The Mean Machine

-

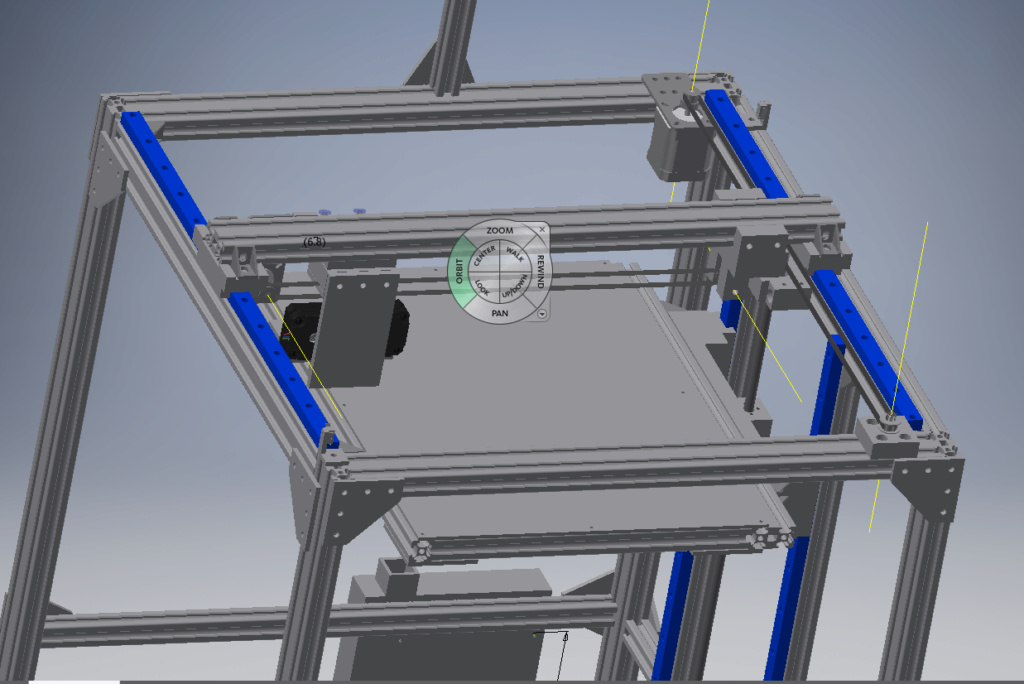

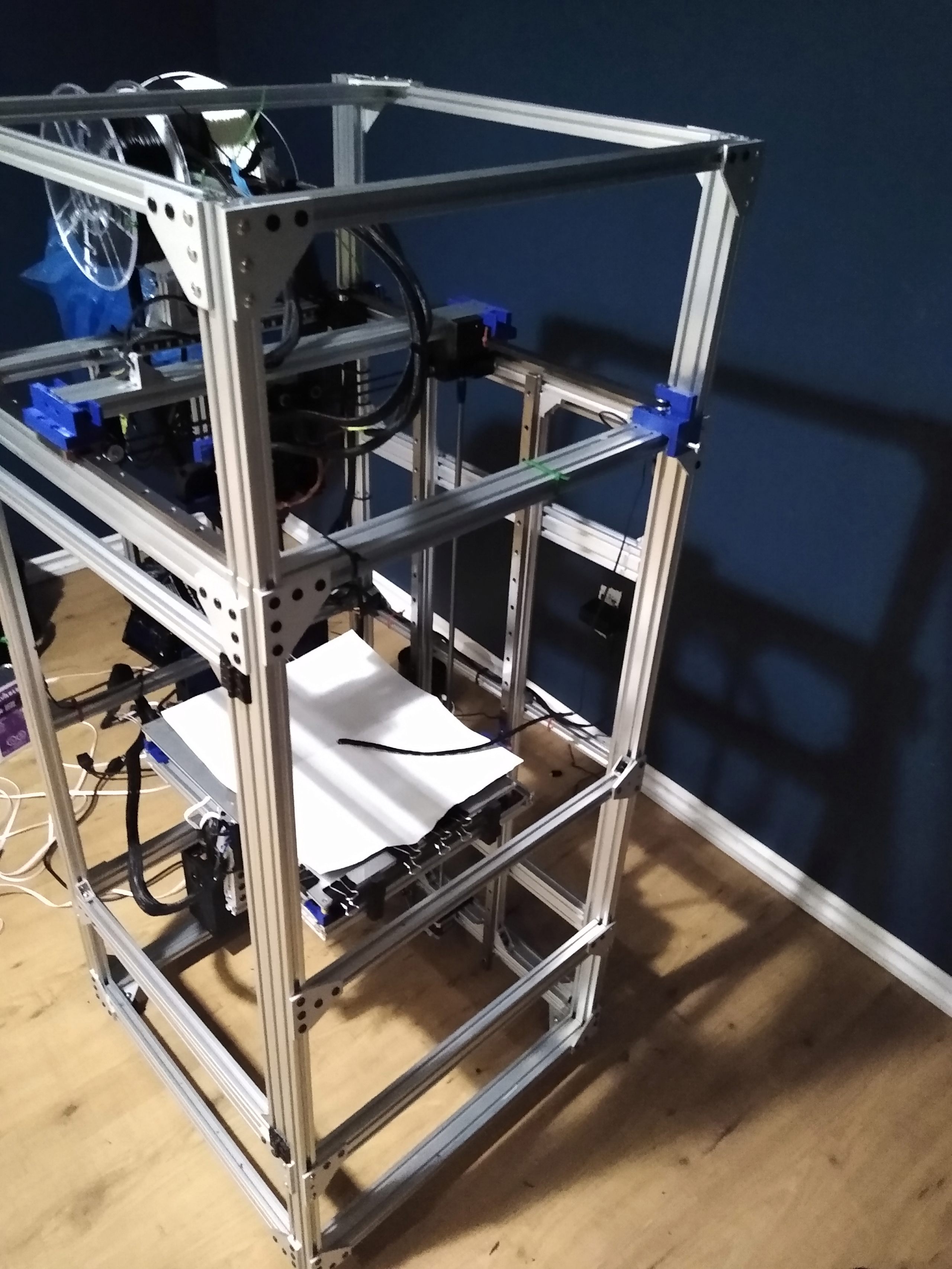

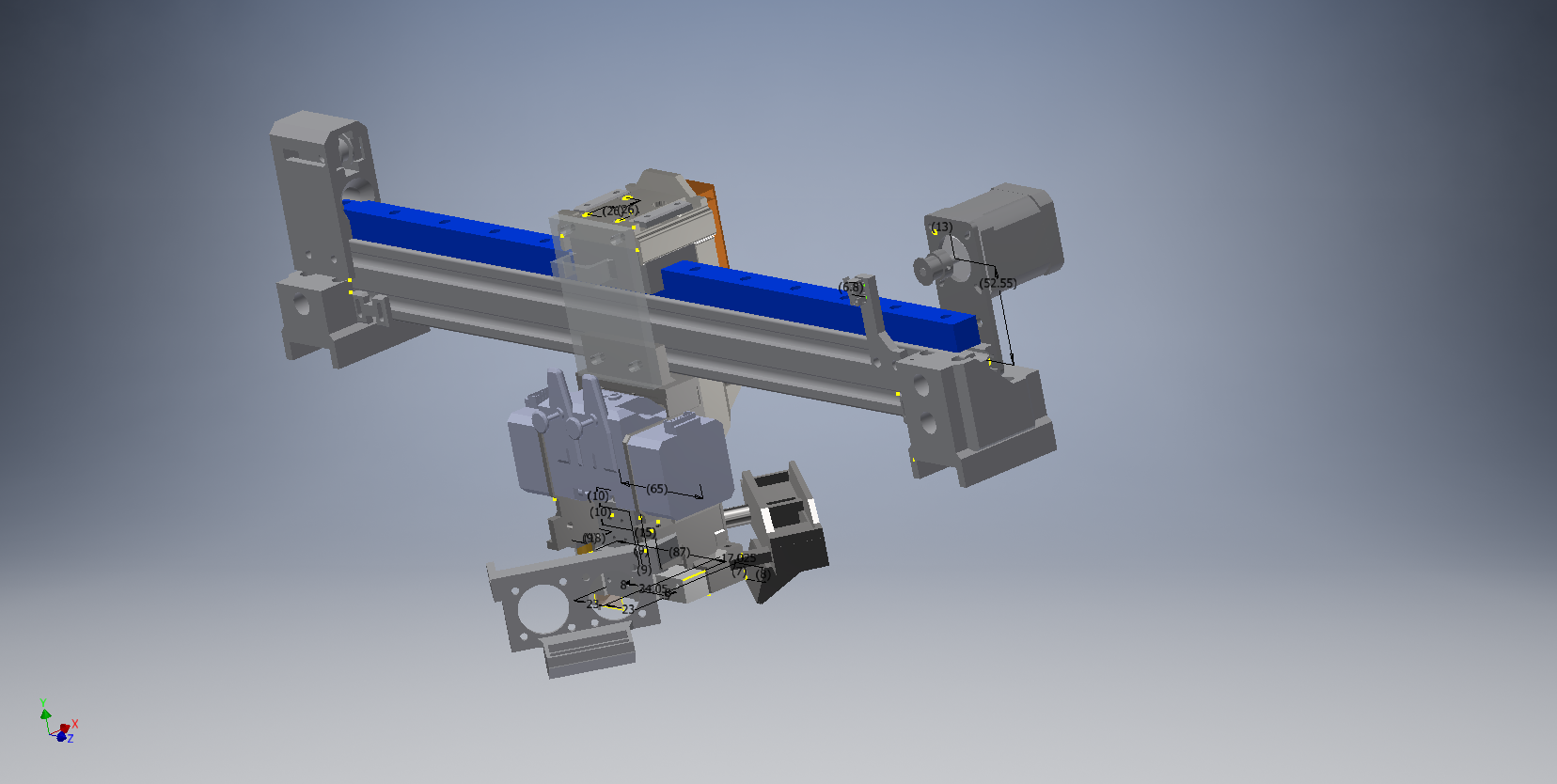

Here my machine , it has a duet 3 running in stand alone , i had a rostock max v2 before but i always been unhappy with some of the feature or quality of the piece it would print , i started looking at other printer i wanted dual extrusion capability but couldn't find one that had a decent build size , so i started toying around the idea of designing my own , i Used autodesk inventor a lots for drawing parts in the past so i went to work.

