pretty sure my mesh isnt working... or isnt working well.

-

ok im not sure whats going on here. but im getting close.

this is how ever really effecting my first layer and bed adhesion on larger prints.

using my magnetic bed and my steel shim sheets, i have gotten my warped bed pretty close.. or close enough that the mesh should be able to compensate no problem.

and i have attached my G32

image url)

image url)my here is my config.g

also here is my starting script.

G28 ; home all axes

G29 S1

G1 X-100.0 Y118.00 F6000 ; Move for prime

G1 Z1

G1 E20 F1000 ; Prime Hotend

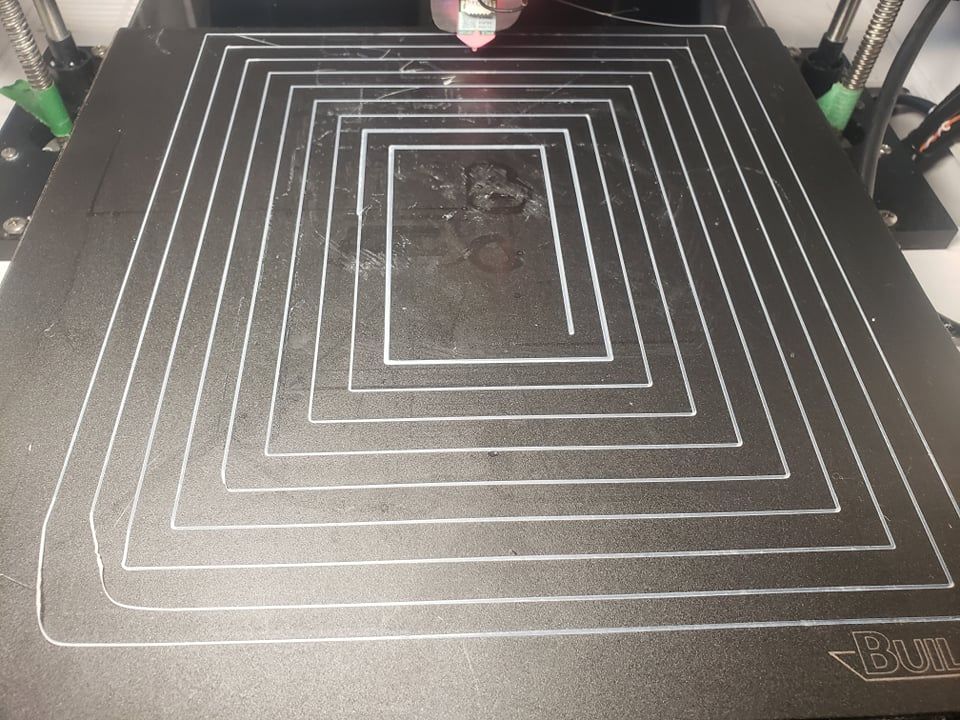

G1 X0 Y0 F6000and here is a photo of what exactly it is doing.

i have just recently added M376 H5 and it didn't seem to make a difference. I have also messed with the baby stepping to try and get it dialed in but its only working on some parts.

The with the mesh bed leveling on marlin i could actually see the z height compensating, how ever i cant see it adjusting at all, but seeing as i have the deviations down to one hundreth it would be hard to see it move.

-

Can you also post your homeall?

It may help to set a slightly negative Z min height in M208

M208 X-114 Y-127 Z0 S1toM208 X-114 Y-127 Z-1 S1This will let you baby step below what the firmware thinks is the bed surface.

For the time being, turn off the taper. We don't want it reducing the compensation prematurely. So set M376 to H0.

M558 P9 C"zprobe.in" H5 F60 T3000 R0.5 A10Try this to improve your BLtouch accuracy a bit. Remove the

X0 Y0 Z1that's a very old syntax, not used anymore.G31 P25 X3.5 Y-20.5 Z5Z5 seems like a very high (and precise integer) trigger height for the BLtouch. When installed properly the bottom of the probe body should be ~8mm above the nozzle tip which will lead to a trigger height of ~2mm.

Also be sure you have the + and - signs for the X Y offset correct. +X to the right, -Y to the front of the nozzle.

