JoergS5 parallel five bar scara

-

I have done some thinking

There are 3 unpowered joints that causes a singularity when they are at 180 degrees, and at 0 (or 360) degrees. Below 180 is stable and over 180 is stable. It would make sense to define the work modes depending on those angles. An angle at 0-180 is one state, 180-360 another state. This would create 8 different modes with the 3 joints (2^3).

First we have the 4 modes that you named:

And then there are the 4 "inside out" modes. The same as 1-4, but on the other side of the machine.

I think that it we use these constraints in the code to pick the right solutions from the equations we will get a fairly simple solution, and it will be complete and general. Both forward and inverse transform should have only one solution in a given working mode, or my theories are wrong.

A few fun positions:

-

@JoergS5 , that wasn't too hard to implement

. The code is a horrible mess and very inefficient, but it works. On my PC.

. The code is a horrible mess and very inefficient, but it works. On my PC.I skipped the extra 4 modes I came up with, they require the arm to travel through a singularity with the hotend joint at 180 degrees. Or even at 0 degrees! I think that is more or less impossible with a stepper driven arm.

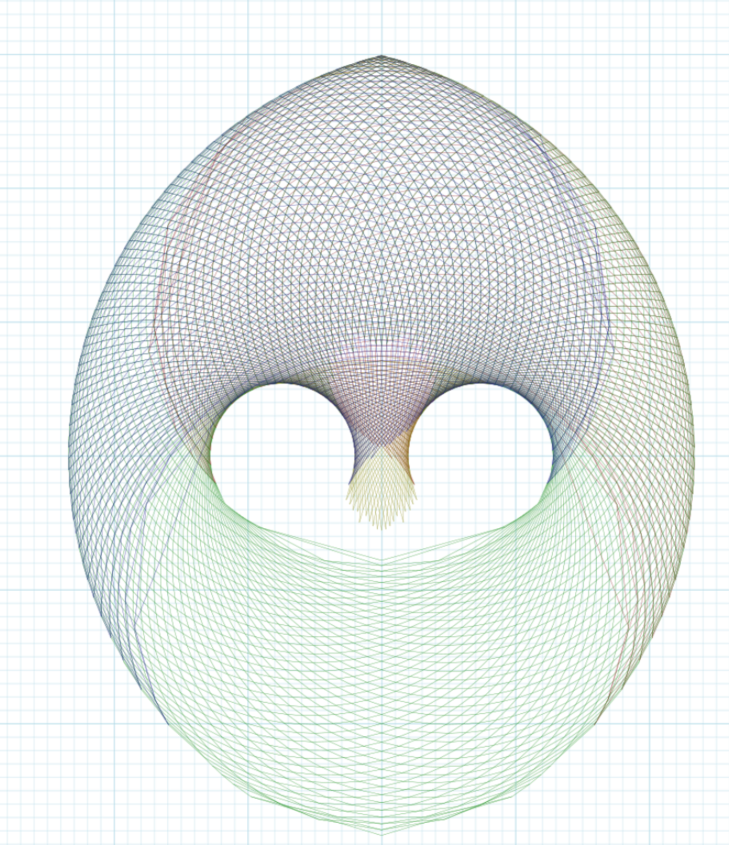

And here is a new updated resolution map from my bot (assuming no collisions with anything and full 360 degree actuators). Green is mode 2, blue and red is mode 1 and 4. Yellow is mode 3.

I'll port it over to the Duet after a cleanup. I only have a Maestro board for the Scara, it has no FPU. So I have to be careful with all the floating point trigonometry. An obvious optimization is to not actually compute the angles of the joints, all we need to know is if it's a left turn or a right turn, that is easy to do without trigonometry.

-

@bondus Your image is very nice. But for 3D printing, we need a continuous print area, so I would restrict it to the red-blue area. That's the main reason why I defined a printable area to be a rectangle. There is a bit additional printable area outside of the rectangle, but I expect only a few % gain.

You can change the print area for your printer by making the distance of the actuators variable (manuallly or by an additional actuator), so you can enlarge or reduce the print area. You mounted the actuators on one aluminium profile, so changing the distance is easy. For every object to be printed there will be an optimal distance: fitting print area with maximum resolution.

