Multiple Heat Bed Conditional (Regional) Start Code

-

Hi everyone,

I've converted my Elegoo Giga into a Duet-controlled machine and wondered if someone could help translate the start code that heats only the required beds (there are 4 x 400mm2) ,

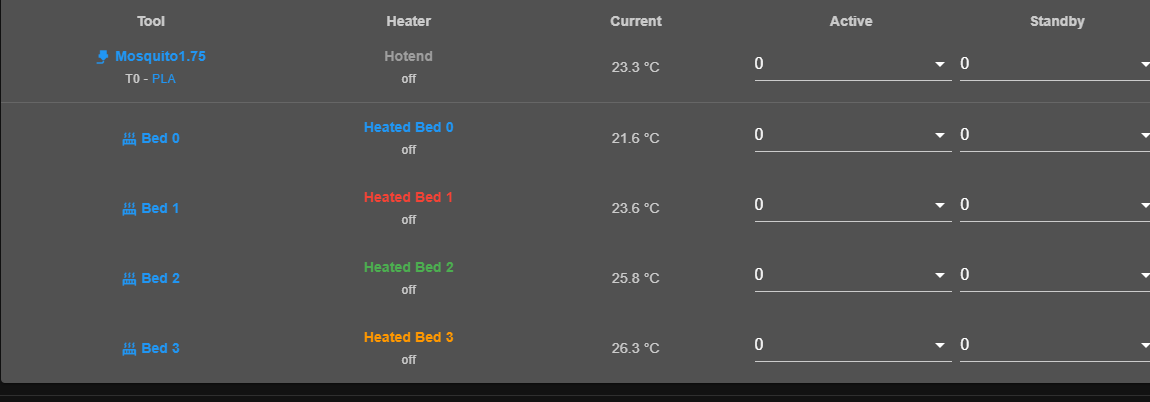

Here's my attempt, which at some point seems to override H0 (my heatbed 0) and in DWC where I have four heat beds, H0-H3, Heat bed 0 gets changed so I have two Heat Bed 1s.

;Machine_use_extruders:1 ;TIME: M400 ; wait for buffer to clear ;[printer_model] ;initial_filament:{filament_type[initial_extruder]} ;curr_bed_type={curr_bed_type} M220 S100 ;Set the feed speed to 100% M221 S100 ;Set the flow rate to 100% M104 S140 ;Giga zoned hot bed control ;Case 1 M140 S0 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) < 405 && (max(0, first_layer_print_min[1])) < 402.5} M140 H0 S[bed_temperature_initial_layer_single] {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405} M140 H1 S[bed_temperature_initial_layer_single] {endif} {if ((first_layer_print_max[1])) > 402.5} M140 H3 S[bed_temperature_initial_layer_single] {endif} {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405 && ((first_layer_print_max[1])) > 402.5} M140 H2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 2 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) < 405 && (max(0, first_layer_print_min[1])) > 402.5} M140 H3 S[bed_temperature_initial_layer_single] {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405} M140 H2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 3 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) > 405 && (max(0, first_layer_print_min[1])) < 402.5} M140 H1 S[bed_temperature_initial_layer_single] {if ((first_layer_print_max[1])) > 402.5} M140 H2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 4 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) > 405 && (max(0, first_layer_print_min[1])) > 402.5} M140 H2 S[bed_temperature_initial_layer_single] {endif} G90 G28 ;home G1 Z10 F300 G1 X{print_bed_max[0]*0.75-50} Y25.5 F6000 ; ;Giga zoned hot bed control ;Case 1 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) < 405 && (max(0, first_layer_print_min[1])) < 402.5} M190 H0 S[bed_temperature_initial_layer_single] {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405} M190 H1 S[bed_temperature_initial_layer_single] {endif} {if ((first_layer_print_max[1])) > 402.5} M190 H3 S[bed_temperature_initial_layer_single] {endif} {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405 && ((first_layer_print_max[1])) > 402.5} M190 H2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 2 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) < 405 && (max(0, first_layer_print_min[1])) > 402.5} M190 H3 S[bed_temperature_initial_layer_single] {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405} M190 H2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 3 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) > 405 && (max(0, first_layer_print_min[1])) < 402.5} M190 H1 S[bed_temperature_initial_layer_single] {if ((first_layer_print_max[1])) > 402.5} M190 H2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 4 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) > 405 && (max(0, first_layer_print_min[1])) > 402.5} M190 H2 S[bed_temperature_initial_layer_single] {endif} G1 Z0.4 F300 M109 S[nozzle_temperature_initial_layer] G92 E0 ;Reset Extruder G1 X{print_bed_max[0]*0.75+50} E30 F400 ;Draw the first line G1 Z0.6 F120.0 ;Move to side a little G1 X{print_bed_max[0]*0.75+47} F3000 G92 E0 ;Reset Extruder ;LAYER_COUNT:[total_layer_count] ;LAYER:0 G29 S1 M376 H10Here's the code from Elegoo -

