What happens to the temperature inside your nozzle?

-

@sebkritikel I've seen plenty of studies about flow rates and hot end temperatures - I've done plenty of them myself. But the assumption is always that the nozzle temperature will be very close to the hot block temperature. I think my tests have demonstrated that this might be a false assumption.

-

Very interesting tests. I think your comment about not being able to test with filament loaded is important. Would that impact the test results? Probably. How much? I really don't know.

It is also likely that different part cooling fans would have very different results. For example, how different would the results be with a berd-air type system that's blowing less volume of air in a more concentrated area? (Berd-air systems also usually are blowing slightly warmer air due to the tube being close to the hot block.)

What about a blower with ducts that blow the air mostly horizontally, just below the nozzle? That might cool the nozzle without needing to deflect on the build plate, but then that cooling impact would be more consistent regardless of the Z height.

(I'm not asking questions to get answers - I'm asking questions so that other people ask themselves the same questions.)

I think your tests underscore something that a lot of people don't like to accept about 3D printing: we really aren't sure exactly how or why things are working, and often times we do things because we know (from experience and testing) that they work, but we really don't completely understand why they work.

Regardless, understanding that deflection of air from part cooling can and will impact nozzle temperature is important, and something anyone should keep in mind.

-

@garyd9 said in What happens to the temperature inside your nozzle?:

It is also likely that different part cooling fans would have very different results.

Exactly so. I thought I had made that point but perhaps not clearly enough. I tried to arrange the fans such that practically no cooling air was being directed at the nozzle. But some proportion of any air that is directed at the part under the nozzle, is likely to get deflected back onto the nozzle. Because every printed part would be a different size and shape, it is impossible to predict how that airflow behaves. All we can say is that some proportion is likely to get deflected back onto the nozzle.

I think your tests underscore something that a lot of people don't like to accept about 3D printing: we really aren't sure exactly how or why things are working, and often times we do things because we know (from experience and testing) that they work, but we really don't completely understand why they work.

Again - exactly so. It's refreshing to find someone of the same mind set. There are numerous unproven theories which happen to nicely explain how something behaves, but which might be fundamentally flawed.

One that comes to mind is hot end pressure build up. We know it happens, we know that pressure advance in it's current form helps to alleviate the effect. But we don't really understand the mechanism behind how that pressure builds up. I've read theories about filament buckling inside the Bowden tube and acting like a coil spring (but I've never seen a picture to prove that's what happens). I've read that the filament itself gets compressed (but I've never seen any test results to prove it). The truth is, we just don't know. We'll accept any theory which explains the behaviour that we observe, but that theory might be flawed. In which case, how can we find a solution? (Or in the case of pressure advance, how can we tune the algorithm if we don't know the root cause of the problem?).

But I'm sure you've heard enough of my deranged, senile, ramblings......

-

Very interesting reading. Thanks for posting!

It's now clear to me that I should use a brass nozzle whenever possible.

The cooling from the deflected air is very significant. I wonder if it also requires more power to the heater. Do you know if there was a significant change in the PWM duty cycle, especially with the brass nozzle?

-

@zapta said in What happens to the temperature inside your nozzle?:

Very interesting reading. Thanks for posting!

It's now clear to me that I should use a brass nozzle whenever possible.

The cooling from the deflected air is very significant. I wonder if it also requires more power to the heater. Do you know if there was a significant change in the PWM duty cycle, especially with the brass nozzle?

I thought it was very clear from the tests that the deflected airflow caused localised cooling of the nozzle, but that the hot block temperature remained largely unaffected. This is partly due to the relatively large thermal mass of the hot block compared to the nozzle, and also the fact that the hot block thermistor is "buried" deep within that mass.

When the fan state changed from fully off to fully on, and with the build plate close to the nozzle, the hot block temperature initially dropped by about 1.1 degrees C before quickly recovering to the set point. This would indicate that there was no significant change to the PWM duty cycle, and that no change to heater power is required.Steel nozzles have their place. They may even be essential with some abrasive filaments (I have read that "glow in the dark" filaments are especially good at wrecking nozzles). So my conclusions are not that one should avoid using steel nozzles, but simply be aware that a higher print temperature may be required and they could be especially sensitive to the "quenching effect" of any part cooling air.

