mellow nf crazy hotend

-

I can see some issues with the V6 but if it is as bad as it sounds then why did Slice Engineering make the 'Copperhead' hot end which is a somewhat improved V6 ?

I don't actually use the V6 heat sink, I use the Chimera heat sink. So far I have only bent one heat break and it took considerable effort. It is still quite usable although when you use the bent heat break in a two material setup it gets to be a pain to keep track of the offsets between nozzles which keeps changing based on the rotational position of the heat break. There are set screws for the heat break and because the nozzle top tightens against the heat break bottom, I have never run into an issue with the nozzle loosening. I have run into the nozzle loosening issue in the common hot ends as used for example in the Creality CR10 as the nozzle never locks against the heat break.

mrehorstdmd, any chance of a URL to point to the hot end you are using ?

-

@deckingman said in mellow nf crazy hotend:

My best guess would be that the 4 "pillars" between the heater block and the (what should be ) cold part are made from solid rod, whereas on the genuine Mosquito, they are are the same 75 micron thin wall tubing. Are you able to take it apart to check?

It came disassembled

.. yes they are tubing, I'd say regular stainless steel, they are very thin walled, easy to damage, tubes ... I didn't measure how thick they are, eyeballing them I'd say .1mm but I will check them under microscope to measure exact thickness

.. yes they are tubing, I'd say regular stainless steel, they are very thin walled, easy to damage, tubes ... I didn't measure how thick they are, eyeballing them I'd say .1mm but I will check them under microscope to measure exact thickness -

@dragonn said in mellow nf crazy hotend:

Dragon Hotend

Seen the dragon few weeks ago, looks like they copied the idea from mosquito but made it bigger and easier to manufacture maybe, dunno ..

I'm cooling the

mosquitomellow crazy hotend with single 25x5mm fan (can't fit bigger fan there nor there will be point imo .. now 25x5mm fans are puny as you know and I have not seen 25x10 .. I have only one on mellow and in theory, I can add one on the back to have push-pull too but they are advertising that it can work without any fans so while it can maybe made to work acceptably, imo this is a total fail

so while it can maybe made to work acceptably, imo this is a total fail  I'll rather go back to V6 or TitanAero as I don't see the benefit of

I'll rather go back to V6 or TitanAero as I don't see the benefit of mosquitothis clone then... I wanted to use it to print PLA not PEEK

-

@jens55 said in mellow nf crazy hotend:

I can see some issues with the V6 but if it is as bad as it sounds then why did Slice Engineering make the 'Copperhead' hot end which is a somewhat improved V6 ?

'cause they wanted to have cheaper hotend in their portfolio ?

-

I used e3d X nozzle for this test, first time I tried X nozzle, they are support to have some polyfobic coating that makes plastic not stick to them ... well ..

(yes I already moved it to V6 ..) this green/blue thing is PLA, I cleaned the inside with nylon (not very good I might add will have to repeat that) but the outside won't clean easy .. will have to check it out later but it's hardly polyfobic

-

Well yes, that makes sense .... but if it was THAT bad, they wouldn't want to sully their brand name with it. It looks like it will only be marginally cheaper but could easily capture more market share from those of us who didn't win in the lottery.

BTW, in Canadian currency the price for the Mosquito is as follows:

Hot end $200

heater $30

temperature sensor $57

fan not listed by vendor

tip $56

Thermal paste $16

For a whopping total of $359 minus the fan

The same supplier lists the E3D V6 full kit with fan for $79 (with heater, sensor, fan and small bit of thermal paste but only a regular nozzle)... and then it has problems printing PLA .....

-

@smece said in mellow nf crazy hotend:

I used e3d X nozzle for this test, first time I tried X nozzle, they are support to have some polyfobic coating that makes plastic not stick to them ... well ..

