Core-XY based on Rat Rig V-Core and Duet 2 Ethernet

-

To late now, I have 24V fans ordered now from Radionics, they will arrive at work before I am back home here on Thursday. Cant do anything till then anyway, at work for the duration. But thanks for the tip, much appreciated.

Jan

-

@deckingman, I ask you cause you seem to have a lot of knowledge when it comes to practical mechanical engineering. I am still not all that clear how I go about fixing glass and flex plate surfaces to a aluminium print bed. I have settled for 340x340 in size but thickness I am not yet clear. Given is a rather large bed I would almost think 15mm but is that realistic to get heated ? For a glass plate I think I would have 4 holes on the sides with knurled M6 or M5 bolts to clamp down an aluminium angle to hold it down. For spring steel I was thinking to make a pattern of holes, example a 5.5mm hole and a M3 thread in the center to have round countersunk magnets bolted to the plate BUT flush with the surface or even 0.5mm below. Do you think the stainless M3 bolts for the magnets and the magnets as such would cause warping of the aluminium plate when heated due to different expansion of aluminium and stainless bolts ? Would the hole pattern itself cause significant warping when heating ?

Its a lot f questions, but given the price and work involved I'd rather get this right the 1st time. I am even thinking of sending a CAD file to a factory, Weerg for example can make such a plate for approx 450 Eur including all the magnet pattern (25 holes and center holes with M3 thread etc.).

Jan

-

@snoozer My preference is to have removable build surfaces. Mostly because it allows me to slide one out as soon as a print is finished, then slide another one in so that I can start printing again without waiting for the bed to cool down and heat right up again. For my 400mm x 400mm bed I use 10mm thick aluminium tooling plate but in hind site, 8mm thick would have been sufficient and would warm up faster. On top of that, I use 6mm float glass (un-toughened). I choose glass because it's flat (as long as you don't get it toughened) and relatively cheap. 6mm thick is surprisingly difficult to break. I use 3D lac on the glass because it "just works". I can lay the first layer down at normal print speed - generally 90mm/sec but have managed 300mm/sec and I've never seen anyone lay a first layer down at anything like that speed using any other print surface. Oh and it allows me to print things like this on end https://www.youtube.com/watch?v=vG1WqijJ634&t=63s

To hold the glass in place, I use a couple of thumb bolts with washers that screw into Tee nuts in the bed frame. Then I use some aluminium angle from front to back, with a couple of vertical slots that line up with the thumb bolts. I cut the aluminium angle down along it's length to form just a small lip where it holds the glass. I just press down on the aluminium angle and tighten the thumb bolts to hold the glass in place. To release the glass, I simply slacken the bolts an slide it out forwards. Here is a picture of the side view (without glass). The aluminium build plate was painted matt black because I used to have an IR probe (but hat doesn't play nicely with 3D Lac).

I have no experience of using sprint steel (have no need of it), so can't comment on how best to fix it.

HTH

-

I'm doing the same on a smaller scale 150x150mm; but magnets seems to be stuck in customs so can't say much about how it'll work.

Since aluminium spread the heat quite well I had enough space between my heating traces to embed 3x3 grid of 6x20 pockets from the underside and still have a perfectly uniform temperature on top (measured with thermal camera and masking tape)

For the glass I'm hoping to use magnets as well, use diamond annular cutters or hole saws to make a series of overlapping cuts to make up a shallow pocket to embed something for the magnets to attract to. Waiting to try out the steel first before I start messing with the glass

Havent decided on registration yet, pins, edge, just the magnets, idk,

-

@deckingman Thanks for that explanation. You told me before about the float glass and why you use that. It would be what I would try to use as well. I have room on the top of the print bed on this printer. The bed would be wider than the actual print surface which I also will have removable. I would have Z shaped aluminium profiles along both sides to hold down the glass or 4 clamping arms, not sure yet. That depends also on how I do the enclosure and how accessible it will be then. On the rear end I also have some room on top where I would put two dowels to line up the surface so its forced in an accurate position every time. I have done a bed design yesterday evening with 25 holes for magnets and M3 threads, mounting, gap for thermistor close to the surface etc in Fusion 360 to check a price with Weerg....... yea..... not really, I was slightly unrealistic with my preliminary pricing. It would be almost 600 Euro for a single bed on my dimensions.