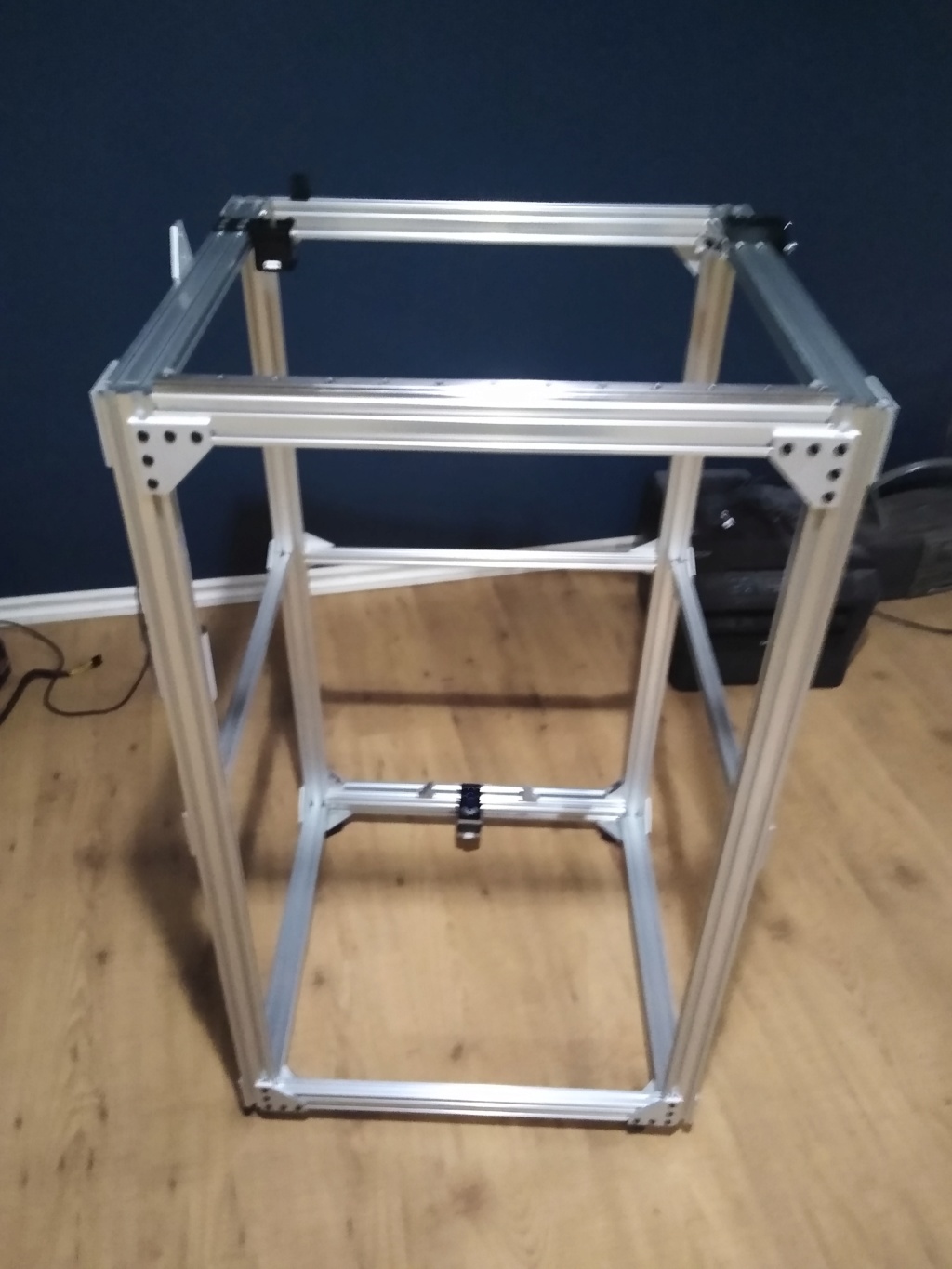

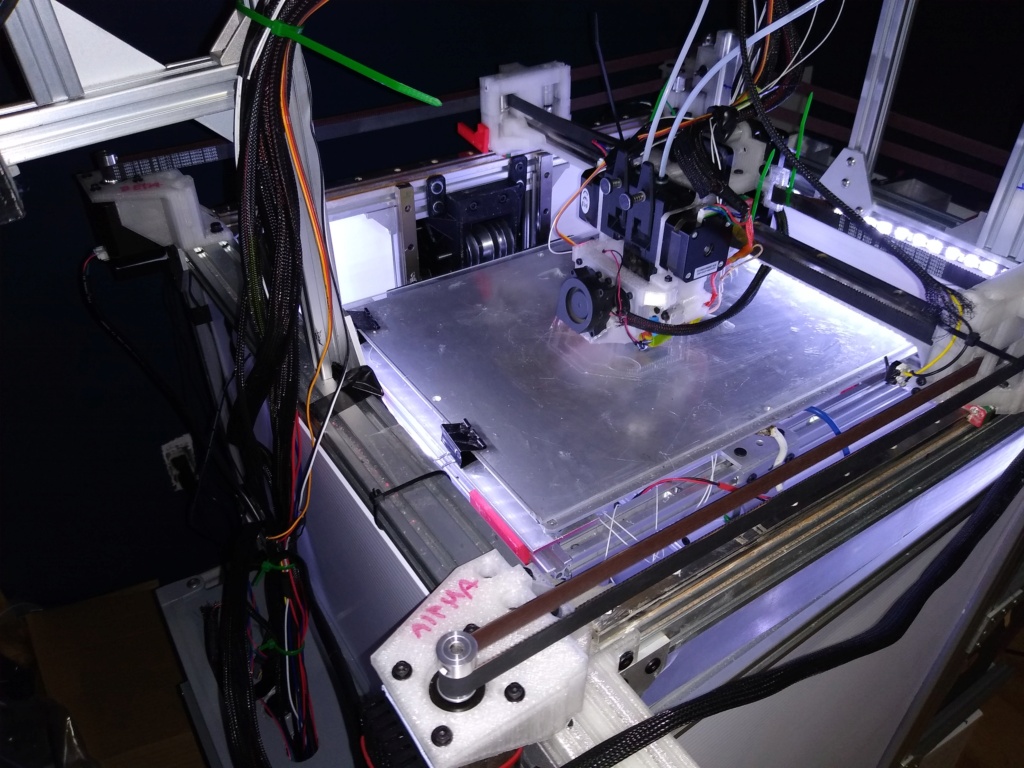

I looked at a few design and when for a more cube design since they seemed more robust than many other design around , main frame is made of 2040 aluminum extrusion bolted together with corner plate with a few reinforcement in the middle of the section the back one as more since it support the vertical rail. it sit on top of 4 big compression spring that act as leg so vibration is not spread back in the frame