Thank you for posting that! I was pondering on trying that nozzle next at $43 * 2 .... so with freight you just saved me a cool $100 (yeah it's only Canadian dollars but it's still better than a poke in the eye with a sharp stick)

Edit: if you read the details it says it will stick 'less' ... not that it won't stick

-

@smece said in mellow nf crazy hotend:

now 25x5mm

I actually found I have 25x10mm 12V few pieces, I assume they will cool way better than these 25x5mm 5V so I'll give it a go with 2 fans push/pull with these bigger 25x10mm 12V ..

-

@jens55 said in mellow nf crazy hotend:

... and then it has problems printing PLA .....

everything else I can explain, the price, why ppl would buy it, everything ... but not this

... if it's not printing PLA there will be a hell to pay

... if it's not printing PLA there will be a hell to pay

@jens55 said in mellow nf crazy hotend:

Edit: if you read the details it says it will stick 'less' ... not that it won't stick

I don't see it stick less ... on another printer where I have same nozzle for ~3 years now, some microswiss hardened steel one (not black, shiny) where I printed a lot of ABS and PETG and it's still shiny .. the alu heatblock is black and disgusting but nozzle is shiny ... this "polyfobic" nozzle didn't print anything and it's already dirty

... just my ranting about e3d today nothing else .. nozzle probbly performs good have not yet done a proper test (got .2, .3 and .5 of those X ones, now I put regular brass one in the mellow as no point using X for any testing now, I doubt that printer will see much printing

... just my ranting about e3d today nothing else .. nozzle probbly performs good have not yet done a proper test (got .2, .3 and .5 of those X ones, now I put regular brass one in the mellow as no point using X for any testing now, I doubt that printer will see much printing  since if it does not become operational till monday it will go in the garage waiting next free time slot to be dedicated to it (and that's not slice nor e3d fault, only my missmanagement of time

since if it does not become operational till monday it will go in the garage waiting next free time slot to be dedicated to it (and that's not slice nor e3d fault, only my missmanagement of time  and stupid decisions)

and stupid decisions) -

@smece said in mellow nf crazy hotend:

I'm cooling the mosquito with single 25x5mm fan (can't fit bigger fan there nor there will be point imo .. now 25x5mm fans are puny as you know and I have not seen 25x10 .. I have only one on mellow and in theory, I can add one on the back to have push-pull too but they are advertising that it can work without any fans

so while it can maybe made to work acceptably, imo this is a total fail

so while it can maybe made to work acceptably, imo this is a total fail  I'll rather go back to V6 or TitanAero as I don't see the benefit of mosquito then... I wanted to use it to print PLA not PEEK

I'll rather go back to V6 or TitanAero as I don't see the benefit of mosquito then... I wanted to use it to print PLA not PEEK

..............and this is exactly what really hacks me of about people buying clones. Not only does it not work, but then the original gets the bad reputation for all the faults that the cheap, crap, clone has.

You say you are quote "cooling the mosquito with single 25x5mm fan". But you are not ! You are cooling the cheap crap "mellow nf crazy" hot end with a single fan. Then you go on to say "I'll rather go back to V6 or TitanAero as I don't see the benefit of mosquito" but you haven't tried a Mosquito! Just a cheap crap clone that looks like one.

It reminds me of a post I saw elsewhere some time back from someone who bought a cheap, crap, clone of a Diamond hot end that didn't work. It later transpired that the cheap crap clone was actually made from brass plated steel rather than solid brass. But rather than face up to the fact that the cheap clone was crap, the OP insisted that all Diamond hot ends were crap.

-

@jens55 said in mellow nf crazy hotend:

Well yes, that makes sense .... but if it was THAT bad, they wouldn't want to sully their brand name with it. It looks like it will only be marginally cheaper but could easily capture more market share from those of us who didn't win in the lottery.

BTW, in Canadian currency the price for the Mosquito is as follows:

Hot end $200

heater $30

temperature sensor $57

fan not listed by vendor

tip $56

Thermal paste $16

For a whopping total of $359 minus the fan

The same supplier lists the E3D V6 full kit with fan for $79 (with heater, sensor, fan and small bit of thermal paste but only a regular nozzle)... and then it has problems printing PLA .....

