Having problems with Anycubic Kossel Linear Plus calibration

-

that bed would account for the slight irregularities that you are seeing. so you will need to print with mesh bed levelling enabled.

check with M122 that the bed was actually loaded and is active.

-

@Veti

M122:

=== Move ===

Hiccups: 0, FreeDm: 169, MinFreeDm: 163, MaxWait: 26536ms

Bed compensation in use: mesh, comp offset 0.000so mesh is enabled. Then why the nozzle height is good at center but too low at x-50 y-50 for example? I thought with mesh enabled nozzle height should be more accurate at all points.

One more thing, on loading bed mesh (G29 S1) i get this:

Warning: the height map was loaded when the current Z=0 datum was not determined probing. This may result in a height offset.

What am i missing? -

just checking, but you did generate a new heightmap when i asked you to run the G29?

-

@Veti

Yes, this is a new map. I run S8 autocalibration when adjusted Z probe height. Rebooted printer. Checked that with z0 paper can be just dragged under the nozzle in bed center after that.

After that i run G28 and G29 S0 P"heightmap.csv"

When finished i check that the map is generated (can be viewed in DWC).

Rebooted printer again. Run G28 and G29 S1. Check that z0 is good at bed center. Move to x-50 y-50 and check z0 again - it occurs too low (paper is stuck under the nozzle).

M122 shows that mesh is active at that moment. -

@SnakeSP said in Having problems with Anycubic Kossel Linear Plus calibration:

x-50y0 - ok

x-50y-50 - too low

x-50y50 - a bit too highhmm. i am thinking there might be a slight effector tilt that shows up due to the distance from the probing point to the nozzle.

if you are willing to invest an euro this is what i have swapped to as a probe on my kossel linear plus.

https://de.aliexpress.com/item/32838312776.html

its cheap and has nearly no offset. -

@Veti

Yes, thought of that thing, possibly will do.

I'm using stock Anycubic probe right now and have a BL Touch clone, but cannot try it with stock effector. Need to print a custom effector to try BL Touch.

So yes, this thing is worth trying except for wait time till it gets to me from China. -

the bltouch mounts will have a significant offset in the x and y direction. if there is effector tilt, then that will also cause problems.

-

@Veti

indeed.

Anyway, there is no fast way to change the Z probe at the moment, so i have to carry on with what i have.

Here is the test print result. PETG at 70C table and 225C nozzle (factory recommendations are 60 and 220-245).

Speed down to 20 mm/s. No offsets or babystepping used.

I'd say the good print was only in the front middle and front left (though nozzle was too low there during tests). Center is a complete mess, but this is possibly due to table being worn off there (i had a bad print where plastic was literally smashed into table there). The other prints have delaminations at corners mostly.

Full size

-

Made a lot of experiments. Understood that i'm an idiot, but that's ok, i always suspected that.

I always thought that calibrating with nozzle just touching paper gives enough hight. But it occurs that it is better to have a nozzel at around 0.3 mm from bed (given that the bed surface is not perfectly flat). That was my mistake from the very start. I should have started with bigger babystep and go down until getting best results.

Many thanks to you all who helped me to understand this!Finally got first layer sticking all over the bed (there are some minor imperfections sometimes but mostly at the bed edge which is not used very often).

Got this on 70C bed, 240С hotend, +0.10 babystep, first layer width 90%.

So looks like the sweetspot is found.Now i'm confused with this question: what to do with this? I mean using babystep at every print start does not look like permanent solution. So what is the correct way to do it? Change the Z height in delta settings or use First layer height = 150% setting in slicer or use Z-offset = 0.15 setting in slicer or change the Z probe height to current - 0.15 and recalibrate?

I think using First layer height = 150% is the best solution (in Simplify3D at least) as it will raise extrusion amount enough to give the good layer.

-

you adjust the G31 Z offset by the babystepping value that works for you.

then run the delta calibration again and use those values. -

@Veti

Tried to do so and after calibration and new bed mesh correction ended up with not sticking again... Strange.

Reverted to the working values and made corrections in slicer (extrusion height and width on first layer) - works fine. Will keep this setting for now. -

@SnakeSP said in Having problems with Anycubic Kossel Linear Plus calibration:

Tried to do so and after calibration and new bed mesh correction ended up with not sticking again...

did you increase or decrease the z offset. i sometimes get the direction confused and decrease it because the baby stepping was negative.

-

@Veti

I had Z probe height at 15.585 when i got good first layer sticking with babystep +0.1 mm (higher from bed 0.1 mm) which gave me total nozzle height from bed 0.3 mm when printing first layer. Also extrusion was higher than normal.

When i tried to recalibrate i have set Z probe height to 15.485 mm, which is in my understanding moving nozzle 0.1 mm from the bed (lowering Z height is moving nozzle from the bed, increasing Z height moves the nozzle towards the bed), or maybe i'm wrong? -

@SnakeSP

yes correct direction. -

Started from scratch (saved the working config to be sure).

