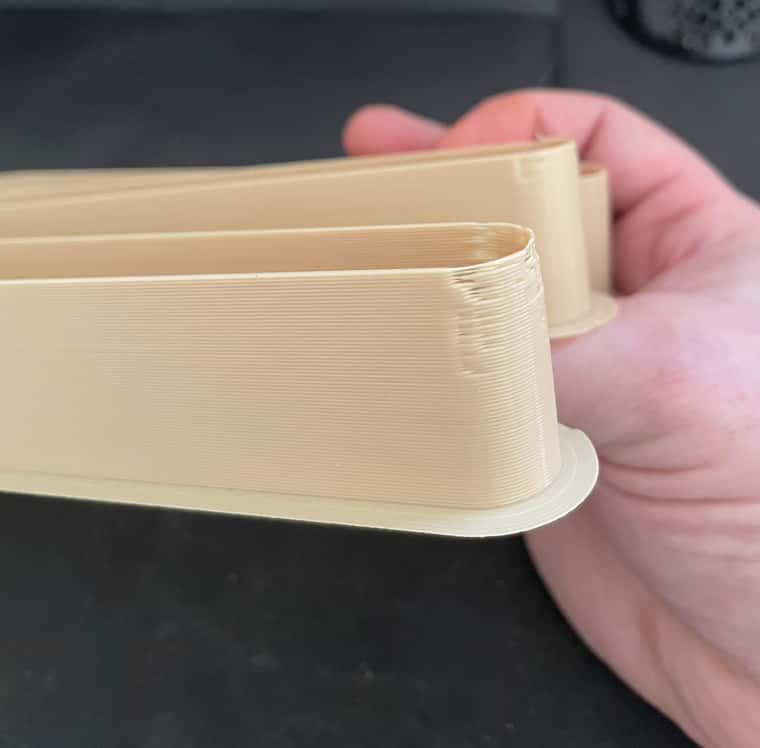

PA issues with max flow rate testing

-

So i was testing max flow rate, 0.6 CHT, rapido HF and i get this weird under extrusion issue on the rounded corners with PA enabled, value is 0.03 PLA. without PA its fine with the same flow rate range. this is testing 20mm3 to 30mm3. Any ideas what could be causing it? jerk or some other setting?

-

@mrwizzard Most likely extruder jerk setting too low. You can set it "silly high" with no adverse effects but too low can interfere with things like PA.

-

@deckingman it's 5mm/s per input shaping recommendations. it only seems to happen at higher flow rates, anything from 1mm3/sec to 25mm3/sec seems fine before it starts getting the above.

-

@mrwizzard the 5mm/sec jerk recommendation for IS applies to X and Y, you can set Z and E independently and should do so.

-

@oliof that's what i meant, 5mm/s for X/Y. my E is plenty high. disabling PA fixes it, but also increasing the jerk for XY to at least 10mm/s with PA fixes it at least up to 35mm3/s then problem starts again. either there's something else i'm missing or there's an issue with RRF's PA. i didn't encounter this with klipper (with a low square corner velocity) but that machine has a different extruder and runs a old volcano, however both are 0.6 nozzles.

-

@mrwizzard share your config.g please

-

@mrwizzard said in PA issues with max flow rate testing:

.................. my E is plenty high....................

Can you quantify this? What is the actual value of your extruder jerk setting? As per my previous post, you can set it to what might appear to be a "silly high" value with no adverse effects but too low can be detrimental to PA

-

@deckingman its 8000mm/min, should it be higher?