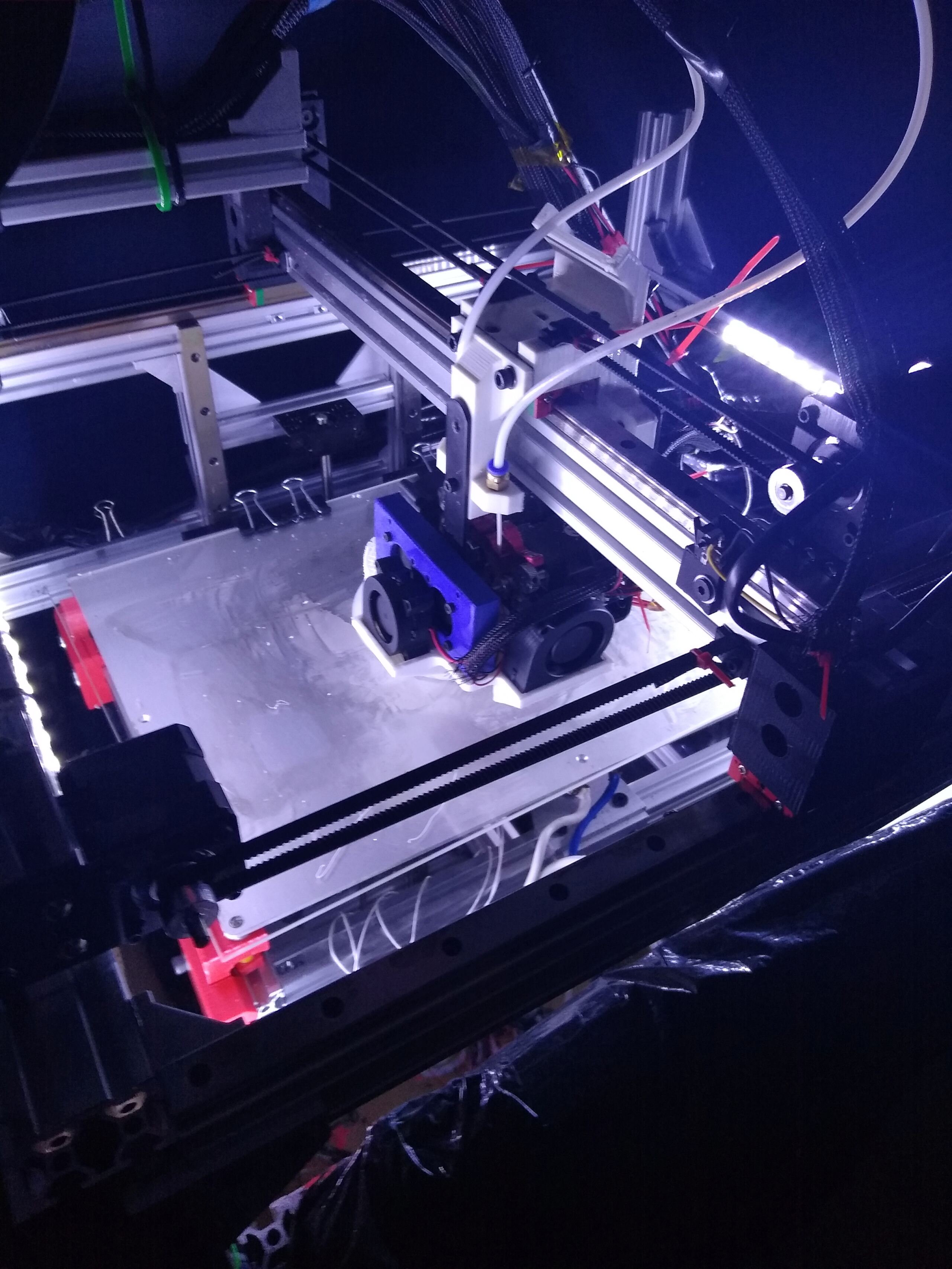

I wasnt ready for the challenge this build was going to bring me , my plan was to use the power supply i was using for my rostock a 850 watt 12 volt pc power supply , the heat bed it on the bigger side 300x400mm caused me many problem , i had to get a mosfet for the bed , still caused wire to melt , ended up having to buy a better mosfet and a dedicated 24volt power supply for the heatbed , it solve all my wire problem now they stay cool , the rest of the machine is still powered by the 12volt unit ,