I get the tooling plate of cast aluminium machined to size 0.1mm tolerance, that should be OK. That was about 80-90 GBP in 15mm I think, have to check 10mm. There was a couple of other suppliers which state no tolerance, they are cheaper but I rather not chance that.

The flex plate is a different drama, I am almost tempted to give up on that for now at least. I can not find anything trustworthy re spring steel in the right dimensions and thickness and it is always with PEI sticker, not powder coated except one Crowdfunding thing that was unsuccessful. If I come back to that idea I can still rethink magnets in the bed and add them later. My reason behind Spring Steel is only because I know it from the Prusa, But you and many other people are very successful with glass, so its must be just a matter of getting used to it. From a surface quality point of view glass must be better anyway and my Prusa print surface does have cracks in places which shows on the bottom side of a print.

I have read you posts re proper mechanical design for a bed that has 0.1mm height difference on the entire surface in a different thread. That is exactly my thinking. Auto Bed Leveling is great but good mechanical build is better in my view. So that's what I am aiming for. How did you mount your tooling plate to the printer ? how do you adjust it to be level in relation to your nozzle ? Re color, I will use a piezo probe, the color will not matter for me.

@bearer, you add magnets from the underside, do I understand that correct ? How much aluminium do you have left between the magnets and your print surface ? I have tried magnets under my original V-Core 3mm plate with the Prusa surface on top and found it did not work for me. My approach would have been to have magnets from the top to avoid having aluminium between the magnets and the surface. The other worry I had was the different expansion with heat and how that would have an impact on the flatness of the aluminium print bed. I understand you don't yet have the magnets so I guess you dont yet have an answer to the latter ?

Re metal inserts in glass, that would worry me even more. I will take a similar path as deckingman did, clamping down the sides and having dowels at the rear end for exact positioning. Plus that way having multiple glass plates to swap is just easier cause of less customisation.

Thank you both for your input. I really value that you share your experience !!

Have FuN!

Jan -

@snoozer said in Core-XY based on Rat Rig V-Core and Duet 2 Ethernet:

How much aluminium do you have left between the magnets and your print surface ?

Only tested around 0.7mm stock left, with random magnets i had on hand; still waiting for the good ones - but seems to let flux through and I can go thinner if needed. Primarily want to keep the top free of adhesives in case I at some point want to glue something directly on, and subsequently use solvents to remove the adhesive again. As far as glass goes, its still on the thinking stage, but wold be convenient to use the same method for everything. As far as differential expansion goes, i didn't measure expansion, but temp was very uniform as far as I could measure with the thermal cam.

-

@bearer I get you re adhesive on the surface. My approach would be never to do that at all as I will always only work with removable print surfaces like glass or spring steel. There will be no situation where I have to glue anything directly to the top of the bed. From below I will have the AC Mains heater, that will be adhesive plus a layer of insulation and some way to keep the insulation in place, probably a thin sheet of aluminium, mesh or a PCB....... I will find some way simple.

Jan

-

Just figured if Prusa can put the magnets under the bed so I can, or at least try it seeing as the pockets would have to be cut regardless; and leaving the top surface intact is just the icing on the cake for whatever the future brings that I haven't thought about yet. As of today I see no reason to glue anything to it, but that can change. I'm getting a 200x200mm knock off of the MK53 bed for my DIY I3 rework as well, so might be able to compare the two, if and when customs get a move on.

