Fly RRF-36 fan tachometer connection -- Solved

-

After a hotend fan failure and subsequent mess decided the printer needs the ability to detect when the hotend fan stops spinning. If I was using the main board for fans or willing to run a tachometer wire along with the toolboard wires I could do this. But I would like to do it from the tooboard if possible. Looking at the schematic the only two pins I think might be usable are gpio18 or gpio19. Is I2C hard coded or can these be repurposed? I am already using the bltouch and the one above it so they are not available.

I already did the 2 printers that do not have toolboards and working on the script to cancel the print if the fan stops.

-

@KenW it looks like GPIO18 and 19 aren't named so I don't think there would be anyway to use them without a firmware update.

@gloomyandy can confirm -

@jay_s_uk @KenW Jay is correct those pins are not accessible in the current build. Are you using both endstop pins?

-

@gloomyandy Yes unfortunately. I have a klicky probe installed in io0.in and am using io1.in and io2.in for the Orbiter Filament Sensor. I guess I could drop the filament unload feature and use io2.in for the tach. It is useful but fan stop detection is more important.

I ran into this earlier with the X endstop, on the Eva it is part of the extruder so they wanted to install it on the toolboard. I changed the X Axis Stop Block into a mount for the microswitch so I could move it off the extruder.

Any chance gpio19 or gpio19 might be named in the future?

-

@KenW I'll look into making those pins visible in a future build. However you might want to check that it works using on of the endstop pins, I'm not sure I've ever tested a tacho fan on a RRF-36 (or any pico based board).

-

@gloomyandy Will do. I am trying to avoid any additional wiring to the extruder since the can cable is a bit over 2 meters long. I originally ran X endstop wiring with it and had issues. So it was moved. I still have the twisted pair for the X endetop in the harness so I could try moving the tach to it if the RRF-36 can't handle the tach signal. I do not care if it is accurate, just detects if the fan is running.

-

@gloomyandy Apparently io1.in and io2.in can only be used for endstops or similar . When an attempt to set it up is done an error of "Error in start-up file macro line 71: Unknown pin name '124.io2.in'" If setup as an endstop or for use with the Orbiter they work fine.

M950 F1 C"124.out1+124.io2.in" Q500 ; Fan 2 uses out1, and using out2.in as a tacho input

I assume that is correct.

So next idea, if it is correct is I could set up an attiny85 to monitor the fan rpm and have it open like an endswitch if the rpm is lower than a set rpm.

-

@KenW said in Fly RRF-36 fan tachometer connection:

@gloomyandy Apparently io1.in and io2.in can only be used for endstops or similar . When an attempt to set it up is done an error of "Error in start-up file macro line 71: Unknown pin name '124.io2.in'" If setup as an endstop or for use with the Orbiter they work fine.

M950 F1 C"124.out1+124.io2.in" Q500 ; Fan 2 uses out1, and using out2.in as a tacho input

I assume that is correct.

So next idea, if it is correct is I could set up an attiny85 to monitor the fan rpm and have it open like an endswitch if the rpm is lower than a set rpm.

try removing the second 124.

soM950 F1 C"124.out1+io2.in" Q500 -

@jay_s_uk Thank you that did it. Did not think of removing the toolboard id. I thought that was needed.

-

@KenW great, at least we know it works.

I'll let @gloomyandy sort out what he wants to do about naming the 2 spare GPIOs -

@jay_s_uk That would be useful, I could use at least one more for the Orbiter load/unload feature. That was nice, stick the filament in and it loads it. Push the button and it pulls it out. And if both GPIO's were to appear I'd move the X endstop back onto the extruder. Less wires dangling all over the printer frame that way.

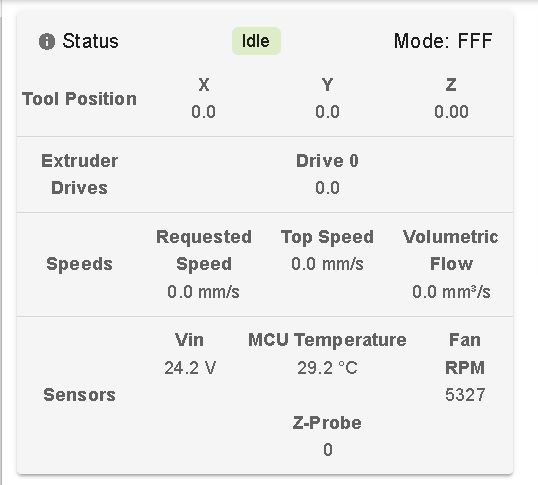

I tested the daemon and it works fine,. This way if a fan ever fails again the printer can shut down before damage happens.