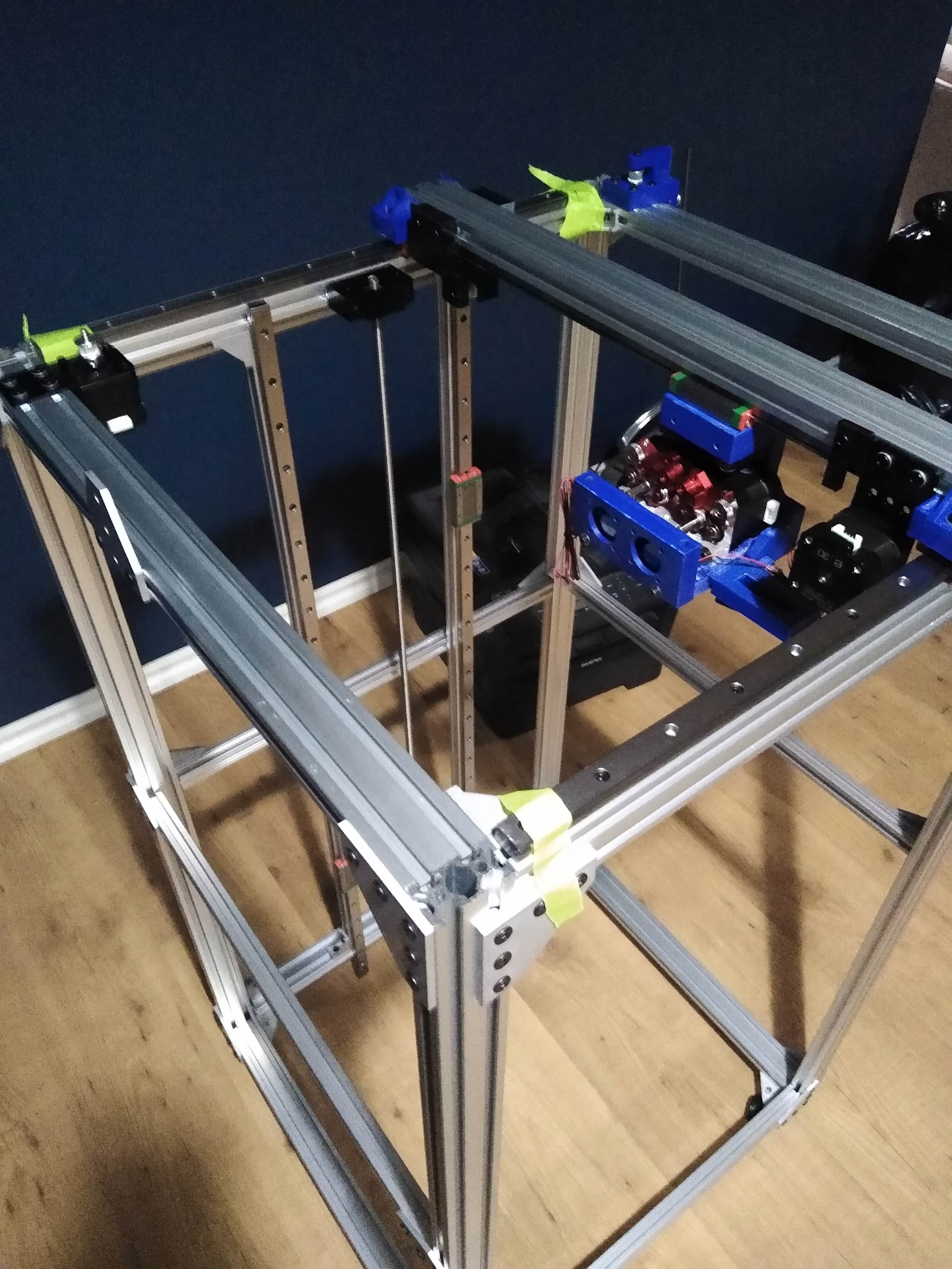

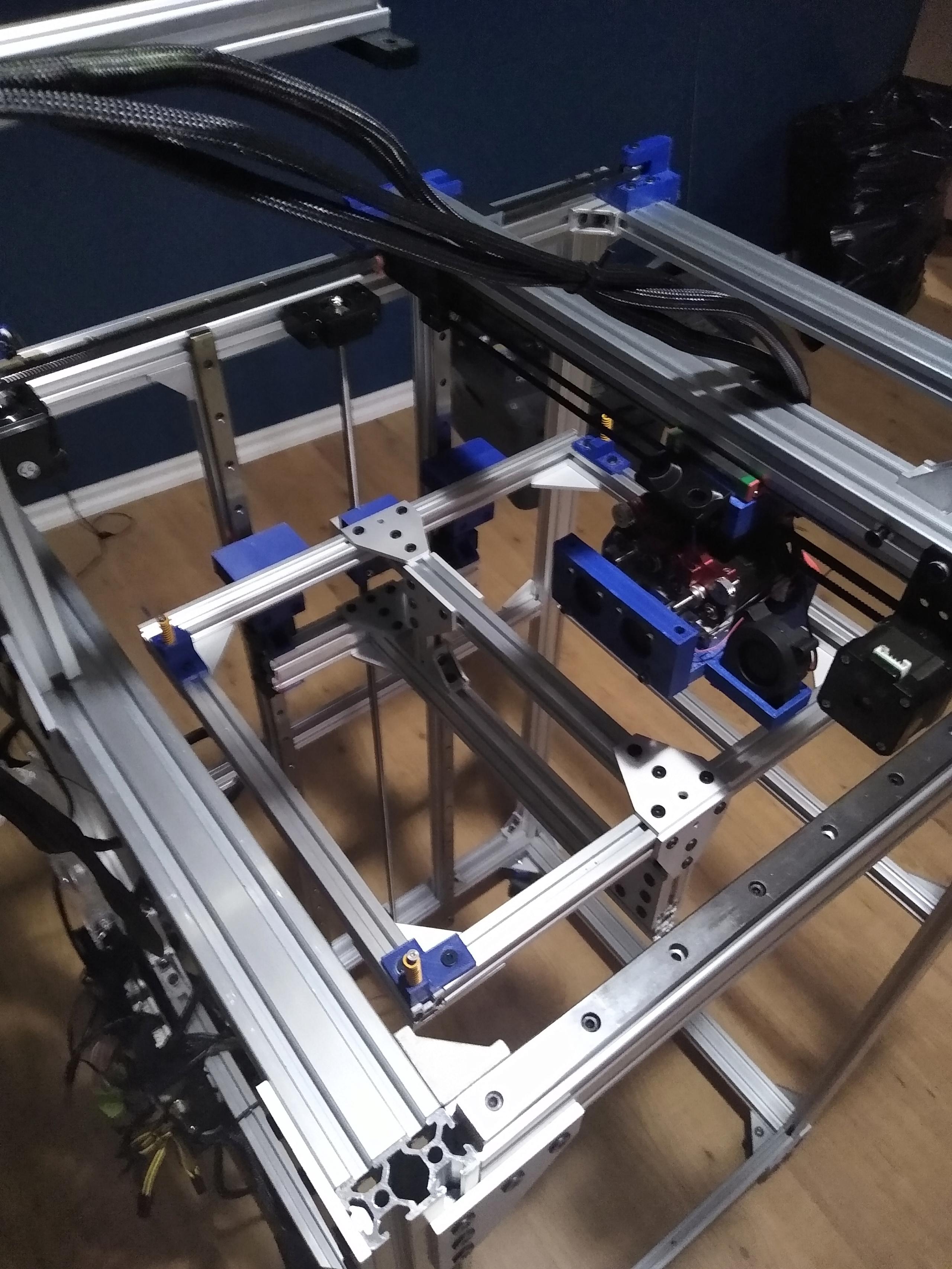

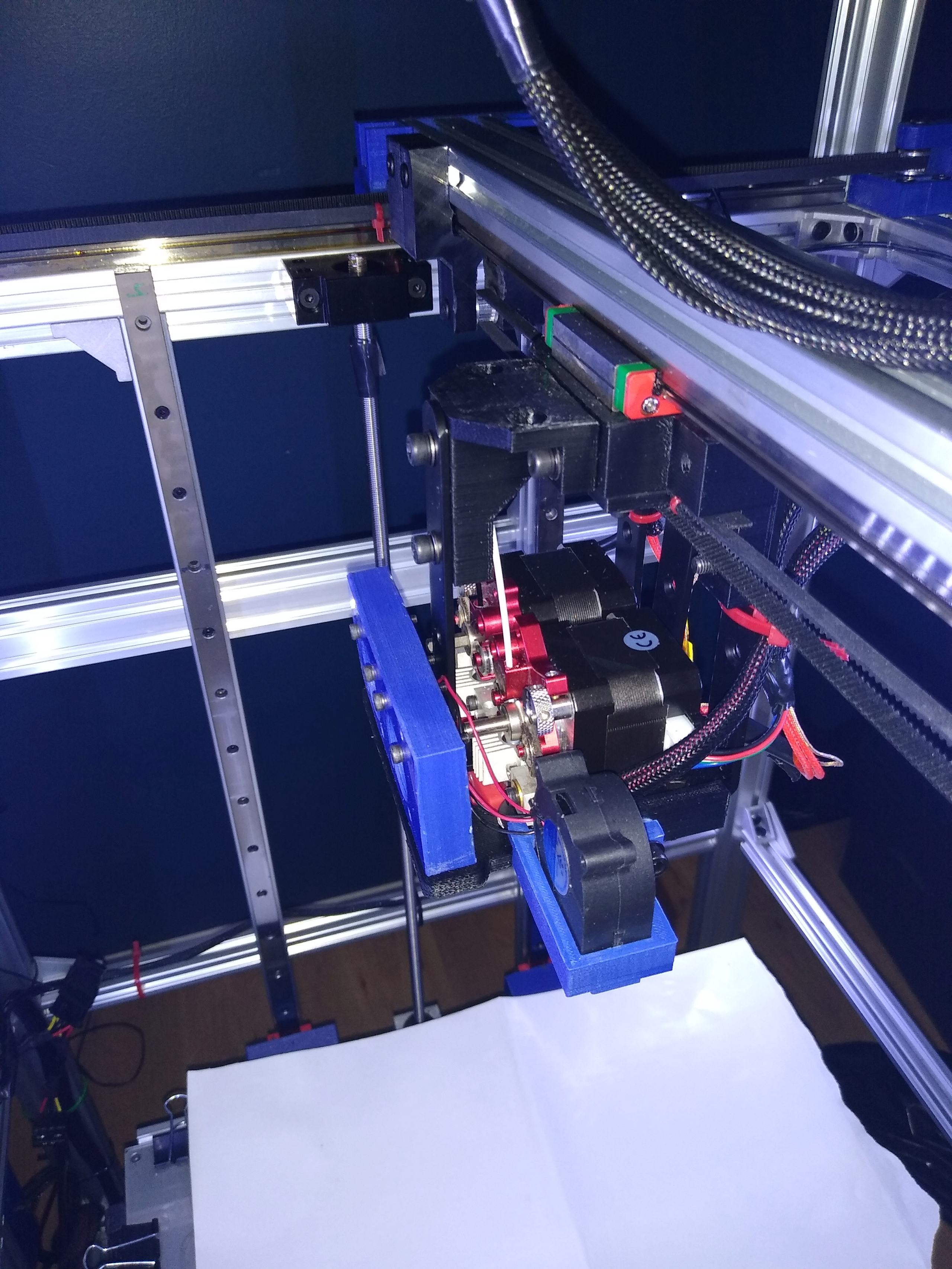

The Y gantry went throw a few change throw the project. each change solved an issue , each axis was supposed to be powered by only one .9 degree stepper motor but due to the weight and inertia of the gantry i had to add another one for the X axis , this solved many vibration problem , then came the Y axis , my original idea wasnt great to tension the belt and then found that the cheap linear rail on the Y axis had play in it since i had it in a reverse position , (should have bought the real hiwin) , ended up changing a few thing gain some MM in the Y axis , fixed most vibration now ,

Printable area so far seem to be around 300x350x600mm .i am using a Flexion HT kit for the extruder. print head has 3 blower to cool the print , 1x40mm and 2 x50mm. All stepper motor are .9 degree. The lead screws is m8 x1 one lead only , it take a while to home and get up but give good resolution on the Z plus the 40mm stepper is sufficient even when power is off to keep the Z up

I still have a few tweak to do here and there but overall it is really close of what i had imagined , i did break my budget a little as well , eventually i will have the whole printer encloses in some Acrylic sheets or similar material, i have 4 set of LED band in the printer as well, all running from the sata connector on the modular power supply ,

