Robotic kinematics

-

@tony73 they are looking good.

I think it would be fun to DIY cross roller bearings, I'll try it, 3D print parts of it first and postprocess with router. Axis 1 is ideal for it, because a big diameter is good for z precision and all wires can be routed through the middle.

-

@JoergS5

can you tell me where you bought the cylinders for the cross roller bearing? -

You can make cross roller bearings with a 3d printer. I've made a few with steel rollers and they came out nicely. Of course they're not going to compare to metal ones so their usage is a bit questionable. Might be just easier to print mounts for normal ball bearings since you're not going to overload them anyway.

https://www.instructables.com/Create-a-Parametric-3d-printable-Slew-Bearing-With/

-

@roiki11 I saw them in the past and I was impressed! Are the orange rollers eatable

?

?Some of my buys and makings are just from fascination about the technology. Trying to make a cross roller bearing in metal is in this category. You're right, normal ball bearings are easier, and I use the ones I showed above. They have 250 and 300 mm diameter. The 300 mm was crap, I have to use the 250 mm version.

-

@tony73 said in Robotic kinematics:

where you bought the cylinders

I buy balls and rollers at Kugel-Winnie in germany. He has a good selection of different tolerance classes, often G10 or better. If you buy, you should buy in one shot what you need, because the tolerance classes are in respect to this sample.

His delivery time is a few days, not the fastest, but I'm very satisfied with the quality. -

Only if you like indigestion.

I've made mine with steel rollers from eBay. They worked fine and were better than plastic. Search for dowel pins and you should find them. 100 cost me about 15-30, depending on size.

-

@roiki11 do you know whether diameter of the rollers are the same as the height, or do I need different sizes? I thought about it: the rollers roll at the side, but grind at the fronts, so diameter should be a bit bigger than the height.

-

The rollers are symmetrical.

-

@roiki11 ok, thank you!

-

I've started to describe my first prototype now, which I call "Type 1" here: https://forum.duet3d.com/topic/20209/robot-type-1-45-cm-belt-gear-direct-drive-r0

The main discussion about gear types, firmware, future direction, status etc. will stay here. -

@JoergS5

Hi! were you able to try the print? -

@tony73 I have some tasks left, but I see the finish line!

The taks left:

- belt tension of big rotation plates is not good enough

- endstops

- calibration of Axis 1 by 3 points

- Axis 1 replace aluminium extrusion through hollow square

- hotend assembly

- better precision of hinges by replacing 8 mm holes by 16 mm F688 ball bearings (currently one arm with 16 mm, one with 8 mm each)

- replace stepper-arm connectors from 2 mm to 4 or 5 mm thick connectors

- wiring and filament routing by hiding in arms

-

@JoergS5

Hello! how is the construction of the robot going? -

I currently improve the build

- combine the balanced arms with the first approach of 4 arm elements for each arm for higher stiffness

- try with wood arms first to avoid waste aluminium material

- axis 1 will get 3 columns, where 2 of them will be able to be changed in height for calibration of print height on the bed

- describe the elements with OpenScad, which has an animation mode also

- the extruder/hotend will be Nema 17 pancake with Bondtech and Volcano hotend. Axis 5 about 800 g, more than calculated.

- maybe I change the arms from 20x10 to 30x10 or 40x10 or 40x20, so wires can be routed inside the arms, and F608 instead of F688 can be used also as an option

-

@JoergS5

Merry Christmas!! how does the modification of the robot proceed? -

@tony73 I wish you a merry christmas too. It's a difficult time, I hope you and all here are well!

I made a pause for a few days, but thinking about how to proceed. I have a good plan how to achieve the goal. I was thinking about the different gears. The belt based gear was a good idea imho, because it's easy to make it. I will proceed on Monday.

After finishing the prototype, I'll develop the firmware for a 6 axis robot with matrix calculations. And a firmware to handle two robots at the same time with collision avoidance.