Got bed heated to 70C, lowered nozzle to scratch the sheet of paper at center. Removed the paper and lowered nozzle -0,8 mm (measured paper thickness) so it was touching the bed (at least i assume).

Set that height to be Z=0.

Used G30 S-1 several times to determine the probe Z height. Saved it to config.g.

Rebooted printer and started S6 autocalibration. Got result about 0.048. Saved it with M500.

Measured Z offset at all points from bed.g with G30 S-1 and updated bed.g with H for each point.

Run S6 autocalibration again and got promising result:

Calibrated 6 factors using 16 points, deviation before 0.016 after 0.010. Saved with M500.

Subsequent calibrations gave results around 0.007.

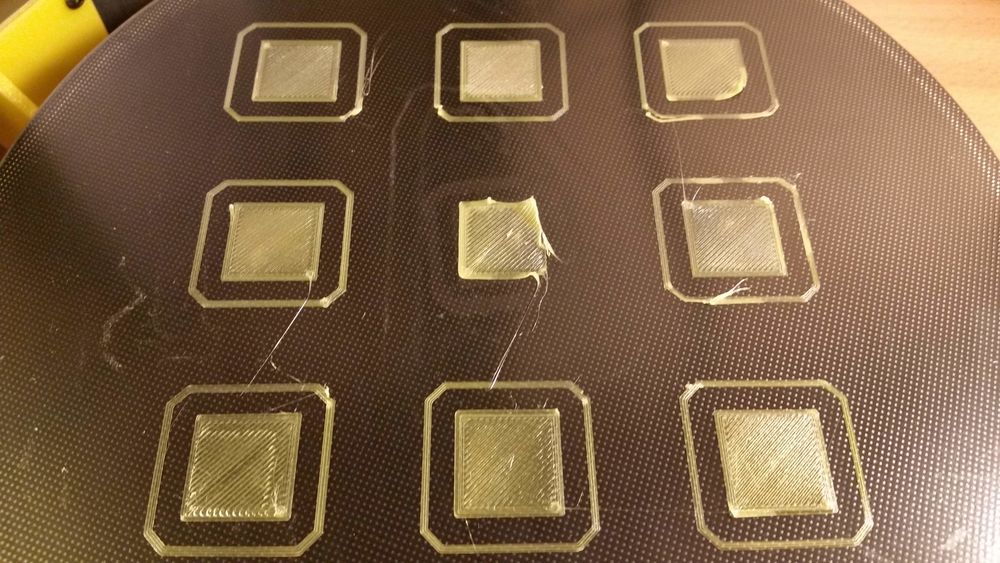

So i tried running test print with 9 20x20 squares all over the bed with First layer height = 100 and First layer width = 100. Almost all came out fine except for one in the front and one at center.

After cooling, cleaning the bed and heating it back to 70C i used G30 to provide Z=0 datum and used G29 to create bed mesh. Results were rather good:

305 points probed, min error -0.091, max error 0.168, mean 0.034, deviation 0.043 (peak points at max radius).

Printing with bed mesh active and same slicer parameters gave exactly the same result as before.

So i tried to use First layer height = 150 and First layer width = 90 as i did before. Print came out almost the same as the one without bed mesh active. Again not sticking at center and front. I do not understand, as it looks like bed mesh is not working.

photo -

it looks like bed mesh is not working.

To be sure, just enter G29 S1 from the console before you start your print.

Apart from that, the max. error from probing is quite high - either your bed surface is deformed or the Z-speed setting for probing is too high.

-

@infiniteloop

I have included G29 S1 into starting script in slicer, so the bed mesh is loaded (checked with M122).

The bed is deformed indeed, but not that much (+/- 0,16 should be compensated without major problems with bed mesh, i assume).

Probing speed is F120, should not be too fast. -

Probing speed is F120, should not be too fast.

Indeed, that’s rather slow.

+/- 0,16 should be compensated without major problems with bed mesh

That depends. The distance between probing points may ignore some details. I don’t know what your current hight map looks like, but according to your latest test prints, it might be interesting to have a closer look at the two areas where the filament delaminates.

For that, you can define a special grid to probe, just one area at a time, with a very narrow grid spacing. The resulting hight map is like a look through a magnifying glass.

Of course this will not cure your problem, in the best case, you only get a better understanding of what happens.

An alternative explanation for the observed delaminations might be a damaged surface, damaged in the sense that the coating in these areas does no longer stick well with the filament.

-

@infiniteloop

The mesh is dense (305 points).

As for the delamination reasons - looks like the nozzle is a bit too low at that points. Babystepping +0.05 solved this, but this again is not permanent solution... -

The mesh is dense

Too lazy to do the math, but the resolution is at approx. 10 mm - not enough for a close look. But talking about babystepping: Do I understand you right that this is only true for prints in these two areas, or does this work for the whole print bed?