There is still a few things i will likely change and upgrade to my liking just to fix the last few issue and then the rest will be to figure out the best CURA setting for the material i use.

Here a few picture from the start to the end , it doesnt show everything otherwise there would be too many picture

The way the bed is attached to the rail this is now one big piece

-

Here a little Update

rant into some minor issues and made a few upgrade

swapped out the cheap chinese rail on the Y axis for a HIWIN HRG15 rail and block , Y axis problem solved,

Decided to had a BL touch as well got the real Antclad one

Next step is to rework my bed leveling system to eliminate the last few minor issue

and then hopefully i can actually start printing some goodies !

-

Well Him still toying around with the printer did a few change again , replaced the Z base for the bed , it now slide easier on the axis , and changed my bed leveling system as well , some further change in the future might be need to make it even easier but for now it good .

Modified the top once more , this time my spool will roll on roller with bearing so it should be smoother printing as well , both barrel of the flexion extruder have been swap for micro swiss Mk10 full metal barrel seem to have fixed many of the clogging issues i had earlier.Seem like so far that the optimal print speed for decent quality is around 40-45mm/s, thinking sometime of maybe trying some more compact stepper motor for the head to reduce the weight there

Still have to make my mind on an enclosure thinking about corrugated plastic but it hard to find sheet with a decent size for minimal cutting unfortunately

-

Hi,

So what sort of problem were the cheap rails causing?

How did you determine that they were the cause?

Thanks.

Frederick

-

@fcwilt there was play between the bloc and rail causing the head to move of probably 1-2 degree in the X axis , causing lower quality on the Y axis , hiwin rail fixed that , had problem with one of the block on the X axis as well , ball would not roll in it i took it a part and couldnt not find the problem so i replaced it by another one seem to be fine now , tolerance on these chinese block and rail are very poor they work OK when there 2 rail on the axis but only one they have too much play they .

-

So after a few print i found out that my main problem of poor quality were due to the flexion extruder not having enough pulling force causing extrusion problem .So i ended up ordering a Bondtech BMG-X2 .

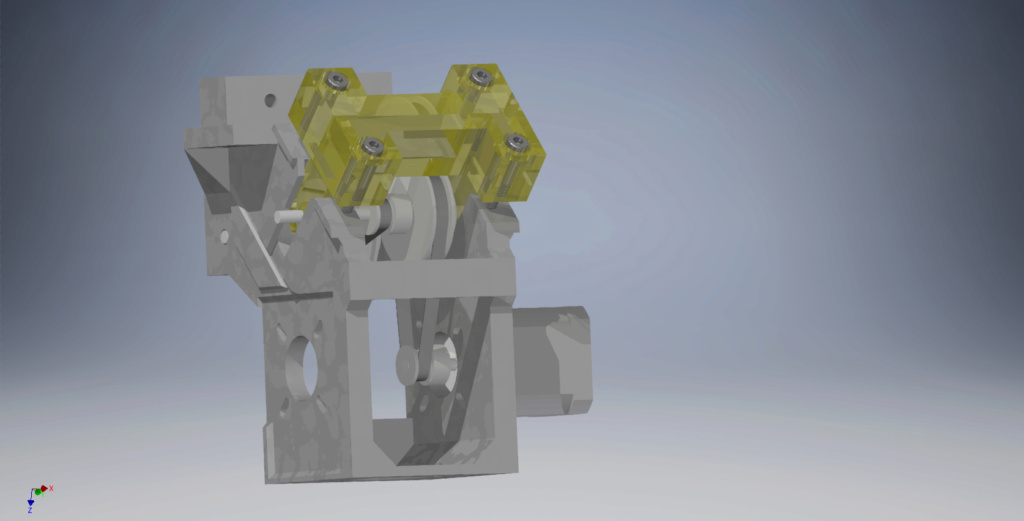

still waiting to get it to double check measurement but here what will most likely be. Bl touch probe will be closer abd on a more solid mount. Had to design an adapter to go from 20mm hole spacing to 34mm so i could use the flexion aluminum bar with my mk10 nozzle as well without having to buy a new hotend.

