heated chamber - cooling

-

Cooling critical parts in the heated chamber can be problematic. Water is always a great way to do it as it's easy contained, routed and has huge thermal mass, but the problem usually is the price. Those copper plates with water channels for cooling motors, special watercooled hotends and other parts can be rather expensive and sometimes we just need to drop the temp "a bit" so cold air brought from outside would solve the problem and will not destroy the heated environment a lot. For this purpose I tried using air brought to the chamber via "hose" presurised by a compressor and while this works like a charm (cooling the motors, belts, hotend..) the amount of air is not small and my small compressor works non stop and it's loud enough to make the whole thing useless... so I was thinking about compressors used for dental equipment. Most dental compressors are quiet. They have "different" motors that do not have those pistons and sound they produce is like a "bigger fan" and they manage to create required pressure and air volume. Anyone tried them? Have any experience with them? Second hand any good?

-

@arhi I've been thinking about getting one of these https://www.youtube.com/watch?v=eO_WL0Vx4BA

Edit. I think it's been renamed to Metabo HPT EC28M

Edit 2. Piston compressors are the noisiest, scroll or screw compressors are the quietyest (from what I've been able to discover but I'm not an expert).

-

@deckingman said in heated chamber - cooling:

Piston compressors are the noisiest, scroll or screw compressors are the quietyest (from what I've been able to discover but I'm not an expert).

yup, I have 2 piston compressors (one miniature 4L meant to be used with airbrush and a 60L one in my garage useful for small work, not enough for serious shop work but I already have a second 80L bottle I need to connect that will make it more useful as the pressure is acceptable). Locally I can chose either piston or screw ones and while screw ones are 1% of the noise, second hand refurbrished screw ones are appros 30 times more expensive than the piston ones. I heard about these dental ones as something "especially quiet" (I think they use screw based compressor) but cheap so I just started researching what/how/why/when/where..

-

@deckingman said in heated chamber - cooling:

This one would be AWESOME replacement for my home compressor (1/5HP 23L/min 6bar) that I paid ~double the price of this EC28M on amazon ?!?!?!! I'ts 8bar, that's more than enough for 99% of the work, 1/2HP, so stronger too ..

-

@arhi Yes, I was quite impressed by it.

-

How much air at what pressure do you need? I have found that the blowers from CPAP machines can move a lot of air under moderate pressure through hoses and do it quietly. I have also printed a similar blower powered by a hard disk drive motor (or any other BLDC motor) that will move similar amounts of air.

A $10 BLDC driver is all that's needed to drive the motor. You can use model airplane motors or HDD motors.

The 3D printed impeller comes off the printer balanced so there are no issues with spinning it at 20k rpm.

People were going bananas over this a couple months ago when they were trying to design low cost ventilators for COVID-19 patients.

-

@mrehorstdmd said in heated chamber - cooling:

How much air at what pressure do you need? I have found that the blowers from CPAP machines can move a lot of air under moderate pressure through hoses and do it quietly. I have also printed a similar blower powered by a hard disk drive motor (or any other BLDC motor) that will move similar amounts of air.

I sleep with a CPAP machine and I think it would be superb for any cooling action for the 3D printer BUT I never opened the CPAP machine and they are so god damn expensive and hard to get in this middle of nowhere s^%$thole that I never considered them for anything other than what they are made for

