Help me avoid rookie mistakes - CoreXY design

-

Hi Guys!

Been lurking around here for a while and want to get some input on my build.

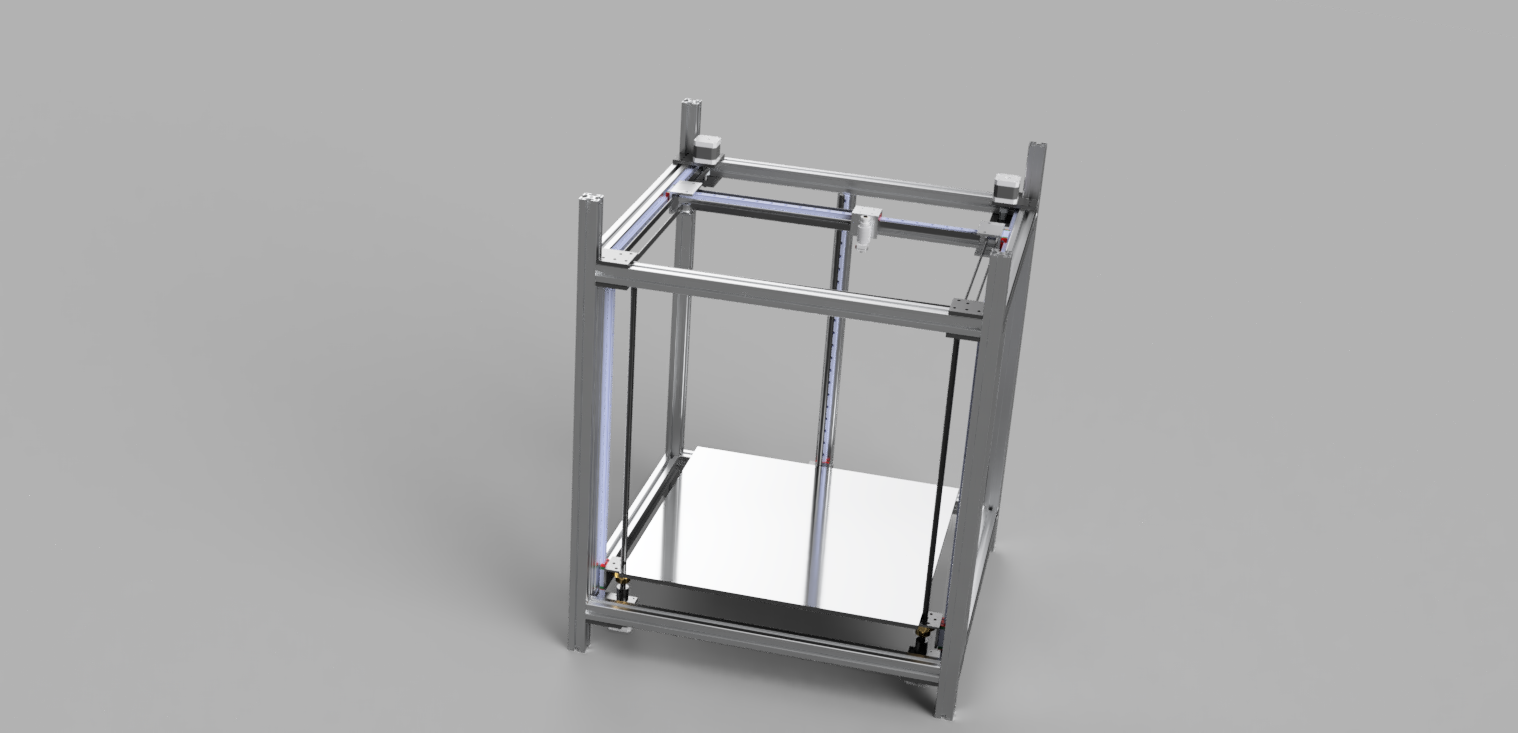

I've worked with printers, lasers and other NC-machines for a while, but this is my first 3d-printer build.My main goal is to build a rigid quality machine. Hopefully it will be able to maintain quality at high speeds (hopefully 200-300mm/s).