-

you could also install a second rail on the underside of the x axis. thast would further reduce any play from just one rail

-

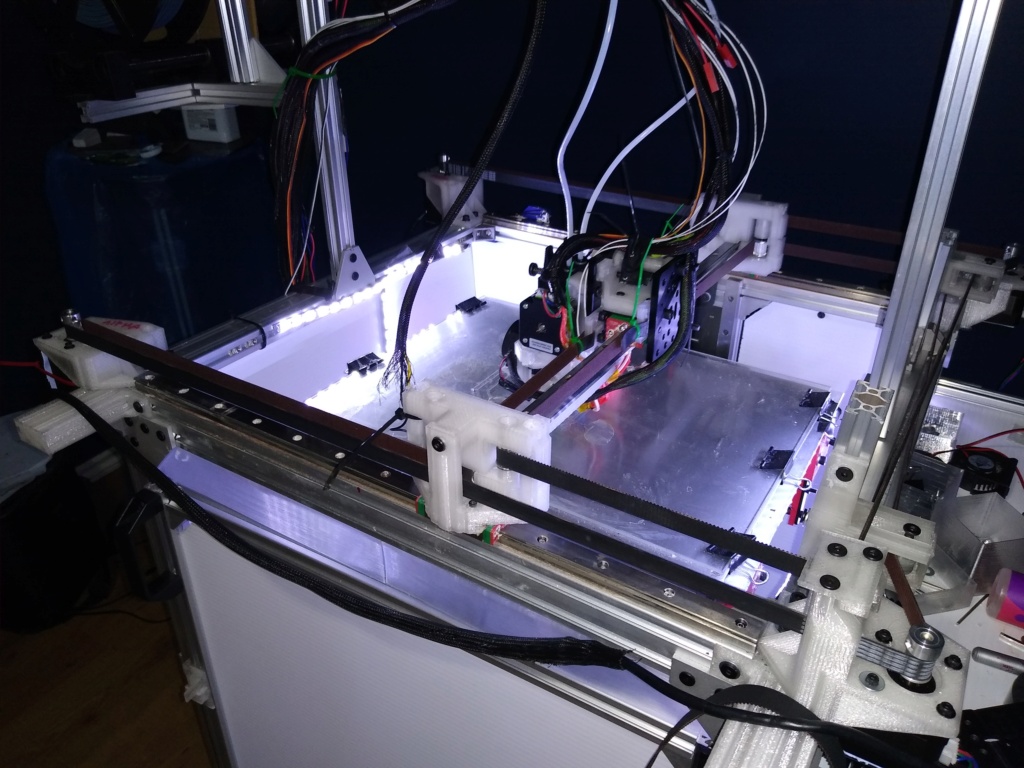

that is actually my Y axis it has an hiwin HGR15 rail with double ball bearing on both side there no play in there

-

Well here a little update ,

Him about done fixing problem on my printer , the BMGx2 swap seem to have fixed extruder quality issue , i Had a Z pattern on the side , found out my leadscrew was flexing under the weight , Tried some belt like some suggested , added a slight counter weight so the bed doesnt go down and make it easier to go up , it seem so far that the weight is enough that when power is off the torque of the stepper motor is enough to hold it, still have to refine a few things but it work so far , Z pattern is gone . Next step is to move all the electrical into a bigger box for better cable managements and look .

thinking about adding a few more aluminum extrusion on the right side and make some shelf to put some of the roll and add weight to the overall printer

-

So here another update , ended up swapping the 3d printed elctrical box for an actual box , way bigger , inside it still a mess lol , but at least on the outside it now look cleaner and good , still have ot make my mind on what to use to enclose the printer. still got to tweak 1-2 things , but overall mechanic it working the way i want it or close of it .

was finally able to put some of the sticker i had laying around , gotta love the one from the folk at filaments.ca

-

Well here a little update , the Belt system for the Z axis has been working pretty good so far , i swapped my belt tensionner on the X axis as well , the aluminum one would i believe slightly flex when the carriage would change direction putting a finger on then you would feel slight vibration from then so i drawed some and printed them , just need to test to see if it actually changed something , last few print i did were looking decently good compared to before or what my old rostock max v2 could do .

still need a few more tweaking i believe but him not too far to get a perfectly smooth surface without seeing any layer difference while printing a .1mm layer height.

in the future i will get some more aluminum extrusion and had a few shelf on one side so i can put the multiple box of material i have , at the same time it will make the machine a little more heavier and should reduce vibration as well

-

here a quick picture of the new belt tensionner it does look better ! it print better as well, it seem to have got rid of most of the vibration that i could feel before .