-

@snoozer said in Core-XY based on Rat Rig V-Core and Duet 2 Ethernet:

@deckingman

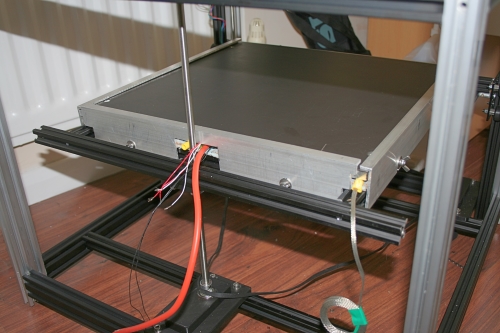

......................How did you mount your tooling plate to the printer ? how do you adjust it to be level in relation to your nozzle ?The tooling plate is fixed to a frame made from 2020 Vslot. The plate is 400mm x 400 mm and has a 240v silicone heater which is 360mm x 360 giving a 20mm border around the edges. I fitted 2 layers of semi rigid insulation under the aluminium to aid warm up time. I drilled 4 off 5mm clearance holes in the aluminium, about 70mm in from the font edge and 10mm in from the sides and counter sunk these holes. Then I used 5mm countersunk screws through these holes into Tee nuts in the aluminium extrusion. I just marked the holes and drilled them with a hand held power tool (but I'm well practised in that sort of thing). Here is a picture

...and here is a picture showing the "sandwich".

I fixed some flat aluminium strip to the front and back to act as a trim and hide the edges. This is just screwed through into more tee nuts in the frame. Here is a view of the rear.

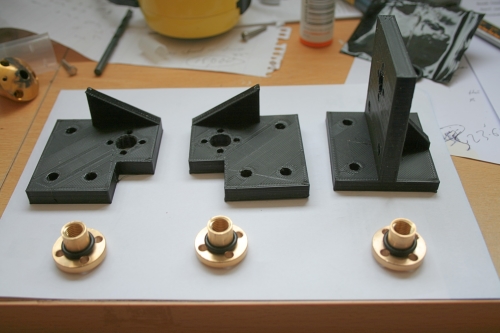

The bed is supported on 3 screws. I designed mounts that fix to the frame and take the lead screw nuts. There are O rings between the nut and mount.

Here is on assembly seen from the side.

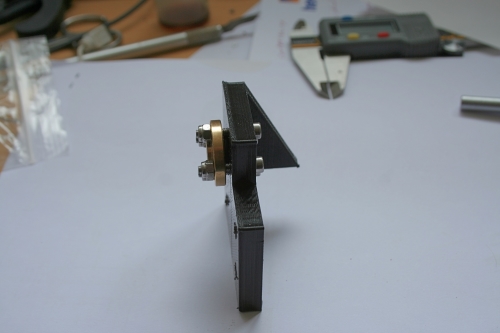

The nut is fixed to the mount using 4 bolts and "Nylok" nuts which are tensioned to just start compressing the O ring. This allows some flexibility in the joint to counter any effect of something not being completely square, as would be the case before the bed was levelled.

There are two vertical linear guides. These use OpenBuilds gantry plates, to the middle of which is fitted a ball joint type rod end fitting. A bolt fixes through the rod end ball into a Tee nut in the frame. Again, this constrains any X or Y movement but allows some flexibility for the bed to be levelled without imparting any twisting forces. Here is a picture of the lead screw nut and linear guide fixing in place.

The bed is driven by a single Nema 17 and continuous belt. To level the bed, I simply slacken off two of the pulleys and rotate the screws. I position the nozzle close to each screw, then use a slip gauge of about 10mm thick and adjust the screws so that it juts touches the gauge. then tighten all the pulley and that's levelling done I dismantle or move the printer.

I use the nozzle as a probe. The nozzle mount has a precision positioning switch attached and can move a few mm in Z but not in X or Y due to a number of steel dowels running in oil filled bronze bushes. I doubt you'd be interested in how I do that but I can elaborate if you need me to (but I think you'll find all that information on my blog)..

Ref the spring steel - all those magnets seem a PITA and what is the benefit? AFAIK, it allows you to remove the plate and flex it to get the part off. But for the cost, you could likely buy a dozen sheets of glass that you can swap between - even more if you have to factor in the cost of getting magnets inserted into the build plate. 3D lac makes parts stick like the proverbial but when the glass cools, they just fall off. So I'm not sold on the idea personally.