-

@deckingman said in What happens to the temperature inside your nozzle?:

[...]

I've read theories about filament buckling inside the Bowden tube and acting like a coil spring (but I've never seen a picture to prove that's what happens). I've read that the filament itself gets compressed (but I've never seen any test results to prove it). The truth is, we just don't know.

[...]I would say that this type of behaviour is very well-understood generally via Hooke's law. Everything is just a series of interconnected springs of various stiffness. There are obviously going to be more factors in reality, but even steel is compressible -- PLA and PTFE even moreso.

-

Nice article thanks for sharing.

And it highlights perfectly why I never think of a printing temperature as something set in stone, (or something you should actually follow) I never follow any set temp, as has already been mentioned here, experience is the key.

As you have mentioned, there is a thread where we were discussing how certain rolls of PETG are requiring to be printed at a much lower temp than the norm, its was the pre-conceived idea of what temp the material "should" be printed at that tripped the OP of that thread up

Just because the display says X doesn't mean the material will print at X, which is why I always advise anyone to almost ignore the number and print a temp tower, the number being displayed might mean nothing in the same way your test has confirmed, if you print a temp tower and go on "look" the actual number is irrelevant, it just serves as a place holder to set the slicer at.

-

@bot said in What happens to the temperature inside your nozzle?:

I would say that this type of behaviour is very well-understood generally via Hooke's law. Everything is just a series of interconnected springs of various stiffness. There are obviously going to be more factors in reality, but even steel is compressible -- PLA and PTFE even moreso.

That may be true if you subscribe to the belief that the only factors in determining the pressure in a hot end can be attributed to external applied mechanical forces acting on an elastic body. This of course precludes the possibility that for example, the energy input in the form of heat, has no effect.

-

@CaLviNx Exactly so.

-

@deckingman This sounds like a job for Fusion 360 Event Simulation!

-

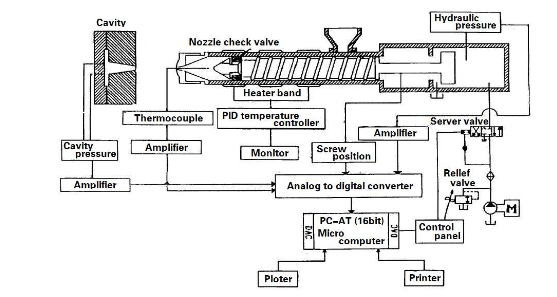

@bot Nah, we need to knock up one of these to establish the PVT properties

-

@deckingman Now we're talking!

In about 2013 I read a fair chunk of the "Plastic Extrusion Handbook" so that block diagram looks quite familiar.

I couldn't agree more. We should use the tools already available and used in industry to understand our own nearly-equivalent problems.

-

@deckingman said in What happens to the temperature inside your nozzle?:

I thought it was very clear from the tests that the deflected airflow caused localised cooling of the nozzle, but that the hot block temperature remained largely unaffected. This is partly due to the relatively large thermal mass of the hot block compared to the nozzle, and also the fact that the hot block thermistor is "buried" deep within that mass.

I would think that the thermal mass will affect transitions but for the steady state the heater will need more energy to compensate for the energy loses from the deflected air cooling. I will try to look at PWM on my printer and see what happens, if at all, with the deflected air cooling. Just for curiosity.

BTW, do you think that a silicon sock like this, with a tiny nozzle hole, would protect the nozzle better from air cooling? https://ooznest.co.uk/product/e3d-v6-silicone-sock-pro/

-

@zapta said in What happens to the temperature inside your nozzle?:

BTW, do you think that a silicon sock like this, with a tiny nozzle hole, would protect the nozzle better from air cooling? https://ooznest.co.uk/product/e3d-v6-silicone-sock-pro/

I would think it highly likely, yes.

