Tips to mitigate vertical artifacting Duet 2 Wifi

-

@Veti No worries on that. It's kind of a mess at the moment, but here are some shots of the stuff that matters.

-

-

Looking at the long spans on the belts remind me of another issue I had (I run a delta though). The constant tension on the motors eventually affected the bearings in the motors. I eventually replaced the motors, but I also added in thrust bearings* between the pulley and the motor, so any lateral pull on the motor shaft is limited by the pulley pushing down on the thrust bearing against the motor. Granted the motors were also like 7 years old so they did good. Still, I'd at least consider these since they are easy to replace, inexpensive, and they worked great for me removing a visible deflection in the motor shaft when the belts were tightened. Tuning after that I tuned for better jerk and accel, but that could have been the motor model changing. Still, these did have noticeable improvement on the hash pattern for the old motors before I replaced them, but the artifacts were not fully resolved until I changed slicers. I had to format my computer recently and didn't deem those pictures as worthy of backup....heh.. and it's kind of hard to describe how it changed to a kind of fainter or less pronounced but crisper or finer lines at the same time.

*- https://www.amazon.com/gp/product/B07QKKYKR8/ -

taking the last picture as a reference.

the belt at the top motor is angled and goes from the bottom path to the top path. that could be the cause of those artefacts. the belt would be constantly pushed upwards on the pulley.

looking at the bottom motor. here the belts are not parallel. this will cause dimensional inaccuracies. the belt path creates a triangle where the belt moved is longer than the axis movement it causes.

That part of the belt path and the one on the x axis has to be parallel to the extrusions. -

@Veti I will take another look, I might have to make some modifications. I don't know if the setup I have now will let me get any closer.

-

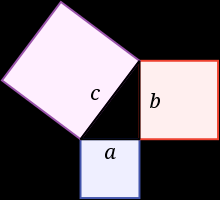

This is to illustrate why the inner belts need to be parallel.

Assume C is the belt with a length of 11cm (high numbers to make the point)

A is the length of the y axis that it can move and is 10cmYou are printing a straight Line in Y direction with a length of 11cm.

The Motors pull 11cm of the belt, but the y axis only moves 10cm. causing the line to be printed to have a length of 10cm.

Even worse. if you dont have the same triangle on the other side of the y, you now have 1cm extra belt in your belt path. this reduces the belt tension.

-

I would be surprised if the exoslide printer design had such a common corexy flaw.

-

@Veti Check this out, top pic, Gates belts. Bottom pic cheap Amazon belt. My only guess if the cheap belt teeth are more forgiving.

-

that is indeed an interesting result. i guess time to wait for the toothed idlers to arrive.

the belts from your pictures do not look like gates belts though.

-

@Veti They are gates high temp belts. That could be the issue. Maybe these are stiffer then regular belts. https://www.printedsolid.com/products/gates-powergrip-2gt-high-temp-belt-1m

-

@brotherchris not to be the party pooper but I have standard 2GT with toothed idlers and I get the same issue as yours (or at least the end result is very close).

I ended up re-engineering the whole thing, now waiting for a few more piece to arrive to see if it actually worked.

-

@matt3o No, great to hear, I am too working to find ways to improve.