Battling sources of vibration and noise

-

@Nxt-1 Ug, that sucks.

-

Finally some decent news, the dampers arrived as predicted on the 25th. Installation was quick and easy, two setscrews and done. On thing that I noticed right away is that they are light, the datasheets specs them at 61g. Compared to the ~300-400g of lead I had on there before, that's absolutely nothing. This made my quite hesitant as to there performance.

Yet after some first moves I can say that the dampers do not disappoint. Not a magical noise reducer by any means but they definitely take the edge off and bring the noise down to something acceptable. I need to do some more testing but at this point I'd say they are worth ~€120 for a set.

At this point I still plan to have the motor brackets machined out of steel, but for a number of reasons (including cost) that will have to wait for a while. What I do want to try out soon-ish is removing the stepper face dampers again. Just to see what would happen.

-

Nice.

(filler text).

-

@Nxt-1, now that you've had the mechanical clean dampers on for a bit, have you observed any print quality effects?

-

@Kolbi said in Battling sources of vibration and noise:

@Nxt-1, now that you've had the mechanical clean dampers on for a bit, have you observed any print quality effects?

I am sorry for the late reply, I have been and will continue to be limited on time for 3D printing stuff sadly. My opinion has not really changed since my last post. I have done some small prints now and then with the Duet running all out at 2.4A and the noise is acceptable. I still have to test without the face dampers and printing at the outer edges (so the carriages have to move faster) but I do not have a plan for when I am going to do that.

In terms of actual print quality I see no difference. There were no real print quality issues to improve on anyway. If anything I'd expect increased ringing at corners due to the increased rotational inertia. Yet again the viscous clutch style internals of the dampers should combat that as much as possible.

-

@Nxt-1, thanks for the update - definitely interesting subject matter.

Cheers,

Kolbi -

It seems things never go as planned, but in a good way this time

Yesterday I got a marketing email notifying me off 50% cnc machined parts in stainless for a couple of days, so I guess it is go time.