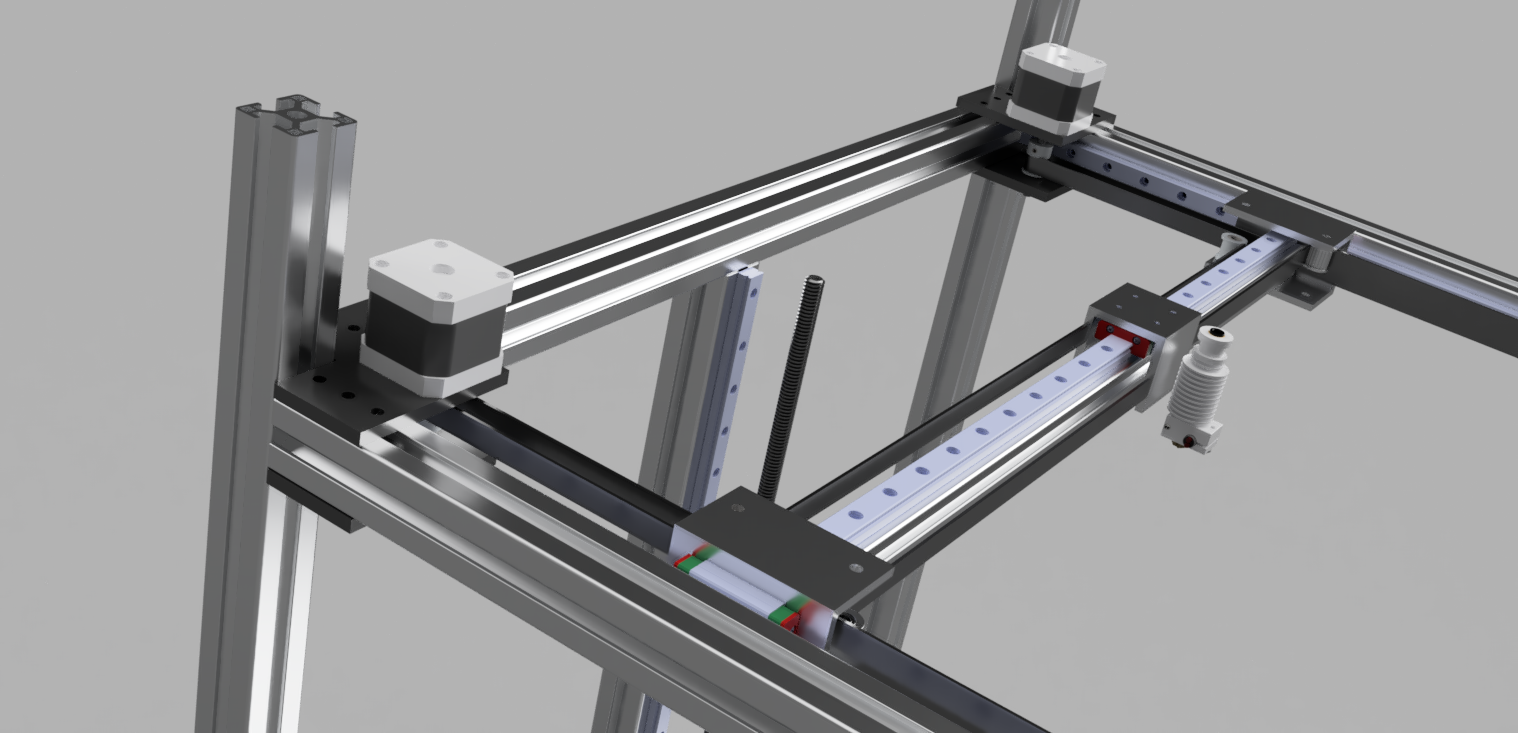

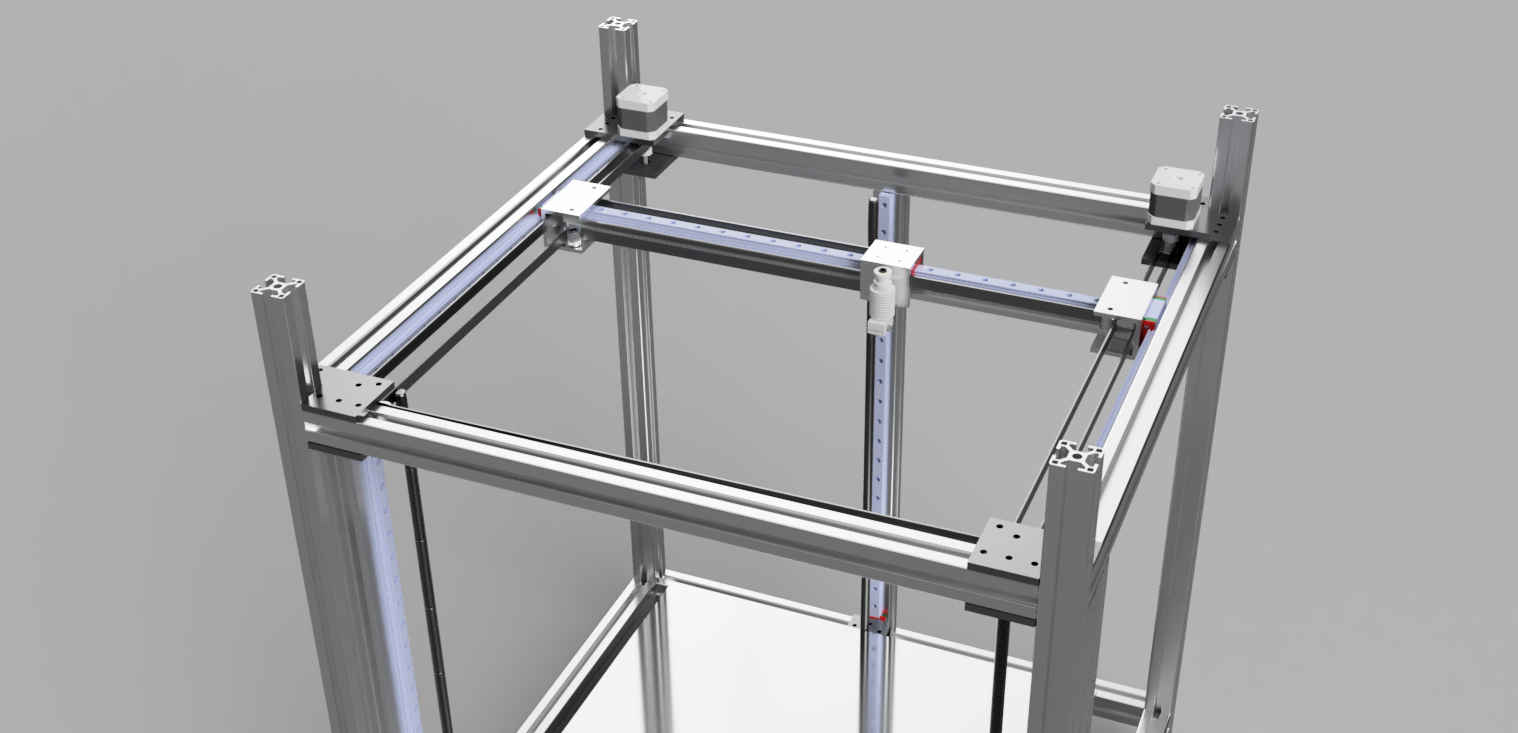

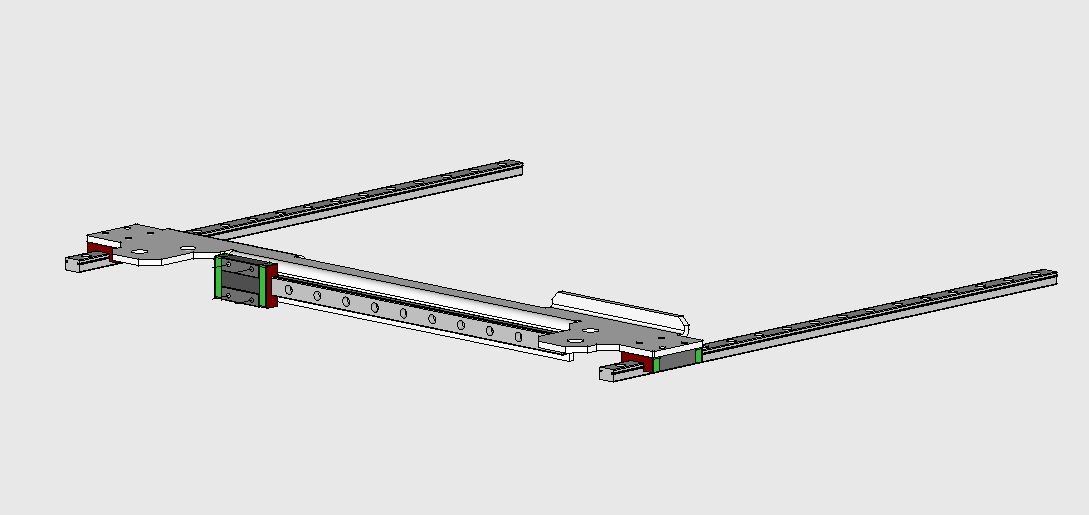

To give some perspective, the extrusions are 30x30mm and the aluminium bed measures 500x500 (printable area ca 400x400mm)

I wont take credit for the design, it's heavily inspired by 3d distributed [3ddistributed.com] but I also looked at railcore, BLV-Cube etc. for inspiration.

Any opinions, really don't want to make any rookie mistakes since it's my first build.

Thoughts and questions:

-

Belt path? I chose to place the 9mm GT2 belts inside the frame (instead of the more common approach to put it above the frame) for two reasons - easier to enclose, and primarily because I imagine it will be more rigid since all moving parts are in the same plane (?) The cost is of cause a bit of print are. Would any other belt path design be more rigid?