I'll check the video and if I can find more info of what kind of fan is inside

but that really can be a good solution

but that really can be a good solution -

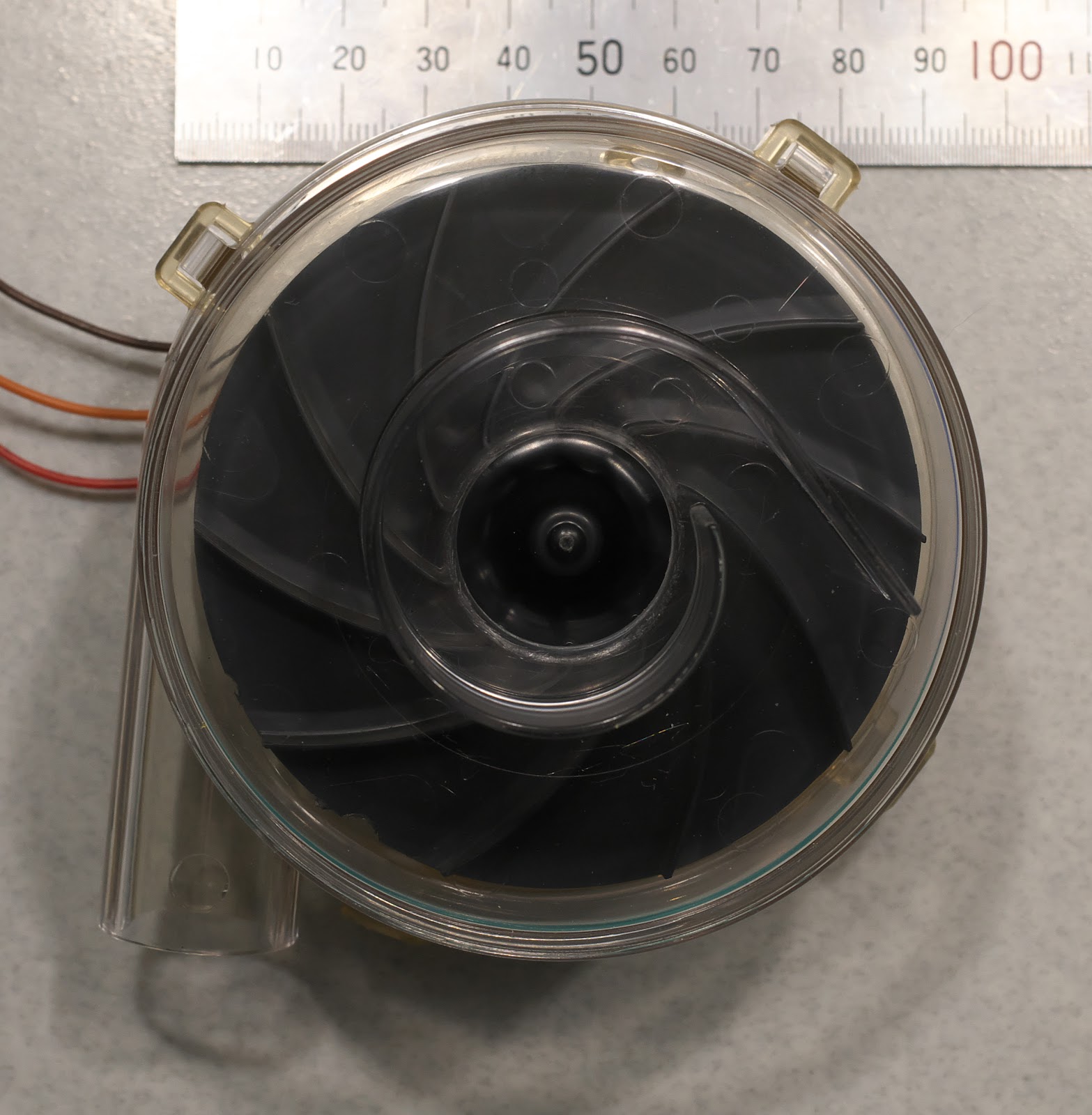

@arhi here's a blower from a CPAP machine- it's about 80mm diameter:

This is the one I copied to make a printed version:

-

interesting, rather thin disk with small surface of fins moving so much air with significant pressure..

-

Yeah, I was shocked when I saw it.

My printable impeller was a direct copy of the impeller in that CPAP blower.

-

@mrehorstdmd any stl's of the final device that works? I have some beefy bldc motors

.. I think I still have one 300A motor+esc sitting in a box unopened for years

.. I think I still have one 300A motor+esc sitting in a box unopened for years  that I wanted to use as cnc spindle and gave up

that I wanted to use as cnc spindle and gave up

-

@arhi The last file I linked was the fusion360 design file. You can open it to look at it in 3D in your web browser, and can download it in several formats including stl. I designed the impeller hub to fit the HDD motor I was using so you'll likely have to modify it to fit whatever motor you use. It is intended that the motor go inside the lower half of the box so the swirling air can help keep it cool. You'll probably have to modify the box a bit too.

A 300A motor might be overkill for this application... but it should make for an interesting series of youtube videos, maybe called "Does it Blow?". You can start with the first printed impellers disintegrating in slo-mo when you spin up the motor, then move on to things like blowing prints off the bed when they finish. The print will go flying, there will be papers flying around the room, a cat hissing, dogs barking, babies crying, murder hornets buzzing, etc. It'll go viral!

-

@mrehorstdmd said in heated chamber - cooling:

@arhi The last file I linked was the fusion360 design file.

missed that one, great

I designed the impeller hub to fit the HDD motor I was using so you'll likely

I might use hdd motor as well have enough of them and they are super quiet

A 300A motor might be overkill for this application... but it should make for an interesting series of youtube videos, maybe called "Does it Blow?".

I was thinking about how to test max rpm that 3d printed part can survive but I'm not sure this motor can do too many rpm's as IIRC it was designed to be used with huge propeller so high torque, not too much speed, but will check, need to find it first I remember when I purchased it but have not seen it in many years

I was thinking about how to test max rpm that 3d printed part can survive but I'm not sure this motor can do too many rpm's as IIRC it was designed to be used with huge propeller so high torque, not too much speed, but will check, need to find it first I remember when I purchased it but have not seen it in many years

I have some smaller ones (purchased same time same store in Budapest

) that are high rpm low torque, I got the appropriate propellers for them and those are the fairly small ones but still generate loads of trust (iirc 2.5kg but I'm not sure need to find my notes) due to speed, wanted to use them for some super fast gimbal platform but never got around doing it

) that are high rpm low torque, I got the appropriate propellers for them and those are the fairly small ones but still generate loads of trust (iirc 2.5kg but I'm not sure need to find my notes) due to speed, wanted to use them for some super fast gimbal platform but never got around doing it