great prints with PLA, but terrible with pre-foamed LW-PLA

-

I'm having trouble getting my printer dialed in with polymaker pre-foamed lw-pla from colorfabb.

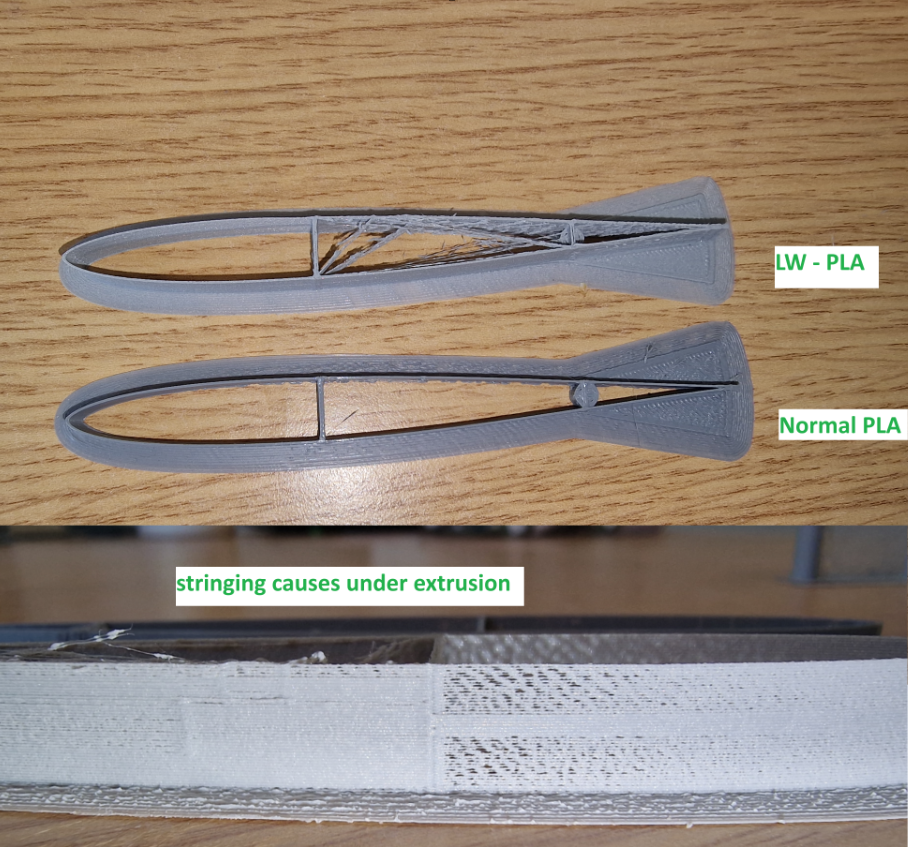

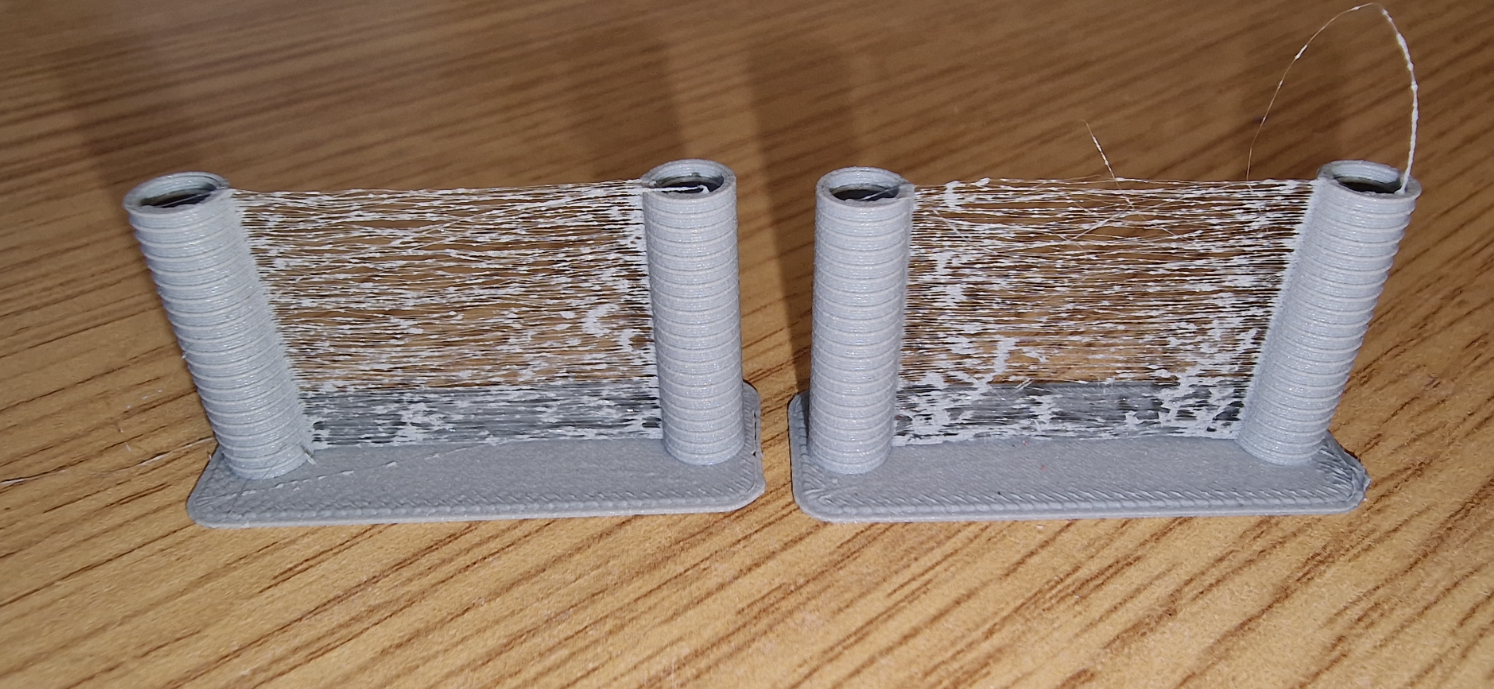

I seem to get a lot of stringing during the travel moves, which causes under-extrusion.

you can see this in the image below.PLA was printed at 230C and 0.2mm retraction at 60mm/sec

lw-pla PLA was printed at 190C and 0.8mm retraction at 60mm/secits is a very short direct drive so normally I need very little retraction.