Have you measured your trigger height like this? https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe#Section_Calibrate_the_Z_probe_trigger_height

-

Hey, ya i have attached the home all .

everything seems to be working as expected, with the exception of some times when its homing x or y it actually stops prior to gettting to the end switch. but if i hit it again it always does. the bl touch is working great. at least from what i can see, except the mesh.

the reason my x and y values are negative, is because i added the build tak magnetic plate and when it homed the bl was probing off of the build tak, so i made it so that i homes to the centre of the bed. setting the negative values was the only way i could figure out how to do that.

also i did measure my z height according to the dozuki

-

@Phaedrux also, when i printed my mount for the bl, i forgot to factor in that the probe pin pops out for the probing, so i will have to redesign it once i get things working.

-

@joehsmash I would try changing M84 S2 to a higher S value, as the value means that the Z stepper will go into idle after every 2 seconds of inactivity. While printing with mesh compensation, this means a lot of idle-nonidle changes.

-

@joehsmash said in pretty sure my mesh isnt working... or isnt working well.:

with the exception of some times when its homing x or y it actually stops prior to gettting to the end switch

In your homeall file you can increase the distance of the Y move to make sure it always goes far enough to hit the switch.

You have

G1 H1 X-215 Y-215 F4200 ; Course home X and Y

Change the Y-215 to Y-500. Same for X just in case.@joehsmash said in pretty sure my mesh isnt working... or isnt working well.:

when it homed the bl was probing off of the build tak

The BLTouch needs to be positioned before probing. In your homeall it's set to move the nozzle to X0 Y0 before probing. The way you've done it by making the 0,0 origin the center of the bed is a perfectly valid way of doing it.

-

@JoergS5 ill change that now.

-

@Phaedrux i also just realized that my values for the x and y arent even close to the min max set in the config, i made some changes just before i posted the homeall.

i also made the changes to the probing, and its probing each spot twice now, and is probing really slowly.

its on its last line now, ill post the height map when its finished

-

@joehsmash What you can check also, is whether the nozzle and bed heating conditions while measuring are the same as when you print, because bed heatup could warp the bed. The bed could warp downside also, lowering adhesion.

A magnetic bed could have a negative influence on the BLTouch also. (e.g. https://forum.duet3d.com/topic/10366/another-bed-leveling-weirdness )

-

@JoergS5 i did notice that i some times get anomalies just like that, but what i have found atleast on my machine is that it was something mechanical or something weird. but ive always sorted it out.

here is the new mesh level, im going to take out the shims in the front portion to lower it, now that its a little more accurate.also it made no difference in the first layer print. more towards the front of the bed, it doesn't adhere.

-

@joehsmash it's interesting that you have a separation horizontal line in the middle of the bed. This line is visible in the first image also. Maybe this is due to a mechanical reason?

-

nah, i manually added metal shims under the flexible metal plate. it looks worse than it is, but i have already adjusted the shims and that hump is now gone.

i have lowered the layer height so that its actually too low and its adhering but its clearly not right yet.

-

-

@joehsmash I would remove the XYZ values in M558.

M558 P9 C"zprobe.in" X0 Y0 Z1 H5 F120 T3000

=>

M558 P9 C"zprobe.in" H5 F120 T3000

They are parameters of an old firmware version (< 2). -

-

@joehsmash sorry, I've overlooked it.

The idea I had was that maybe your BLTouch offset is still wrong somehow, so the mesh compensation is at the wrong place.

-

I suspect that part of the problem may be a mismatch between the heightmap and the actual nozzle position. The heightmap is only accurate for the nozzle if the offsets are correct. So please double check your nozzle/probe x y offsets. If there is a mismatch it could be lifting when it should be dropping, etc.

https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe#Section_Measuring_Probe_X_Y_Offset

The other factors for good first layer adhesion is a very clean be, appropriate temps for bed and nozzle, and accurate flow rate. The first layer height could be perfect, but if those other things aren't right it won't stick either.

-

@Phaedrux i just re did my spacing for my probe, and you were correct, it was out.

new measurements were x0 y-26

reprobing the bed now and am going to try a test print

-

-

Your trigger height still shows as 5mm. Have you done the calibration for that too?