-

config

; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M669 K1 ; Select CoreXY mode ;M575 P1 B57600 S1 ; Comms parameters for PanelDue M564 S1 H1 ; Forbid axis movements when not homed ;M918 P2 R6 C30 E4 F200000 ; Fysetc 12864 display ;M150 R255 B255 P255 S2 X2 ; Network M550 PVoron V2.4 ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP (for DWC) M586 P1 S1 ; Enable FTP (for remote backups) M586 P2 S0 ; Disable Telnet ; --- Z Drive map --- ; _______ ; | 8 | 7 | ; | ----- | ; | 9 | 6 | ; ------- ; front ; ; (looking at the printer from the top) ; Drive directions M569 P0 S0 ; A M569 P1 S0 ; B M569 P3 S0 ; Extruder M569 P9 S1 ; Z0 M569 P8 S0 ; Z1 M569 P7 S1 ; Z2 M569 P6 S0 ; Z3 ; Motor mapping and steps per mm M584 X0 Y1 Z9:8:7:6 E3 ; Z Axis ;M584 U0 ; M350 X16 Y16 Z16 E16 I1 ; Use 1/16 microstepping with interpolation everywhere ;M92 X80 Y80 Z400 ; Set XYZ steps per mm (1.8deg motors) M92 X160 Y160 Z400 ; Set XYZ steps per mm (0.9deg motors) M92 E708.91 ; Set Extruder steps per mm clockwork 2 ;M92 E617.6470588 ; configure steps per mm galileo2 ; Drive currents M906 X1650 Y1650 Z900 E700 ; XYZ and E current M906 I50 ; Idle current percentage M84 S240 ; Idle timeout ; Endstops M574 X2 S1 P"xstop" ; Xmax endstop M574 Y2 S1 P"ystop" ; Ymax endstop M574 U1 S1 P"e0stop" ; Probe Docked M574 Z0 P"nil" ; no Z endstop ; Axis travel limits M208 X0 Y0 Z-1 S1 ; Set axis minima M208 X352 Y360 Z275 S0 ; Set axis maxima ; Bed leveling M671 X-50:-50:400:400 Y0:430:430:0 S20 ; Define Z belts locations (Front_Left, Back_Left, Back_Right, Front_Right) M557 X5:340 Y5:310 S50 ; Define bed mesh grid (inductive probe, positions include the Y offset!) ; Accelerations and speed M98 P"/macros/print_scripts/speed_printing.g" M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 A"Bed Heater" ; configure sensor 0 as thermistor on pin bedtemp (heater sensor) M308 S2 P"e1temp" Y"thermistor" T100000 B3950 A"Bed Plate" ; configure sensor 2 as thermistor on pin e1temp (mic6 sensor) M950 H0 C"duex.e2heat" T2 Q60 ; create bed heater output on out0 and map it to sensor 2 (mic6 sensor). Set PWM frequency to 60Hz to prevent flicker M140 P0 H0 ; Mark heater H0 as bed heater (for DWC) M143 H0 P1 T0 A2 S120 C0 ; Regulate (A2) bed heater (H0) to have pad sensor (T0) below 120°C. Use Heater monitor 1 for it M143 H0 P2 T0 A1 S125 C0 ; Shut off (A1) bed heater (H0) if pad sensor (T0) exceeds 125°C. Use Heater monitor 2 for it M143 H0 S115 ; Set bed heater max temperature to 120°C, use implict monitor 0 which is implicitly configured for heater fault M307 H0 B1 S0.6 D30 ; Enable Bang Bang mode and set PWM to 60% to avoid warping ;M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0 ;M950 H0 C"duex.e2heat" T0 Q60 ; create bed heater output on out0 and map it to sensor 0 ;M143 H0 S115 ; set temperature limit for heater 0 to 100C ;M307 H0 B0 R0.748 C121.2 D4.98 S0.60 V24.0 ; Bed ;M140 P0 H0 ; Mark heater h0 as bed heater (for DWC) ; Hotend heater M308 S1 A"Hotend" P"e0temp" Y"thermistor" ; Hotend is e3d thermistor M950 H1 C"e0heat" T1 ; M307 H1 B0 R2.383 C158.6:132.0 D4.85 S1.00 V24.0 ; M143 H1 S300 ; Set temperature limit for heater 1 to 300C ; MCU sensors M308 S3 Y"mcu-temp" A"MCU" M308 S4 Y"drivers" A"Duet Drivers" M308 S5 Y"drivers-duex" A"Duex Drivers" ;M308 S6 P"e1temp" Y"thermistor" T100000 B3950 A"Bed Plate" ; configure sensor 0 as thermistor on pin temp0 M308 S7 P"duex.e2temp" Y"thermistor" T100000 B3950 A"Chamber Temp" ; configure sensor 0 as thermistor on pin temp0 ; Chamber temperature sensor via temperature daughterboard pins on Duex ;M305 S"Ambient" P104 X405 T21 ; Set DHT22 for chamber temp ;M305 S"Humidity [%]" P105 X455 T21 ; Set DHT22 for chamber humidity ; Z probes global mag_probe_x = 62 global mag_probe_y = 358 global bed_is_leveled = false ;M558 K0 P8 C"^e1stop" T18000 F600 H5 A5 S0.01 R0.2 ;G31 K0 P500 X0 Y25 Z1.410 ; ? ;M558 K1 P8 C"^zstop" T18000 F240:60 H2 A10 S0.005 R0.2 ;G31 K1 P500 X0 Y0 Z1.80 ; Z switch offset (if positive, greater value = lower nozzle. if negative, more negative = higher nozzle) ; Fans M950 F0 C"fan0" Q250 ; Create fan 0 (hotend) on pin fan0 and set its frequency M106 P0 S1 H1 T50 ; Configure fan 0: Thermostatic control is turned on, based on sensor #1 M950 F1 C"fan1" Q250 ; Create fan 1 (cooling)on pin fan1 and set its frequency M106 P1 S0 H-1 ; Configure fan 1: Thermostatic control is turned off ;M950 F2 C"duex.fan3" Q250 ; Create fan 2 (electronics) on Duex pin fan3 (frequency is fixed on Duex) ;M106 P2 S0 H-1 ; Configure fan 2: Thermostatic control is turned off ;M950 F4 C"fan2" Q30 ; Create fan 4 (electronics bay) on pin fan2 and set its frequency ;M106 P4 S0.25 H1 T50 ; (busted?) Run the fans at 25% if the hotend is over 50C ;M106 P4 S0 H-1 C"Bay Fans" ; Manual fan triggering... with thermostatic mode they are always at 100%? ; LEDs M950 H3 C"nil" ; free up e3_heat pin M950 F3 C"duex.e3_heat" M106 P3 S255 B0 H-1 C"Top Lights" M950 H4 C"nil" ; free up e3_heat pin M950 F4 C"duex.e4_heat" M106 P4 S0 B0 H-1 C"Nevermore" ; Tools M563 P0 D0 H1 F1 ; Define tool 0 using fan 1 for M106 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Misc M912 P0 S-4 ; MCU temperature calibration (yours will be different) M593 P"zvdd" F33 S0.0 ; ;M376 H2 ; Fade mesh out compensation over 2mm Z M143 M501 ; load config-override.g T0 ; select tool 0 ;M915 X Y Z S12 R1 ;M955 P0 C"spi.cs3+spi.cs4" I50 ;Accelerometerspeed_printing.g

M566 X500 Y500 Z60 E8000 ; Set maximum instantaneous speed changes (mm/min) M203 X25000 Y25000 Z6000 E15000 ; Set maximum speeds (mm/min) M201 X10000 Y10000 Z600 E1800 ; Set maximum accelerations (mm/s^2) M204 P10000 T10000 ; Set printing acceleration and travel accelerations