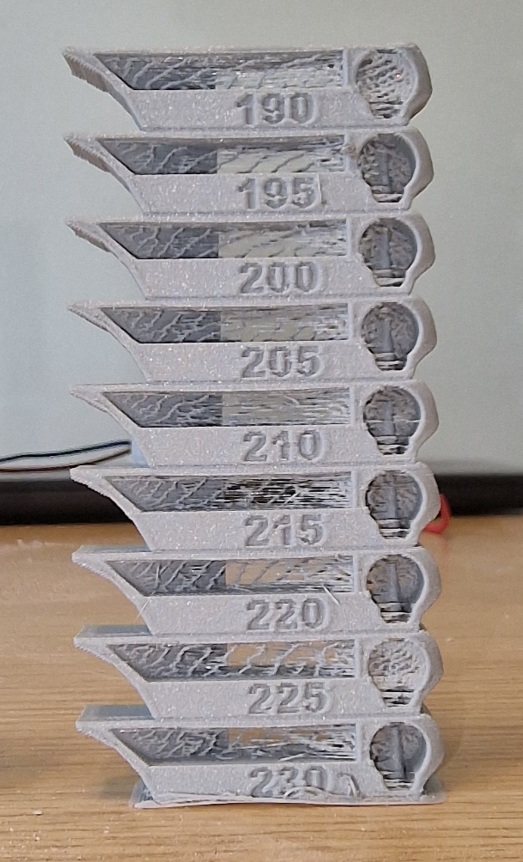

I then went on to print a temp tower and a few retraction tests in the LW-PLA

Temp doesn't seem to make any difference, but the manufacturer says 190-210c

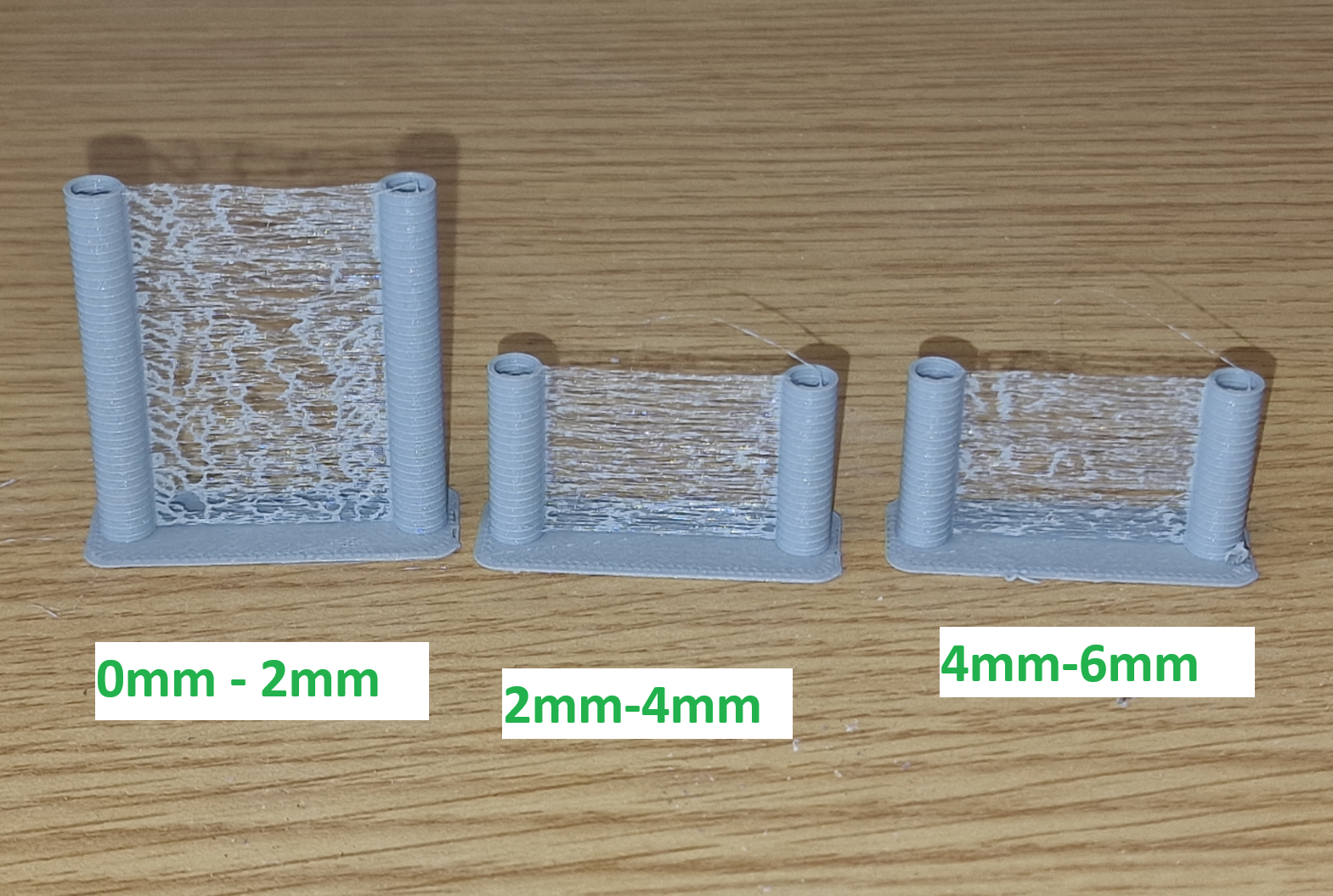

I then went on to print some retraction tests in the lw-pla at 190C.

To me they pretty much all look the same. 6mm is a huge amount of retraction.