-

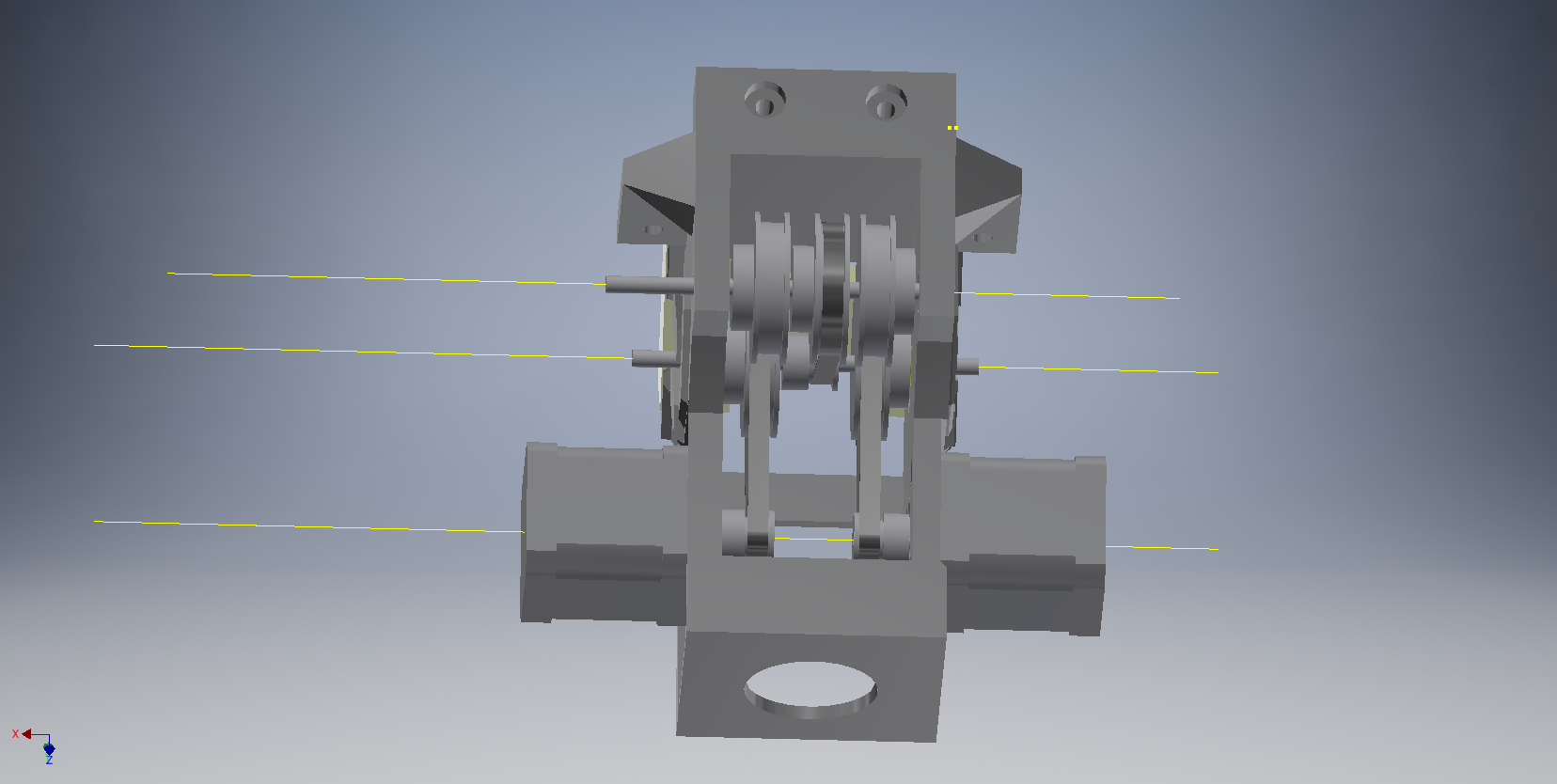

Here another update , i have ordered a duet 3 expansion board so i could mount a second motor facing the other one in the Pulley box for the Z , with the addition of this i will be able to get rid of the temporary counter weight . my Z will be powered by 2x60mm .09 stepper motor now. i as well redesigned a bit the carriage for a more better look and functionality .

Added as well pivot area now for the cooling fan in the front and back just need to remove a screw and they will pivot so that they wont be suspending in the air , less chance of breaking those tiny wire and faster access if i have to.Since my printer is on the big side , i will be adding a few shelf on the right side so i can put the multiple box of material giving me extra weight on the machine so probably less vibration as well.

-

got most of my part today unfortunately i was missing some 2040 for the shelf so him missing one shelf right now , got rid of my counter weight , added the second 60mm nema 17 in the pulley box . the 3hc is wired and installed and everything seem to work good . Only things left now is to reprint the 2 main part for the head , and figure a way to close the front half on top . Getting close of completion on this project which ive started around a year ago now

-

Swaped out many of my part on the Y axis for what i had redesigned , print are coming better it seem so far , added the last shelf as well , that give a lot more weight to the printer , the whiole machine doesnt move as much as it used to now , vibration should be lower as well. still figuring out how i will finish the enclosure as well got a few idea just cant make my mind lol !

-

Looks good! I like the electronics enclosure box.

-

Well after multiple TEST and print , i wasn't happy with the current speed and result it was still better than my old rostock max v2 but i wanted more. this build has been a good learning experience with multiple challenge for the last year, yep one year of tweaking reprinting piece , changing them , upgrading again lol

Well from a cartesian style printer i present you the next evolution of my printer . it is now a corexy . Learning from some of my mistake i redesigned the Y axis way lighter and the head as well . eliminated a lot of pieces as well i would say . since i had the hardware and spare motor i went with something a little more complex . 2 motor per axis so total of 4 motor moving the gantry . i figure out that since most people only have a single extruder while i have a dual i would need some more torque so adding a extra motor per axis should help preventing losing step.

I still need to reprint the Y gantry for a few minor tweak . it seem that for once now i will be able to achieve my goal of a constant print speed of 50-60mm/sec minimum . Before the redesign my acceleration for x-y axis were around 400 since the switch i have been able to test up to 1750 and believe the final number will be higher . Switched to 12mm gates belt and pulley as well from 6mm . That 12mm belt was expensive, the printer use around 4.5m of it .

-

Well here another update on my printer , replaced the 6mm belt for the Z axis for some 12mm , and changed the pulley as well to 20 teeth from 60 and had to readjust my e-step seem i gain around 3X the step now , when machine is off my bed doesnt go down anymore with the switch to smaller pulley there enough torque now . next step is to finish the top once i get more extrusion and reprinting my motor mount making them beefier. then it should be fun printing time !

-

So finally got the aluminum extrusion I was waiting for , next step is to redesign my spool holder and position , than rework my cable to tidy the whole things . Plus a few minor tweak here and there . I think overall no further major change and finishing my enclosure

So finally got the aluminum extrusion I was waiting for , next step is to redesign my spool holder and position , than rework my cable to tidy the whole things . Plus a few minor tweak here and there . I think overall no further major change and finishing my enclosure -

!

!Got some time to work on the printer , partially completed my enclosure , moved my spool behind the machine now