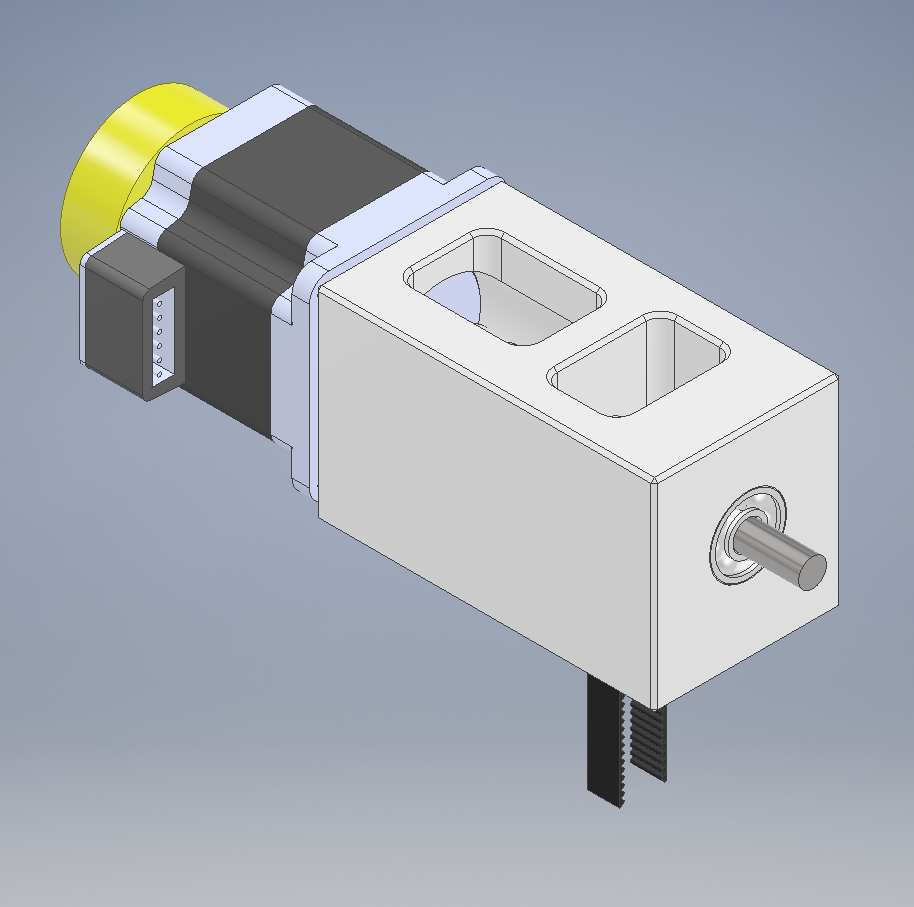

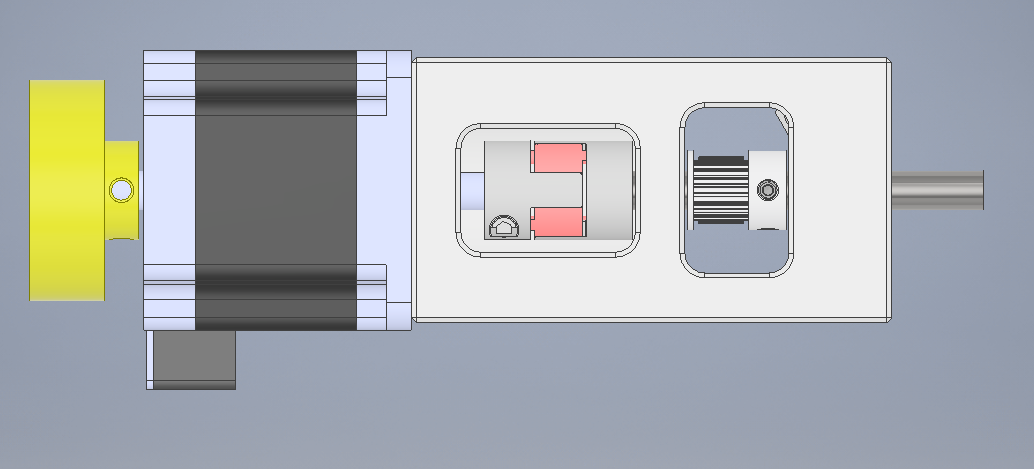

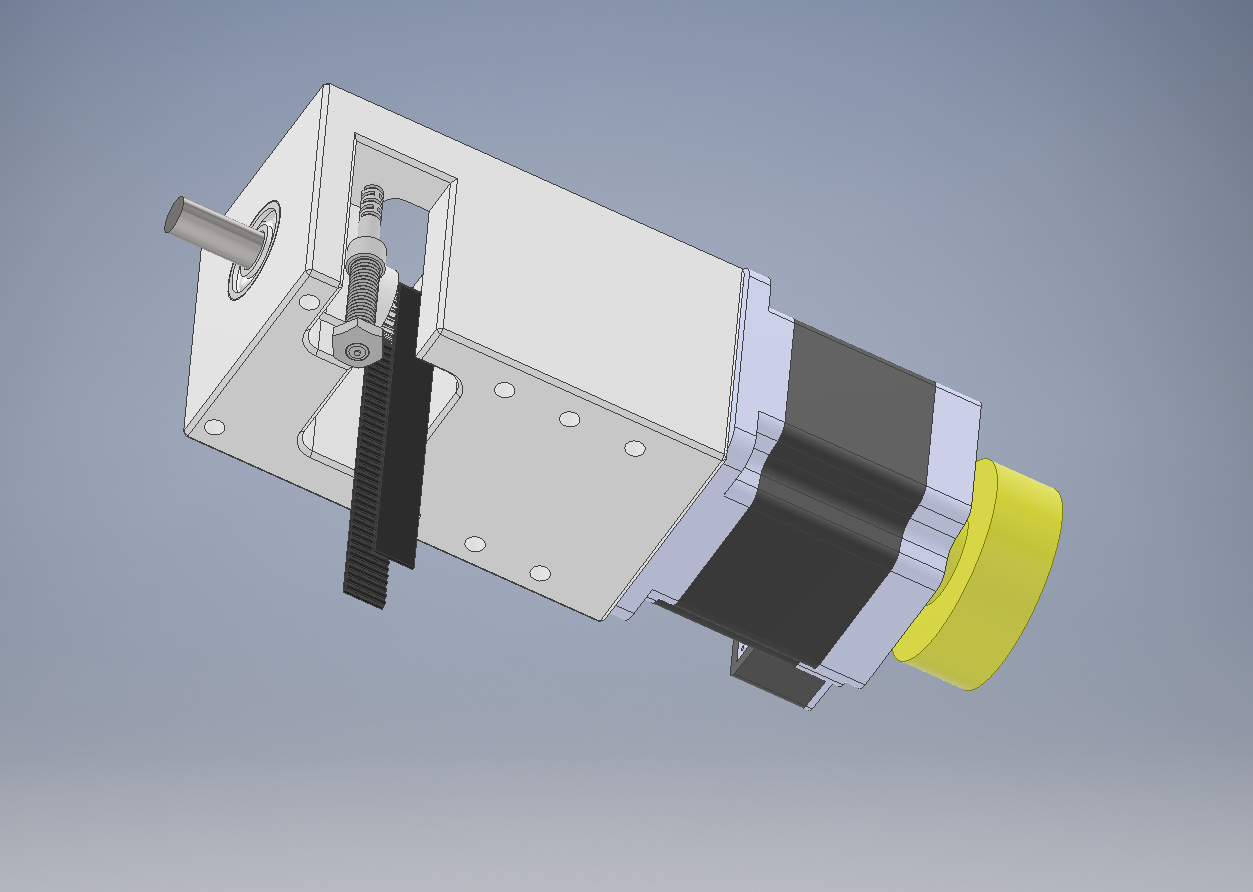

Yesterday I got a marketing email notifying me off 50% cnc machined parts in stainless for a couple of days, so I guess it is go time.I have attached some pictures of the complete assembly as well as the step file for the backet itself. If you have remarks, shooth.