-

@deckingman wow, that's well build and thanks for the detailed explanation. Having three lead screws is probably the 100% solution to have straight movement. I have as per the V-Core kit 2x 2020 v-slot extrusions where the bed in hooked in on the back. Two lead screws a bit off center towards the back. This WILL flex along the way on the 2020 v-slot from Z-min to Z-max. I am not sure how much ofc but its designed that way. I was always skeptical using belts to connect lead screws to transfer drive torque, I would have considered it to keep the drives in sync. Given your aim for perfection I assume possible flex in the belt drive with the load of the bed and print is not a real issue ? I particularly like the way you have the bed guide "rails" flexible connection to your bed, nothing can get bend or stuck that way. The play in those "ball joints" is small enough to not matter or did you put some pre-tension on ? Your concept with the three lead screws could be implemented on my V-Core as well. I think for this build I stay with the way the V-Core is designed and instead of leveling the entire bed frame structure to precision I maintain the precision adjustment between the aluminium bed and frame with three pre-tensioned springs, bolts and knurled nuts. In the process of the build and the ongoing addition of parts I have already settled for the fact this is only a start for me on the Core XY track. I will stick with the machined aluminium plate and glass surface idea and get that ready to rock. Its really the only thing left now, Piezo probe, aluminium bed and part cooling. Then tuning everything and setting up slicer profiles for different layers heights etc is the big job in my mind. The goal is obviously to make the Prusa as my go-to printer obsolete.

I almost forgot, do you have some aluminium spacers between your aluminium plate and the 2020 v-slot or is the insulation as such the spacer ? Re drilling, I have the use of the bench drill in a friends workshop, Simply drilling holes in the right place and proper angle wont be a problem. Making slots and precise holes for magnets would have been but I am not taking that route, Glass it is.....

Thanks !!!

Jan -

@bearer the bed of the Prusa mk3 is a PCB heater, no solid aluminium. The magnets are embedded in that, It feels like a pretty strong pull from the magnets, I doubt you get the same result easy through an aluminium plate unless you leave a very thin thickness of material where the magnets are. But I guess testing would not be that hard if you had a piece of aluminium cut off or so.

Jan

-

@deckingman and WOW again re the "floating" hotend. Just looked through the blog. Have you chosen the mechanical precision approach over lets say a piezo cause that's what you can do best or is there other considerations that stopped you from using a piezo probe ?

Jan

-

@snoozer I don't have spacers between the aluminium plate and the 2020 extrusion but if I was doing it again, I would use them. In fact, it's on my list of things to do. The reason is that the semi rigid insulation is slightly compressible, which means that if I don't tighten the fixing screws by the same amount, it is possible to distort the plate.

I have no problems with belt stretch and that is with using standard 6mm GT2 timing belt. But I do use 1mm single start Lead screws so the torque requirement to drive them is low. Of course, you don't have to use 6mm wide belts, nor indeed do you need to use 2mm pitch belts. The steps per mm are determined by the lead of the screws and the step angle of the motor. So the interconnecting belt can be any size and pitch.

Ref machining slots in aluminium - I have done this in the past using a wood working router and HSS (high speed steel) cutter. Paraffin is the best lubricant to use when machining aluminium IMO but if you take small cuts, you can do it without any coolant or lubricant.

-

@snoozer said in Core-XY based on Rat Rig V-Core and Duet 2 Ethernet:

@deckingman and WOW again re the "floating" hotend. Just looked through the blog. Have you chosen the mechanical precision approach over lets say a piezo cause that's what you can do best or is there other considerations that stopped you from using a piezo probe ?

Jan

Several reason really. Firstly, fitting a Piezo to a Diamond hot end is difficult to do. Secondly, a Peizo needs some sort of interface board whereas a simple switch does not. Lastly, the "mechanical approach" isn't a problem for me but I can see how it might be for a "non-mechanical engineer". Having said that, it's not hugely difficult - the mounts that take the bushes and dowels are both printed parts so it's not the ultimate in precision engineering.

