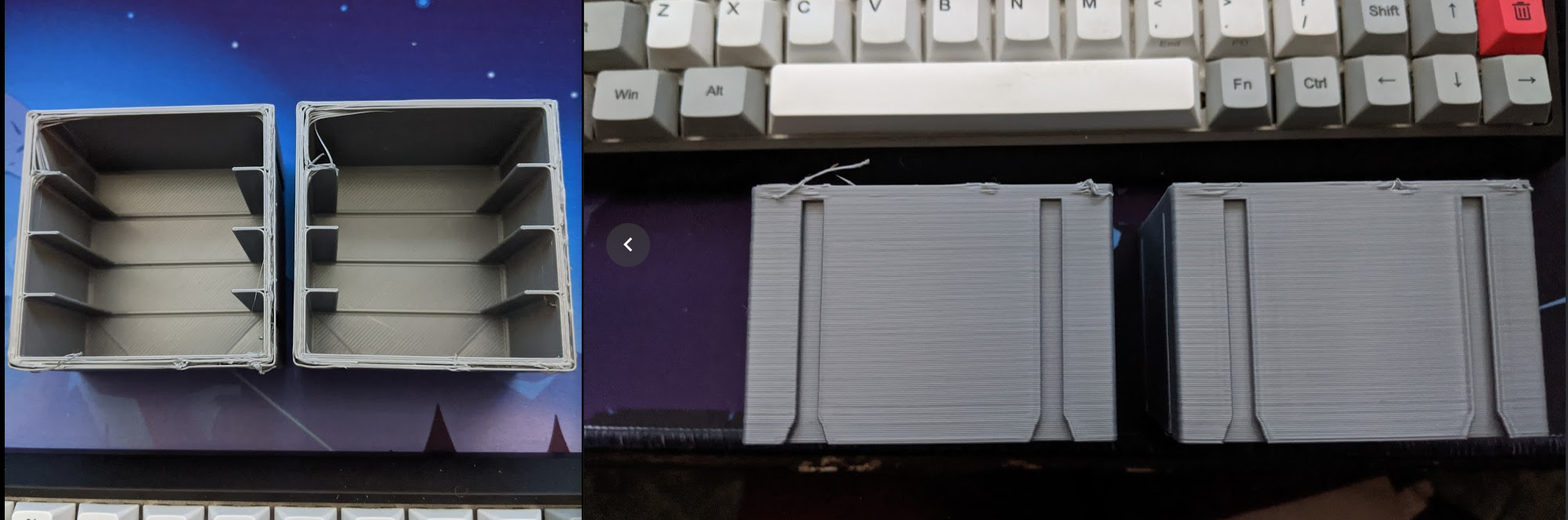

Identical artifacts/issues on two parts on the same print job

-

These were printed at the same time on my single extruder corexy build. The issues are consistent and appear on both objects. not sure why. is this a slicer issue? it seems too consistent to be something like a blob or extruder malfunction. The same object prints fine on my other printer. although they're pretty much different in every way.

Im having a rough few days with things going wrong if you've seen my recent post history lol.

-

@Turbo Bumping because i was able to upload the picture finally.

-

Would need to see some more information to get any real feedback.

Details on the printer (extruder, nozzle, etc etc)

slicer settings and config.g settings, etc.Just based on the photo, printing too fast?