I design a printer where the heatbed fits the to be printed 3D object, so only the needed area needs to be heaten up. Together with the actuator distance and optimal arm lengths, a best print result can be achieved. -

@JoergS5, I have disabled all the limit checks just to see that all the math works as intended. When I turn the limits on all is back to normal. I'm a computer scientist, not an engineer. I want the theory right

.

.

Before this logic was implemented there were areas (even in reasonable print areas) where forward and inverse transforms did not agree. The changes for this are just the "if"s in getTheta() and getForward(), no major changes.There are some cases where the math breaks down and forward and inverse transforms do not agree. This is totally expected

since it is along the singularity lines. Figure 10 in the DexTAR paper (https://pdfs.semanticscholar.org/4f94/5b3db879c18c8fdf2b01860d8a9b2f9a274d.pdf) shows this very clearly. That is a fantastic figure.It's an interesting idea to have adjustable actuator distance. I think that if you want to build a useful printer you have to pick a work mode and choose the length of the arms and distance of the actuators to get a reasonable large printer area. Mode 2 benefits from having long distal arms, mode 1 and 4 are better with equal length arms and a big distance between the actuators. I imagine that for mode 1 and 4 you could even have different lengths of left and right to maximise work are.

I made a github repo, https://github.com/bondus/5barscara. Right now there are just the lab files for the kinematics (copy pasted from the kinematics from RRF) and the test program drawing those fancy pictures. I'll add my version of the RRF kinematics once I got the new stuff ported over.

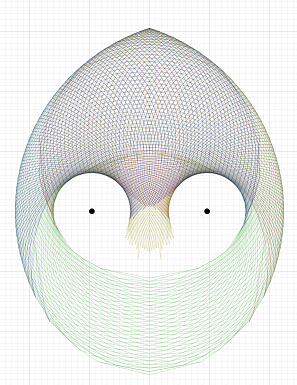

Some pupils (actuators) for the masked five-bar-man:

Be careful with a partially heated bed, you might warp it.

-

@bondus nice face LOL - take it as logo for the printer...

I didn't mean a partially heated bed, but a small bed. For every to be printed object a separate heat bed.

-

I made the face interactive using some JS and html: https://fivebarscara.000webhostapp.com/test.html.

It's a little web page where you can input arm lengths, actuator distance and work mode. And interactively see the work areas, and the arms moving. Move the mouse over the work area and the arms will pop up. Different colours for different work modes.

It's quite mesmerizing.

I might add the angle limitations to the interface. It could be a useful tool for anyone brave enough to build a five bar scara. It's still useful to understand how fire bar scaras moves.

-

@bondus The tool is nice. I have ideas for improvement

I used arms lengths 400, so a zoom in/out would be nice. Showing the coordinates of the hotend point would be nice to know the printable area. -

I pushed my current 5 bar code to https://github.com/bondus/5barscara/tree/master/rrf, it's what I use on my printer right now.

The main thing compared to @JoergS5's implementation is the more general angle logic. As explained above.

And it's updated to the current RRF.

The code needs some love to be production quality, but it works good as is. -

I found this interesting implementation a few days ago, http://3dgems.blogspot.com/2016/01/scara-based-3d-printer-v3-details.html.

This kinematics should handle it. It is a work mode 2 arm with a very long negative cantilever on the left arm. It should work as long as the hotend is not offset from the straight cantilever. -

@bondus Thanks for the link, this seems to be a very stiff construction. The print area seems to be limited somehow, because the arms are in each other's way.

I've started building my Scara now, I will have images soon. Then I will update the source in RRF3 (including your improvements and bug fixes) and make a push request to David. My current plan to implement the endstops: set proximal arms perpendicular to base line and measure them for parallelism.

-

Looking forward to those images of your machine.

I have been struggling a bit with the calibration of the printer. It is not accurate enough to print parts for itself.

I made some experiments with printing a calibration item, measuring it and feeding it into a program to compute the actual homing angles, and adjustment to the arm lengths. I have not not been successful. Yet.

Your idea to move them to 90deg and measure parallelism and perpendicularity (is that a word?) is faster and easier. Adding S1 to a G1 command moves the arm to a specified angle, G1 S1 X90 Y90.