-

Out of stainless?

Might be a little bit overkill

Also, retaining rings for the bearings? Or are you planning on them being a press-fit?

-

@theruttmeister said in Battling sources of vibration and noise:

Out of stainless?

Might be a little bit overkill

Also, retaining rings for the bearings? Or are you planning on them being a press-fit?

100% stainless is overkill, but it's a deal of economics at this point. I want them made out of steel instead of aluminum just because of the higher mass. And with the sale I have access to as this point stainless is actually cheaper then the other steels and just about the price of alu. So I figured stainless it is

Good point I should double check the bearing fits, I did plan them to be a loose press fit.

-

It's about time for an update on this topic, perhaps even the final one.

I have received the stainess brackets a couple of weeks back and installed them right away. At first, with the stepper face right against the face of the bracket but that was not a success. The idea for that was that bolting the stepper to the bracket would form 1 rigid system with a larger mass and thus resulting in less vibrations. In reallity the bolted connection does not provide enough clamping force to form one rigid system, but rather the stepper vibrating against the bracket.

With that option scrapped I re-installed the stepper dampers I used before. This helped as expected a great deal and brought the noise levels down to that I was used to from the 3D-printed brackets, or lower. I never really did numerical measurements of sound pressure levels due to a lack quipement to do that properly. So it is quite hard to say whether the noise is lower that it was before with the plastic brackets, if so not by a whole lot.

For me this concludes this series of thread around the noise topic. I have exhausted all the things I wanted to try out in short to medium term and achieved decent results along the way. In the longer future I might experiment with different steppers and possibly another style enclosure.

-

interesting for me - also I think your efforts bear some note of overkill but I am similar

Trying to give ideas:

Trying to give ideas:If you have money to spare, you could try dedicated stepper motor couplings like the "stepflex STF" for dampening of steppernoise?

And if you have time to spare you could try out all things possible with the trinamic chips in software?

And if you want to touch the stepper again: What about these supersmooth steppers from "lin engineering", from what I have seen in your fotos (oriental 0.9°) a similar resolution/power should be obtained from the "G5709 series". You get them cheap on the bay sometimes but I do not know how many of these offered there are actually "copies" and not original...

Did you have time to try the https://duet3d.dozuki.com/Wiki/Gcode#Section_M593_Configure_Dynamic_Acceleration_Adjustment ?

Just thingking out loud

-

@LB said in Battling sources of vibration and noise:

interesting for me - also I think your efforts bear some note of overkill but I am similar

Trying to give ideas:

Trying to give ideas:If you have money to spare, you could try dedicated stepper motor couplings like the "stepflex STF" for dampening of steppernoise?

Do you expect these to preform significantly better than the rather generic couplings I have now?

And if you have time to spare you could try out all things possible with the trinamic chips in software?

I havent really tried anything here, AFAIK you can only tune some parameters aiding in standstill noise with the drivers on a Duet 2. (which isn't an issue here) Correct me if I am wrong

And if you want to touch the stepper again: What about these supersmooth steppers from "lin engineering", from what I have seen in your fotos (oriental 0.9°) a similar resolution/power should be obtained from the "G5709 series". You get them cheap on the bay sometimes but I do not know how many of these offered there are actually "copies" and not original...

A different brand of steppers might be on the long term planning and the ones you refer to could be interesting. It seems Lin Engineering does't spec the coil inductance though which is very important in combination with the 24V we have available with the Duet 2's

Did you have time to try the https://duet3d.dozuki.com/Wiki/Gcode#Section_M593_Configure_Dynamic_Acceleration_Adjustment ?

I have thought about that but even though there are vibrations in the motor/mount the prints are smooth. So there is noting for DAA to smooth out

-

@Nxt-1 said in Battling sources of vibration and noise:

And if you have time to spare you could try out all things possible with the trinamic chips in software?

I havent really tried anything here, AFAIK you can only tune some parameters aiding in standstill noise with the drivers on a Duet 2. (which isn't an issue here) Correct me if I am wrong

The Duet 2 uses TMC2660 drivers, that don't have stealthChop, which would be the big thing to try.

Unless you set something different they should have defaulted to spreadCycle, which makes them much quieter than something like an Allegro or TI driver...

Although you might get different results changing that parameter, fixed off-time tends to be nasty (it can give some really unpleasant resonant noise), but its worth testing the 0-2 values for D.I once got someone to try replacing resistors on an Allegro step-stick... you don't want to hear a printer with drivers that run at 16kHz.

People were upset from about 50 feet away.I've got a nice (and relatively cheap) BLDC servo, I still need to test it and see what sort of noise it makes...