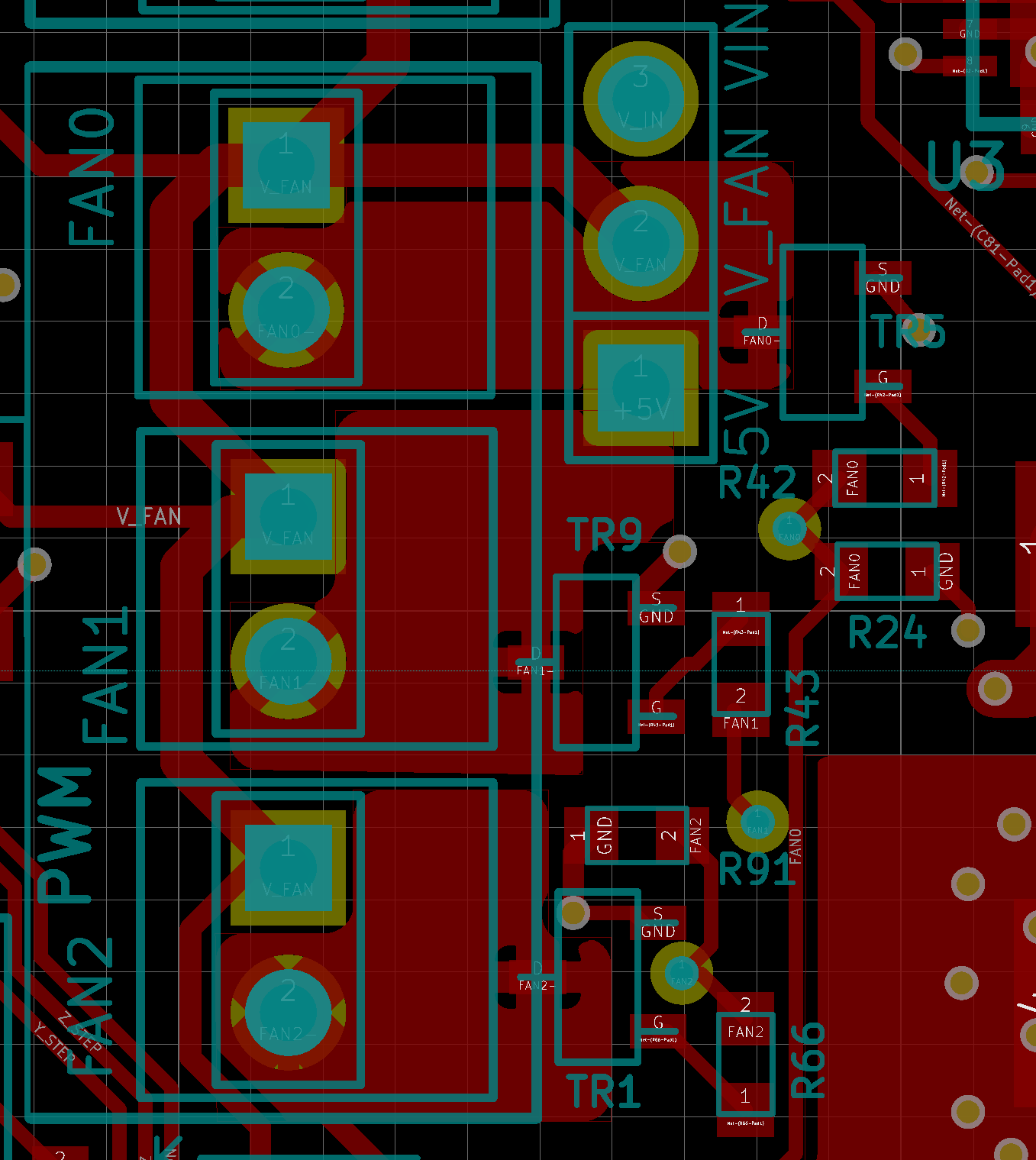

i think fan0 mosfed died.