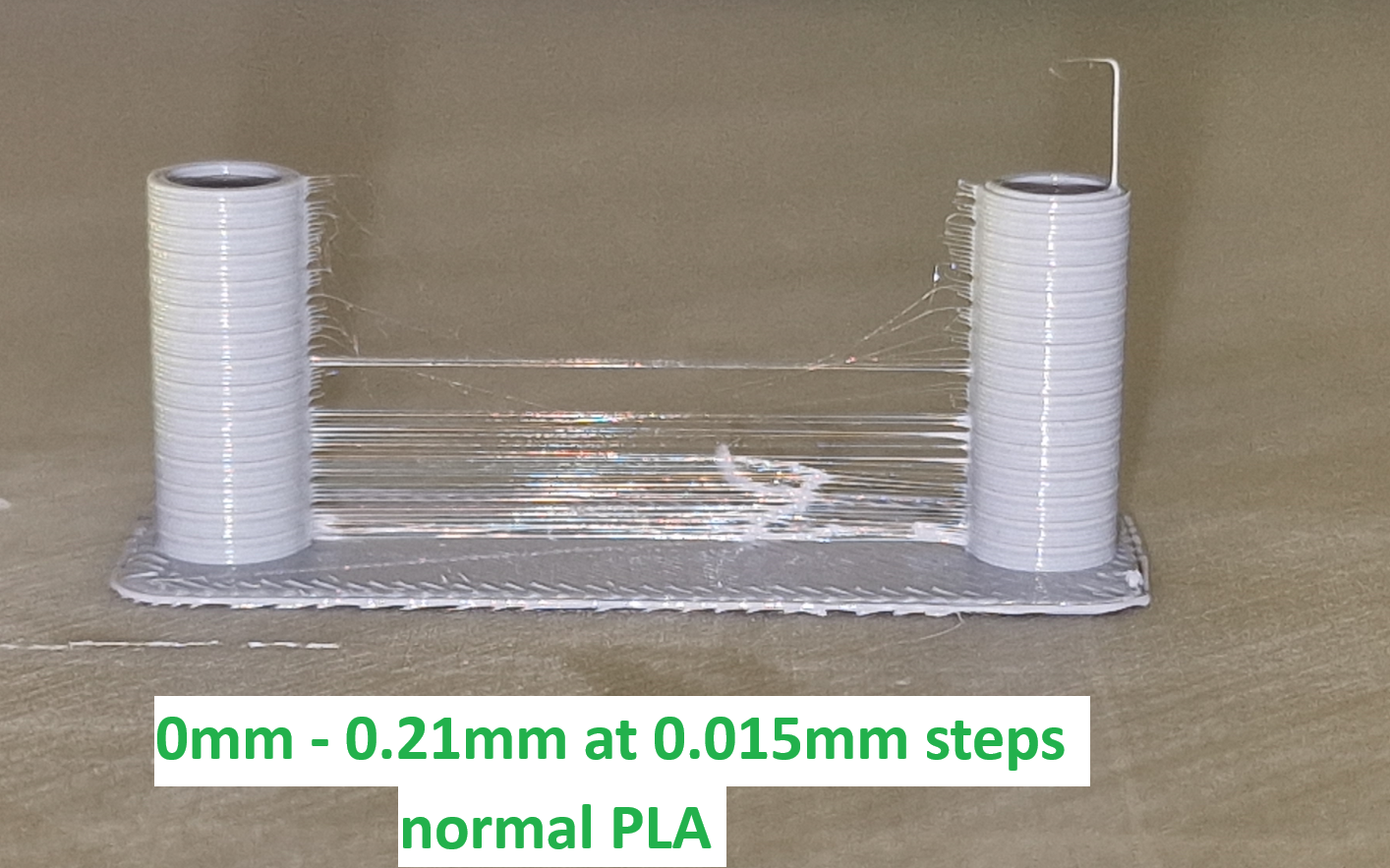

To put this in perspective, this retraction tower was printed with the same profile, but at 230C in normal pla. the top of the tower is 0.4mm retraction

Any suggestions on what to try next?

-

@nick9one1 Try retracting slower. That might help.

-

@nick9one1 If retracting more slowly doesn't work then you could try compensating for the filament that gets pulled out of the nozzle by adding an extra restart amount after each retraction.

-

@tas thanks. Will print another tower at 30mm sec retraction (half what I previously set)

I did briefly test with the extra restart amount but it makes the prints really ugly with lots of blobs

-

@nick9one1 Yes, the extra restart is not a good solution.

Another option might be faster travel.

-

Have you tried drying your filament? I know that PLA is not too sensitive to moisture absorption but I have had some very surprising results happening with drying.

-

@tas travel is set in the slicer at 150mm sec.. which seems quite fast already?

30mm sec left, 60mm sec right

-

@jens55 I havent, but the filament is new and was vacuum packed, with dessicant.

-

@nick9one1 150mm/s is more than fast enough. So that is not solving the problem.

@jens55 has a very good point. I have had to dry filament that was fully sealed with dessicant to get it to behave. I'm not sure how sensitive this LW-PLA is to moisture. When all else fails dry the filament.

If even drying doesn't work you could try wiping after retraction.

-

@nick9one1, just because you took a brand new roll out of a vac pac, this is no guarantee it's dry.

I have had new and wet filament straight out of the bag. -

When you solve this. please be sure to post what it was that worked.