-

@zapta said in What happens to the temperature inside your nozzle?:

I would think that the thermal mass will affect transitions but for the steady state the heater will need more energy to compensate for the energy loses from the deflected air cooling.

I think you need to look again at the results https://somei3deas.wordpress.com/2020/05/21/the-effect-of-deflected-part-cooling-air-on-brass-and-steel-nozzle-temperatures/

With regard to your assumption, the important thing to note is that, after the fans were turned on and after the initial temperature drop of the hot block, it very quickly recovered. So the control system reacted to the temperature drop and adjusted the PWM value accordingly. If the heater had insufficient power, then the control system would go to 100% PWM (fully on) but the temperature would not recover to the set point.

But there are far too many variables to assume that would be the case for every hot end. The surface area of the hot block, the amount of air flowing over that area, and the size (wattage) of the heater would all play a part. But it's easy to check if the heater is sufficiently powerful. Simply turn on the fans and see if the hot end temperature recovers to the set point. If it doesn't, then before compensating by fitting a more powerful heater, consider mitigating the problem by insulating the hot end (fit a silicone sock), or adjust the part cooling air flow (volume and/or direction).

-

Hi @deckingman, I made a quick experiment on my printer, measuring the the effect of the material cooling fan and nearby bed on the PWM of the hotend, results are below.

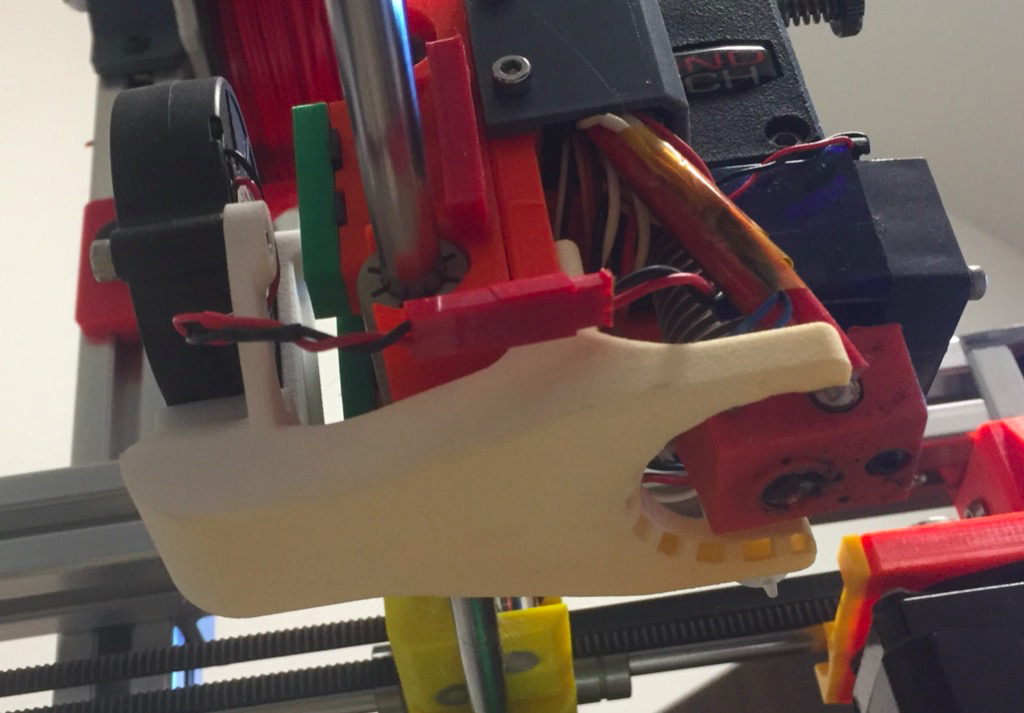

Invariants: 200C, with silicon sock, brass nozzle, no filament, heatsink fan on. A picture of my setup is at the bottom here.

Variables: material fan on/off. Bed close/far from nozzle.