-

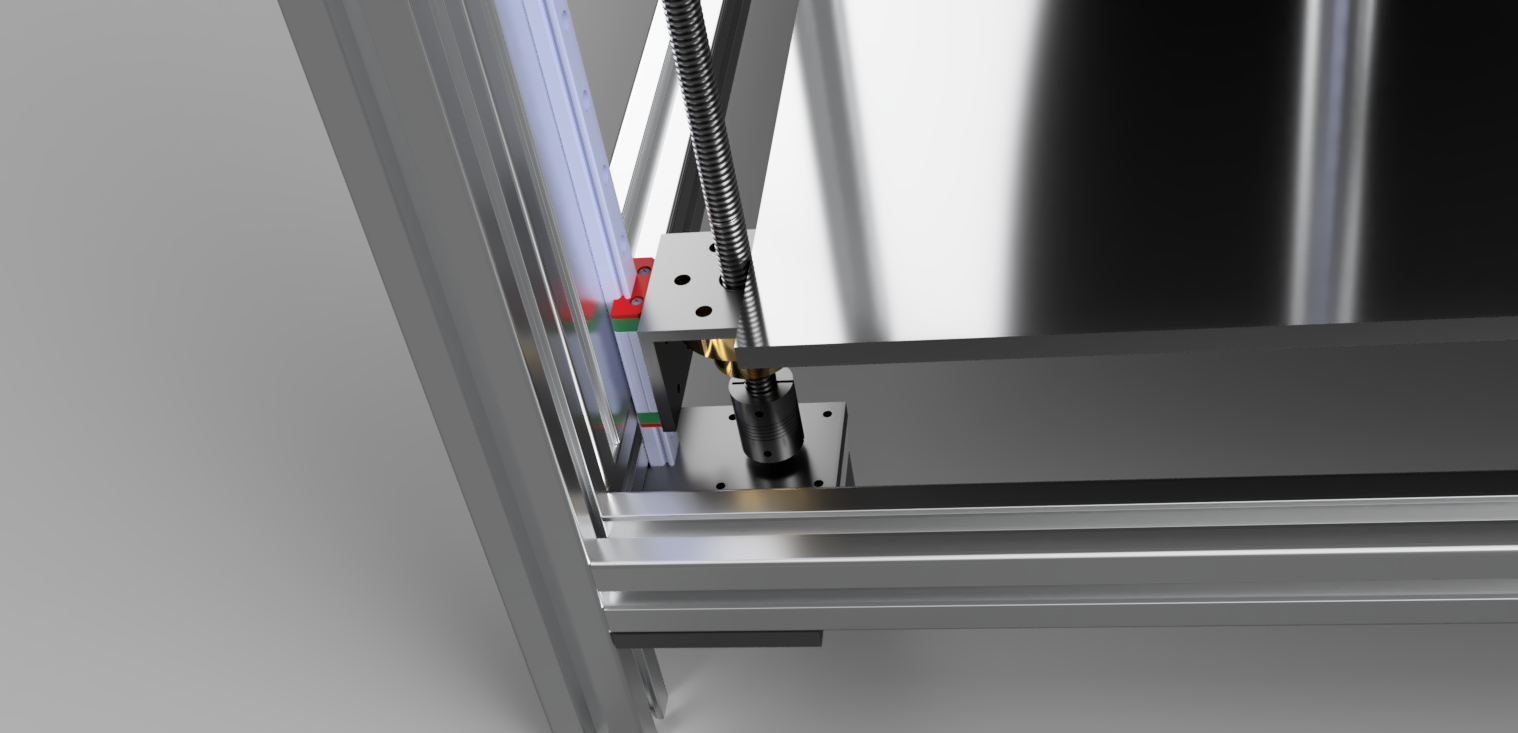

Z-axis mount? How would you fasten the aluminium tool plate in the angle mounts? I'm thinking of placing a spring washer or a short spring between the screw and the mount to allow some movement for heat expansion and allow the independent Z axis motors to do their job.Would that be sufficent? Is it preferable to have the linear guide and lead screw in axis as on the pictures, or should them be placed side by side or any other way?

-

Torque? Im planning on using these 59Ncm steppers, but with a custom ordered longer shaft so I can fit the big pulleys and a bearing supporting the long shaft [www.omc-stepperonline.com]

How much does the pulley weight affect the speed/acceleration/quality? Lighter is better ofc, I've looked at the Zesty Nimble as a extruder, but how much would 150g stepper motor affect the performance? -

I'm planning on running the Duet3 on 32v to give the steppers voltage to overcome the EMF at high speeds. Is that a bad idea? Would this require active stepper cooling? How do I feed 24v to the hotend, buck-converter or separate power supply?

-

Rigidity? The motor and idler-mounts will reinforce the corners, and I will also add corner brackets on the outside and the enclosure will also provide some rigidity. the motor mounts are 6mm and the U-profile used for the gantry is 4mm. Is that enough?

Do you see any design flaws?

What would you say the "weakest link" in the design is?Please let me know what you think and please ask questions if the renderings are unclear (I haven't placed out all the screws etc. yet).

-

-

Having worked a fair amount with the RailCore at our makerspace, one of the the things that was important to me with my CoreXY build was having an unobstructed view to the extruder for peeping the first layer. So in my build (derived from BLV cube), the belts don't go across the front, and my top front horizontal frame member will be several inches above z=0. Looks like you might be able to achieve that by putting your AB motors in front. Just my 2c.

-

The following represents my opinion at first glance, i.e. it doesn't necessarily have to be entirely correct:

An absolute parallelism of the two rails is extremely important for a good running of the Y-axis (i.e. the two linear rails). With your arrangement, I see difficulties to get this.

I think that such an arrangement (please only note the Y-rails) can be aligned better and easier:

Oh, please NEVER use the cheap china rails for X and Y - I speak from experience.

