Making an epoxy granite machine base

-

Holy Moly!

-

if you can't get the pigment out just to a chalk outline of a smurf..?

are you planning on having some thermal insulation between the bed, or will it stay at temps well below where the epoxy start getting softer?

-

@bearer said in Making an epoxy granite machine base:

are you planning on having some thermal insulation between the bed, or will it stay at temps well below where the epoxy start getting softer?

It might not be very clear in the previous pictures, but in order for the heat to creep from the bed all the way to the epoxy, I would need to be rocking some pretty serious bed temps

. In fact the bed only makes contact with the three ball joints it rests on. (the balls from that came with the smart effector actually)

. In fact the bed only makes contact with the three ball joints it rests on. (the balls from that came with the smart effector actually)

-

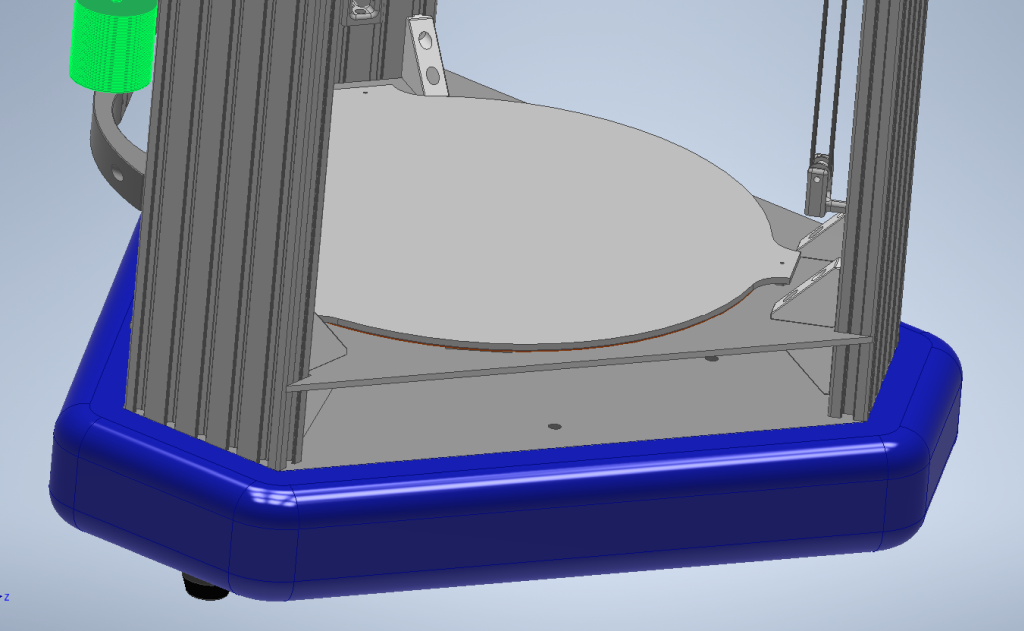

Finally a next progress report

I got some transparent high gloss top coat on polyester base. This is what was recommended by the same place that I got my epoxy from. I applied four coats with progressively finer sanding in between the layers. I am quite happy with the result, the EG base is now more or less smooth to the touch on the sides and perfectly glossy on top.

The next step is to fill the towers with sand. And I also have some materials on the way to replace the white printed corner brackets with some more rigid 3060 metal brackets.

-

@Nxt-1 said in Making an epoxy granite machine base:

drilling some d10mm holes in the bottom plate of the printer to allow M12 threads to be tapped. Six bolts were screwed in downwards, purely to have some extra surfaces where the epoxy can adhere to. (picture 1) Then followed a quick test fit with the empty mold and pr

How did you fixed the bolts in the vertical rail ? Or what type of profile was it?

-

@c310 said in Making an epoxy granite machine base:

@Nxt-1 said in Making an epoxy granite machine base:

drilling some d10mm holes in the bottom plate of the printer to allow M12 threads to be tapped. Six bolts were screwed in downwards, purely to have some extra surfaces where the epoxy can adhere to. (picture 1) Then followed a quick test fit with the empty mold and pr

How did you fixed the bolts in the vertical rail ? Or what type of profile was it?

The towers are 30150 aluminium extrusion, with the center holes tapped to M10. The M12 bolts you quoted actually sit the other way around in the frame. The pike trough the bottom and sit in the epoxy base.

-

I never thought I would see a Delta that would approach the weight of my corexy. 104KG. Never even considered filling the extrusions with sand though. That would add another 15KG for me. And you'll never catch up once I add the drawers.

-

@macguyver said in Making an epoxy granite machine base:

I never thought I would see a Delta that would approach the weight of my corexy. 104KG. Never even considered filling the extrusions with sand though. That would add another 15KG for me. And you'll never catch up once I add the drawers.

There are plans in the making for a V2 of the printer that would add, guesstimating, another 30kg to the printer

-

@Nxt-1 Have you considered putting the aluminum base at the bottom of the casting and encapsulating the extrusions in the casting? Would probably add a tremendous amount of rigidity and dampening.

-

@macguyver said in Making an epoxy granite machine base:

@Nxt-1 Have you considered putting the aluminum base at the bottom of the casting and encapsulating the extrusions in the casting? Would probably add a tremendous amount of rigidity and dampening.

Yes, I have, and it would add rigidity if done properly. This is normally how it should be done, however you need rather thick sections of EG surrounding the metal core before it really becomes beneficial. This was not really something feasible for this project as this would require more epoxy (expensive as hell), large molds, intricate work holding, thick sections of EG and is only practical for a 100% finished design. My design is still evolving quite a bit as I go along. (the build log in my bio might give you an idea)