-

@snoozer One other thing before I forget. When using a thick aluminium plate, mounting of the temperature sensor requires some thought. The "normal" method is to have the sensor built into the heater or sandwiched between the heater and the aluminium plate. This is problematic because when the heater comes on, the interface between the heater and the plate heats up quickly and so the heater turns off again (or the PWM value reduces). But it takes time for the heat to penetrate the plate and reach the upper surface. So if the heater is cycling on and off (or high and low) quite quickly due to the position of the temperature sensor, then it takes an inordinately long time for the top surface of the plate to reach print temperature. My solution was to drill a 3mm diameter hole in the edge of the plate, as deep as possible and as close to the top surface as possible without breaking through, and fit the temperature sensor in there. So the sensor "sees" the temperature close to the upper surface, rather than the temperature of the bottom surface. Of course, after a period of time, thermal conduction means that both surfaces will be more or less at the same temperature but during the warm up period, this is not the case.

-

@deckingman I know what you mean, in my original design I had a small slot and hole designed in my CAD model for the thermistor. So for my current plan I thought of either having a hole in the center from below or as you do from the side.

Jan

-

I have thought of redesigning my hotend/extruder mount to use less space and also to include a piezo probe. Someone else has done a pretty good looking design already.

https://www.thingiverse.com/thing:3600079

I have exported the design from OnShape to be able to work on it in Fusion 360. This should resolve my desire for a more compact mount including piezo probe. I share it once I am done.

Jan

PS: I have abandoned the idea of a quick release tool holder for this printer. Maybe I look into that idea again on my next build.

-

Very frustrating day today...... the design above was evidently made around a clone Titan Aero, the original has issues fitting on the mount. I needed longer bolts for the stepper mount and the hotend is shorter apparently, I had to trim some of the part cooling duct off. The belt attachment is for ppl with a LOT of patience but I did get it done in the end. A nice baseline design but I will do that again from scratch and fix the issues I found. So far I can not recommend it for an original E3D Titan Aero. On the positive side, its very compact and gives a few mm more print area.

Jan

-

Hello,

I am finally getting somewhere. After resolving some of the issues with the Titan Clone Mount I spend some time getting Slic3rPE set-up. My approach to that was basically a mix of the Prusa settings and some input from the a Railcore II300 profile I found online. I can not claim that I would know all the details what each parameter actually does but so far I have a working printer setup and print setup for 0.2mm and 0.1mm layer height. One of the things I struggled with most was priming of the nozzle prior to the actual print. The way Prusa does it did not really work so I have taken that from a Railcore profile. I can run both print profiles at 100% with very nice looks and at 200% for a very fast print. I have speeds set to 60mm/s for perimeters 30mm/s for external perimeters and 80mm/s for infill and support, 20mm/s for the 1st layer. Some distortions are noticeable after sharp corners for example printing a cube. Printing it at 200% speed that obviously gets worse. It is in no way so bad that it would worry me for now but something that shows there is some unwanted vibration. I will look into that once I have my final bed finally on the printer.

Another issue I ran into was heat in the wrong place of the hotend. I had the Titan Aero fan set to 70% to reduce noise. That was not a good idea, on an longer print I started missing steps on the extruder and it finally ground through the filament. The problem was the fan was to slow to provide enough cooling. So my heatbreak was clogged and I had to disassemble the Titan Aero to remove the blockage. This has not happen since I run at 100% fan speed.

I have no good light here to take pictures of prints, I take them with me to the office and post pictures later today or tomorrow.

Have FuN!

Jan -

@deckingman, You mentioned 3DLAC as printing aid you use on your glass surface, I have been looking at it seems there are 2 versions, an aerosol can called 3DLAC and a pump spray called 3DLAC Plus. Which is the one you use successful ? I have ordered 4 float glass surfaces now 320x320x6mm at 27 Euro. I find that is dead cheap, really no point if wrecking my head over flex plates. With the machined aluminium its the first time I try my virtual UK shipping address provided by DPD. I hope that works out.

Have FuN!

JanPS: The glass comes from a local supplier, If I get a ride tomorrow I can pick it up. At that price I assume its measured with a measuring tape and hand cut. Probably have to find a way to make the edges less dangerous