-

I built this little toy to play with a more agile arm. The only things that collides are the proximal arms. It happily does all work modes. With very poor precision

I wish I had more duets, or some other lesser board that could run RRF. The little 8-bit arduino chokes up fast. It's like being back in the 80's, but with better tools.

-

@bondus your image reminds me of my first model to understand parallel scara. I built it from wood. Playing around with it really helped understanding the idea.

If you want to try alternative electronics, you can try Cortex M7 based boards. The disadvantage is of course that all other things like stepper drivers are missing, compared to Duet.

-

Some of the academics have strange ideas. Found this oddity in an (unpublished) paper:

I need to sign up to the university again to get access to all the pay-walled academic papers. -

I finally started working on a calibration method again, my arm produced horribly twisted prints. It works now.

I did something similar to how klipper does delta calibration. You print a model, measure a lot of distances and feed that into a program that figures out what arm lengths (4 of them) and homing angles you have.

It's doing a pretty brutal search looking for a solution with the least sum of square of errors.

It took a few models and measuring methods to get it working. Too few or not properly selected measurements made it find strange solution, the resulting printed models where right but other prints were twisted.

I could probably steal the model and method used by klipper delta calibration. It looks like they have a clever method to make it ignore the errors introduced by printed walls being slightly too big or small.

I'm not sure what to do with the code. I could port it to javascript and integrate it into the little tool I made before.

This calibration tool is pretty necessary if you build the printer with printed parts and hand tools, it's hard to get things exact and it's hard to measure the built printer.

Before calibration to the left: P161.40:161.40 D207.00:206.00 B227.00:151.50

After calibration to the right: P161.18:162.43 D208.28:209.97 B227.84:152.16

I did some experiments with crazy print speeds and accelerations. Printing at 300mm/s and 12000mm/s/s acceleration works fine mechanically. The extruder complains and the ghosting is horrible, but the arm keeps up fine

https://www.youtube.com/watch?v=MW8HApFoy38

https://www.youtube.com/watch?v=MW8HApFoy38

It's quite fascinating running with very high acceleration. I wish my machine was stiffer. -

@bondus You have a nice printer and good speed.

I am still gathering ideas about two main aspects building the printer:

- how to make stiff arms and hinges without backlash. Using a gear 1:30 without backlash between stepper and arm

- diy an optical encoder to define the exact end stops

I know what you mean with your comment about university. I tried to get access to researchgate, but without success. They only accept if you're a student or have written a scientific article. I tried it two times. Fortunately some articles are open access.

-

There is an interesting article: Dissertation "Neuartige Drehgelenke für reibungsarme Mechanismen – Auslegungskriterien und Berechnungsmethoden" von Kern 2013, discussing about backlash free hinges. This should allow a higher precision of the arms.

-

@joergs5 said in JoergS5 parallel five bar scara:

how to make stiff arms and hinges without backlash.

My very naive implementation with preloaded thrust bearing works amazingly good for the elbows. It is definitely not the right way of doing it and I expect the bearings to break pretty fast.

I got some fancy angular contact bearings on aliexpress, very nice ABEC-5 bearings, just $5 a piece. DexTAR use two of those in each elbow, preloaded, as they are supposed to be used. But my prototype with those bearings and printed parts does not work very well. PLA is too soft.You are right chasing backlash! A small backlash or flex is amplified further out.

Don't forget to make the tower the arms are attached to as stiff as possible. My tower is a bit soft with 3 12 mm rods and a single 3060 extrusion to the top. It's hard to find space for the tower if you want good mobility for the arms. Reprap morgan has an interesting arrangement of the pipes in it's tower, triangulation is good.

"Neuartige Drehgelenke". Interesting, bushings and flexible joints. I have to dust off my German and have a closer look...

-

@joergs5 said in JoergS5 parallel five bar scara:

diy an optical encoder to define the exact end stops

Double sided tape and a piece of bent metal. That's why I need calibration

-

The calibration is not perfect.

Small configuration errors gets amplified when you get close to singularities. The bent line at the top are ~50mm from where the distal arms are at 180°.

I need a bigger bed