You only need buy the hot end for 200 C$. You can use a cheapo heater and it'll likely work just as well but maybe not as reliably. You don't need buy the high temperature sensor, you can use any cheapo thermistor if all you want to print is "normal" filaments. You don't need buy the vanadium nozzle - you can use any M6 x 1 threaded nozzle. You don't need to buy the Boron Nitride paste, you could use something like Loctite 8065 (or nothing at all).

As for problems printing PLA, are you sure or is that just hearsay? Do these problems exist with the genuine part of just the cheap clones (we can see above how problems with cheap clones tarnish the reputation of the genuine article). Are the "problems" down to user error? i.e. people turning the printer or fan off before the hot end has fully cooled.

-

@deckingman yes you are 10000% correct, I hate that too and then I do it too subconsciously

... now to my defence I did say numerous times it's a clone and I'v seen images of original showing something completely different and .. and ...

... now to my defence I did say numerous times it's a clone and I'v seen images of original showing something completely different and .. and ...but yes, serious mistake, and just for the sake of web indexes I'll try to go trough my messages in this topic and edit them

EDIT: I found only one place I called it "mosquito" and I fixed it, if you see any other lemme know

@deckingman said in mellow nf crazy hotend:

As for problems printing PLA, are you sure or is that just hearsay?

I hope the PLA problems (I never heard about them btw) are from these clones and not from original as if they did not fake the imagery (and I doubt they would dare) there's no way PLA will jam there... now, as I mentioned, there's an original waiting to be installed on the Wanhao D9 and we gonna test the crap out of it

.. and I'm gonna take same thermal images with same camera I imaged the mellow so I will update this thread (in few weeks I think)

.. and I'm gonna take same thermal images with same camera I imaged the mellow so I will update this thread (in few weeks I think) -

@jens55 This is the one I used: https://www.aliexpress.com/item/32865420265.html?spm=a2g0s.9042311.0.0.6e4a4c4dKNUgrr