;Machine_use_extruders:1 ;TIME: M400 ; wait for buffer to clear ;[printer_model] ;initial_filament:{filament_type[initial_extruder]} ;curr_bed_type={curr_bed_type} M220 S100 ;Set the feed speed to 100% M221 S100 ;Set the flow rate to 100% M104 S140 ;Giga zoned hot bed control ;Case 1 M140 S0 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) < 405 && (max(0, first_layer_print_min[1])) < 402.5} M140 T0 S[bed_temperature_initial_layer_single] {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405} M140 T1 S[bed_temperature_initial_layer_single] {endif} {if ((first_layer_print_max[1])) > 402.5} M140 T3 S[bed_temperature_initial_layer_single] {endif} {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405 && ((first_layer_print_max[1])) > 402.5} M140 T2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 2 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) < 405 && (max(0, first_layer_print_min[1])) > 402.5} M140 T3 S[bed_temperature_initial_layer_single] {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405} M140 T2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 3 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) > 405 && (max(0, first_layer_print_min[1])) < 402.5} M140 T1 S[bed_temperature_initial_layer_single] {if ((first_layer_print_max[1])) > 402.5} M140 T2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 4 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) > 405 && (max(0, first_layer_print_min[1])) > 402.5} M140 T2 S[bed_temperature_initial_layer_single] {endif} G90 G28 ;home G1 Z10 F300 G1 X{print_bed_max[0]*0.75-50} Y0.5 F6000 ; ;Giga zoned hot bed control ;Case 1 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) < 405 && (max(0, first_layer_print_min[1])) < 402.5} M190 T0 S[bed_temperature_initial_layer_single] {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405} M190 T1 S[bed_temperature_initial_layer_single] {endif} {if ((first_layer_print_max[1])) > 402.5} M190 T3 S[bed_temperature_initial_layer_single] {endif} {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405 && ((first_layer_print_max[1])) > 402.5} M190 T2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 2 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) < 405 && (max(0, first_layer_print_min[1])) > 402.5} M190 T3 S[bed_temperature_initial_layer_single] {if ((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) > 405} M190 T2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 3 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) > 405 && (max(0, first_layer_print_min[1])) < 402.5} M190 T1 S[bed_temperature_initial_layer_single] {if ((first_layer_print_max[1])) > 402.5} M190 T2 S[bed_temperature_initial_layer_single] {endif} {endif} ;Case 4 {if (min(print_bed_max[0], first_layer_print_min[0] + 32) - 32) > 405 && (max(0, first_layer_print_min[1])) > 402.5} M190 T2 S[bed_temperature_initial_layer_single] {endif} G1 Z0.4 F300 M109 S[nozzle_temperature_initial_layer] G92 E0 ;Reset Extruder G1 X{print_bed_max[0]*0.75+50} E30 F400 ;Draw the first line G1 Z0.6 F120.0 ;Move to side a little G1 X{print_bed_max[0]*0.75+47} F3000 G92 E0 ;Reset Extruder ;LAYER_COUNT:[total_layer_count] ;LAYER:0If anyone has any thoughts on how this could be modified to Duet appropriate code I'd appreciate it