-

FYI guys...

i managed to make fan2 work.. but somehow fan0 aint doing it...

also, when i was about to solder the self resetting fuse (vssa), after removing the soldered wire for the temporary pot... i checked continuity and it had continuity... so the old fuse was working.

yeah... very strange.

-

@weput said in i think fan0 mosfed died.:

so the old fuse was working

i think i've seen dc42 suggest waitng a day or two to see if the self resetting fuse recovers - but i though you had trouble with the fans, not the VSSA fuse that is for the thermistor ground connection?

-

trouble with both.

i received the package (finally) with the spare parts.

-

my board is hardware version 1, so this is not a self reset fuse...

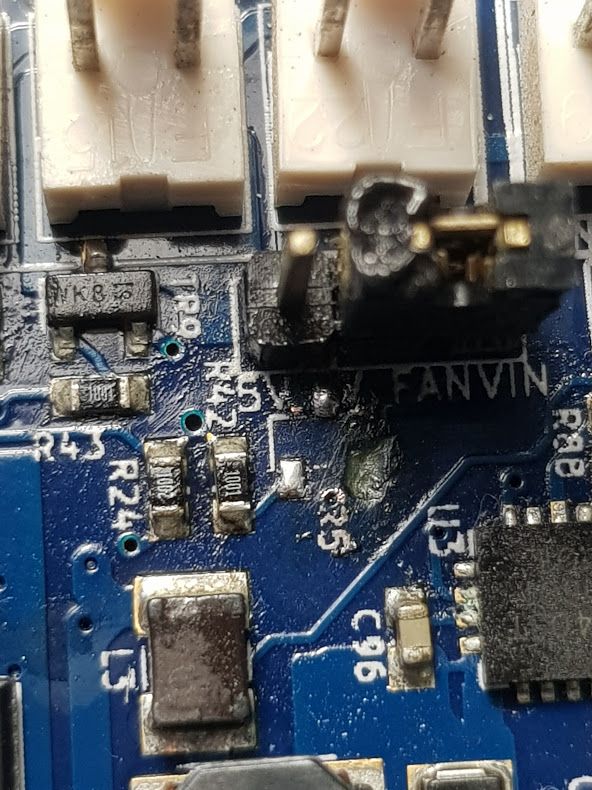

on the fan1 blown transistor,.. it seems i fucked up the board when cleaning/removing the old part.

-

@weput said in i think fan0 mosfed died.:

it seems i f***ed up the board when cleaning/removing the old part.

these things happen with too much heat, the copper becomes delaminated from the substrate.

not the end of the world, we have all the files we need to find a workaround, the missing pad is a ground connection, so you could solder in the mosfet, and run a wire from the leg with no pad to any other ground pin

(edit: fixed silkscreen on top of screenshot) -

thanks m8.

I was looking at the old pictures and notice the cooper was conected to the pin path... so i tried to add more thin until it made contact..

not sure if it worked... im connecting the board now.

-

@weput said in i think fan0 mosfed died.:

not sure if it worked

if not you can just add a short jumper wire to another ground pin (suitably sized for the current the fan needs)

-

-

honestly, i dont know how i fucked up the connector that bad... i just placed the soldering iron and used the suction thing ... added flux and repeat.

-

@weput said in i think fan0 mosfed died.:

i dont know how

its a tiny pad and trace so it heat up quickly, and has very little surface area for the adhesive that weakens at high temperatures so care needs to be taken when working on such pads. (the fault current could also weaken the trace before you started working on it)

pre heating the board helps a lot as you need less time to melt the solder and less risk of pulling a pad, but its fixed now and thats what matters in the end

-

@bearer said in i think fan0 mosfed died.:

pre heating the board helps a lot as you need less time to melt the solder and less risk of pulling a pad, but its fixed now and thats what matters in the end

yeah.

this board was a gift from a good friend... there is some sort of added value there...

plus, is a good feeling this flashbacks of soldering thing... you see, i have a degree in electrical engineering; but since i moved to management i didnt touched my soldering iron in 15 years.

had to buy a new one because the old weller broke off when i tried to change the tip.