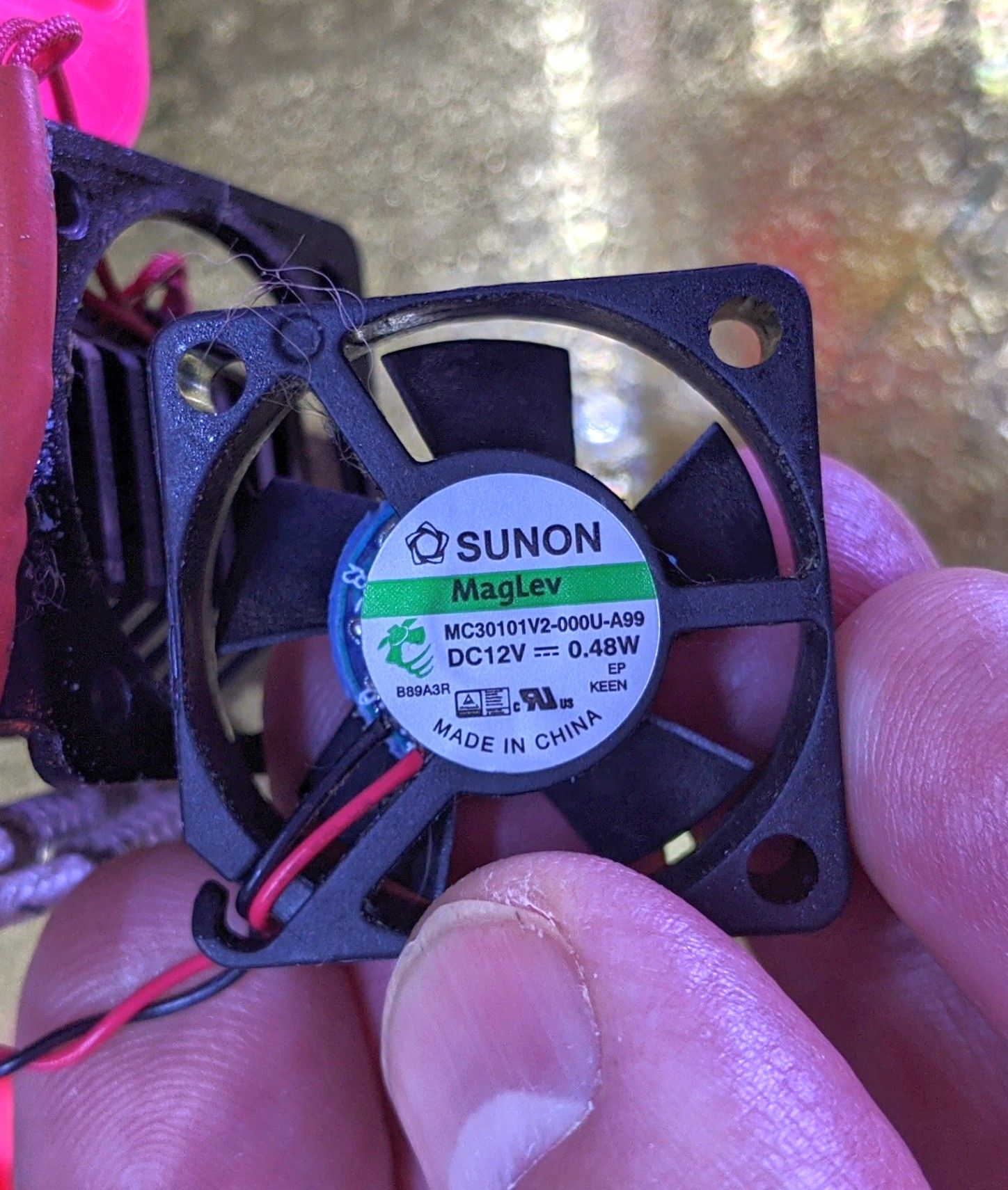

I've replaced an E3D V6 on a printer at the makerspace with one of these also. I originally thought my printer's 50C enclosure killed the fan, but the one at the makerspace behaved exactly the same way- it ran quietly for a couple hours then started making a lot of noise. I replaced it with a Sunon fan that I bought from Digikey for $7 IRIC (maybe obsolete now):

Sunon doesn't make 30mm 24V fans, so I use a buck converter to drop the voltage from the controller to 12V to drive the fan.

-

@mrehorstdmd Off topic but that's kind of spooky because I recently ordered some of the exact same fans for a project I'm working on. The only difference is that the part number contains "V3" instead of "V2". May I ask if they play nicely with PWM do you happen to know?

-

@mrehorstdmd said in mellow nf crazy hotend:

Sunon

I use TON of SUNON fan's in my projects, mostly 'cause they are only brand I can get locally that's not some longjonchina ... so a lot of experience with those. That one is good for hotend, not good for part cooling

@deckingman said in mellow nf crazy hotend:

May I ask if they play nicely with PWM do you happen to know?

MAGLEV ones don't play nicely with PWM. They don't have a bearing and they depend on the speed of the fan to keep them floating on the magnetic bearing, when you drop the speed they quickly start to vibrate and die (tbh "quickly" is a relative term here, I have maglevs working for 20+ years, and pwm-ed ones usually last year - two so "quickly" here is "a year").. those with air bearing are even worse so for PWM controlled fans (part cooling) you want fan with a bearings (sunon makes those too but they are famous for maglev line). the maglev line is perfect for hotend, I have some maglev 30mm and 40mm that are running, full blast, for 2 decades without a stop in a fairly dusty environment without a glitch, and for the same CFM they are quieter than noctua

-

We're hopping into the conversation a little late, but hopefully, we can shed some light on the PLA printing issue raised by @wesc. Despite the Mosquito being a high-temperature hotend, it can most definitely print PLA. In fact PLA is the second most common filament we print internally, after PA.