Thanks

Nate

ps my config -

; Configuration file for RepRapFirmware on Duet 3 Main Board 6HC ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.8 on Thu Dec 12 2024 17:45:30 GMT+0000 (Greenwich Mean Time) ; General G90 ; absolute coordinates M83 ; relative extruder moves M550 P"GigaDAM" ; set hostname ; Accessories M575 P1 S0 B57600 ; configure PanelDue support ; Network ; Wait a moment for the CAN expansion boards to become available G4 S5 ; Accelerometers M955 P121.0 I54 ; configure accelerometer on board #121 ; Kinematics M669 K0 ; configure Cartesian kinematics ; Smart Drivers M569 P0.0 S0 D2 ; driver 0.0 goes forwards (Y axis) M569 P0.1 S1 D2 ; driver 0.1 goes forwards (X axis) M569 P0.2 S1 D2 ; driver 0.2 goes forwards (Z axis) M569 P0.3 S0 D2 ; driver 0.3 goes forwards (Z axis) M569 P121.0 S1 D2 ; driver 121.0 goes forwards (extruder 0) ; Motor Idle Current Reduction M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X0.1 Y0.0 Z0.2:0.3 ; set axis mapping M671 X-20:870 Y0:0 S1.5 ; position of leadscrew/bed pivot point at left and right of X axis M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M906 X1950 Y2050 Z1400 ; set axis driver currents M92 X53.875 Y134.45 Z1005 ; configure steps per mm M208 X0:800 Y10:800 Z0:1020 ; set minimum and maximum axis limits M566 X900 Y400 Z12 ; set maximum instantaneous speed changes (mm/min) M203 X12000 Y12000 Z1080 ; set maximum speeds (mm/min) M201 X500 Y500 Z20 ; set accelerations (mm/s^2) ; Extruders M584 E121.0 ; set extruder mapping M350 E16 I1 ; configure microstepping with interpolation M906 E900 ; set extruder driver currents ;M92 E526 ; steps per mm 2.85 JBPlanetary M92 E395 ; configure steps per mm 1.75 LGX ;M92 E774 ; configure steps per mm Orbiter M566 E120 ; set maximum instantaneous speed changes (mm/min) M203 E5600 ; set maximum speeds (mm/min) M201 E250 ; set accelerations (mm/s^2) ; Probes ;M558 K0 P8 C"!121.io0.in" H5 F800:80 T8000 ; 2.85 probe configure unfiltered digital probe via slot #0 M558 K0 P8 C"121.io0.in" H5 R0.4 A3 S0.02 F800:80 T8000 ; 1.75 probe configure unfiltered digital probe via slot #0 G31 P500 X7 Y-4 Z0.320 ; set Z probe trigger value, offset and trigger height M557 X25:780 Y75:780 S40 ; Endstops M574 X2 P"io4.in" S1 ; configure X axis endstop M574 Y2 P"io2.in" S1 ; configure Y axis endstop M574 Z1 S2 ;M574 Z1 P"io1.in+io3.in" S1 ; configure Z axis endstop ;Filament Sensor M591 D0 P1 C"121.io1.in" S1 ; simple sensor (high signal when filament present) connected to IO_4 for drive 0, enabled ; Sensors M308 S0 P"temp0" Y"thermistor" A"Heated Bed 0" T100000 B4725 C7.06e-8 ; configure sensor #0 M308 S1 P"temp1" Y"thermistor" A"Heated Bed 1" T100000 B4725 C7.06e-8 ; configure sensor #1 M308 S2 P"temp2" Y"thermistor" A"Heated Bed 2" T100000 B4725 C7.06e-8 ; configure sensor #2 M308 S3 P"temp3" Y"thermistor" A"Heated Bed 3" T100000 B4725 C7.06e-8 ; configure sensor #3 M308 S4 P"121.temp0" Y"thermistor" A"Hotend" T100000 B4725 C7.06e-8 ; configure sensor #4 ; Heaters M950 H0 C"out4" T0 ; create heater #0 M143 H0 P0 T0 C0 S110 A0 ; configure heater monitor #0 for heater #0 M307 H0 R0.130 K0.159:0.000 D2.97 E1.35 S1.00 B0 ;M307 H0 R2.43 D5.5 E1.35 K0.56 B1 ; configure model of heater #0 M950 H1 C"out5" T1 ; create heater #1 M143 H1 P0 T1 C0 S110 A0 ; configure heater monitor #0 for heater #1 M307 H0 R0.130 K0.159:0.000 D2.97 E1.35 S1.00 B0 ;M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1 M950 H2 C"out6" T2 ; create heater #2 M143 H2 P0 T2 C0 S110 A0 ; configure heater monitor #0 for heater #2 M307 H0 R0.130 K0.159:0.000 D2.97 E1.35 S1.00 B0 ;M307 H2 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #2 M950 H3 C"out7" T3 ; create heater #3 M143 H3 P0 T3 C0 S110 A0 ; configure heater monitor #0 for heater #3 M307 H0 R0.130 K0.159:0.000 D2.97 E1.35 S1.00 B0 ;M307 H3 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #3 M950 H4 C"121.out0" T4 ; create heater #4 M143 H4 P0 T4 C0 S285 A0 ; configure heater monitor #0 for heater #4 M307 H4 R2.832 K0.407:0.000 D13.13 E1.35 S1.00 B0 V24.8 ; 1.75mm Heater ;M307 H4 R3.885 K0.568:0.424 D9.79 E1.35 S1.00 B0 V24.2 ; 2.85mm Mosquito Heater ;M307 H4 R3.602 K0.516:0.010 D8.95 E1.35 S1.00 B0 V23.3 ; configure model of heater #4 previous 2.85 Extruder ; Heated beds M140 P0 H0 ; configure heated bed #0 M140 P1 H1 ; configure heated bed #1 M140 P2 H2 ; configure heated bed #2 M140 P3 H3 ; configure heated bed #3 ; Fans M950 F0 C"121.out1" ; create fan #0 M106 P0 S0 L0 X1 B0.1 ; configure fan #0 M950 F1 C"121.out2" ; create fan #1 M106 P1 S0 B0.1 H4 T45 ; configure fan #1 ; Tools ;M563 P0 S"Mosquito2.85" D0 H4 F0 ; create tool #0 M563 P0 S"Mosquito1.75" D0 H4 F0 ; create tool #0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C ; Miscellaneous ; Custom settings M911 S21.0 R23.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" -

IF statements in RRF must be indented, so none of the statements you have will be working.

https://docs.duet3d.com/User_manual/Reference/Gcode_meta_commands#conditional-construct

It looks to me like to me IF statements are from a slicer START G-Code section.

They may be workable there, but only the M140 commands should end up in your job g-code.