-

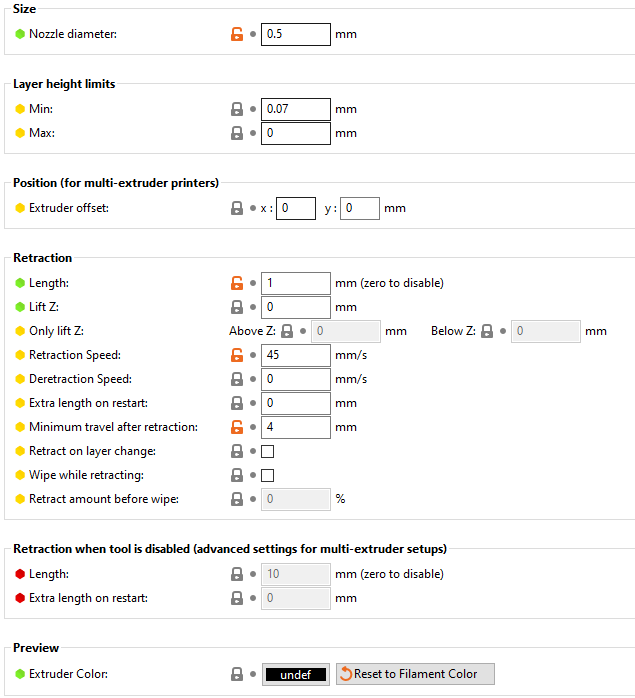

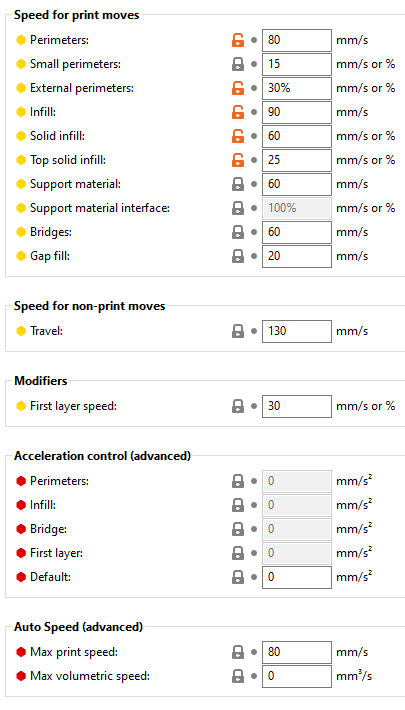

@Phaedrux Titan Aero Extruder on a Dbot frame, .5mm e3d nozzle at .35 layer height. Let me know if any more info is needed

Config.g file

; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S0 ; Drive 3 goes forwards M569 P4 S1 ; Drive 4 goes forwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X100 Y100 Z423 E394 ; :870(E2) ; Set steps per mm (Start:Z415) (chimera value 870) M566 X1000 Y1000 Z240 E600:600 ; Set maximum instantaneous speed changes (mm/min) (OG E600:600) M203 X18000 Y18000 Z2400 E3600:3600 ; Set maximum speeds (mm/min) M201 X1250 Y1250 Z250 E2000:2000 ; Set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E850:850 I50 ; Set motor currents (mA) and motor idle factor in percent M84 S30 ; Set idle timeout ; Axis Limits M208 X-10 Y-10 Z0 S1 ; Set axis minima (chimera/original y value = 0) M208 X300 Y185 Z300 S0 ; Set axis maxima ; Endstops M574 X1 Y2 S3 ; Set endstops controlled by motor load detection ; Z-Probe M574 Z1 S2 ; Set endstops controlled by probe M307 H3 A-1 C-1 D-1 M558 P9 H5 F750 T7200 G31 X25.9 Y0 Z02.3 P25 ; Probe Offset - Increase for Nozzle down, Decrease for Nozzle up (chimera value .6) M557 X26:280 Y5:185 S50:45 ; Define mesh grid ; Heaters M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0 ; Heater 1 M143 H0 S110 ; Set temperature limit for heater 0 to 110C M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H1 S275 ; Set temperature limit for heater 1 to 275C ; Heater 2 (disable for Titan Aero) ;M305 P2 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 2 ;M143 H2 S275 ; Set temperature limit for heater 2 to 275C ; Fans M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S165 T55 H1:2 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P2 S0 I0 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0CSlicer Settings (.6 line width)

-

your thermistor configuration is wrong. B4138 is the default.

but that should not cause layer shifts. -

@Veti if it works is it wrong? i dont ever have temp issues.

-

@Turbo

you might be printing at the wrong temperature. -

@Veti what would be the correct value?

-

@Turbo

what is the exact type of thermistor you have? -

@Veti the one that comes with the e3d v6 ecosystem of hotends. nothing special.

Seems to be 104gt from google results -

if its a genuine e3d then its B4725 C7.06e-8

-

@Veti so would the code just look like...?

M305 P1 T100000 B4725 C7.06e-8 R4700 ; Set thermistor + ADC parameters for heater 1also what about the bed heater? its a keenovo assembly

-

in rrf2 yes

-

@Veti newbie question but how can i tell if i have rrf2 or not? thats the code on the printer in question, and this is the code on my other printer. Different M commands

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T100000 B3988 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limitalso i now realize i have the bed therm for this config set as an e3d therm and not the actual one. i think theyre backwards.

-

-

@Turbo said in Identical artifacts/issues on two parts on the same print job:

M906 X1000 Y1000 Z1000 E850:850 I50 ; Set motor currents (mA) and motor idle factor in percent

what motors have you got?

-

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 2.05.1 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2020-02-09b1 -

so you are on rrf2 here.

-

@Veti mototrs are part no 17hs19-2004s1.

I dont think theyre the culprit because i have had good prints before with them. The printer sat for 6 months or so so i came back to a bunch or random issues and not remembering much about the printer -

@Turbo said in Identical artifacts/issues on two parts on the same print job:

17hs19-2004s1.

those are 2A motors. you are running them with not enough current. set the current to 1500ma