Although I had gotten pretty good ones, now Hiwin-Rails are in my printer and now it is much 'smarter'. -

@thwe

Thank you, I think your right. My design relies on the frame being on point. Even though I will be able to adjust it a bit by shimming the plates holding it together from the outside (not sketched in the pictures yet) your solution is definitely easier. (How do you even measure a 500x500 frame being square within 0.1mm?)My idéa is to keep all the moving parts, rails, gantry, motors, belts in the same plane which is surrounded by the top frame to constrain the forces. But I don't know how much that will help in practice...

Yeah, choosing components is the hard part. I've read that many are happy with BST Automation and Robotdigg which seems to be quality controlled china rails at least...

-

What @thwe said.

Aligning two rails on the same plane (assuming you align the frame well), is much much easier.

Oddly one of the very interesting bits of design feedback I've heard, is put the rails under the extrusions, not on top. That way they don't collect dust.

Seems silly, but its actually really nice.Not using coreXY would be more rigid. Don't get me wrong, H-bot (or a weird monstrosity I designed) would be less stiff.

Basically, with the type of bearings, mounts (I'm assuming metal) and frame you've selected, all of your lack of rigidity will be from belt stretch. Two ways to minimize that stretch are to reduce the length of belt and increase its width. CoreXY uses a longer belt than you would have on a conventional cartesian/flying X motor. The flying X motor adds more weight and wiring complexity, so it might outweigh any advantage...

TLDR:

Wider belts is the easiest way to get more stiffness.

Its also really important to design in a way to adjust the belt tension!2

I wouldn't.

Having the bed be structural and heated is a big challenge. If you are going to heat that bed (which will take lots of power, look at an SSR) then you want to both mechanically and thermally isolate it from a separate frame that is the actual Z stage. I've had great results just using nylon foam as a structural spacer. It can be glued, is a great insulator and rigid enough to work well mechanically. Its still a foam though and will happily absorb any expansion of the bed.

Screws and rails in-axis, its theoretically better, I think your bigger issue is that you seem to be relying on the motors own bearings to carry all the vertical load. They are not designed to do that, you should think about including a thrust washer.3

How much does that gantry weigh? I'm guessing 450g for the extrusion. Plus the weight of the rail, rotational mass of the motors etc, if you are worried about the weight of the pulleys, don't be. If you mean the extruder? Its more significant, but the difference is going to be small compared to the mass of everything else, at least for acceleration not involving X.

If you really want to get higher speeds use bigger motors. NEMA23's are not much more expensive and produce vastly more torque. I don't know why everyone is so fixated on NEMA17's...4

How fast do you need to go? 24V, 32 tooth GT2 pulleys and NEMA23's get me up over 500mm/s... Which given the huge mass of my extruder, is quite scary.

More voltage is better for speed... And you can always just use the Duet3's heated bed circuit to drive your extruder and only supply 24V to it.

You shouldn't need to actively cool the steppers if they are big enough. People tend to have to when they undersize the motors, overdrive them to get enough torque, then discover they get crazy hot (although good steppers will run hot enough to burn you without being damaged themselves).

You could also get an external relay or SSR to drive an extruder heater, although I'd try and avoid that myself. There is also the Toolboard 1LC if you can get one.

I'd suggest trying 24V at first.5

How are you actually connecting your uprights to the crossbars? I don't see anything for that. But there are lots of easy ways to do that. If you haven't already go look through Misumi's website and see the millions of options. Including getting them to machine stuff into the ends of the extrusions.

The rest seems fine, although I wouldn't use u-channel for the gantry. If you change it the way @thwe suggests you can use flat brackets, which is way easier.And to echo what @whopping-pochard said, if you move (in fact you can probably just remove completely) the 'front' crossmember, you get a much better view of the printhead/nozzle.

Similar theme, with the extruder mounted on top of the gantry, you have very little space around it for things like fans for cooling prints. Or fans to cool the extruder itself.Don't forget to plan for filament mounting, and electronics!