Generally, if users are having jamming issues with the Mosquito when printing PLA it can be quickly remedied by adjusting retraction and cooling fan settings. If you hear of anyone having issues when printing PLA, please have them reach out to us. We're here to help solve problems.

-

@smece said in mellow nf crazy hotend:

I used e3d X nozzle for this test, first time I tried X nozzle, they are support to have some polyfobic coating that makes plastic not stick to them ... well ..

I am running an E3D NozzleX in my v6 heaterblock, mainly because crashing a brass nozzle into something tends to deform the nozzle enough to throw off the alignment of the dual nozzles on the Chimera. And although these are quite pricey when compared to a brass nozzle, they are still a fairly cheap way to ensure that things will keep on working the same for a reasonable amount of time.

So far I am happy. PETG stringing makes little to no mess, have not yet seen those dreaded black blobs in a print that occur when the nozzle picks up stringing and drops it on the print when buildup has passed a critical amount. Whatever sticks to the nozzle is easy to remove.

Regarding cheap clones of whatever: you may get less than what you pay for, but you will never get more. Accurate machining and good quality base materials are often not required to make parts perform well initially, but accurate machining keeps parts performing well day in, day out. Compare a Papst fan with Chinesium. Day 1 both work well. Day 100 the Chinesium fan makes a lot of noise or stops working, the Papst keeps on humming like it did on day 1.

Frustration continues after the joy of saving a few bucks is long forgotten. In the end buying decent quality stuff saves money overall. Higher initial expense, but less money spent on failures and replacements, higher resale value, less headaches.

-

@SliceEngineering said in mellow nf crazy hotend:

We're hopping into the conversation a little late

Better late than never. Thanks for jumping in!!

Generally, if users are having jamming issues with the Mosquito

After my experience with a clone (very highly reviewed clone !! and the build quality is surprising, I'm sure you had one to look at

) I'd say that most of the "users" complaining don't have original

) I'd say that most of the "users" complaining don't have original

when printing PLA it can be quickly remedied by adjusting retraction and cooling fan settings.

Can you share the max retraction length, retraction speed settings please, I'm quite interested to know how those values on original mosquito compare to other all-metal hotends I have (hexagon, 1730, e3d-v6, d3d-titanaero, microswiss..) .. So far the hexagon can survive the most (almost 3mm) while others, depending on the material, won't go over 1mm

-

I had big problems with printing PLA with my Mosquito and experienced multiple jams.

In the end, I printed an adapter that let me mount a 30mm fan and the extra cooling cured all my problems. In retrospect, this could have been caused by the fact that my mount fits fairly closely behind the hot end and was probably reducing the air flow. Now, with the larger fan, the fact that the mount is just behind the hot end leads to the cooling air being reflected down onto the print, which is far from ideal for some filaments. So, my next change will be rotating the hot end by 90 degrees so that the exhaust air is not impeded by the mount. This may let me go back to the original 25mm fan, but to be honest, the 30mm fan is quieter and the adapter lets me point the intake of the 30mm fan slightly upwards to avoid the intake turbulence from also cooling the print and print bed.

-

@smece hopefully most have not had these issues with the real Mosquito. But if they have, we are certainly here to support our customers and will provide assistance with troubleshooting, or replacement hotends if that was required. Part of the cost of a legitimate product is paying the customer/technical support staff to provide lifetime support after the sale. The cloners don't have those costs.

Retraction length varies based on filament type and printing speed, but our general guidance for direct-drive extruders paired with the Mosquito is to set retraction to the same distance as the diameter of the nozzle you are printing with.

Ex: when printing with a 0.4 mm nozzle, set the retraction distance to 0.4 mm in your slicer.

For Bowden setups, the length of the Bowden tube heavily influences necessary retraction lengths and will require some tuning. We recommend halving the retraction setting used with your previous hotend (before Mosquito installation) and tuning from there.

Those lower retraction distances are the result of a well-defined melt zone with a sharp transition from solid to liquid plastic. For longer/larger print jobs this actually helps to reduce the time of the print substantially.