idlers and shoulder bolts in a corexy

-

okay this I bet is going to sound silly.

I'm building (trying to) my 400x400x400 corexy and trying various motion system options.

Am I delusional or using decoupled idlers (ie: one shoulder bolt per idler) results in better quality print compared to 2-idlers-per-bolt?

I was using aligned idlers on the gantry then I tried with aligned idlers on the front blocks, but it seems that using separate idlers everywhere results in better quality (I'm 3d printing all the blocks).

I don't have hard proof... I'd need to print the same model with the same filament with all the configs. Just wanted to know if you experienced something similar or you have some math to back my story

-

How did you mount the pulleys/shoulder bolts? What do the printed pulley mounts look like?

If they are solidly mounted it shouldn't make any difference, except that it is easier to keep the belts aligned with the guide rails when the pulleys are stacked- there are fewer places for errors to creep in.

-

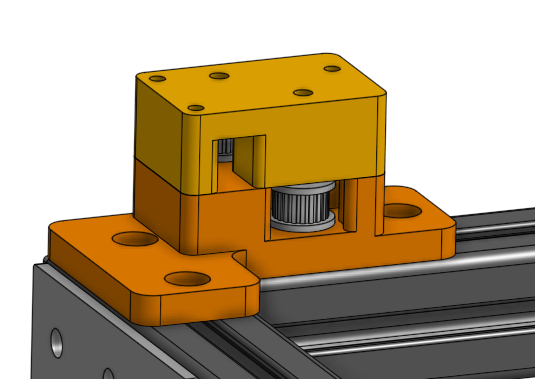

This is the front idlers block (2 shoulder bolts)

The version with aligned idlers is basically the same, just... aligned

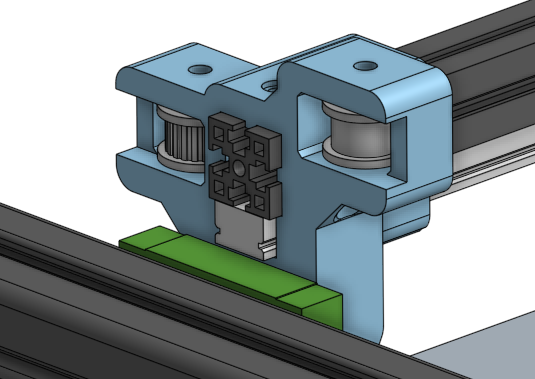

This is on the gantry

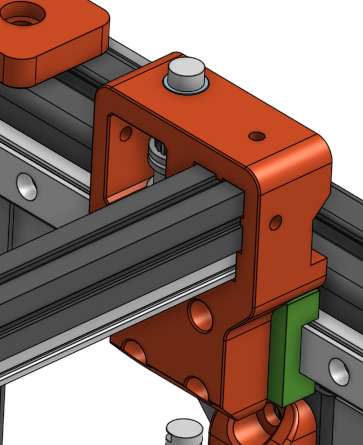

This is on one shoulder bolt

The extrusion on the gantry is 15x15, the frame is made of 30x30.

-

It looks solid enough....