-

@JoergS5

is everything okay with you? I hope so !! in my family and relatives everything is fine! I wait for your prototype and I agree with you! choosing belts and pulleys is a good idea! The perfect but expensive alternative is with harmonic drive !!! if you do the firmware for the 6-axis robot it will be the maximumof the masterpiece !!!! I discovered something that could be useful, I helped a friend to fix an old VHS video recorder, the rotating head (this in the photo)

it is aluminum, two bearings a steel shaft, the two aluminum cylinders of the head are (similar) to a crossed roller bearing, it is very precise, tested with comparator! ľ steel axle is 6mm, it can carry not very big weight, but it could be used for a robot like your prototype, but smaller size !! too much weight can be a problem !! -

@tony73 thank you, we are well in the family, but some friends and related had the virus. Which remembers us how serious it is!

I will try to build a robot as small as possible as next prototype*), your little precise roller bearing may be useful if you want to rebuild it. I have a VHS recorder also, I'll look into it, this is a good idea. If it can be used, buying some old defect recorders in ebay may be an option. I should look into an LP player also, but I have only an expensive one which I still need. But I have several old harddrives, maybe those have valuable parts too. I wanted to try building a tesla turbine from them (as an experiment), but this is not so important like the robot project. Reusing existing parts was a very good idea from you! I will search what I have... Hard drives rotate with high speed and high precision, they should have good hinges.

*) I'd like to build one for printing 10x10x10 cm objects, placeable everywhere, and nice looking. Light with Bowden hotend.

Developing a multiple 6 axis robot is my goal from the beginning. I described the idea in https://reprap.org/forum/read.php?185,824669 what I want to achieve. A parallel scara, robot, and cantilevered cartesian printer can print from one side, so one can use 4 of them on every side to print at the same time. This would be my goal, together with an additional robot from downside to hold the object (to turn it for overhangs without support material) and with robot from the upside with a camera to control the quality of the print. So 6 robots at the same time. A lot of drivers, a lot to do for the firmware

I did not think I could develop firmware for a 6 axis robot, so I started with parallel scara, now 5 axis robot, 6 axis robot comes next, then multiple robots with collision detection.

-

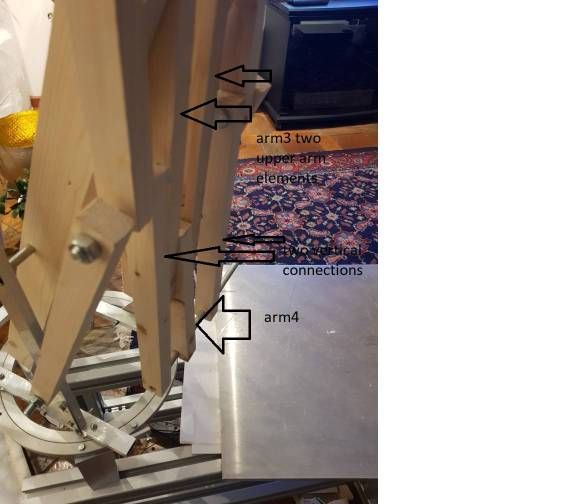

I thought until today that a parallelogram structure with R1 mode would be the best solution. But when arm3 is in line with the vertical arm4 (always when arm 3 is vertical too), the vertical arm4 is very unstable, similar to a singularity:

Mathematically arm 4 stays vertical, but every part has a few micrometers play. Arm 4 can rotate some mm because of that.

Unfortunately the regions where arm 3 is vertical is at a lot of places (a cone from bed Z0 towards axis 1 high Z). This limits the precision advantage of R1 mode. I'll concentrate on R0 mode now, with actuator 4 for axis 4.

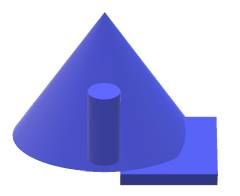

Problematic conic area where arm 4 can rotate with xy inaccuracy (if axis 5 rotates, this area is even bigger):

Kuka KR700 has a different solution for the arm elements which fixes the 4th axis, this may still be an option for a R1 mode. I let R1 remain in the firmware, but will not build robots with R1 mode for some time. This means, Duet 2 and Mini 5+ need an extension board for 6 actuators.

The Type 1 prototype has 8 actuators:

- 5 for the 5 axes

- 1 for extruder

- 2 to calibrate axis 1, standing on 3 columns, 1 of them fixed, 2 of them to be calibrated by actuator with differential screws.

For Type 1, Duet 3 and Mini 5+ are used together with the 3HC board, Mini 5+ using one of 3HC's drivers for the Nema 23 of axis 2 with 3.5 A.

-

This post is deleted!