Measurement: average current to the heater, using a Uni-T DC clamp. This is a linear proxy of the PWM. With 100% PWM (during initial heating) the current is 1.23A which is ~30W at 24V. All measurements are in steady-state, not during transitions.

Results:

#1. fan off, bed far, 0.39A

#2. fan on, bed far, 0.55A

#3. fan on, bed close, 0.75A.Observation: Bringing the bed close to the nozzle ('deflecting'), increases the power by ~25%. This is to compensate for the extra cooling of the nozzle.

I would guess, based on your results, that with a steel nozzle, the #2 -> #3 power increase will be smaller due to the lower thermal conductivity fo the nozzle, which means that the tip of the nozzle will be cooler as you shown. This assumes that most of the deflected cooling is on the nozzle (?).

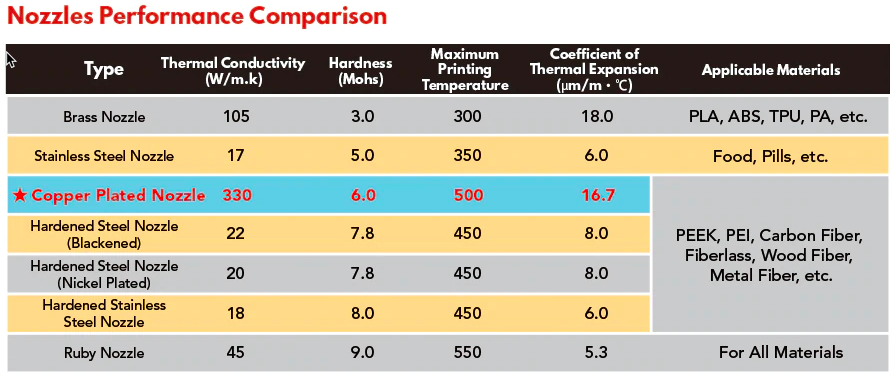

BTW, Aliexpress (Trianglabs) has this chart. It suggest that 'copper plated nozzle' is even better in this regard and the ruby is better than steel.

My setup:

-

@zapta As I said, every hot end configuration and part cooling fan combination will behave differently but I guess you have answered your question about whether your heater will be sufficiently powerful for your particular set up (which it is).

A couple of observations if I may. I note that the ends of your heater cartridge are exposed (not covered by the sock). So much of the required increase in power may be due to cooling air being deflected over the heater cartridge ends, rather than purely as a result of being deflected over the nozzle tip.

I take anything published by Chinese cloners with a huge pinch of salt. What do they mean by "Copper Plated Nozzle"? Do they mean the base material is copper which is plated with something else, or do they mean the base material is something else which is plated with copper? They've quoted the thermal conductivity of copper but used a hardness value of medium steel. So it either has a hard coating with low thermal conductivity, or it has a soft(is) coating with higher conductivity. The specification shows the best of both but that can't be true in reality.

-

Yes, that's correct, some of the deflected air heat loss is not from the nozzle. I don't have a steel nozzle to compare with the PWM with that of bronze.

@deckingman said in What happens to the temperature inside your nozzle?:

I take anything published by Chinese cloners with a huge pinch of salt. What do they mean by "Copper Plated Nozzle"

Copper coated by a harder material. The other way around wouldn't have much benefit. This is from Trianglelab. They know 3D printing.

-

@zapta said in What happens to the temperature inside your nozzle?:

Copper coated by a harder material.

In which case, their claimed thermal conductivity is false.

This is from Trianglelab. They know 3D printing.

That's the funniest thing I've heard in a long time

-

Interesting test. A couple of questions/thoughts. Did you take any steps to ensure that the sensor made good thermal contact with the material of the nozzle and that the same thermal contact was maintained for the different nozzles? Is the nozzle open to the air at the tip (and if it is what happens if you block it)? If the nozzle is open it could be that there is airflow through the nozzle (or even just inside the tip of the nozzle) that may be cooling the sensor/inner walls of the nozzle tip. If any direct air cooling like this is taking place it could be that it varies depending upon exact nozzle shape and/or the position of the sensor and wiring withing the nozzle.